well, it s doable if one is satisfied with a THD ratio that

is ten fold higher than when adding an EF buffer stage....

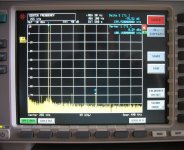

Charts will tell maybe

Please do not measure THD at 1kHz, measure, please THD at 100kHz. Many transistors does a very slow amplifier.

Okay, here you are. Would you kindly show your THD measurement at 100kHz.

Attachments

OI OI OI

I think we need to remember that when driving even a single pair of VERTICLE FETS, we need a fair wack of current across their gate to keep them stable. They need to be driven tightly! 10 Pairs - This needs to be thought about carefully! HF Distortion will be up the shoot... I reckon an MJE350/340 will do the driving nicely! Better yet, MJE15032/33.

Nice Layout though - 5*s

On the front of cooling... In one lot of amplifiers I designed, we ended up with 2 x 2000W RMS in a 2U package, so needless to say we needed to get rid of a lot of heat! Two things emerged from months of idea's... Increase the number of output devices - ie use way more than you need, which as we all know will drop the total heat dissapation dramatically, and number 2 : We got a car radiator company to build a run of mini radiators. these fitted in a 2U case and were very efficient at cooling. The answer is to have a very thick piece of material for the output devices to mount onto. 4 x 80mm fans attached to each "heat sink" for forced cooling. These were mounted against the sides of the case, an blew he hot air out, sideways. Just about the entirety of the side panels were vents, to obtain as much free flow as possible.

It did the job in around 300 touring amplifiers.

I think we need to remember that when driving even a single pair of VERTICLE FETS, we need a fair wack of current across their gate to keep them stable. They need to be driven tightly! 10 Pairs - This needs to be thought about carefully! HF Distortion will be up the shoot... I reckon an MJE350/340 will do the driving nicely! Better yet, MJE15032/33.

Nice Layout though - 5*s

On the front of cooling... In one lot of amplifiers I designed, we ended up with 2 x 2000W RMS in a 2U package, so needless to say we needed to get rid of a lot of heat! Two things emerged from months of idea's... Increase the number of output devices - ie use way more than you need, which as we all know will drop the total heat dissapation dramatically, and number 2 : We got a car radiator company to build a run of mini radiators. these fitted in a 2U case and were very efficient at cooling. The answer is to have a very thick piece of material for the output devices to mount onto. 4 x 80mm fans attached to each "heat sink" for forced cooling. These were mounted against the sides of the case, an blew he hot air out, sideways. Just about the entirety of the side panels were vents, to obtain as much free flow as possible.

It did the job in around 300 touring amplifiers.

Last edited:

On the front of cooling... In the lat lot of amplifiers I designed, we ended up with 2 x 2000W RMS in a 2U package, so needless to say we needed to get rid of a lot of heat! Two things emerged from months of idea's... Increase the number of output devices - ie use way more than you need, which as we all know will drop the total heat dissapation dramatically, and number 2 : We got a car radiator company to build a run of mini radiators. these fitted in a 2U case and were very efficient at cooling. The answer is to have a very thick piece of material for the output devices to mount onto. 4 x 80mm fans attached to each "heat sink" for forced cooling. These were mounted against the sides of the case, an blew he hot air out, sideways. Just about the entirety of the side panels were vents, to obtain as much free flow as possible.

It did the job in around 300 touring amplifiers.

Similar to ARX amplifiers from austrailia?

@ Workhorse

Not sure about that, as I have not seen them yet... I was in South Africa at the time.

I know that the crown CSL range had something similar going on with an aluminium heatsink with really thin fins, and air being forced out through the side of the case. The ones we build looked exactly like a radiator, however, the company who made the cooling units advised that copper was more efficient because of the space constraint.

Not sure about that, as I have not seen them yet... I was in South Africa at the time.

I know that the crown CSL range had something similar going on with an aluminium heatsink with really thin fins, and air being forced out through the side of the case. The ones we build looked exactly like a radiator, however, the company who made the cooling units advised that copper was more efficient because of the space constraint.

Seems like many followed this schemeYep... Something Like That!

Attachments

Got to love how the PCB has been cut around the Toroid.... You would want to make sure your design was right the first time.

You would want to make sure your design was right the first time.

I still think that a radiator style cooling device is the go if you are trying to get rid of loads of heat quickly. The only limit is how tightly they can pack the foils between the plates, and how many high velocity fans you can attach to it!

I still think that a radiator style cooling device is the go if you are trying to get rid of loads of heat quickly. The only limit is how tightly they can pack the foils between the plates, and how many high velocity fans you can attach to it!

OI OI OI

I think we need to remember that when driving even a single pair of VERTICLE FETS, we need a fair wack of current across their gate to keep them stable. They need to be driven tightly! 10 Pairs - This needs to be thought about carefully! HF Distortion will be up the shoot... I reckon an MJE350/340 will do the driving nicely! Better yet, MJE15032/33.

Nice Layout though - 5*s

MJE15032/33 Very slow

I use 2SA968B/2SC2238B

OI OI OI

On the front of cooling... In one lot of amplifiers I designed, we ended up with 2 x 2000W RMS in a 2U package,

I recommend three types of cooling:

1. On basic Al plate. Without the fan.

2. Al on the side wall. Without the fan.

3. On the wall of the tunnel inside the box. Fan air racing through the tunnel.

2SA968B/2SC2238B

200V max!

and current about 100-150 mA is wrong !

Build your ownand current about 100-150 mA is wrong !

You'll like

You'll likeIMO

With those sort of power figures, reliabiliy needs to be 110%. I would be steering clear of just "getting by". Why not replace the 2sa968B/2sc2238B with something strong like 5200/1943. That way you do not need to worry about voltage/current or cooling. They are fast 30M and cheap. It will also enable you to drive the VERT's with plenty of current.

I will be interested t see how this module turns out...

I think you are being very very VERY optimistic with your cooling requirements. THIS MODULE WILL REQUIRE FORCED COOLING! Unless of course you intend using a piece of aluminium the size of a football field...

With those sort of power figures, reliabiliy needs to be 110%. I would be steering clear of just "getting by". Why not replace the 2sa968B/2sc2238B with something strong like 5200/1943. That way you do not need to worry about voltage/current or cooling. They are fast 30M and cheap. It will also enable you to drive the VERT's with plenty of current.

I will be interested t see how this module turns out...

I think you are being very very VERY optimistic with your cooling requirements. THIS MODULE WILL REQUIRE FORCED COOLING! Unless of course you intend using a piece of aluminium the size of a football field...

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- amp 1000W/2000W, IRFP240/9240