About what happens with high frequency energy :

- Voice coils are inductive

- Voice coils placed in a ferromagnetic environment are even more inductive, except when the pole piece is shorted with a copper ring

So loudspeakers are inductive [their impedance increases progressively for higher frequencies], and thus, very high frequency energy never turns into heat because this energy is actually never delivered to the speaker because of the very high and reactive impedance of the voice coil at very high frequencies

The maximum energy is delivered to any driver just at its mid band.

In direct radiators, most of this energy [89-89.9%] is used to accelerate and decelerate the moving mass while a very small amount is dissipated into heat in the voice coil [10%] and radiated to the air as acoustic energy [0.1-1%].

When horn loading, a noticeable amount of energy is radiated to the air [20-50%] while the rest is used to accelerate and decelerate the moving mass [40-70%] and dissipated as heat in the voice coil [10%]

[Percentages are just approximations to help making an idea of what happens with amplifier power]

- Voice coils are inductive

- Voice coils placed in a ferromagnetic environment are even more inductive, except when the pole piece is shorted with a copper ring

So loudspeakers are inductive [their impedance increases progressively for higher frequencies], and thus, very high frequency energy never turns into heat because this energy is actually never delivered to the speaker because of the very high and reactive impedance of the voice coil at very high frequencies

The maximum energy is delivered to any driver just at its mid band.

In direct radiators, most of this energy [89-89.9%] is used to accelerate and decelerate the moving mass while a very small amount is dissipated into heat in the voice coil [10%] and radiated to the air as acoustic energy [0.1-1%].

When horn loading, a noticeable amount of energy is radiated to the air [20-50%] while the rest is used to accelerate and decelerate the moving mass [40-70%] and dissipated as heat in the voice coil [10%]

[Percentages are just approximations to help making an idea of what happens with amplifier power]

Rod Elliott's site has a good description of power compression, here: http://www.sound.westhost.com/tweeters.htm

He explains the same thing, an overdriven amplifier will

send more power the tweeter.

So loudspeakers are inductive [their impedance increases progressively for higher frequencies], and thus, very high frequency energy never turns into heat because this energy is actually never delivered to the speaker because of the very high and reactive impedance of the voice coil at very high frequencies

Re: So higher frequencies

Don't try to fix a problem that doesn't exist

Coolin said:than the tweeter can handle might be able to be absorbed or maby shunted to ground to improve sound quality?

Coolin

Don't try to fix a problem that doesn't exist

Tweeter failure mode.

One mode I've never seen written about is lead fatigue.

I've repaired many a tweeter that I did not exceed power handling. Instead, another mechanism was involved.

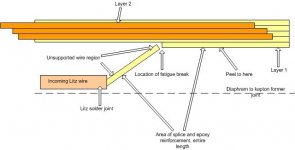

When a tweeter wire leaves the lincoming litz, to get to the voice coil, two things can happen to it..

First, there is flexure fatigue..However, this will occur as a result of too low a frequency being introduced to it, below resonance, where the tweeter does not couple to the air efficiently. I rarely see that..

The second one, I see all the time..

Just before the tweeter wire is formed into the vc, it is NOT part of the coil...It is not supported by the epoxy or polyimid of the coil, but it is in the magnetic field gap. Since it is a wire, carrying current, and not orthogonal to the field...there will be a force on that wire..

Since that wire is not supported for some distance, it will have it's own resonant frequency which is typically in the ultrasonic range. If that range of frequencies (which will occur by clipping) is provided to that tweeter wire, it will flex a lot w/r to the vc...leading to flexure fatigue and eventual failure.

This can be seen by examination of the break of the wire with either a 60 X stereoscope, or a metal scope in the 100 to 200 x range. The surface of the wire immediately around the break will have a textured surface, due to slip plane deformations..this is the look a tensile stress test specimen will have after you take it off the instrom..

The current tweet of choice for me, a Selenium D205TI, 2 inch VC, has failed twice from this..and both times, I simply spliced a very small wire at the break, and then used a good epoxy to bond the wire to the moving part of the diaphram.

I informed Selenium of this failure mode, and recommended they bond the lead in wire down to prevent this in the future.. They said thanks, they'll send me a free pair of replacement diaphrams as a thank you...(never got them, BTW..guess they forgot?)

The repairs are still working strong, even after I continue to abuse them.

One mode I've never seen written about is lead fatigue.

I've repaired many a tweeter that I did not exceed power handling. Instead, another mechanism was involved.

When a tweeter wire leaves the lincoming litz, to get to the voice coil, two things can happen to it..

First, there is flexure fatigue..However, this will occur as a result of too low a frequency being introduced to it, below resonance, where the tweeter does not couple to the air efficiently. I rarely see that..

The second one, I see all the time..

Just before the tweeter wire is formed into the vc, it is NOT part of the coil...It is not supported by the epoxy or polyimid of the coil, but it is in the magnetic field gap. Since it is a wire, carrying current, and not orthogonal to the field...there will be a force on that wire..

Since that wire is not supported for some distance, it will have it's own resonant frequency which is typically in the ultrasonic range. If that range of frequencies (which will occur by clipping) is provided to that tweeter wire, it will flex a lot w/r to the vc...leading to flexure fatigue and eventual failure.

This can be seen by examination of the break of the wire with either a 60 X stereoscope, or a metal scope in the 100 to 200 x range. The surface of the wire immediately around the break will have a textured surface, due to slip plane deformations..this is the look a tensile stress test specimen will have after you take it off the instrom..

The current tweet of choice for me, a Selenium D205TI, 2 inch VC, has failed twice from this..and both times, I simply spliced a very small wire at the break, and then used a good epoxy to bond the wire to the moving part of the diaphram.

I informed Selenium of this failure mode, and recommended they bond the lead in wire down to prevent this in the future.. They said thanks, they'll send me a free pair of replacement diaphrams as a thank you...(never got them, BTW..guess they forgot?)

The repairs are still working strong, even after I continue to abuse them.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- pro amplifiers vs. home audio amplifiers