I got tired of having those minimalist preamps with no features. I like a remote control. I like gain matching between inputs. I like balance. I like LED displays. So I started designing a new preamp, the design of which is about 80% complete. The basics are:

Two channels (dual mono)

3 balanced inputs

6 unbalanced inputs

2 balanced outputs (for bi-amplification)

CS3318 programmable gain attenuator/amplifier

OPA1632 line drivers

Choice of DC, AC, and transformer coupling on the inputs

Remote control

8-character 5x7 LED display

Analog stuff is powered from super-regulated +/-9V supplies, with separate secondaries for each channel. Digital 3.3V power comes from a separate transformer and power supply.

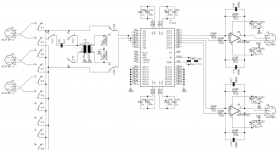

I'm just starting to come to grips with the amount of drawing necessary, but I have the power supplies, the input controls, and the preamp channels mostly drawn. I'll post them up here when I complete each bit. Here's one channel, although the symbols for the single-ended inputs run off the bottom. If you can't read it, a PDF is also attached. And the preliminary bill of materials is also attached for reference.

Link to BOM

Link to PDF

Two channels (dual mono)

3 balanced inputs

6 unbalanced inputs

2 balanced outputs (for bi-amplification)

CS3318 programmable gain attenuator/amplifier

OPA1632 line drivers

Choice of DC, AC, and transformer coupling on the inputs

Remote control

8-character 5x7 LED display

Analog stuff is powered from super-regulated +/-9V supplies, with separate secondaries for each channel. Digital 3.3V power comes from a separate transformer and power supply.

I'm just starting to come to grips with the amount of drawing necessary, but I have the power supplies, the input controls, and the preamp channels mostly drawn. I'll post them up here when I complete each bit. Here's one channel, although the symbols for the single-ended inputs run off the bottom. If you can't read it, a PDF is also attached. And the preliminary bill of materials is also attached for reference.

Link to BOM

Link to PDF

Attachments

I like a remote control.

Ja, me too!

What kind of microprocessor are you going to use? An atmel?

Have fun, Hannes

Hi jwb

If you have not already thought... and because you will use a MCU... take a look in latching type relays with double coils (like set and reset) for use as input selectors. There are two options of almost same quality. Panasonic DS2E and Omron G6AK. Beneffit of latching type it is obviously their mechanical armature to keep the contacts in place without the need of continuous operation of coils, thus absence of any EMI in the input signal.

Fotios

If you have not already thought... and because you will use a MCU... take a look in latching type relays with double coils (like set and reset) for use as input selectors. There are two options of almost same quality. Panasonic DS2E and Omron G6AK. Beneffit of latching type it is obviously their mechanical armature to keep the contacts in place without the need of continuous operation of coils, thus absence of any EMI in the input signal.

Fotios

don't use atmel . . . . they may not be around in 6 months time.

Ouch

That would hurt as I only own an atmel-programmer

Anyway, that wouldn't be the first occasion using obsolete parts

Have fun, Hannes

EDIT: by the way, thanks fotios for the tip - a very elegant suggestion!

fotios said:Hi jwb

If you have not already thought... and because you will use a MCU... take a look in latching type relays with double coils (like set and reset) for use as input selectors. There are two options of almost same quality. Panasonic DS2E and Omron G6AK. Beneffit of latching type it is obviously their mechanical armature to keep the contacts in place without the need of continuous operation of coils, thus absence of any EMI in the input signal.

I considered using latching relays but I rejected the idea because I don't like that the contacts themselves are magnets. That seems like a big drawback. I'm not driving the relays directly off the microprocessor. I'm driving them through '595 shift registers, which in turn drive a common emitter NPN. Also I've taken care to design the +3.3V supply to have .01Ohm impedance out to 200MHz. I _think_ it should be pretty quiet. I hope!

And yes I was planning to use an AVR since that's what I know how to program best.

jwb said:

I considered using latching relays but I rejected the idea because I don't like that the contacts themselves are magnets.

From those that i know, the coils are electromagnets and not permanent magnets in all types of relays. When the supply is turned off, then the coils becomes no magnets furthermore. There is not any physical magnet inside, only a coil arround a ferite. In latching type, the action of electromagnetic coil is momentary, and 5ms of activating it is more than enough for the mechanism to latch the contacts. There is not the need for further supply the coil with voltage to keep the contacts in place.

Fotios

Correct. And it's not the contacts themselves that are magnetic anyway. The contacts are carried on metal strips which are themselve attached to a steel plate. It is this plate that is spring-loaded and actuated by the electromagnetic pole piece of the relay.

Better relays sometimes even have gold plated silver contacts (certainly non-magnetic).

Better relays sometimes even have gold plated silver contacts (certainly non-magnetic).

Bonsai said:

don't use atmel . . . . they may not be around in 6 months time.

What makes you say that? Their MPU's are certainly superior to the PIC junk that Microchip offer!

jwb said:In a latching relay the contact itself is a permanent magnet.

SQLGuy said:Correct. And it's not the contacts themselves that are magnetic anyway. The contacts are carried on metal strips which are themselve attached to a steel plate. It is this plate that is spring-loaded and actuated by the electromagnetic pole piece of the relay.

Better relays sometimes even have gold plated silver contacts (certainly non-magnetic).

In a common type relay (non latching) there is not the same effect?

If you consider that your remark it is right and that it does make sense, then it is better to inform about this mistake mr. Nelson Pass because in his X0.2 preamplifier he uses Panasonic DS2E latching relays. From there it comes my proposition.

I don't know who are you dear friends from USA. Maybe you are designers of relays. Me, in Greece, by no way

Greetings

Fotios

I'll have to take a look at how those latching relays are constructed. I can't think off-hand of why the contacts themselves would need to be magnetic... and I can certainly think of reasons why you wouldn't want them to be.

What I have generally seen for relays set up to latch is that you use one contact to close a circuit to power the coil itself. So, in this case, you're using a normal relay that will latch itself closed once initially triggered, and remain closed until power is removed.

What I have generally seen for relays set up to latch is that you use one contact to close a circuit to power the coil itself. So, in this case, you're using a normal relay that will latch itself closed once initially triggered, and remain closed until power is removed.

SQLGuy said:Better relays sometimes even have gold plated silver contacts (certainly non-magnetic).

Are you sure that are non-magnetic? If yes, then jwb may be informed about this from the datasheet of Panasonic and Omron for their latching type relays:

1) Panasonic DS2E contact material: Gold-clad Silver

2) Omron G6AK234 contact type: Bifurcated crossbar AgPd (Au-clad)

3) Omron G6AK274 contact type: Bifurcated crossbar Ag (Au-clad)

Notes:

Ag = chemical symbol of Silver

Pd = chemical symbol of Paladium

Au = chemical symbol of Gold

Greetings

Fotios

That's interesting information, thanks. I actually can't find the specification for the contact plating on the G6K type relay in the data sheet, although I do see it in the G5A datasheet.

Update: the contact material is listed in the euro market datasheet but not in the usa market. Weird.

Update: the contact material is listed in the euro market datasheet but not in the usa market. Weird.

SQLGuy said:... and I can certainly think of reasons why you wouldn't want them to be.

Sorry, but i can't understand why you said that.

Fotios

What about the Axicom FP2 latching relay? It has better specs than the Omron or Panasonic and costs much less. Frankly I am suspicious of its low price, but it has Au-clad AgNi contacts, rated for 100 million operations, lower rated contact resistance, and has a 100 times lower minimum permissible load (100µV vs. 10mV) and only costs $2.15

http://ecommas.tycoelectronics.com/...08-98005EpdfEnglishENG_SS_108-98005_E.pdf

http://ecommas.tycoelectronics.com/...08-98005EpdfEnglishENG_SS_108-98005_E.pdf

SQLGuy said:What I have generally seen for relays set up to latch is that you use one contact to close a circuit to power the coil itself. So, in this case, you're using a normal relay that will latch itself closed once initially triggered, and remain closed until power is removed.

Latching type relays, apparted from:

1) One or two coils which push or pull a clear mechanical latching armature.

2) A mechanical latching armature, which push the contacts to close or open.

3) A set of 2 or 4 contacts in form either SPDT or DPDT.

The operation of latching relays it is similar with flip-flops. For this reason some times called also bistable. In the type of single coil, the same coil is used to close or open the contacts simply by inverting its polarity. In the type of two coils, the one is used to close the contacts and the other to open the contacts.

The trick of latching is found inside the mechanical armature. It is executed from a smart mechanism which apparted from a ratchet and a cam.

In industrial applications, these relays called Power Saving Relays instead latching, because they haven't the need of continuous supply of coil to keep closed the contacts. For this it cares the smart mechanical armature. In some cases the latching armature is apparted from a spring or a magnet, according to the demand exists.

Fotios

jwb said:What about the Axicom FP2 latching relay? It has better specs than the Omron or Panasonic and costs much less. Frankly I am suspicious of its low price, but it has Au-clad AgNi contacts, rated for 100 million operations, lower rated contact resistance, and has a 100 times lower minimum permissible load (100µV vs. 10mV) and only costs $2.15

http://ecommas.tycoelectronics.com/...08-98005EpdfEnglishENG_SS_108-98005_E.pdf

I think the difference is found in the contact alloy? I am not sure. Panasonic and Omron offer contacts which can carry 3A continuous current instead Axicom reffers 2A. The rest specs are almost the same. The issue is the reliability in practice and not in papers. This depends on the manufacturer trustability. If i was in your place, maybe Omron because are less expensive from Panasonic and a little most expensive from Axicom.

Fotios

fotios said:

Sorry, but i can't understand why you said that.

Fotios

Magnetic contacts would, in most cases, be non-stainless ferrous metals. That means they would be prone to oxidation, especially if being repeatedly heated, cooled, and exposed to arcs.

Also, magentic materials lose magnetism when heated. High current relay contacts that rely on the magnetism of the contacts themselves might become bad connections under high current.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Preamp with features!