Hello Everyone. I have been posting on a different Adcom thread as I have been working my way through a restoration of an old Adcom GFA-565. Rather than add to the bottom of that long and very old thread, I decided to start posting my project here on a nice new thread..

The initial posts for this project can be found at:

http://www.diyaudio.com/forums/solid-state/114702-damaged-adcom-565-monoamps-3.html#post4605057

The initial posts for this project can be found at:

http://www.diyaudio.com/forums/solid-state/114702-damaged-adcom-565-monoamps-3.html#post4605057

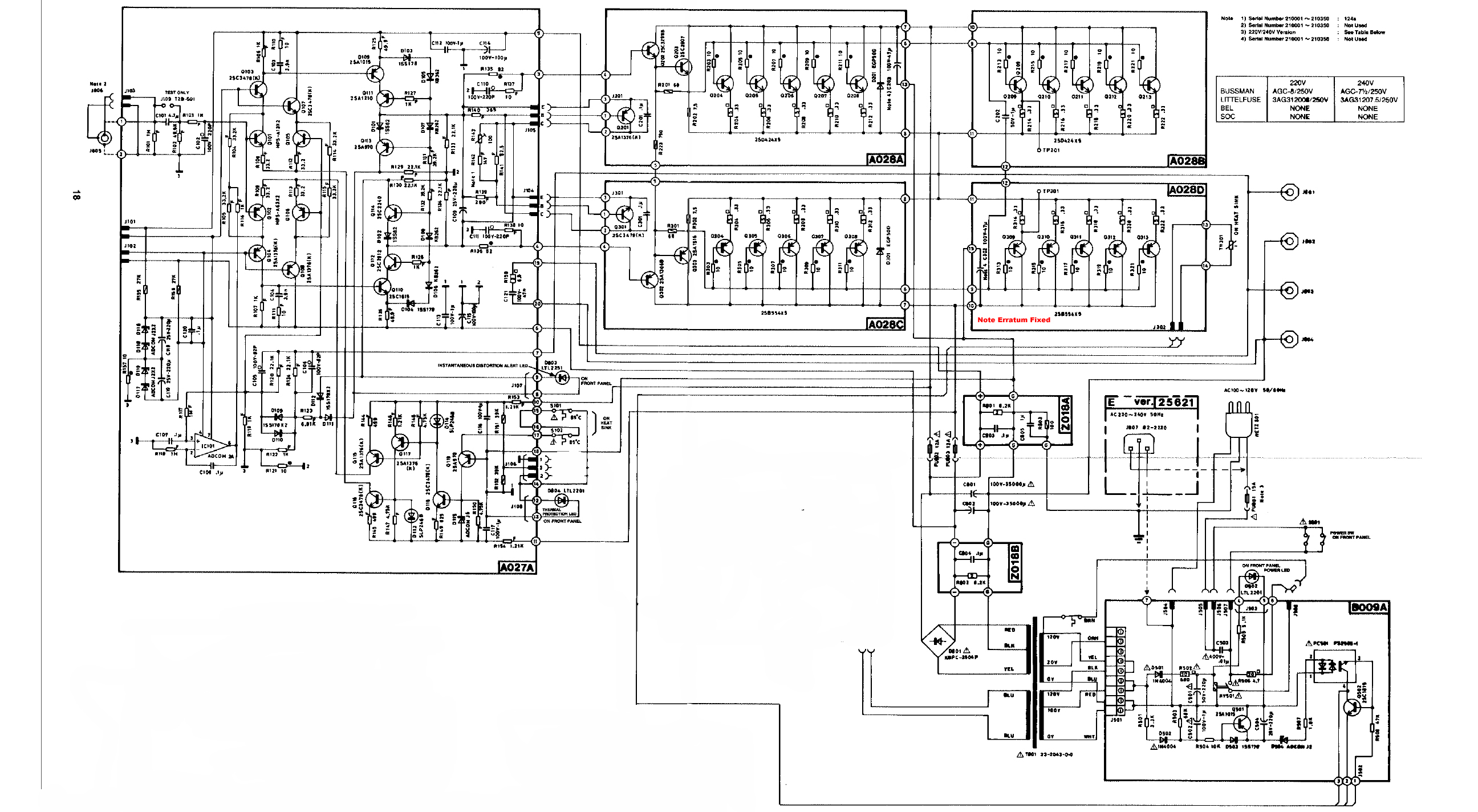

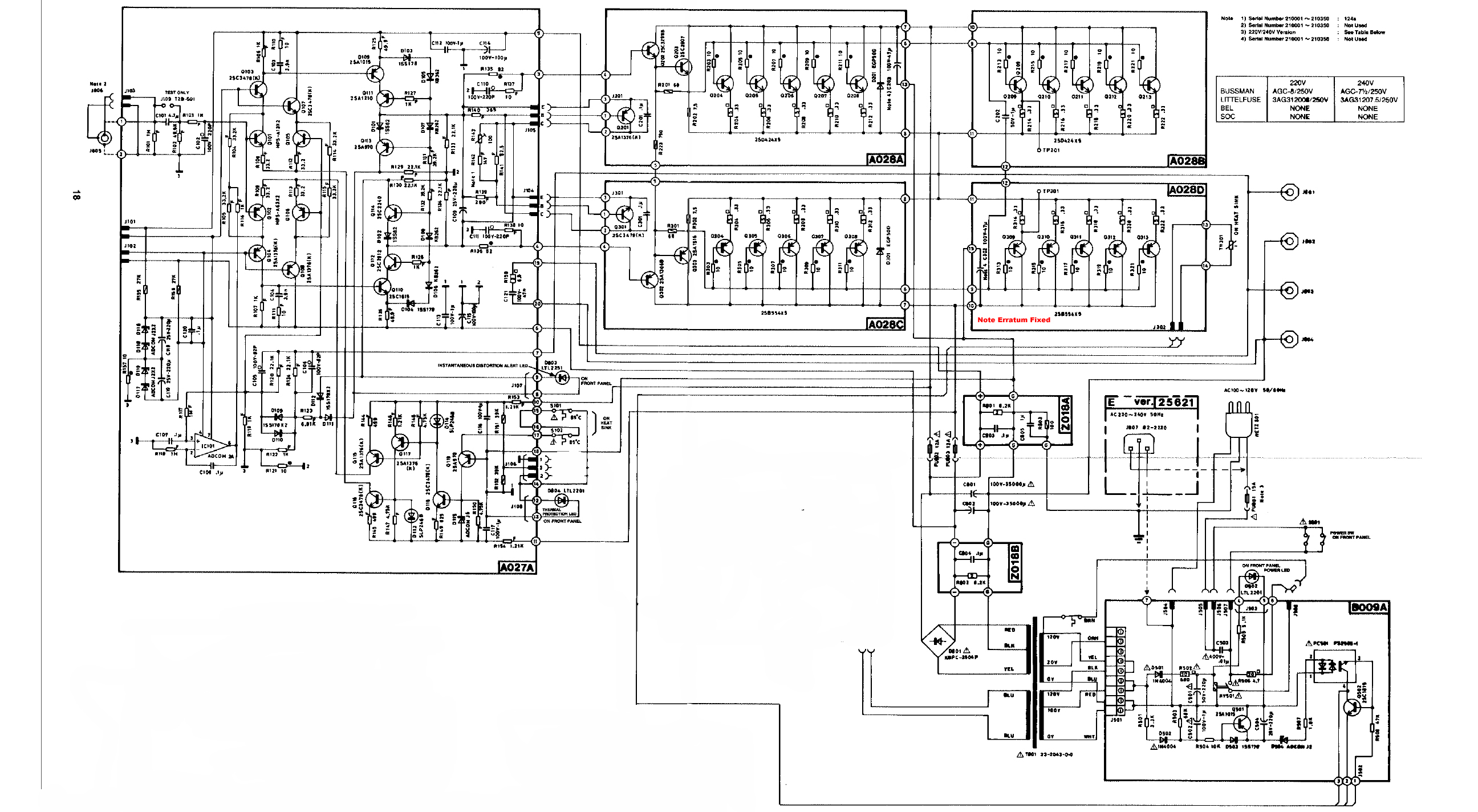

As provided at the other thread, I had found it somewhat difficult to use the schematic in the service manual because it was separated into two pieces, and also had a bunch of fan control stuff that wasn't of any use to me (my unit doesn't have the fan assembly).

So here, for anyone's use, is the schematic from the manual joined up on a single page.

You can also view or download this at:

http://mv-makoto.com/AdcomGFA-565SchematicJoined.jpg

So here, for anyone's use, is the schematic from the manual joined up on a single page.

You can also view or download this at:

http://mv-makoto.com/AdcomGFA-565SchematicJoined.jpg

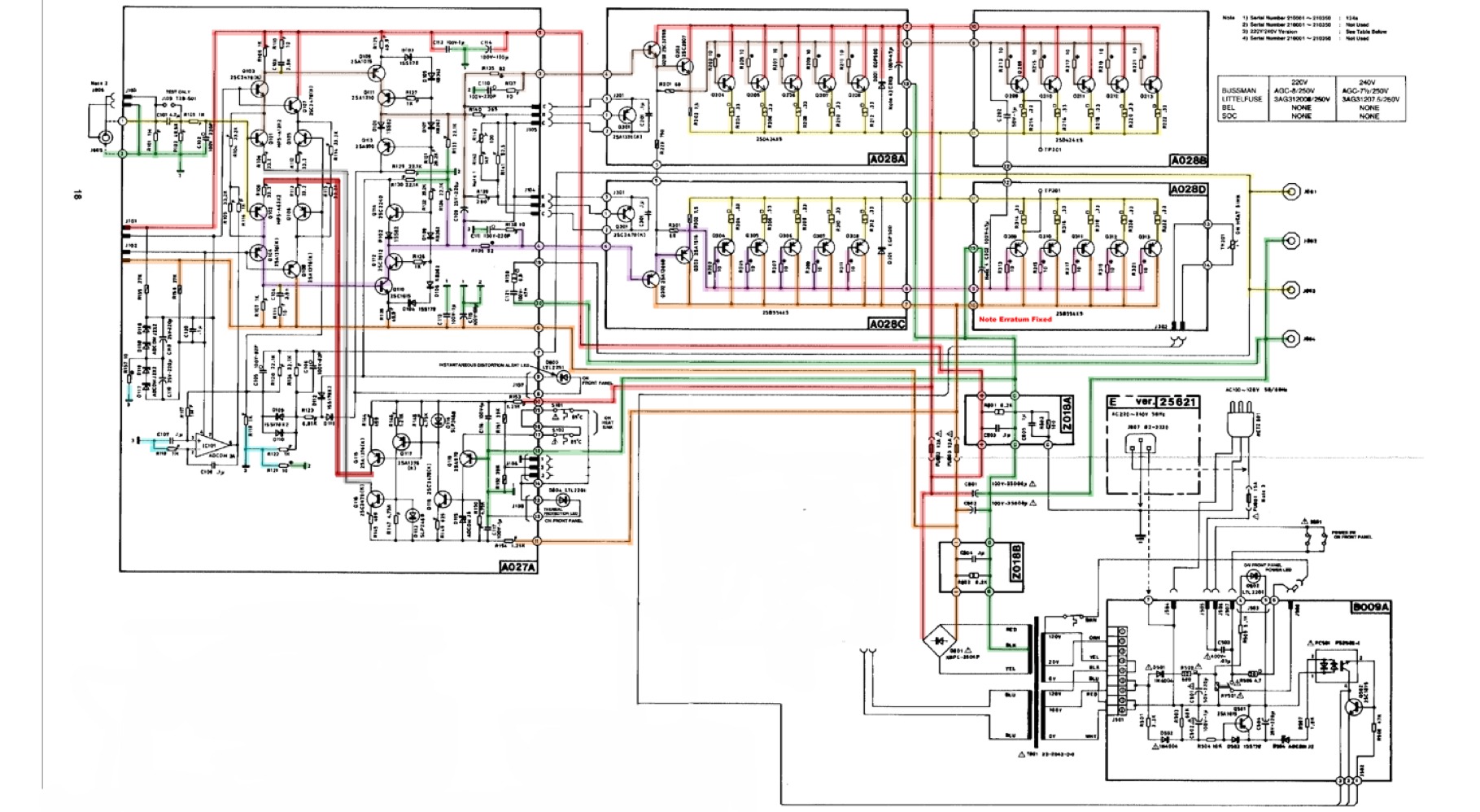

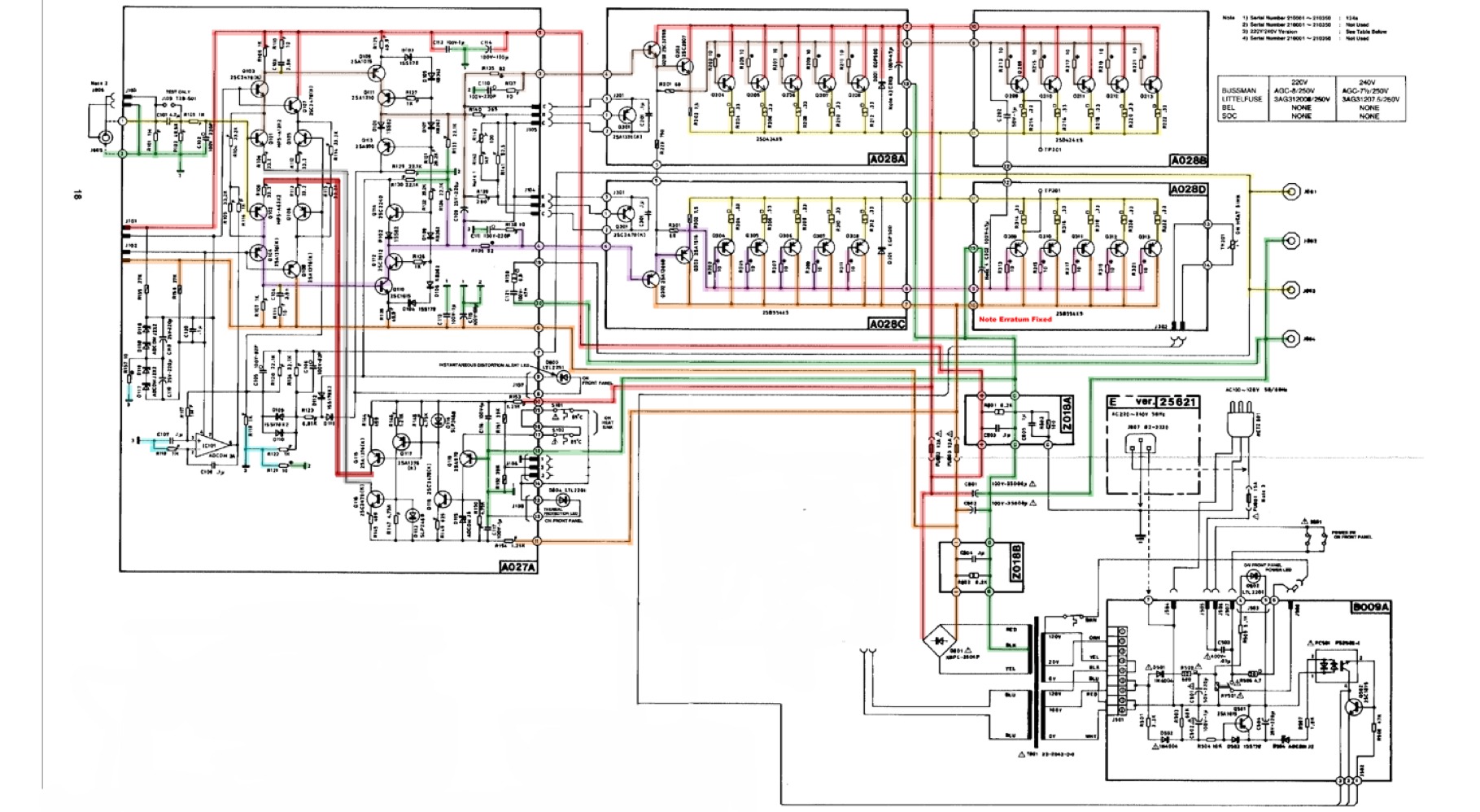

In addition, I found it useful to trace the various parts of the circuit so I could better understand what signals and voltages I should find where, and also separate the various sub sections and functions of the circuit.

Here is the schematic with some of the signal and voltage paths highlighted in different colors. Green is ground, light Red is positive DC, light Orange is negative DC, Yellow is full cycle audio signal (which is found at the input to the amp, and at the output), Purple is negative half cycle audio, Brown is Positive half cycle audio, and Dark Red and Grey are the positive and negative tail current lines for the differential input circuits.

Here is the schematic with some of the signal and voltage paths highlighted in different colors. Green is ground, light Red is positive DC, light Orange is negative DC, Yellow is full cycle audio signal (which is found at the input to the amp, and at the output), Purple is negative half cycle audio, Brown is Positive half cycle audio, and Dark Red and Grey are the positive and negative tail current lines for the differential input circuits.

Last edited:

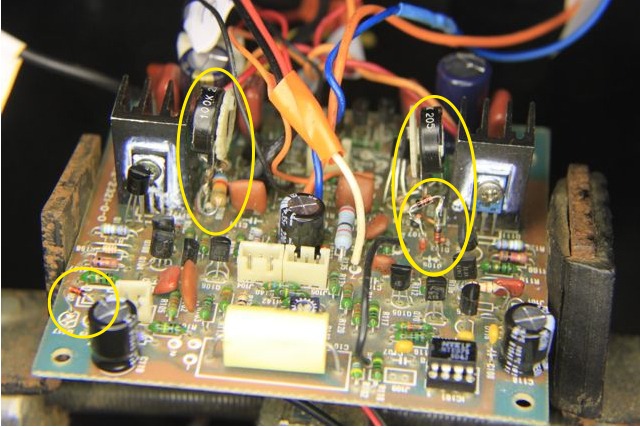

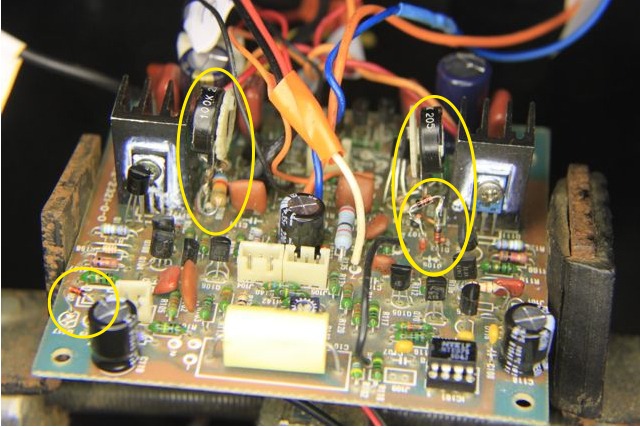

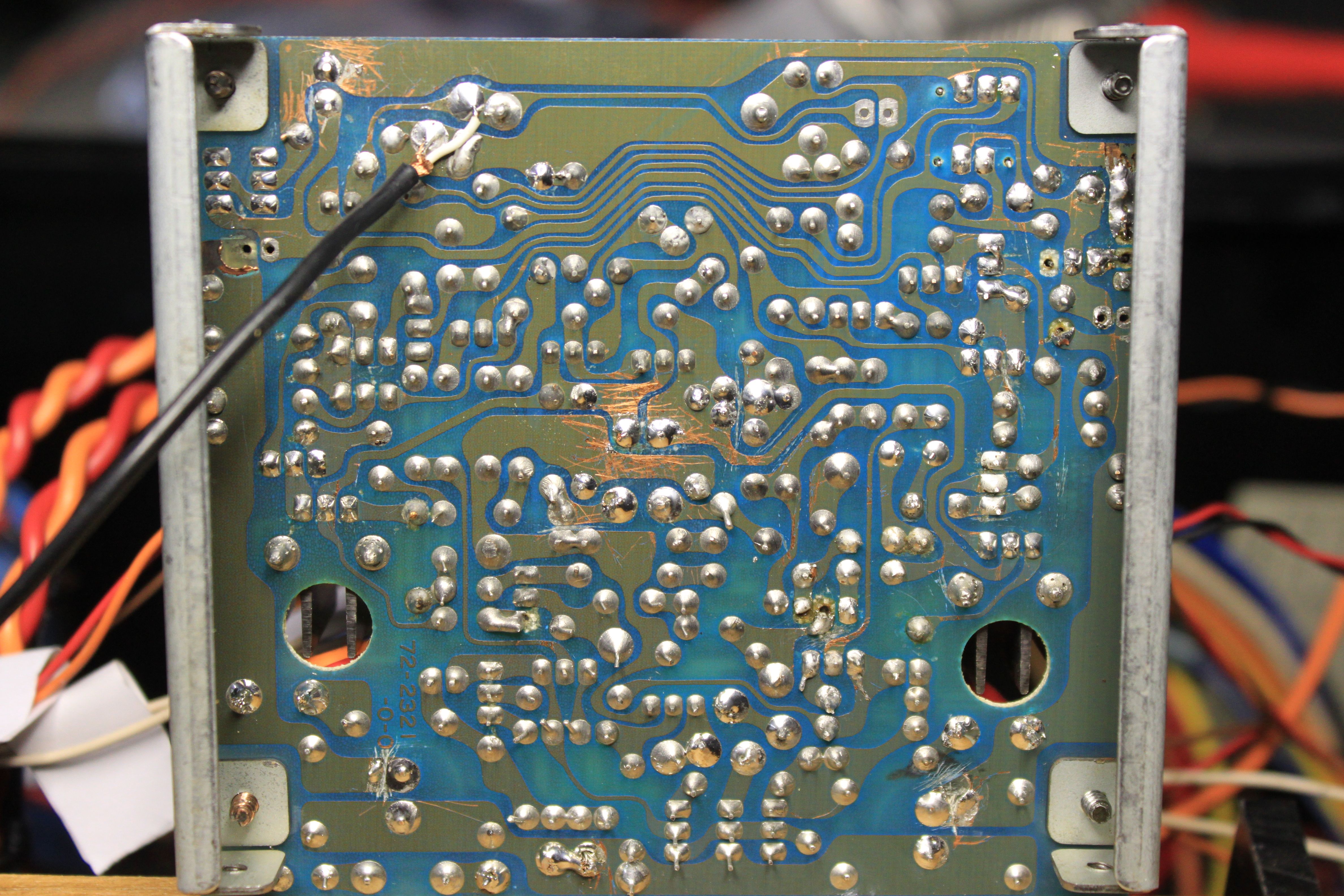

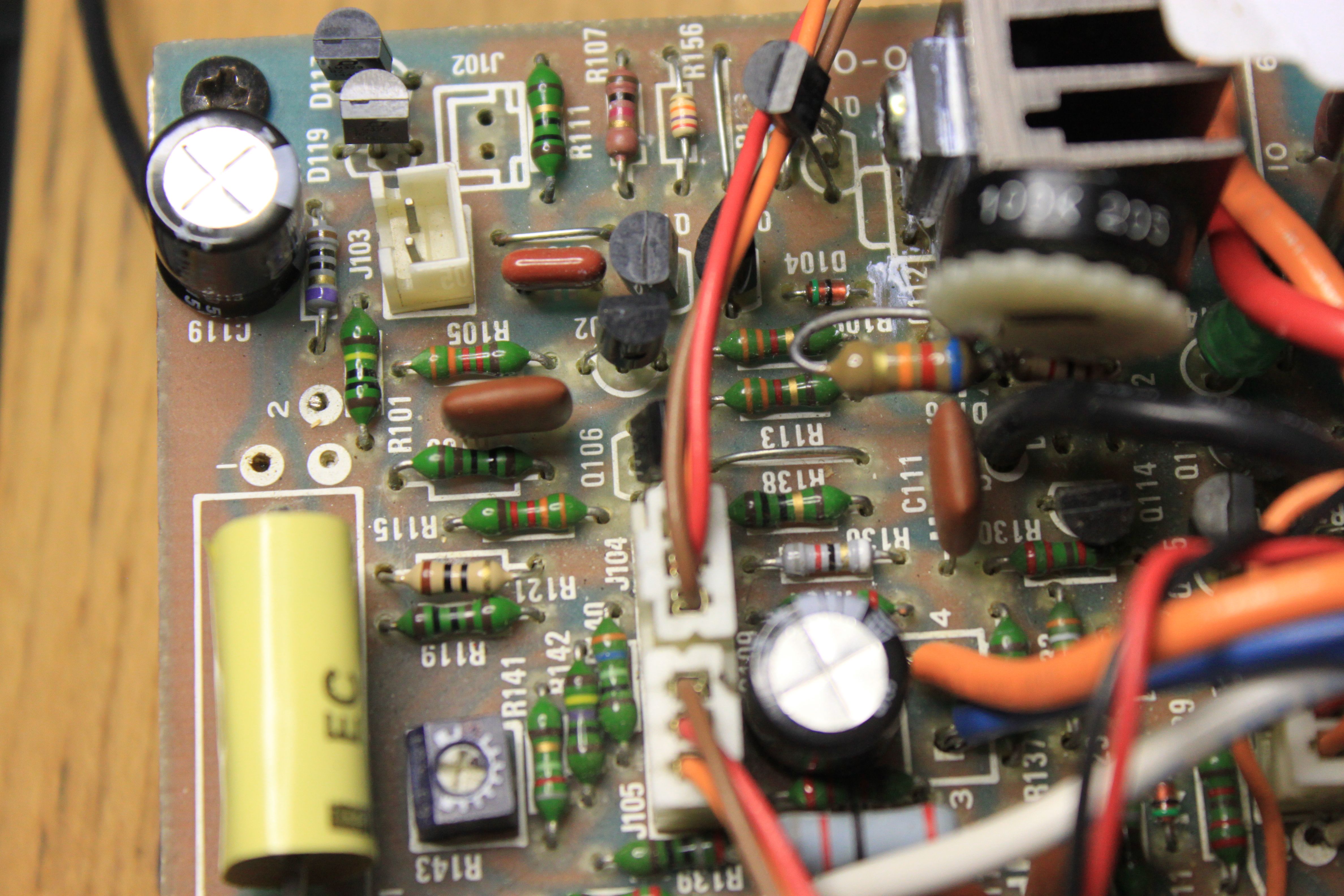

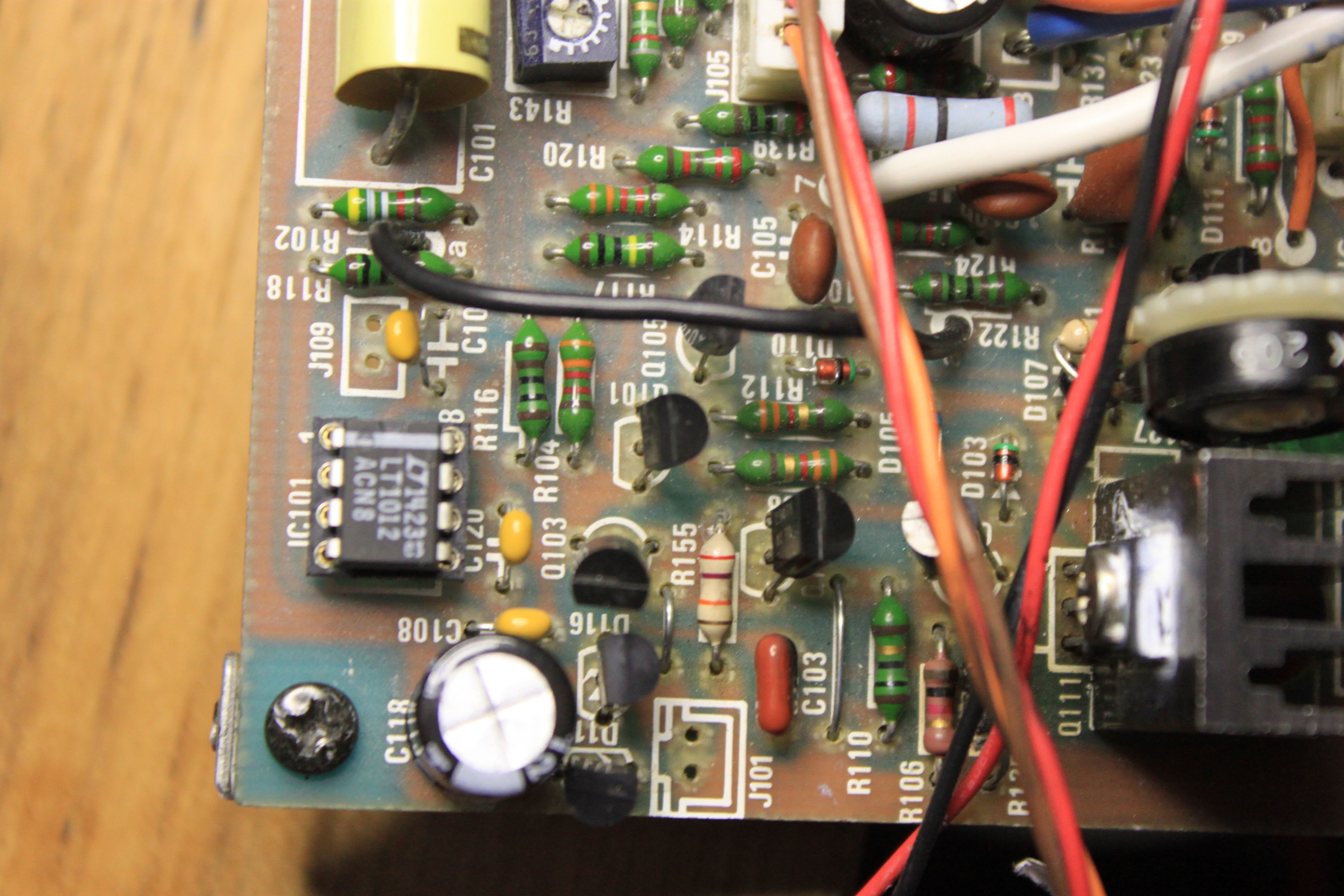

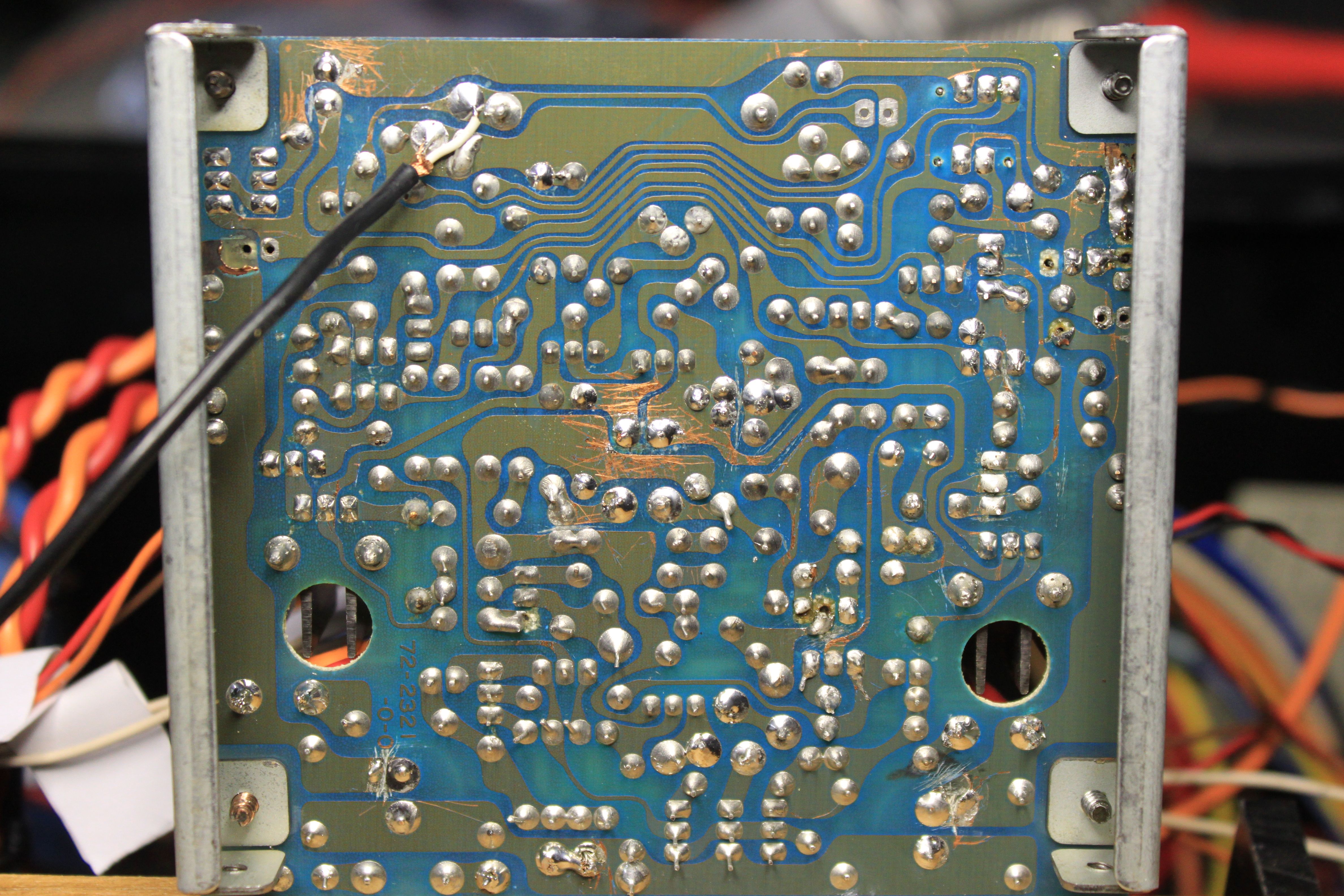

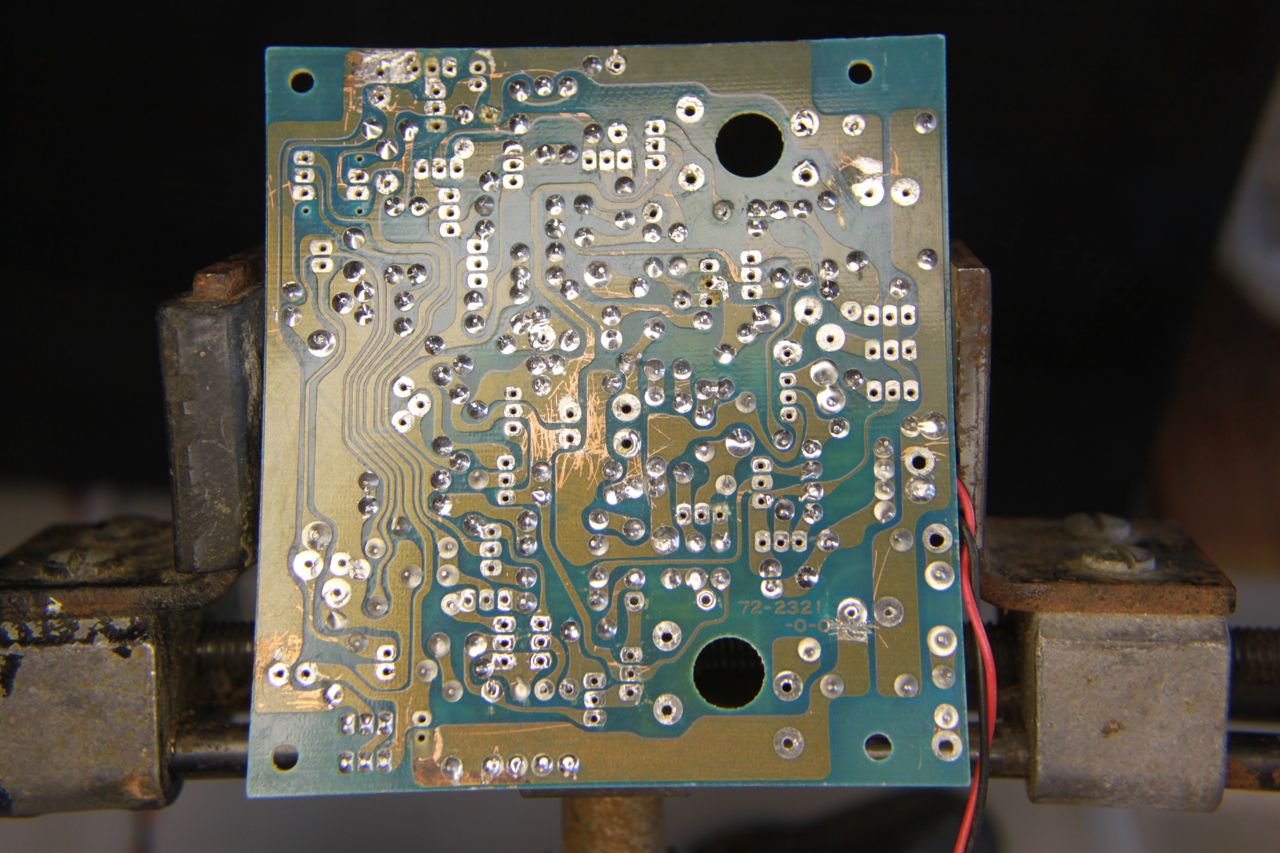

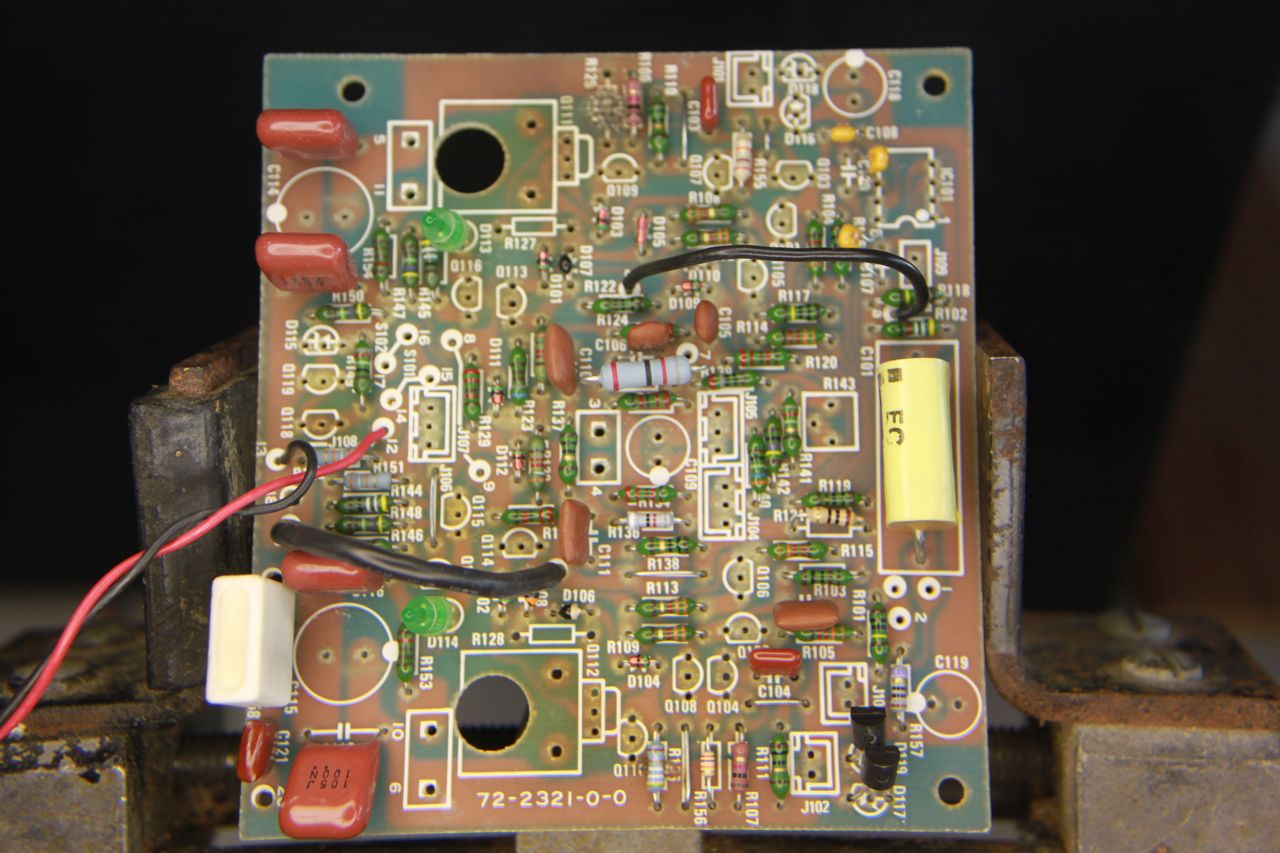

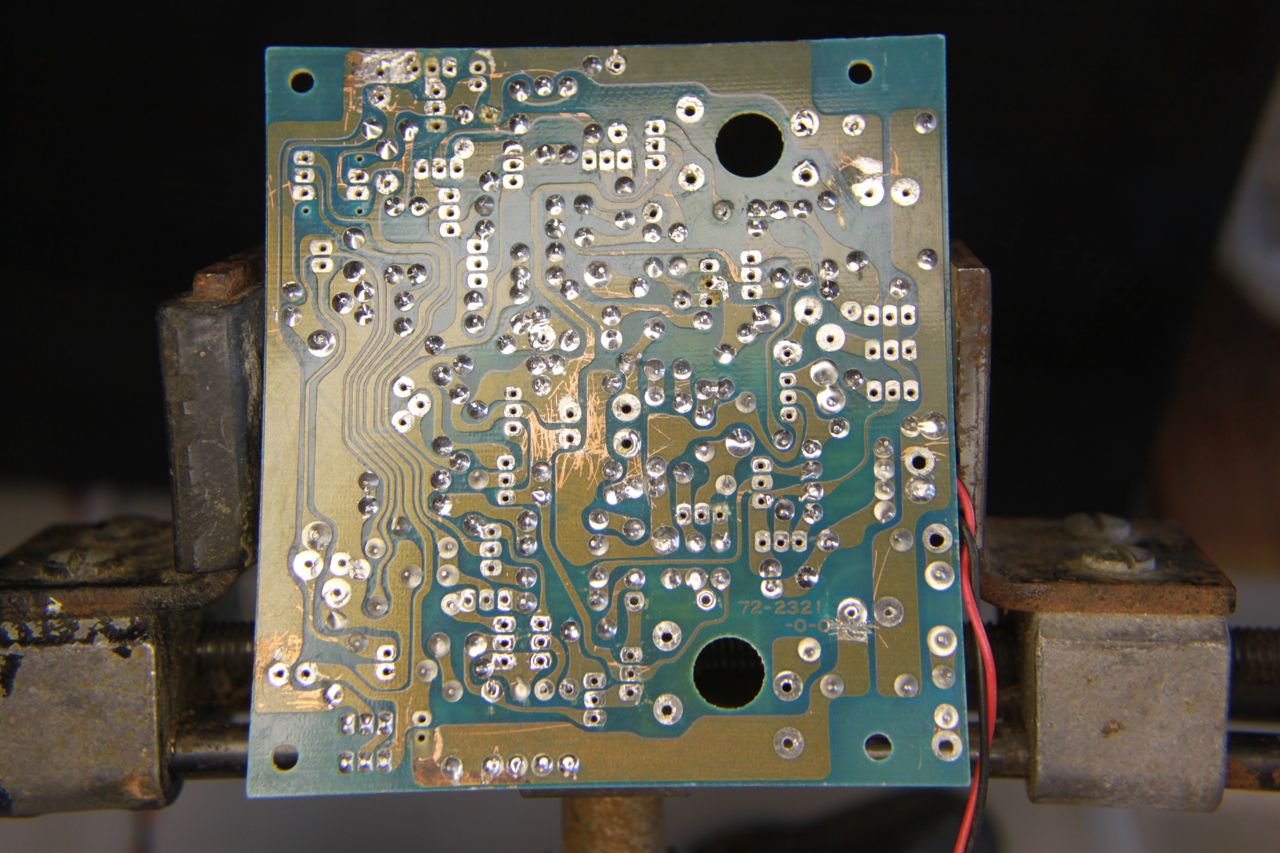

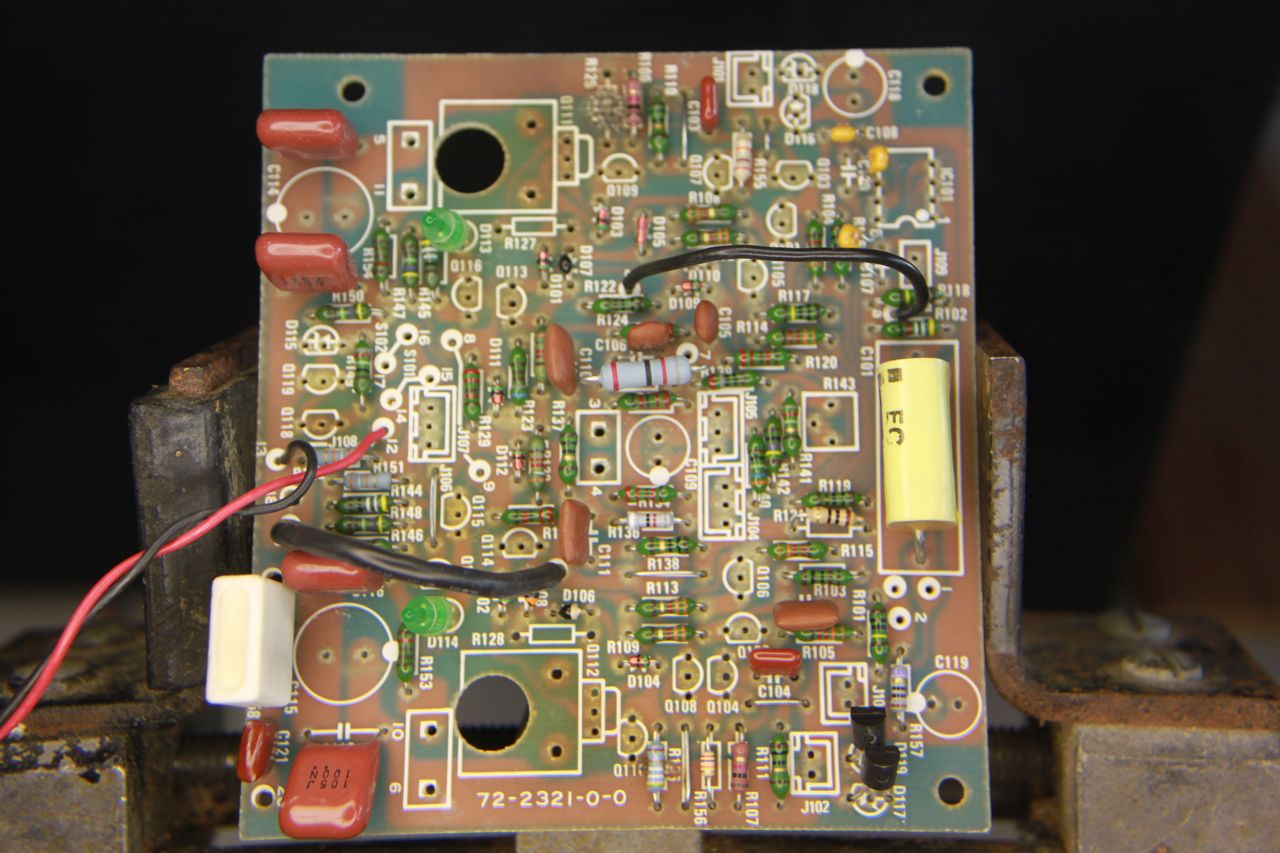

Here is a closeup image of the control board that I have been working on.

I have replaced the electrolytic caps, and cleaned up some amazingly bad soldering on the back side of the board...

In this photo you can see a number of issues. First, the PO seems to have taken matters into his own hands relative to the bias controls. The two trim pots with resistor assemblies under them apparently are meant to replace R127 and R128, which were 1K 1% resistors in the origin. This contraption allows variation between 980 and 36K ohms...Apparently someone didn't do their resistor value homework...

The next issue is that the precision low noise voltage references D116/D117 and D118/D119 have been replaced by single diodes of some unknown type.

The last issue is that the varistor D105 has been replaced by the little trio of flying diodes.. Yikes!!!

I have new diodes and a varistor on order (as well as a full set of other transistors and a fe other parts), and will see how this works once I have put it back to its original form.

Not shown is the fact that at some point the PO decided to add a 100 uf blocking cap on one of the outputs. I'll bet that sounded great..... :-(

Lastly, for some reason the leakage resistors and the mica bypass caps on the big filter caps were also missing. Those probably didn't do much harm (other than the HF noise reduction from the bypass caps), but one wonders who was mucking around in this amp.. It seems they had SOMe understanding of electronics, but not enough to fix it properly!!

I have replaced the electrolytic caps, and cleaned up some amazingly bad soldering on the back side of the board...

In this photo you can see a number of issues. First, the PO seems to have taken matters into his own hands relative to the bias controls. The two trim pots with resistor assemblies under them apparently are meant to replace R127 and R128, which were 1K 1% resistors in the origin. This contraption allows variation between 980 and 36K ohms...Apparently someone didn't do their resistor value homework...

The next issue is that the precision low noise voltage references D116/D117 and D118/D119 have been replaced by single diodes of some unknown type.

The last issue is that the varistor D105 has been replaced by the little trio of flying diodes.. Yikes!!!

I have new diodes and a varistor on order (as well as a full set of other transistors and a fe other parts), and will see how this works once I have put it back to its original form.

Not shown is the fact that at some point the PO decided to add a 100 uf blocking cap on one of the outputs. I'll bet that sounded great..... :-(

Lastly, for some reason the leakage resistors and the mica bypass caps on the big filter caps were also missing. Those probably didn't do much harm (other than the HF noise reduction from the bypass caps), but one wonders who was mucking around in this amp.. It seems they had SOMe understanding of electronics, but not enough to fix it properly!!

OK, so I got the board rewired and replaced the parts that were obviously bad. I fired it up, and the output is pegged at 60 volts (I am using a 300 watt 8 ohm resistor as a load).

I am not sure if doing this will upset the bias circuits, but I disconnected the signal lines between the control board and the output stages. With this done, the DC offset at the output drops to a nice 24 mv. So that seems promising!

The input board clearly has some pretty significant issues.

A couple of observations:

Q111, the big transistor attached on one of the heat sinks, is running pretty hot. The other one is cool to the touch.

With power applied, the collector of Q101 is at 79 volts (!!), The Emitter is at about 7.5.

The other side of R104 is at 2.2 volts

In contrast the Collector of Q102 is at -11 volts, and the emitter is at 1.1 and the other end of R109 is at 1.2 volts.

I see signal on the bases of Q101 and Q102, but no signal on the collectors of Q101 or Q102.

I think I may remove the front end transistors and test/replace them, and then see how it works.

Anyone have any other ideas???

Scott

I am not sure if doing this will upset the bias circuits, but I disconnected the signal lines between the control board and the output stages. With this done, the DC offset at the output drops to a nice 24 mv. So that seems promising!

The input board clearly has some pretty significant issues.

A couple of observations:

Q111, the big transistor attached on one of the heat sinks, is running pretty hot. The other one is cool to the touch.

With power applied, the collector of Q101 is at 79 volts (!!), The Emitter is at about 7.5.

The other side of R104 is at 2.2 volts

In contrast the Collector of Q102 is at -11 volts, and the emitter is at 1.1 and the other end of R109 is at 1.2 volts.

I see signal on the bases of Q101 and Q102, but no signal on the collectors of Q101 or Q102.

I think I may remove the front end transistors and test/replace them, and then see how it works.

Anyone have any other ideas???

Scott

Hi Scott,

Could you please post a high resolution picture of the control PCB as it is right now?

When you are troubleshooting a DC offset problem, don't connect a load. There isn't any point as we already know it will draw a lot of current. Once the load is disconnected, repeat your observations as to what is running hot and what isn't. With the DC offset pegged to one supply, places that normally would show signal will not. The stage is no longer in a linear mode. Its stuck to the rail.

With DC Offset issues, you should remove the op amp, then try it again. You will have an offset if everything is working properly, but it won't be very high. A few volts worst case.

The problem with the leaky electrolyte would cause exactly what you are seeing. The previous repair person was obviously convinced they cleaned it all up. It is entirely possible that the conductive solution is still there. You would have to clean the PCB, and the parts (or replace them with new). This stuff is incredibly tenacious and difficult to actually get rid of. To clean the board means to strip all the parts off the affected area. That includes the diff pairs, op amp and the regulators. Include any components in that area and be certain there are no original capacitors on that PCB. Then, take a tooth brush and scrub that board using a vinegar solution, then a baking soda solution (acid, then a base). I had a difficult one that took ages to clean. % cleaning sessions with parts removal and replacement each )$*@Q*& time. It was ... frustrating to say the least. I finally got it clean. I can't be sure what cleaning solution did the job to be honest with you. You should also try dish washing soap and water.

That electrolyte that came out of the capacitors was nasty stuff. It will corrode anything metallic that it comes in contact with over time. You have to get to it early, don't leave it sit there corroding away.

-Chris

Could you please post a high resolution picture of the control PCB as it is right now?

When you are troubleshooting a DC offset problem, don't connect a load. There isn't any point as we already know it will draw a lot of current. Once the load is disconnected, repeat your observations as to what is running hot and what isn't. With the DC offset pegged to one supply, places that normally would show signal will not. The stage is no longer in a linear mode. Its stuck to the rail.

With DC Offset issues, you should remove the op amp, then try it again. You will have an offset if everything is working properly, but it won't be very high. A few volts worst case.

The problem with the leaky electrolyte would cause exactly what you are seeing. The previous repair person was obviously convinced they cleaned it all up. It is entirely possible that the conductive solution is still there. You would have to clean the PCB, and the parts (or replace them with new). This stuff is incredibly tenacious and difficult to actually get rid of. To clean the board means to strip all the parts off the affected area. That includes the diff pairs, op amp and the regulators. Include any components in that area and be certain there are no original capacitors on that PCB. Then, take a tooth brush and scrub that board using a vinegar solution, then a baking soda solution (acid, then a base). I had a difficult one that took ages to clean. % cleaning sessions with parts removal and replacement each )$*@Q*& time. It was ... frustrating to say the least. I finally got it clean. I can't be sure what cleaning solution did the job to be honest with you. You should also try dish washing soap and water.

That electrolyte that came out of the capacitors was nasty stuff. It will corrode anything metallic that it comes in contact with over time. You have to get to it early, don't leave it sit there corroding away.

-Chris

Hi Chris;

Thanks for responding.

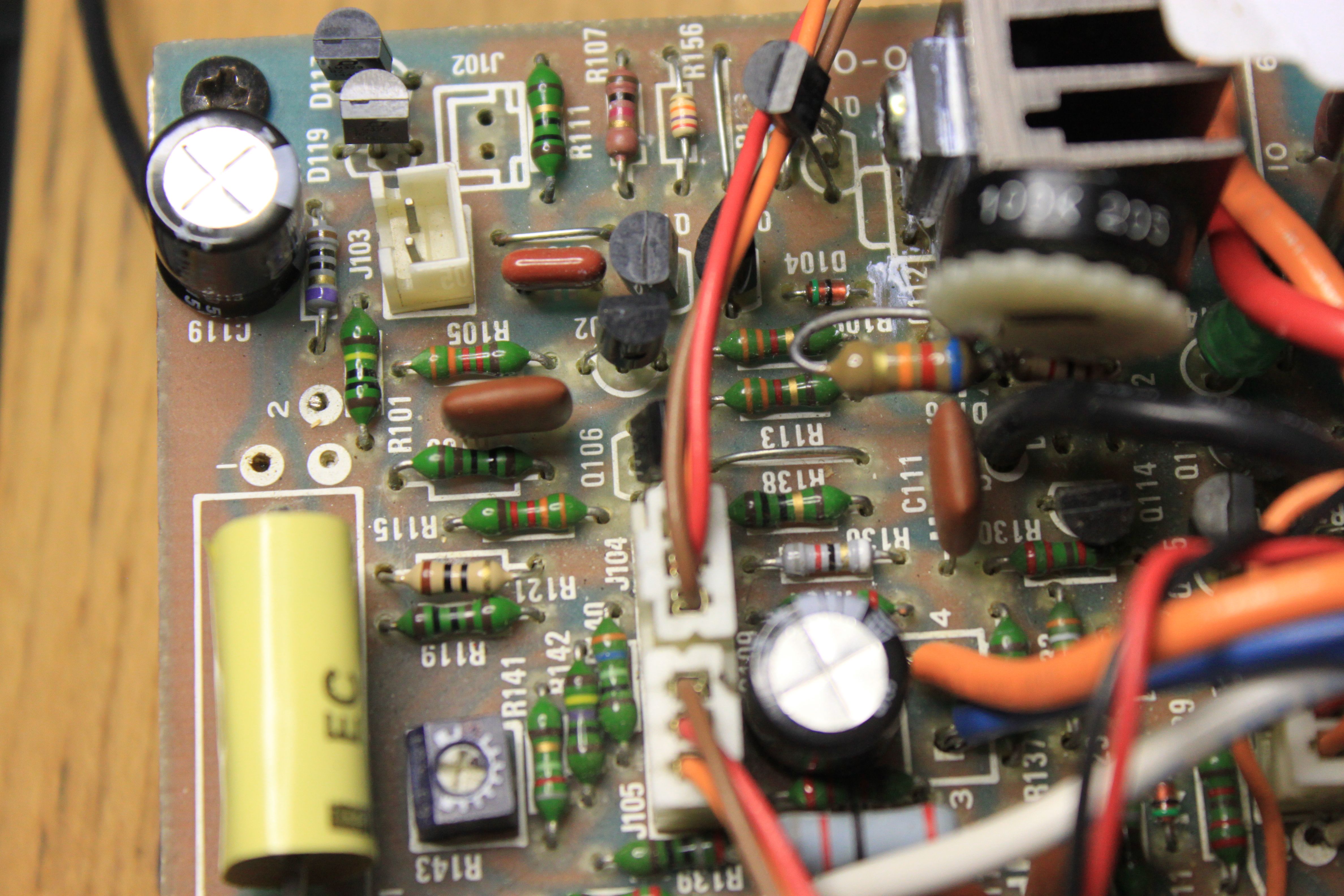

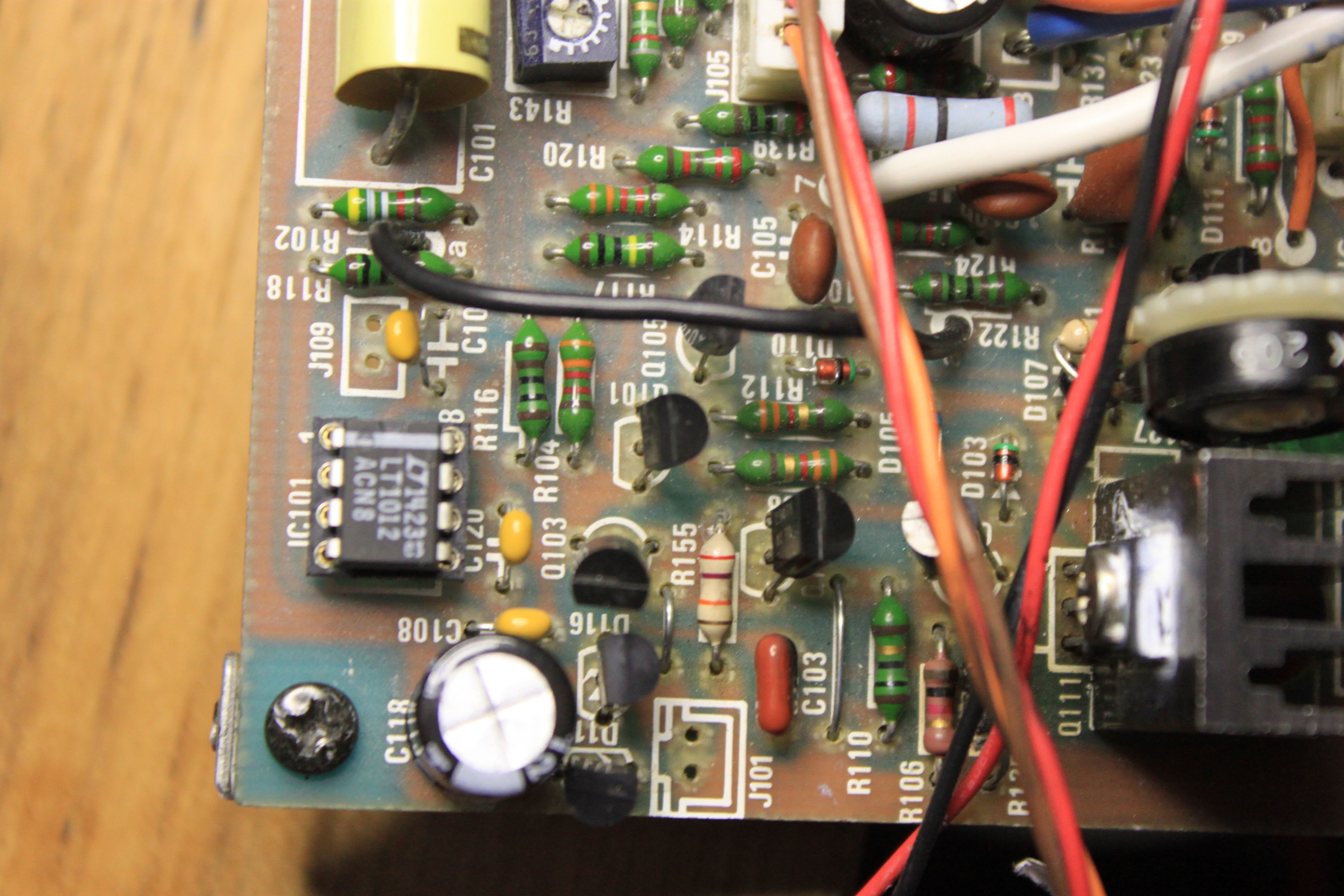

Here are a couple of closeups of the component side of the board around the caps, and one of the solder side There is some foil damage, but nothing too severe. The scratches are from the PO.

I have not yet replaced R127 and 128 but I set the pot networks that replaced them at 1K ohms within about +/-10 ohms. You can also see that the op amp was replaced using a socket. The op amp in there now is one I put in.

It sounds like my next step should be to remove the major components, test them, clean the crap out of the board, and then put the components back in replacing anything that is suspect.

Thanks for responding.

Here are a couple of closeups of the component side of the board around the caps, and one of the solder side There is some foil damage, but nothing too severe. The scratches are from the PO.

I have not yet replaced R127 and 128 but I set the pot networks that replaced them at 1K ohms within about +/-10 ohms. You can also see that the op amp was replaced using a socket. The op amp in there now is one I put in.

It sounds like my next step should be to remove the major components, test them, clean the crap out of the board, and then put the components back in replacing anything that is suspect.

Last edited:

Hi Scott,

Yes, I'm afraid so.

It sure looks like there was a problem with the capacitor electrolyte leaking.

When you rebuild the PCB after cleaning, lose the IC socket for one, also the network of stuff with the trimmer control. It appears that the previous hack artist had some problems with their soldering skills for sure. I would suggest that you use some liquid solder flux before stuffing the board to tin any iffy areas that need solder. One trick that works well is to use some solder wick that has some solder in it already. Use the flux on the area after it has been scraped clean, then rub with the soldering iron with the solder wick between the iron and the board. The mesh will fine rub the copper and deposit the solder in one go. Then you can solder component leads without overheating anything. I hope this makes your life a little easier.

Yes, I'm afraid so.

It sure looks like there was a problem with the capacitor electrolyte leaking.

When you rebuild the PCB after cleaning, lose the IC socket for one, also the network of stuff with the trimmer control. It appears that the previous hack artist had some problems with their soldering skills for sure. I would suggest that you use some liquid solder flux before stuffing the board to tin any iffy areas that need solder. One trick that works well is to use some solder wick that has some solder in it already. Use the flux on the area after it has been scraped clean, then rub with the soldering iron with the solder wick between the iron and the board. The mesh will fine rub the copper and deposit the solder in one go. Then you can solder component leads without overheating anything. I hope this makes your life a little easier.

OK, so I disassembled the control board (took the connector jacks, caps and all transistors off). Wicked and reflowed all the remaining solder joints, and then cleaned the board several times.

I used a couple of different very nasty hydrocarbon cleaners with a plastic scrub brush, and gently blow dried the board between cleanings. I used the little nozzle sprayer to thoroughly wash down the board under and around all the components. We used to use nasty stuff like this in heated ultrasonic baths for electronic components, so I was pretty sure it would work.

Here is one of the cleaners I used (the first was an automotive intake cleaner that had acetone, heptane and toluene. It instantly removed all the solder flux, and a good quantity of cloudy residue. I didn't save it because there was a lot of flux in it (I smeared rosin flux all over the board when I was wicking it). The second was this electronic cleaner, which is mostly various hexane compounds. It is super volatile and turns everything icy cold, so cold you get condensation on the parts unless you blow dry them.

Anyway, I was surprised to find that after the intake cleaner freed a bunch of crap (including the flux), the electronics cleaner still ended up with a lot of cloudy crap. Here is the catch bowl after two cycles. I eventually went through this about five times, until the off flow was clean...spraying and scrubbing with the brush, in all different directions, on both sides of the board. I got about three bowl-fulls like this before it came out clean.

Here are a few pics of the board post soldering and cleaning. You can see that at some point in its life R125 got smoked pretty spectacularly...

The board is clearly a LOT cleaner than it was, so good call Chris! And way to go nasty hydrocarbons!

I then checked all the transistors I had removed. Apparently Q112 was replaced at some point with some "equivalent" device. I ordered a new one of that and the mate Q111.

One of the 3478 transistors was shorted (not sure which of Q103, 107, 116 or 118 it was - since they were out of the circuit). I ordered new ones of these

One of the 1376 transistors was open (again, not sure which of Q104, 108, 115 or 117 it was - since they were out of the circuit). I ordered new ones of these

Q110 had been replaced by some "equivalent". I ordered a new 2SC1815.

I was able to buy some of these via Mouser, but most of them I found on eBay (some int he US, and some in the UK - I don't trust buying things from the far east).

So, sometime next week, when the parts arrive, I'l get back to this, re-install the parts and give it another go..

Note too that at some point the PO cut the traces at the 100 UF caps. Very strange.. So I'll have to jumper across those gaps...

Cheers all.

Scott

I used a couple of different very nasty hydrocarbon cleaners with a plastic scrub brush, and gently blow dried the board between cleanings. I used the little nozzle sprayer to thoroughly wash down the board under and around all the components. We used to use nasty stuff like this in heated ultrasonic baths for electronic components, so I was pretty sure it would work.

Here is one of the cleaners I used (the first was an automotive intake cleaner that had acetone, heptane and toluene. It instantly removed all the solder flux, and a good quantity of cloudy residue. I didn't save it because there was a lot of flux in it (I smeared rosin flux all over the board when I was wicking it). The second was this electronic cleaner, which is mostly various hexane compounds. It is super volatile and turns everything icy cold, so cold you get condensation on the parts unless you blow dry them.

Anyway, I was surprised to find that after the intake cleaner freed a bunch of crap (including the flux), the electronics cleaner still ended up with a lot of cloudy crap. Here is the catch bowl after two cycles. I eventually went through this about five times, until the off flow was clean...spraying and scrubbing with the brush, in all different directions, on both sides of the board. I got about three bowl-fulls like this before it came out clean.

Here are a few pics of the board post soldering and cleaning. You can see that at some point in its life R125 got smoked pretty spectacularly...

The board is clearly a LOT cleaner than it was, so good call Chris! And way to go nasty hydrocarbons!

I then checked all the transistors I had removed. Apparently Q112 was replaced at some point with some "equivalent" device. I ordered a new one of that and the mate Q111.

One of the 3478 transistors was shorted (not sure which of Q103, 107, 116 or 118 it was - since they were out of the circuit). I ordered new ones of these

One of the 1376 transistors was open (again, not sure which of Q104, 108, 115 or 117 it was - since they were out of the circuit). I ordered new ones of these

Q110 had been replaced by some "equivalent". I ordered a new 2SC1815.

I was able to buy some of these via Mouser, but most of them I found on eBay (some int he US, and some in the UK - I don't trust buying things from the far east).

So, sometime next week, when the parts arrive, I'l get back to this, re-install the parts and give it another go..

Note too that at some point the PO cut the traces at the 100 UF caps. Very strange.. So I'll have to jumper across those gaps...

Cheers all.

Scott

Last edited:

Hi Scott,

I think you did a really good job of cleaning that board. I should try some of that cleaner the next time I get a "capacitor job". It cost me more than a ton of time scrubbing to clean those boards I had in. You cleaned the parts too - right? They also get contaminated. Once that is done, rebuild it while your memory is still fresh. Installing the new parts will be much easier when that time comes.

You found a bunch of good reasons why it didn't work, so good work. Check the resistors with a meter. They can open up without showing any problems externally. Take nothing for granted.

Now for the news you don't want to hear. The differential pairs must be matched. You're going to need some way of matching them that is better than the transistor test function in a meter. Transistors are very, very sensitive to temperature changes, so that means your parts should be handled with pliers to connect them to the tester. You must not touch them with your hands as that is enough to throw off the reading. Its a real pain in the neck.

-Chris

I think you did a really good job of cleaning that board. I should try some of that cleaner the next time I get a "capacitor job". It cost me more than a ton of time scrubbing to clean those boards I had in. You cleaned the parts too - right? They also get contaminated. Once that is done, rebuild it while your memory is still fresh. Installing the new parts will be much easier when that time comes.

You found a bunch of good reasons why it didn't work, so good work. Check the resistors with a meter. They can open up without showing any problems externally. Take nothing for granted.

Now for the news you don't want to hear. The differential pairs must be matched. You're going to need some way of matching them that is better than the transistor test function in a meter. Transistors are very, very sensitive to temperature changes, so that means your parts should be handled with pliers to connect them to the tester. You must not touch them with your hands as that is enough to throw off the reading. Its a real pain in the neck.

-Chris

Well, fortunately, none of the diff pairs (MPSA13 and MPSA63) are bad.. So hopefully I dodged a bullet on that!! Looks like just a couple of the active load and bias transistors are bad. I have some MPS pairs (10 each), so, if I need to, I'll set up a current source and do the matching. Your point about temp is interesting. I think it might be useful to heat the pair with a heat gun so they are at the same temp, and let them cool together, so they are at the same temp during the test.

Good point on cleaning the parts before I put them back... BTW, I was absolutely astounded at the amount of of crap that came off the board!! at first I thought it was dust, but after several good washings and scrubbings the crap just kept coming off! I'll probably wash it a few more times just because I have more stuff in the can!.. Hydrocarbons are (sometimes!!) your best friend...

Thanks so much for your support on this! I WILL make this amp work!

Just so you know, this amp will drive the sub in my home setup.

I have a combination LP, iTunes, and 24 bit FLAC setup, controlled using an iPad (not the LPs, of course - that would be some app!). The iPad either supplies ACC files through the digital port of an Airport Express, or it controls an HDD with FLAC files that pass from the airport ethernet to the Airport TOS link. The LP input goes through an APT Holman preamp. Each of these go to a DSP (MiniDSP) box I built that implements a digital EQ and crossover unit. The HF output of the DSP is digital and goes back via an Arcam AirDAC to a GFA 555 that drives a set of Magnepan MGIIs, The LF output goes to a GFA535 (will go to the 565) that drives a 12 inch sub. I used the MiniDSP UMIK and the RoomEQ software to measure the room through the system and develop EQ filters for the DSP. The resulting system is flat in the room from 15 Hz to about 18KHz...Sounds very sweet..

Best,

Scott

Good point on cleaning the parts before I put them back... BTW, I was absolutely astounded at the amount of of crap that came off the board!! at first I thought it was dust, but after several good washings and scrubbings the crap just kept coming off! I'll probably wash it a few more times just because I have more stuff in the can!.. Hydrocarbons are (sometimes!!) your best friend...

Thanks so much for your support on this! I WILL make this amp work!

Just so you know, this amp will drive the sub in my home setup.

I have a combination LP, iTunes, and 24 bit FLAC setup, controlled using an iPad (not the LPs, of course - that would be some app!). The iPad either supplies ACC files through the digital port of an Airport Express, or it controls an HDD with FLAC files that pass from the airport ethernet to the Airport TOS link. The LP input goes through an APT Holman preamp. Each of these go to a DSP (MiniDSP) box I built that implements a digital EQ and crossover unit. The HF output of the DSP is digital and goes back via an Arcam AirDAC to a GFA 555 that drives a set of Magnepan MGIIs, The LF output goes to a GFA535 (will go to the 565) that drives a 12 inch sub. I used the MiniDSP UMIK and the RoomEQ software to measure the room through the system and develop EQ filters for the DSP. The resulting system is flat in the room from 15 Hz to about 18KHz...Sounds very sweet..

Best,

Scott

Hi Scott,

If the output goes DC, that can reverse bias the input transistors and ruin them. They will still test okay, but may have increased noise and different gain. In every Adcom amp I have looked at (all amplifiers actually), the diff pair has drifted out of balance. That's if they were ever in balance to begin with. Do your best to match them.. If the originals match - great! You may find that the pairs are better matches split up. Once you are done matching, hold them together with some heat shrink tubing with a touch of thermal compound between them.

I know there is a DC servo, but the sound quality is better with matched input pairs. A DC servo can't fix that.

-Chris

If the output goes DC, that can reverse bias the input transistors and ruin them. They will still test okay, but may have increased noise and different gain. In every Adcom amp I have looked at (all amplifiers actually), the diff pair has drifted out of balance. That's if they were ever in balance to begin with. Do your best to match them.. If the originals match - great! You may find that the pairs are better matches split up. Once you are done matching, hold them together with some heat shrink tubing with a touch of thermal compound between them.

I know there is a DC servo, but the sound quality is better with matched input pairs. A DC servo can't fix that.

-Chris

Ahh, OK, good to know. I have a supply of darlingtons and the parts to make the current source. So I'll do that before I start re-assembling the board.

What are the tail currents used?

Thanks

Scott

What are the tail currents used?

Thanks

Scott

2.2 mA seems awfully low! At 10 mA Ic, the MPA darlingtons have an Hfe of about 5000, so that makes the base current about 0.22 uA each (for an Ic of 1.1 mA ea). Seems very low. I suppose that's why the thing is so sensitive to noise and thermal effects.

Scott

Scott

Hi Scott,

You asked for tail currents. That is for the differential pair (each one in this case). Are you asking for bias current now?

-Chris

You asked for tail currents. That is for the differential pair (each one in this case). Are you asking for bias current now?

-Chris

Yes, when you said operating at the same "tail current" I thought you were talking bias current as provided by the emitter current source in the amplifier (many texts and lectures I read call that the differential pair 'tail current'.. ie. the current draw from the common tail of the pair).

As I understand the diff pair matching, I will need to set up a current source that biases the transistors at the typical emitter current they will operate at (either a negative or positive current on the emitter leg, depending on which polarity of the transistors I am matching), that is, at 1/2 of the "tail current" provided by the current source in the amplifier), measure the collector voltage for one, put the other into the exact same circuit (so all other values are the same), and then measure the collector voltage on that one. When I get two that have the same collector voltage I have a match. This means that in that circuit, at that bias current,and at that temp, the collector currents are the same, so the Hfe is the same.

In the diff configuration, I would assume a matched diff pair with a balanced input (zero differential voltage) and a common constant current source in the emitter leg would draw exactly the same current, so, to the extent that they are matched, the current source in the emitter circuit of the amp would be split equally between the two arms of the diff pair.

I was originally going to try to match them in pairs in a differential configuration, but that would mean that the collector resistors would also need to be exactly the same. So using the exact same circuit, and installing the transistors using tweezers, one atet another, so as to not heat them with my hands, then all of the operating conditions should be about the same. I suppose the best way to do this would be in a temp controlled oven, but I don't have one here.. I plan to have them all in the same tray, and then put them in the circuit one by one, leave them in for the same amount of time, and then measure and record the collector voltage. I can then find the matches after the measurements, and then go back and verify them.

Just as a back of the envelope calculation: Since the input of this amp is direct coupled, without any other bias circuitry, an effective input impedance of about 22K ohms (at a 1 volt line input level) would result in a total base current for both input transistors of about 50 uA (25 uA each), so at an Hfe of about 5K, the collector current in each transistor would be about 125 mA...

As I understand the diff pair matching, I will need to set up a current source that biases the transistors at the typical emitter current they will operate at (either a negative or positive current on the emitter leg, depending on which polarity of the transistors I am matching), that is, at 1/2 of the "tail current" provided by the current source in the amplifier), measure the collector voltage for one, put the other into the exact same circuit (so all other values are the same), and then measure the collector voltage on that one. When I get two that have the same collector voltage I have a match. This means that in that circuit, at that bias current,and at that temp, the collector currents are the same, so the Hfe is the same.

In the diff configuration, I would assume a matched diff pair with a balanced input (zero differential voltage) and a common constant current source in the emitter leg would draw exactly the same current, so, to the extent that they are matched, the current source in the emitter circuit of the amp would be split equally between the two arms of the diff pair.

I was originally going to try to match them in pairs in a differential configuration, but that would mean that the collector resistors would also need to be exactly the same. So using the exact same circuit, and installing the transistors using tweezers, one atet another, so as to not heat them with my hands, then all of the operating conditions should be about the same. I suppose the best way to do this would be in a temp controlled oven, but I don't have one here.. I plan to have them all in the same tray, and then put them in the circuit one by one, leave them in for the same amount of time, and then measure and record the collector voltage. I can then find the matches after the measurements, and then go back and verify them.

Just as a back of the envelope calculation: Since the input of this amp is direct coupled, without any other bias circuitry, an effective input impedance of about 22K ohms (at a 1 volt line input level) would result in a total base current for both input transistors of about 50 uA (25 uA each), so at an Hfe of about 5K, the collector current in each transistor would be about 125 mA...

Hi Scott,

Well, that is how my transistor balancer jig works. You must use a pair of transistors as that eliminates the temperature variable. However, I just discovered something. I was balancing some transistors for an amplifier that runs the diff pair hotter. It runs at 6 mA, and at that current, the transistors balance faster and are more stable. The correlation between the higher current and the lower ones still needs to be confirmed, but doing this at the higher current is less of a PITA.

Resistors. Yes. They should be matched. I used 1% resistors, then ordered 0.1% resistors. 4 100 R and 4 10 K. The 100 R is for collectors (PNP and NPN). The 10 K ones are for the base connections. It works extremely well and completely solves my "transistors matched for beta, are not mated very well some times" issue. Now everything behaves and is predictable.

-Chris

Well, that is how my transistor balancer jig works. You must use a pair of transistors as that eliminates the temperature variable. However, I just discovered something. I was balancing some transistors for an amplifier that runs the diff pair hotter. It runs at 6 mA, and at that current, the transistors balance faster and are more stable. The correlation between the higher current and the lower ones still needs to be confirmed, but doing this at the higher current is less of a PITA.

Resistors. Yes. They should be matched. I used 1% resistors, then ordered 0.1% resistors. 4 100 R and 4 10 K. The 100 R is for collectors (PNP and NPN). The 10 K ones are for the base connections. It works extremely well and completely solves my "transistors matched for beta, are not mated very well some times" issue. Now everything behaves and is predictable.

-Chris

OK. My original plan was to match them at the same time, but then I realized that the matching would depend heavily on the match of the various resistors in the circuit.

I suppose that the higher temp aspect you observed is that when the transistors are generating their own heat, they are much less sensitive to ambient temp, hence my thought of doing the matching in a temperature controlled oven. Even if it is a few degrees above ambient, it will eliminate variations since there is no air current to speak of. I suspect you could to the same by putting the jig in a styrofoam cooler, so the temp would be stable, and there would be no stray air currents. Maybe another approach would be to do that, but put a 50 watt light bulb in the cooler as well..to raise the temp to some stable value.

So, when you say 6mA, is this the Ie constant current source value? AS noted earlier, even 6mA in a darlington means a base current in the microamps region..

What is the circuit you use for matching? Base to collector resistor, plus collector resistor and base current source/sink? No base to ground resistor?

I suppose that the higher temp aspect you observed is that when the transistors are generating their own heat, they are much less sensitive to ambient temp, hence my thought of doing the matching in a temperature controlled oven. Even if it is a few degrees above ambient, it will eliminate variations since there is no air current to speak of. I suspect you could to the same by putting the jig in a styrofoam cooler, so the temp would be stable, and there would be no stray air currents. Maybe another approach would be to do that, but put a 50 watt light bulb in the cooler as well..to raise the temp to some stable value.

So, when you say 6mA, is this the Ie constant current source value? AS noted earlier, even 6mA in a darlington means a base current in the microamps region..

What is the circuit you use for matching? Base to collector resistor, plus collector resistor and base current source/sink? No base to ground resistor?

Hi Scott,

Yes, they generate their own heat to the extent that a simply foam "hood" fits over and is quite enough for isolating them. I drop a box, about 4"square over the matcher to kill air currents. When I designed it, it had to be stable and easy to use, and not take up a lot of space. What came together answered all the requirements. It will work fine at 1 mA tail current or less, but it does take a fair bit longer to settle down. I have nothing else that will allow matches to this level.

I built three of these things. One one perf board that I used so much that I decided to commit it to copper. The next used the header jumpers and the one I just made uses DIP switches. These are switched to select the tail current. It's easy to match a pair, then check the match at various current levels.

All this thing is, is a differential pair that places the transistors in thermal contact and has a built in current source for each polarity. This allows me to accurately measure the differences in current each one draws by simply hanging a meter between the collectors. By making it a stable arrangement, you can also measure across the 10 K base resistors to read base current, then individual collector currents to figure out the real beta under the conditions of operation. Nothing about this is automatic.

I have attached a couple images that show the basic schematic and a picture to show you a detail of how the current source is set up. Notice the foam under the pass transistor to thermally isolate the LED voltage reference. This makes the current source more stable for temperature changes as the LED tracks the transistor temperature.

-Chris

Yes, they generate their own heat to the extent that a simply foam "hood" fits over and is quite enough for isolating them. I drop a box, about 4"square over the matcher to kill air currents. When I designed it, it had to be stable and easy to use, and not take up a lot of space. What came together answered all the requirements. It will work fine at 1 mA tail current or less, but it does take a fair bit longer to settle down. I have nothing else that will allow matches to this level.

I built three of these things. One one perf board that I used so much that I decided to commit it to copper. The next used the header jumpers and the one I just made uses DIP switches. These are switched to select the tail current. It's easy to match a pair, then check the match at various current levels.

All this thing is, is a differential pair that places the transistors in thermal contact and has a built in current source for each polarity. This allows me to accurately measure the differences in current each one draws by simply hanging a meter between the collectors. By making it a stable arrangement, you can also measure across the 10 K base resistors to read base current, then individual collector currents to figure out the real beta under the conditions of operation. Nothing about this is automatic.

I have attached a couple images that show the basic schematic and a picture to show you a detail of how the current source is set up. Notice the foam under the pass transistor to thermally isolate the LED voltage reference. This makes the current source more stable for temperature changes as the LED tracks the transistor temperature.

-Chris

Attachments

- Home

- Amplifiers

- Solid State

- Yet Another Adcom GFA-565 Thread