Not so simple. They are going to heat it up, then dunk it in the varnish so it sucks in the varnish as it cools, evacuate the container to pull any trapped air out, then eventually bake the transformer to cure it.

This is a large company that makes transformers for mass production, not a one-man boutique that might improvise some of the manufacturing process.

This is a large company that makes transformers for mass production, not a one-man boutique that might improvise some of the manufacturing process.

SQLGuy said:Not so simple. They are going to heat it up, then dunk it in the varnish so it sucks in the varnish as it cools, evacuate the container to pull any trapped air out, then eventually bake the transformer to cure it.

This is a large company that makes transformers for mass production, not a one-man boutique that might improvise some of the manufacturing process.

Well Paul, if it is so, then you are very lucky. Because this procedure that you reffer and which i know very well, i have seen with my eyes when i gave an x-former for repairing... with this procedure of heating up can disassempled the core as i remember.

You will get back a good stuff. Don't forget to leave it to dry thoroughly.

Regs

Fotios

This evening I removed the transformer from the amp to get it ready to send back for revarnishing. (By the way, it weighs in at exactly 25 lbs).

Out of curiosity, I hooked it up on my bench to see how loud it was outside of the case. I found it to be pretty quiet - I had to press my ear to it to hear any hum.

So, I then took some jumpers to hook it back up to the amp while it was still sitting on my bench. It's a slight bit louder under load, but still pretty quiet - I could probably hear it in a quiet room from no more than three feet away (and, by "hear it," I mean be able to distinguish the hum from ambient room noise well enough to tell whether it was on). So, I guess it is resonance with the case that's causing the more noticeable mechanical hum when the transformer's in the amp.

Any ideas on damping this? There's room enough that I could put rubber washers under and on top of the tranformer's feet, but a rubber isolation mount would be too high... making the transformer sit higher than the case top.

Also, does this sound like I should still send the tranformer back to be revarnished, or just look into what I can do to make it quieter once mounted?

Thanks,

Paul

Out of curiosity, I hooked it up on my bench to see how loud it was outside of the case. I found it to be pretty quiet - I had to press my ear to it to hear any hum.

So, I then took some jumpers to hook it back up to the amp while it was still sitting on my bench. It's a slight bit louder under load, but still pretty quiet - I could probably hear it in a quiet room from no more than three feet away (and, by "hear it," I mean be able to distinguish the hum from ambient room noise well enough to tell whether it was on). So, I guess it is resonance with the case that's causing the more noticeable mechanical hum when the transformer's in the amp.

Any ideas on damping this? There's room enough that I could put rubber washers under and on top of the tranformer's feet, but a rubber isolation mount would be too high... making the transformer sit higher than the case top.

Also, does this sound like I should still send the tranformer back to be revarnished, or just look into what I can do to make it quieter once mounted?

Thanks,

Paul

Attachments

By looking in the picture attached, i have to say one and only one thing:

This is one of the most beautifull EI x-formers that i have seen in my life!

I am reffered concretelly in the shielding of core. Instead the usual external belly band, here it exists a total screening of core with copper band! Amazing good work! Accordingly, i don't believe that your x-former has any issue of malfunction (except than it is overdriven from heavy loading, but this is another history) thus you must search the problem somewhere else. Some times, the problem caused from the parts of rectification and smoothing stages. Check the bridge rectifiers, the reservoir capacitors for leakage and everything else part incorporated in power supply. Many times, a small short caused from a damaged part does not cause blowing fuses.

Good luck.

Fotios

This is one of the most beautifull EI x-formers that i have seen in my life!

I am reffered concretelly in the shielding of core. Instead the usual external belly band, here it exists a total screening of core with copper band! Amazing good work! Accordingly, i don't believe that your x-former has any issue of malfunction (except than it is overdriven from heavy loading, but this is another history) thus you must search the problem somewhere else. Some times, the problem caused from the parts of rectification and smoothing stages. Check the bridge rectifiers, the reservoir capacitors for leakage and everything else part incorporated in power supply. Many times, a small short caused from a damaged part does not cause blowing fuses.

Good luck.

Fotios

Hi Fotios,

Glad you like it, though copper was a theme for this amp, so they probably did this as much for appearances as for shielding. I believe that in the later version (200cx) they had a complete copper box over the transformer.

I don't think I understand your theory, though. Connected by jumpers to the amp, but not physically installed in the case, the transformer is quiet. Why do you think it's a problem with the amp (rectifiers/caps) that would be causing it to be noisy?

Current draw is also correct. My amp is biased for about 100W at idle, and the draw on the line at idle is a little over 1A (at 120V).

Paul

Glad you like it, though copper was a theme for this amp, so they probably did this as much for appearances as for shielding. I believe that in the later version (200cx) they had a complete copper box over the transformer.

I don't think I understand your theory, though. Connected by jumpers to the amp, but not physically installed in the case, the transformer is quiet. Why do you think it's a problem with the amp (rectifiers/caps) that would be causing it to be noisy?

Current draw is also correct. My amp is biased for about 100W at idle, and the draw on the line at idle is a little over 1A (at 120V).

Paul

Paul, just a moment please. I think that we spend our time in conjectures... Why i said this? Facts!

1) I have a Rotel integrated amplifier (in which included a phono stage as usually) which of the 400VA EI xformer presents an amazing loud mechanical noise, but no one buzz noise is audible from speakers (be it so phono input is selected and the volume is turned at full) except than the hiss noise produced from the active - passive parts inside, and this make sense of course. One thing a noisy transformer and other thing if its noise can pass thru the audio path.

2) You did not informing us if you have bought this amplifier from second hand or if you are its owner from the start. From the picture attached in one of your posts, it is obvious that this amplifier has undergone several modifications which - as can suppose - are not specified from the official constructor. BTW i have a good information here: Single solid copper conductors, though are uggly and not flexible, have a great beneffit compared with multiclone flexible cables which is their very small stray capacitance.

3) I don't believe that a serious company like PS Audio sell amplifiers for domestic use, with noisy outputs. Instead, i believe that something wrong happened in this amplifier... either from a repair work during those 25 years or from an attempt for a supposed upgrade with hi-end caps, resistors etc arround.

Consequently, please forget those i have mentioned in my previous post. From my experience, when i am faced with a serious problem inside a project, many times my attempts to resolve it result in a real confusion of cables, resistors, capacitors connected arround different parts. If the problem remains, then i leave everything for a couple of days to calm down, and the next day with clear mind i remove everything i have added. After this, i start again the inspection and usually i find-out the real origin of problem, consequently the appropriate cure.

I have a question: What are those two multiclone speaker cables under the two PCBs? Ground straps?

Regs

Fotios

1) I have a Rotel integrated amplifier (in which included a phono stage as usually) which of the 400VA EI xformer presents an amazing loud mechanical noise, but no one buzz noise is audible from speakers (be it so phono input is selected and the volume is turned at full) except than the hiss noise produced from the active - passive parts inside, and this make sense of course. One thing a noisy transformer and other thing if its noise can pass thru the audio path.

2) You did not informing us if you have bought this amplifier from second hand or if you are its owner from the start. From the picture attached in one of your posts, it is obvious that this amplifier has undergone several modifications which - as can suppose - are not specified from the official constructor. BTW i have a good information here: Single solid copper conductors, though are uggly and not flexible, have a great beneffit compared with multiclone flexible cables which is their very small stray capacitance.

3) I don't believe that a serious company like PS Audio sell amplifiers for domestic use, with noisy outputs. Instead, i believe that something wrong happened in this amplifier... either from a repair work during those 25 years or from an attempt for a supposed upgrade with hi-end caps, resistors etc arround.

Consequently, please forget those i have mentioned in my previous post. From my experience, when i am faced with a serious problem inside a project, many times my attempts to resolve it result in a real confusion of cables, resistors, capacitors connected arround different parts. If the problem remains, then i leave everything for a couple of days to calm down, and the next day with clear mind i remove everything i have added. After this, i start again the inspection and usually i find-out the real origin of problem, consequently the appropriate cure.

I have a question: What are those two multiclone speaker cables under the two PCBs? Ground straps?

Regs

Fotios

Hi Fotios,

Sorry but I think we're not on the same page here.

Here's a whole recap of progress. Some of it is covered earlier in this thread and some is covered in one or two other posts.

1. I bought this amp used and blown up.

2. I exchanged a few emails with the original designer, Paul McGowan, who advised that replacing the outputs with On Semi devices (since the orginal NEC's are unavailable, and MJ2119x's were actually used in the later 200cx) "...shouldn't be a problem."

3. I replaced the blown outputs, drivers, resistors, bias transistors and fuses. I also replaced all electrolytics other than the main filter caps.

4. The amp was then working, but had noticable noise through the speakers, especially from one channel.

5. I spent a lot of time trying to find the noise from the one channel. I eventually tracked it down to a 1K resistor installed where a 10K resistor belonged (in the feedback loop from the DC servo). This looked to be a production mistake. Putting a 10K in there reduced the noise to a comparable level of the quieter channel.

6. Unfortunately, during the step 5 troubleshooting, I accidentally touched the collectors of two of the VAS transistors together, blowing one of them. These are fairly difficult to get 2N6556's. I ended up replacing all 2N6556's with KSA1220A's. Noise level of the quiet channel remained the same with the KSA1220A's to what it was with the 2N6556's. The KSA's have the added advantage of being fullpacks, so they can not get blown if someone should accidentally bump their heatsinks again (in fact, they wouldn't get blown anyway, because it was the 150V offset that blew the 2N6556, and the KSA's are rated 160V)

7. With all of this done, and the amp running very quietly (electrically) with no input (350uV or so at the outputs). I reinstalled the amp in my system. I was then still getting noise from ground loop and EMI. That's why I asked about converting to balanced inputs = better immunity to ground loops. I eventually rearranged most of my power cords to plug into one outlet, and that resolved the ground loop issue.

8. The last concern I had with the amp, and still have, is mechanical noise from the transformer. Electrically, the amp is now very quiet; with the preamp at a middle level, you have to put your ear right to the speakers to notice any noise. However, the mechanical noise from the transformer, when it's mounted in the amp, is definitely noticable from my listening position (4 or 5 meters from the amp). That brings us back to where we are now: with the transformer removed from the amp, but wired to it, the noise is undetectable beyond 1m. So, I would expect, it's a mounting problem.

Paul

Sorry but I think we're not on the same page here.

Here's a whole recap of progress. Some of it is covered earlier in this thread and some is covered in one or two other posts.

1. I bought this amp used and blown up.

2. I exchanged a few emails with the original designer, Paul McGowan, who advised that replacing the outputs with On Semi devices (since the orginal NEC's are unavailable, and MJ2119x's were actually used in the later 200cx) "...shouldn't be a problem."

3. I replaced the blown outputs, drivers, resistors, bias transistors and fuses. I also replaced all electrolytics other than the main filter caps.

4. The amp was then working, but had noticable noise through the speakers, especially from one channel.

5. I spent a lot of time trying to find the noise from the one channel. I eventually tracked it down to a 1K resistor installed where a 10K resistor belonged (in the feedback loop from the DC servo). This looked to be a production mistake. Putting a 10K in there reduced the noise to a comparable level of the quieter channel.

6. Unfortunately, during the step 5 troubleshooting, I accidentally touched the collectors of two of the VAS transistors together, blowing one of them. These are fairly difficult to get 2N6556's. I ended up replacing all 2N6556's with KSA1220A's. Noise level of the quiet channel remained the same with the KSA1220A's to what it was with the 2N6556's. The KSA's have the added advantage of being fullpacks, so they can not get blown if someone should accidentally bump their heatsinks again (in fact, they wouldn't get blown anyway, because it was the 150V offset that blew the 2N6556, and the KSA's are rated 160V)

7. With all of this done, and the amp running very quietly (electrically) with no input (350uV or so at the outputs). I reinstalled the amp in my system. I was then still getting noise from ground loop and EMI. That's why I asked about converting to balanced inputs = better immunity to ground loops. I eventually rearranged most of my power cords to plug into one outlet, and that resolved the ground loop issue.

8. The last concern I had with the amp, and still have, is mechanical noise from the transformer. Electrically, the amp is now very quiet; with the preamp at a middle level, you have to put your ear right to the speakers to notice any noise. However, the mechanical noise from the transformer, when it's mounted in the amp, is definitely noticable from my listening position (4 or 5 meters from the amp). That brings us back to where we are now: with the transformer removed from the amp, but wired to it, the noise is undetectable beyond 1m. So, I would expect, it's a mounting problem.

Paul

Thanks Paul for the elucidation.

Now, i can understand absolutelly your problem. As i said, i have a similar noise issue with my last amplifier like your. The good news are that i have examine the noise source which in my case it is the wrong place of pcbs against xformer (straight magnetic flux infection of small signal stages) as well the poor ripple rejection of voltage regulators for the balanced input circuits (i have found also the cure for this by adding two transistors in output of regulators). The bad news are that i am forced to redraw and to reconstruct new pcbs to include the bug fixes.

Oh my! Again from the start

I wish you easiness and success, because this issue is difficult to resolve it.

Crazy idea! Try to encapsulate xformer with epoxy rosin.

Regs

Fotios

Now, i can understand absolutelly your problem. As i said, i have a similar noise issue with my last amplifier like your. The good news are that i have examine the noise source which in my case it is the wrong place of pcbs against xformer (straight magnetic flux infection of small signal stages) as well the poor ripple rejection of voltage regulators for the balanced input circuits (i have found also the cure for this by adding two transistors in output of regulators). The bad news are that i am forced to redraw and to reconstruct new pcbs to include the bug fixes.

Oh my! Again from the start

I wish you easiness and success, because this issue is difficult to resolve it.

Crazy idea! Try to encapsulate xformer with epoxy rosin.

Regs

Fotios

Hmmm... I may try getting the transformer potted, but first I'm going to try some rubber washers under and on top of the mounting tabs. These washers should isolate things a bit, and should also raise the transformer so that only its mountings are in contact with the case, rather than the whole bottom of the transformer.

On the down side, this will eliminate any heat sinking that the transformer was getting from the case.... but I wouldn't expect a good transformer to get that hot.

I'll let you know how it goes.

Cheers,

Paul

On the down side, this will eliminate any heat sinking that the transformer was getting from the case.... but I wouldn't expect a good transformer to get that hot.

I'll let you know how it goes.

Cheers,

Paul

OK, here's the (near) final result:

Back when I first repaired the amp, I made a comment on this site that the contactor relay (120V AC coil) had to go, because it was too mechanically noisy. This amp uses a contactor to save wear and tear on the power switch.

Funny thing is, I somehow got the idea that the noise was all from the transformer and not from the contactor. The transformer does make a bit of noise, and remounting it with rubber washers (done this evening) probably helped, but, after getting the transformer reinstalled I tried an experiment: I checked the mechanical noise of the amp switched on at the power switch (contactor energized) versus with the amp turned on by me pushing the contactor closed with a screwdriver. The result - the contactor was responsible for quite a bit more noise than the transformer.

So, last thing for this amp will be a nice 25A solid state relay in place of the contactor... then I can call it done!

(BTW, anyone have any negative experiences with solid state relays in amplifiers? if so, I may see about adding a cap and diode to energize it with DC instead)

Back when I first repaired the amp, I made a comment on this site that the contactor relay (120V AC coil) had to go, because it was too mechanically noisy. This amp uses a contactor to save wear and tear on the power switch.

Funny thing is, I somehow got the idea that the noise was all from the transformer and not from the contactor. The transformer does make a bit of noise, and remounting it with rubber washers (done this evening) probably helped, but, after getting the transformer reinstalled I tried an experiment: I checked the mechanical noise of the amp switched on at the power switch (contactor energized) versus with the amp turned on by me pushing the contactor closed with a screwdriver. The result - the contactor was responsible for quite a bit more noise than the transformer.

So, last thing for this amp will be a nice 25A solid state relay in place of the contactor... then I can call it done!

(BTW, anyone have any negative experiences with solid state relays in amplifiers? if so, I may see about adding a cap and diode to energize it with DC instead)

Here's an update on this amp:

After a long time at the manufacturer, and a redip in varnish, the guys that made the transformer concluded that it was not (by their standards) noisy. They did think that the decorative cover PS Audio had put on it might be rattling. When I got it back I removed the cover and resinstalled it. It is still humming, but it's no-longer noticable from across the room, so I can live with it for now.

Another source of mechanical noise was the contactor (they use a big A/C relay in these amps to take the load off of the power switch). I tried converting the contactor to DC operation with a rectifier and a capacitor. It was quieter (though not silent) like that for about 1/2 an hour, then the coil burned up. So I installed a Teledyne solid state relay instead. The SSR was pretty much a drop-in replacement, and it IS silent.

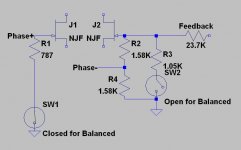

Attached is what I did to allow balanced or unbalanced inputs. The balanced inputs, to my surprise, result in a 6dB loss driving the amp, but they're a definite success in removing input and ground loop noise. I'm very happy with the results.

After a long time at the manufacturer, and a redip in varnish, the guys that made the transformer concluded that it was not (by their standards) noisy. They did think that the decorative cover PS Audio had put on it might be rattling. When I got it back I removed the cover and resinstalled it. It is still humming, but it's no-longer noticable from across the room, so I can live with it for now.

Another source of mechanical noise was the contactor (they use a big A/C relay in these amps to take the load off of the power switch). I tried converting the contactor to DC operation with a rectifier and a capacitor. It was quieter (though not silent) like that for about 1/2 an hour, then the coil burned up. So I installed a Teledyne solid state relay instead. The SSR was pretty much a drop-in replacement, and it IS silent.

Attached is what I did to allow balanced or unbalanced inputs. The balanced inputs, to my surprise, result in a 6dB loss driving the amp, but they're a definite success in removing input and ground loop noise. I'm very happy with the results.

Attachments

Sorry to be a bit late to this - but it got bumped and I just saw it.

I've had very good luck with using transformers to do the balanced/unbalanced thing. Works great on the output of the DCX2496.

If you just want to play, get some cheap ones, but for much better quality at not too bad cost, try some Jensen transformers. They sound very good. The nickel core are very nice.

And if you like the way that sounds, replace the output stage of the DCX with the transformers only. That's the way to go.

I've had very good luck with using transformers to do the balanced/unbalanced thing. Works great on the output of the DCX2496.

If you just want to play, get some cheap ones, but for much better quality at not too bad cost, try some Jensen transformers. They sound very good. The nickel core are very nice.

And if you like the way that sounds, replace the output stage of the DCX with the transformers only. That's the way to go.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Unbalanced to balanced input conversion?