The original described problem with the unit was... "The device powers up inconsistently, maybe some loose wiring because of age."

upon receiving the unit, it was in pretty rough condition and dirty overall...

so, before plugging it in, i removed the wooden case and looked for something obvious.

first thing i noticed was 2 disconnected wires and a resistor that had one leg detached from the tuner board.

a quick solder and plugged it in to see if it would smoke/blow up in my face.

no smoke, powered on!

the tuner picked up VERY good without an external antenna attached at all!

tested with a speaker and YES SOUND!

controls were terribly dirty so i went through all switches and pots with DeoxIT D5.

its suprising what a little cleaner can do after it has been worked into the dials!

upon receiving the unit, it was in pretty rough condition and dirty overall...

so, before plugging it in, i removed the wooden case and looked for something obvious.

first thing i noticed was 2 disconnected wires and a resistor that had one leg detached from the tuner board.

a quick solder and plugged it in to see if it would smoke/blow up in my face.

no smoke, powered on!

the tuner picked up VERY good without an external antenna attached at all!

tested with a speaker and YES SOUND!

controls were terribly dirty so i went through all switches and pots with DeoxIT D5.

its suprising what a little cleaner can do after it has been worked into the dials!

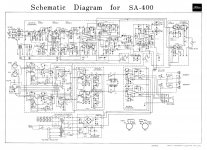

the biggest problem i had found with this specific model is that for some reason there really isn't any service manual out there for it. or atleast that i could locate. i did find the schematic, but thats fairly low resolution and hard to read.

if someone else is looking for the schematic, ill attach it here..

if someone else is looking for the schematic, ill attach it here..

Attachments

Wow! Never seen those before - they are very cool! Thanks for sharing.yeah, they are fairly large ICs...

I'm currently recapping it. This takes forever... Thanks to mouser I was able to get everything but the ceramics.

Ceramics aren't going to go bad. Don't replace them. Especially the ones in the Rf sections - if you get slightly different ones it will need to be retuned.

Ceramics aren't going to go bad. Don't replace them. Especially the ones in the Rf sections - if you get slightly different ones it will need to be retuned.

Sweet! I appreciate an honest answer especially because this was a difficult one to find. This particular piece was on the power supply

As above, don't even physically move any parts in the tuner section that are related to the adjustable and tuned circuits because doing so will alter the alignment (values of stray capacitance will change)

Caps like the one you show are in micro farads, so 0.0022 is actually a 2.2nano farad or 2200 picofarad.

Caps like the one you show are in micro farads, so 0.0022 is actually a 2.2nano farad or 2200 picofarad.

Does anyone know what I could use to replace these caps?

Leave this alone. It might be an arc supression cap. It is critical to use an exact same type, preferrably the one that already sits there.

heres a silly question; if ceramics are so durable, why didnt they use all ceramics throughout?

Ceramics aren't particularly durable but they have their uses. That's a bit simplistic... small low voltage compressed disc type ceramics are a fairly common failure item in much commercial equipment, typically going leaky.

Ceramics make great decoupling caps but generally have lousy temperature stability. They are also only viable in small values. Look how big that 0.0022uf cap of yours is. Imagine how big a 100 or 1000 or 10,000 uf cap would be in ceramic.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Toshiba sa-400