Now, rotate them 180 degrees.

Gajanan Phadte

Good idea, thanks a lot!

John

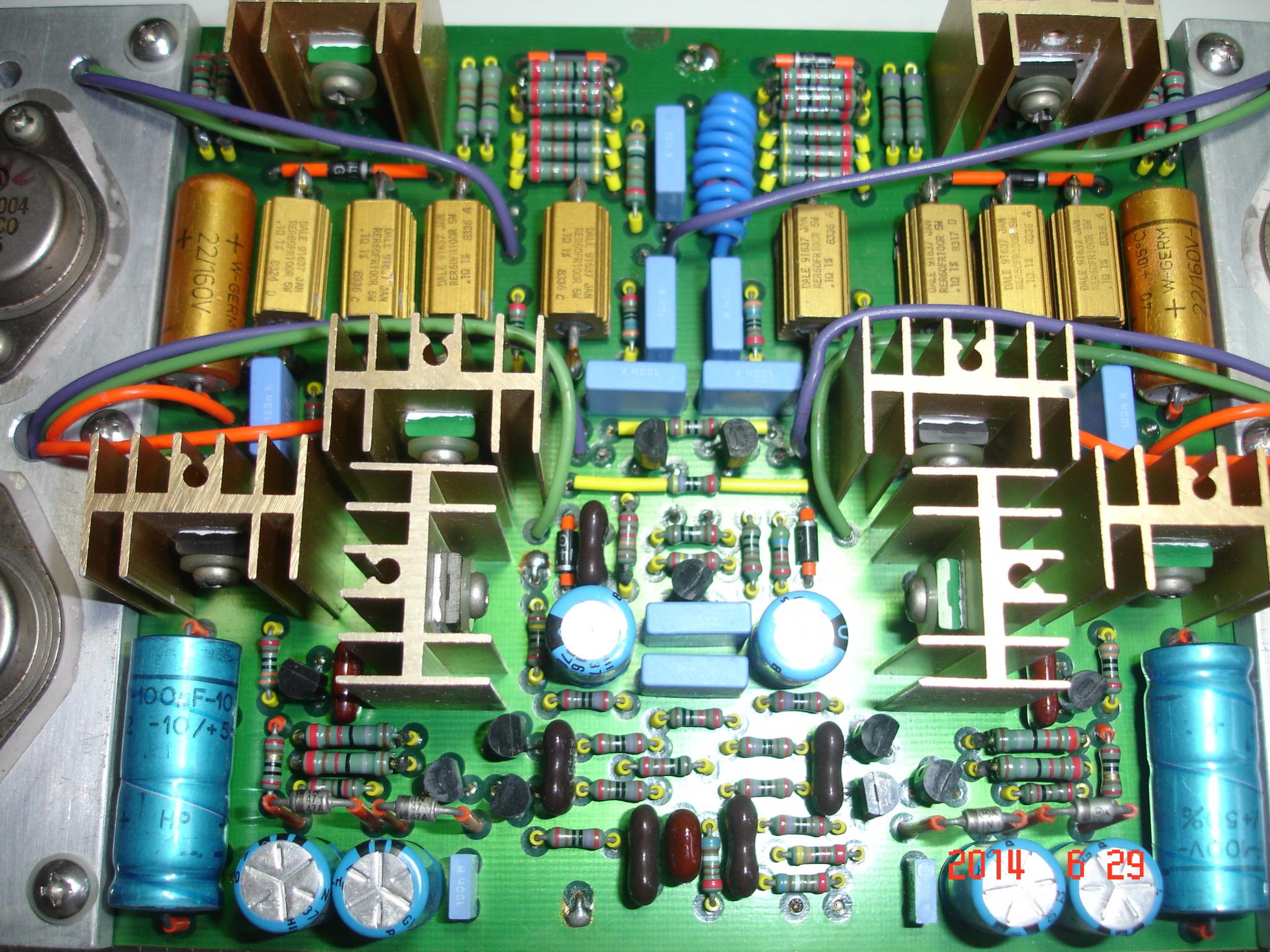

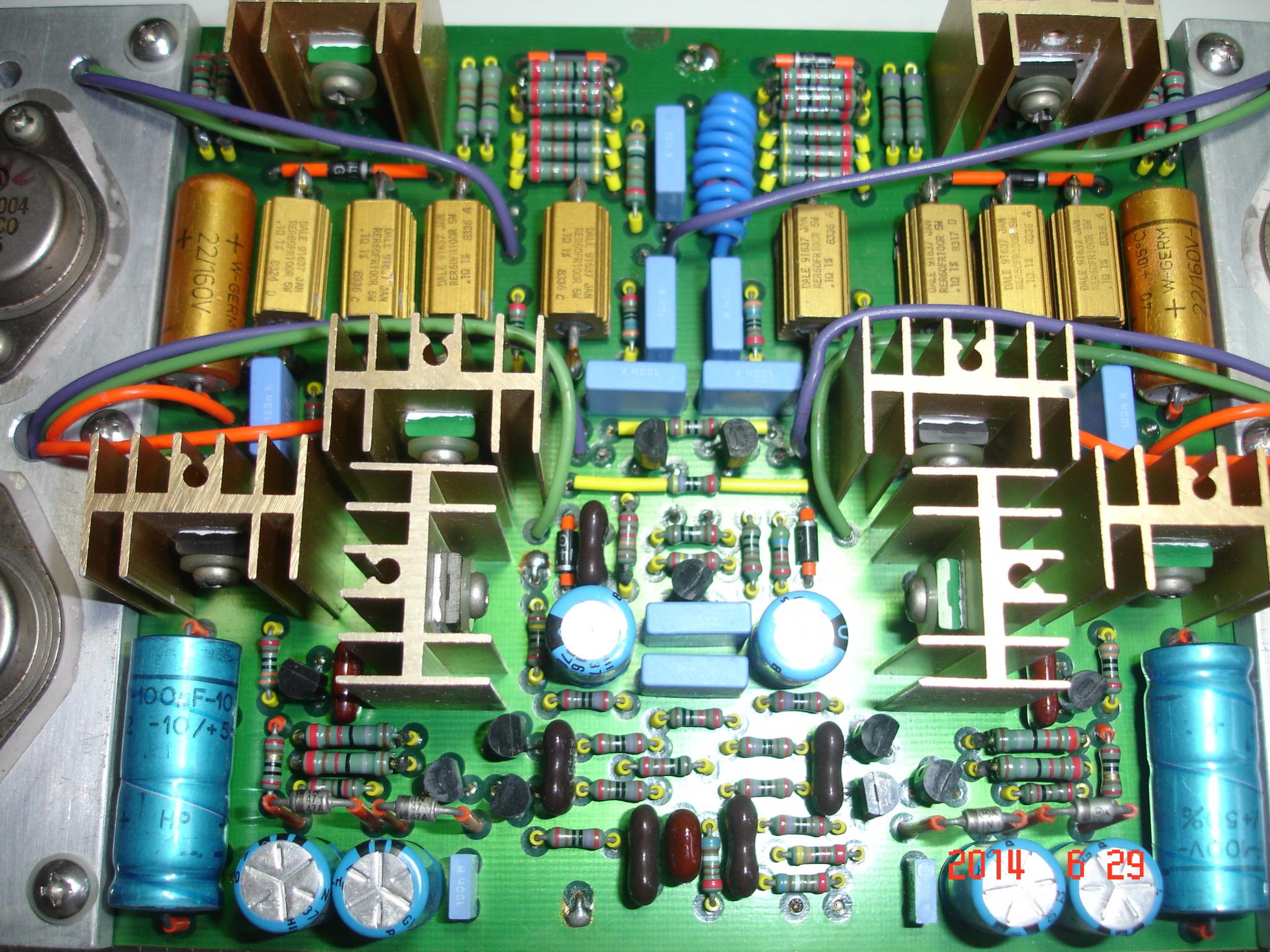

I use TO3 for driver, the circled TO3s on the small plate are the drivers. It according the initial design that M. Leach published in 1975.

The reversion layout in M. Leach current website use TO-220 for driver and locate on main PCB.

I think this may be the reason makes you confused.

There are 8 output TO3s located on the plate that you marked with red vertical bar, there is a 10mm thick plate between it and main heat sinker.

John

I hope this photograph can help for you to figure out my build.

John

Attachments

i hope someone can come up with gerbers of the Super Leach original lay-outs...

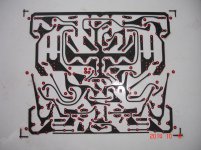

The PCB of my build was by manual with black tape and compact than Leach's original.

John

Attachments

The PCB of my build was by manual with black tape and compact than Leach's original.

John

very good John, what i have in mind also is the incorporation of the 4 TO-3 drivers into the boards...

John, are those yellow tubes ceramic or plastic? how much will a 1000pcs cost?

very good John, what i have in mind also is the incorporation of the 4 TO-3 drivers into the boards...

John, are those yellow tubes ceramic or plastic? how much will a 1000pcs cost?

They are Teflon, cut off from Teflon packaged copper wire.

John

The PCB of my build was by manual with black tape and compact than Leach's original.

What kind of tape?? Is it really possible or strong enough?? I'd like to find different approach to etch a PCB (quickly)

I've used black electrical tape as a resist for a one-off.

Just roll it flat to get good adhesion or the trace will be undercut during etch.

I used a paintbrush during the etch phase to remove most of the copper quickly (and I didn't have enough etchant for a tank anyway).

Just roll it flat to get good adhesion or the trace will be undercut during etch.

I used a paintbrush during the etch phase to remove most of the copper quickly (and I didn't have enough etchant for a tank anyway).

What kind of tape?? Is it really possible or strong enough?? I'd like to find different approach to etch a PCB (quickly)

The tape is of the old method. It is some type of paper tape and may not be available now. This tape was used when PC methods were not available. This artwork would be done on a pvc(?) paper and later used for UV exposure.

Gajanan Phadte

The tape is of the old method. It is some type of paper tape and may not be available now. This tape was used when PC methods were not available. This artwork would be done on a pvc(?) paper and later used for UV exposure.

Gajanan Phadte

Hello Gajanan,

Thanks a lot for your kind description.

I can tell that Jay should be much younger than me.

John

I've used black electrical tape as a resist for a one-off.

Just roll it flat to get good adhesion or the trace will be undercut during etch.

Hmmm... hard to believe it is strong enough, but I will try that sometime...

Hello Gajanan,

Thanks a lot for your kind description.

I can tell that Jay should be much younger than me.

Hehehe

There are loads of different etch resist schemes. In high school we used layout dye and scatched out where we wanted the copper gone. There are also many different ways to etch. I threw away my etch tank years ago. On one ounce copper boards I use a sponge soaked in warm etchant. It works faster than the tank because the corroded copper is constantly being wiped off and uses little etchant. On half ounce boards I put them in a ziplock bag with a small amount of etchant. Immerse it in warm water and rub the suface of the board. Clean up is really simple that way.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Work In Progress... Leach Based Amplifier