These are definitely my people

http://tangentsoft.net/elec/diy-hs.html

Bottom line: the paper clip beats the coins.

http://tangentsoft.net/elec/diy-hs.html

Bottom line: the paper clip beats the coins.

Yes, the beauty of the paperclip idea is that you can use a choice of clip sizes and bend the "fins" in whatever direction is convenient. I love it. Just make sure you have great thermal contact with the device.

I've used "fast-on" connectors wrapped around TO-92 transistors as heatsinks (to reduce thermal variation). Add a [solid] copper wire link between 2 of them for differential pairs, to keep them them [somewhat] thermally 'synchronized'.

I wonder what other household commodities we can use for DIY Audio applications that perform nicely as compared to commercial products.

..Todd

I've used "fast-on" connectors wrapped around TO-92 transistors as heatsinks (to reduce thermal variation). Add a [solid] copper wire link between 2 of them for differential pairs, to keep them them [somewhat] thermally 'synchronized'.

I wonder what other household commodities we can use for DIY Audio applications that perform nicely as compared to commercial products.

..Todd

jwb said:

Bottom line: the paper clip beats the coins.

How do you tell

Its hard to imagine with that little contact surface of the paper clips

The copper coins seems nice, but have to be grinded smooth to work

With the coins tho Im thinking that the insufficient cooling surface might just make heating issues worse, as its just holding back the heat, and dont remove it

Might be why paper clips seem to work better, as they still allow the heat to get away

It says, "naked transistor not yet tested", which to me makes conclusion pointless

Very easy to do a nice effective finger heatsink with any kind of metal sheet, be it alu, copper or what ever

As long as its stable enough to make proper contact

A proper heatsink still seems far more effective, so I really dont see the point, other than its fun

Seems to me he made the same conclusion, or maybe I dont understand it right ?

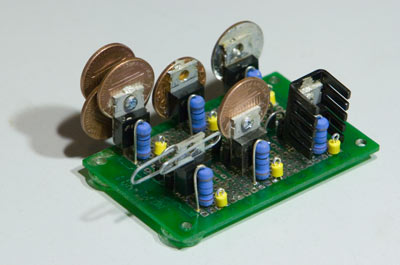

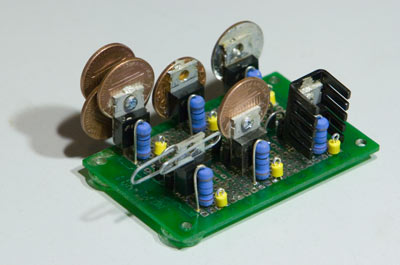

I've used coins as heatsinks for some small bridge rectifier modules (those little tiny round ones). I just stuck them on with epoxy (JB weld,lol) and they worked great. I even built up a larger finned 'heatsink' with a stack of off-set pennies all epoxied together,much like in the picture. It actually worked quite well!

(Edit: I think the trick to using epoxy,is to use some that is meant for (and contains) metal.It probably has lower thermal resistance?! Just a thought.)

(Edit: I think the trick to using epoxy,is to use some that is meant for (and contains) metal.It probably has lower thermal resistance?! Just a thought.)

cbdb said:Ever try pieces of aluminum beer cans? You can cut (with siccors) and bend them to custom sizes and shapes.

To cool a TO-18 transistor. It worked, the trany didn't blow out as it did without the beer-sink.

To cool a TO-18 transistor. It worked, the trany didn't blow out as it did without the beer-sink.As for pennies, you need to get some old ones, pre-1980. They are solid copper. The new ones are only plated.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Paper clips as TO-220 heat sinks