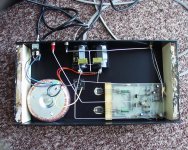

the heat sink is attached to the box with spacers to ensure some air flow instead of glue that was the previous fixing and the top cover was drilled in a CNC laser with 12 stripes 15 cm long each with a gap of 3mm to ensure ventilation ....

humble amplifier construction...

humble amplifier construction...

Im not qualified to answer whether the new transformer installation complies with the double insulation standard .............i had to raise my concerns as i couldnt see a safety earth ............as it has no safety earth i would personally put one in as you say the base is solid alluminium and not some insulation material as the rest of the amp appears to be.

Adding some rail protection fuses would be a good idea also.

Adding some rail protection fuses would be a good idea also.

Last edited:

well not really the all box is made out of plastic , according to the manufacturer iron or steel or aluminum boxes effect sound for the worst together with the screws that hold the all thing together.

so his approach is plastic and glue .... about ground never existed inside the box from the first place

as about ...the phrase :""complies with the double insulation standard "" .... i will have to say this :

In Greece if you market a product that doesn't have real CE marking behind it and proper markings with classification of safety and energy they will shut you down and take you to jail .... for the violation of the regulations which i Presume that apply in all Europe ....i wonder what you do about this in UK ?

so his approach is plastic and glue .... about ground never existed inside the box from the first place

as about ...the phrase :""complies with the double insulation standard "" .... i will have to say this :

In Greece if you market a product that doesn't have real CE marking behind it and proper markings with classification of safety and energy they will shut you down and take you to jail .... for the violation of the regulations which i Presume that apply in all Europe ....i wonder what you do about this in UK ?

A couple of things here. I believe Epi was referring to my amp which does have a aluminium base plate as a heat sink.well not really the all box is made out of plastic , according to the manufacturer iron or steel or aluminum boxes effect sound for the worst together with the screws that hold the all thing together.

so his approach is plastic and glue .... about ground never existed inside the box from the first place

as about ...the phrase :""complies with the double insulation standard "" .... i will have to say this :

In Greece if you market a product that doesn't have real CE marking behind it and proper markings with classification of safety and energy they will shut you down and take you to jail .... for the violation of the regulations which i Presume that apply in all Europe ....i wonder what you do about this in UK ?

Regarding CE regs etc.. my amp dates from c. 1992/1993. I'm sure regs are tight now, but were they back then?

Edit to add: the regs came in in 1993, so my amp precedes them. I'm sure the current NVA amps adhere to all the required safety regs.

Last edited:

Here you go: linkHello,

Please, can you post the link to the russian web page with the schematics of the NVA?

Thanks.

Thanks for the link!

In this page can be seen the drawing of the pcb:

Klang Projekt NVA Zu Besuch

but are too smal and cannot be used for made a pcb. Perhaps can you post a better drawing?

Anticipated thanks

In this page can be seen the drawing of the pcb:

Klang Projekt NVA Zu Besuch

but are too smal and cannot be used for made a pcb. Perhaps can you post a better drawing?

Anticipated thanks

Last edited:

Sorry. The boards are glued back in position so I cannot easily make a drawing. Looking at the board you show, the only difference I'd not is that on mine the power rails are split and joined above board with wire links. Looking at photos of the bigger amps that i can find, this is so that the bigger amps can be powered with separate front and back end power supplies.

In order to get the best from an NVA amp you'll need to get the transformer away from the circuit boards, I found this messing about with the headphone version of the same amp. NVA's top of the range model has a transformer at each corner of the unit, well away from the eletronics. I had similiar a experience with transformer location with a kit amp that had a similar design. Also using an external transformer makes it a lot easier to have one or even two per channel.

Any suggestions for an improved output stage that doesn't require the re-engineering of the rest of the amp?

Any suggestions for an improved output stage that doesn't require the re-engineering of the rest of the amp?

Any suggestions for an improved output stage that doesn't require the re-engineering of the rest of the amp?

o yes of course : none . zilts , nicths .zero....

The four transformers in NVA not used to increase the current of the power supply as usual, each one is used for a separate power supply: four power supplies.

The power outputs of NVA are in four sections, and in the traces of the supply in the pcb have some jumpers. In the High-End brand models the jumpers are removed and each section has its own power supply. This ultra-clean power greatly improves sound quality, dynamics and resolution of small details.

The only amps I know who follow this same design are the extraordinary Luxman 200 series:

Luxman L200, L210, L220 Service Manual free download,schematics,datasheets,eeprom bins,pcb,repair info for test equipment and electronics

As shown in the diagram, they succeed in an effective and economical way. The power transformer output goes to the bridge rectifier which produces the voltage to the output stage, but it is also rectified to produce a separate regulated voltage which feeds the VAS, and this stabilized voltage leads to another, regulated by a zener, to feed the input differential. Each section has its own separate supply.

This small and inexpensive amplifier has an extraordinary sound that you never expected initially judging from his low-end level. It really is a pity that it has ceased manufacturing.

Perhaps something similar can be designed for your NVA. Not take up much space and may be mounted on a small pcb that may be within the amplifier housing.

This perhaps improved the output without re-engineering the rest of the amp. This same technique can be applied to many other amplifiers.

Happy days.

The power outputs of NVA are in four sections, and in the traces of the supply in the pcb have some jumpers. In the High-End brand models the jumpers are removed and each section has its own power supply. This ultra-clean power greatly improves sound quality, dynamics and resolution of small details.

The only amps I know who follow this same design are the extraordinary Luxman 200 series:

Luxman L200, L210, L220 Service Manual free download,schematics,datasheets,eeprom bins,pcb,repair info for test equipment and electronics

As shown in the diagram, they succeed in an effective and economical way. The power transformer output goes to the bridge rectifier which produces the voltage to the output stage, but it is also rectified to produce a separate regulated voltage which feeds the VAS, and this stabilized voltage leads to another, regulated by a zener, to feed the input differential. Each section has its own separate supply.

This small and inexpensive amplifier has an extraordinary sound that you never expected initially judging from his low-end level. It really is a pity that it has ceased manufacturing.

Perhaps something similar can be designed for your NVA. Not take up much space and may be mounted on a small pcb that may be within the amplifier housing.

This perhaps improved the output without re-engineering the rest of the amp. This same technique can be applied to many other amplifiers.

Happy days.

raull 77 sorry but your example is completely out of the picture ...the NVA uses this topology and separates as you said the the power supply to 2 main output transformers and 2 secondary transformers in order to keep a dual mono operation but also dual mono for the input stages .

The Luxman you example simply is integrated , have only one transformer for everything , only have regulated psu for the input stages but still not separated ....obviously if main power amplifier will start to demand current if used in high power this will eventually modulate at some point the input stages due to common ( eventhough regulated ) supply ....

The NVA is absolutely passive pre while the Luxman is a pre with gain so NO !! big time these two machines have absolutely nothing in common

The character of the very honest Luxman has to do that its made with order and its a quality well designed consumer hifi product

Add to the character the well known "" passive" tone control that has no active parts but is seated on the feedback node with the also wonderful sonics and well known stability issues if load is too capacitive or cables are too thin and or too long ...

kind regards

sakis

( we can have endless discussions about amplifiers but from default anyone is made with BDV 66-67 or TIP 142-147 can be excused from both sound and safety aspects .So whats the point ? if the owner of the NVA has the ability to listen to any well made DX amplifier or the P3A will obviously trash the NVA in a few seconds ... )

The Luxman you example simply is integrated , have only one transformer for everything , only have regulated psu for the input stages but still not separated ....obviously if main power amplifier will start to demand current if used in high power this will eventually modulate at some point the input stages due to common ( eventhough regulated ) supply ....

The NVA is absolutely passive pre while the Luxman is a pre with gain so NO !! big time these two machines have absolutely nothing in common

The character of the very honest Luxman has to do that its made with order and its a quality well designed consumer hifi product

Add to the character the well known "" passive" tone control that has no active parts but is seated on the feedback node with the also wonderful sonics and well known stability issues if load is too capacitive or cables are too thin and or too long ...

kind regards

sakis

( we can have endless discussions about amplifiers but from default anyone is made with BDV 66-67 or TIP 142-147 can be excused from both sound and safety aspects .So whats the point ? if the owner of the NVA has the ability to listen to any well made DX amplifier or the P3A will obviously trash the NVA in a few seconds ... )

let me explain this a bit ...

to have a more decent amplifier if we take as a fact that the design of the NVA at least for the input is perfect you need only a couple of things

1) to ensure the thermals either way one may be a proper vbe multiplier that will preserve thermal run away issues or simply run the in the maximum bias but with huge heatsinks ...Will take some hour to warm up but other than that stable ...

2) to remove the miller caps as very well known as sonic killers from the B-C of the output transistors After that serious oscillation is around the corner waiting for you that cannot be cured ( at least with the techniques i am familiar with )

To the above exists only one exception of a working amplifier that solved most of these issues the NP a40 ... biased at 800 ma per device given as a fact hat heatsink will manage that and while the darlington is too busy to handle the bias doesn't oscillate that easy even operating without miller caps on the B-C of the outputs ....

Other than the A40 i have never seen any amplifier based on these outputs that either performs or at least is safe enough ...

to have a more decent amplifier if we take as a fact that the design of the NVA at least for the input is perfect you need only a couple of things

1) to ensure the thermals either way one may be a proper vbe multiplier that will preserve thermal run away issues or simply run the in the maximum bias but with huge heatsinks ...Will take some hour to warm up but other than that stable ...

2) to remove the miller caps as very well known as sonic killers from the B-C of the output transistors After that serious oscillation is around the corner waiting for you that cannot be cured ( at least with the techniques i am familiar with )

To the above exists only one exception of a working amplifier that solved most of these issues the NP a40 ... biased at 800 ma per device given as a fact hat heatsink will manage that and while the darlington is too busy to handle the bias doesn't oscillate that easy even operating without miller caps on the B-C of the outputs ....

Other than the A40 i have never seen any amplifier based on these outputs that either performs or at least is safe enough ...

the heat sink is attached to the box with spacers to ensure some air flow instead of glue that was the previous fixing and the top cover was drilled in a CNC laser with 12 stripes 15 cm long each with a gap of 3mm to ensure ventilation ....

humble amplifier construction...

Sakis...your work is very neat! you put pride in your work. Well done.

This ultra-clean power greatly improves sound quality, dynamics and resolution of small details.

Fully agree. I have always used and promoted this technique. Still, once i had the displeasure to own NVA monos - by far my worst ever amplifier, surpassing in this regard even a Quad 303. They made a fuss about using non-ferrous glued enclosures and glued to heatsinks transistors. Conveniently, these techniques also provided a unique sense of cheapness.

Attachments

Fully agree. I have always used and promoted this technique. Still, once i had the displeasure to own NVA monos - by far my worst ever amplifier, surpassing in this regard even a Quad 303. They made a fuss about using non-ferrous glued enclosures and glued to heatsinks transistors. Conveniently, these techniques also provided a unique sense of cheapness.

wow, those NVA amps are expensive for what they are!. I have never hear a NVA amp but they look cheap build. I hear that the potentiometer that they use are very noisy when changing volume. I would never use glue to attach a transistor to a heat sink!

Long time ago I almost got one of these amps, lucky me I passed!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Beefing up an NVA AP10P Amp