Hi,

I have question regarding FET ZVP3306A.

I do not have any experience with FETs so probably I have damaged FET by de-solder and sold new back without precaution measures (didn't put wire on all 3 legs before soldering, and not grounded soldering iron). Anyway now I have measured my soldering iron tip shows ~9v AC between iron tip and my hand. Not much.

New FET inserted into ESR meter on screen appears as FET, meanwhile de-soldered shows only diode between legs 1-3. Does it mean de-soldered FET will be for sure defective?

But that FET was soldered in before by me, and with it amplifier sounded just right. So what I should see/hear which would indicate that FET is dead and requires replacement?

Can we say that dead FET will not affect sound quality, just will not amplify as much as supposed? So only volume knob position would indicate that FET is dead?

Now I'm listening amp with volume knob on 11:00 position, source is mobile phone volume almost at full power.

I have question regarding FET ZVP3306A.

I do not have any experience with FETs so probably I have damaged FET by de-solder and sold new back without precaution measures (didn't put wire on all 3 legs before soldering, and not grounded soldering iron). Anyway now I have measured my soldering iron tip shows ~9v AC between iron tip and my hand. Not much.

New FET inserted into ESR meter on screen appears as FET, meanwhile de-soldered shows only diode between legs 1-3. Does it mean de-soldered FET will be for sure defective?

But that FET was soldered in before by me, and with it amplifier sounded just right. So what I should see/hear which would indicate that FET is dead and requires replacement?

Can we say that dead FET will not affect sound quality, just will not amplify as much as supposed? So only volume knob position would indicate that FET is dead?

Now I'm listening amp with volume knob on 11:00 position, source is mobile phone volume almost at full power.

Hi

If the FET was bad the Amplifier speaker protection relay would not change over.

An ESR meter would be used to check electrolytic capacitors?

A transistor tester would be used to test FETs for example.

Peak Atlas DCA model DCA55 | Peak Electronic Design Limited

If the FET was bad the Amplifier speaker protection relay would not change over.

An ESR meter would be used to check electrolytic capacitors?

A transistor tester would be used to test FETs for example.

Peak Atlas DCA model DCA55 | Peak Electronic Design Limited

This paper I know, because I had made the repair service for a distributor some months.Try this it worked on one of mine A3i

Unfortunately this instructions don't provide the wanted effect.

The humming could only be eliminated by pressing narrow wooden wedges between the coil body and the R-core. Thus it was a mechanical issue and not an electrical.

Even in most other similar cases just this is the main issue.The R-Core probably didnt hum like that when these amps were released, and switch mode supplies were relatively uncommon. Now they are everywhere and the distorted mains waveform with DC offset that is now common is what pisses the R-Core off.

As Alex said, he designed the amp for a lower supply voltage. Managers playing at being engineers are the cause of the unreliability.

Last edited:

In case you want to have new R-core dual 24v from China for £18 free shipping:

Aliexpress

Aliexpress

R cores can be custom manufactured up to about 2 KVA rating but to enable the larger sizes to to be viable, you'll need very deep pockets and great patience to cover the delays, tooling, set-up and production costs of thousands of units, I imagine.

Does anyone see any low voltage stock product larger than about 80VA available for sale anyway?

Does anyone see any low voltage stock product larger than about 80VA available for sale anyway?

You can buy a fully working A3i for less then the price of the transformer.

Thanks for that link, Audio Service. Interesting, though personally I wouldn't be tempted to simply substitute because of the flux leakage with R cores - its about the same magnitude as E-I laminated types and probably wouldn't be a simple matter of dropping one in the same spot, adjacent to the PCB.

Apparently I'm quite wrong though. Have at look at alexcp's excellent A3i mod. blog here on DIY audio. It's archived and the link was broken (404 error) but you can Google a link from a "Cambridge Audio A3i pics inside" key phrase, for example.

Blog article: Restored and modded Cambridge Audio A3i - diyAudio

Sample Pic: https://www.diyaudio.com/archive/bl...dded-cambridge-audio-a3i-diyaudio_blog-13.jpg

Apparently I'm quite wrong though. Have at look at alexcp's excellent A3i mod. blog here on DIY audio. It's archived and the link was broken (404 error) but you can Google a link from a "Cambridge Audio A3i pics inside" key phrase, for example.

Blog article: Restored and modded Cambridge Audio A3i - diyAudio

Sample Pic: https://www.diyaudio.com/archive/bl...dded-cambridge-audio-a3i-diyaudio_blog-13.jpg

Last edited:

Ian I have replaced a number of R core transformers in A3is with good results.

Its interesting that customers more often than not want legacy Amplifiers restoring back to original.

The cost can sometimes seem unjustifiable but the customer is happy to pay for the time and parts.

It comes down to the cost of something vrs the value.

Value being what the customer is willing to pay.

I remember some years back emailing Alex who designed the A3i.

I sensed he always wanted to produce a version of the A3i that was way better than the original but he was unable to do so due to the management decisions at Cambridge Audio.

Its interesting that customers more often than not want legacy Amplifiers restoring back to original.

The cost can sometimes seem unjustifiable but the customer is happy to pay for the time and parts.

It comes down to the cost of something vrs the value.

Value being what the customer is willing to pay.

I remember some years back emailing Alex who designed the A3i.

I sensed he always wanted to produce a version of the A3i that was way better than the original but he was unable to do so due to the management decisions at Cambridge Audio.

Could I ask for confirmation that all transistors apart input stage, are unbearable hot and it is fine as per design?

In mine A3i all starting with FET and pre-drivers, and drivers are hot as hell, while checking by touching you can't keep touching for more that 1 sec...

Which was never the case in any other amplifier I have repaired designed by Rotel, Yamaha, Marantz Denon etc...

In mine A3i all starting with FET and pre-drivers, and drivers are hot as hell, while checking by touching you can't keep touching for more that 1 sec...

Which was never the case in any other amplifier I have repaired designed by Rotel, Yamaha, Marantz Denon etc...

Yes they are really hot specially the BC630/640 and LEDs and that way it's recommended to replace them and install as high as possible 15/20mm.

If you read this thread from the start you will find performance and reliability upgrades from X_pro that designed this amplifier.

(post 93)

If you read this thread from the start you will find performance and reliability upgrades from X_pro that designed this amplifier.

(post 93)

Last edited:

From post 90 : "Q11 and Q12 have no thermal tracking with output

transistors Q13, Q14 and sensor Q9. But Q9 senses all four Vbe drops

and so the bias current will rise in an unhealthy manner when Q11, Q12

heat up. I regularly add small heat sinks to these in order to combat this

problem."

..

"But even with new LEDs in my opinion the LED current is too high and

so I usually replace R16 and R18 with 10k in both channels. The standard

resistors of 3k3 are deteriorated most times and are in no way 1 watt parts

as seen on the board. Check R8 also."

transistors Q13, Q14 and sensor Q9. But Q9 senses all four Vbe drops

and so the bias current will rise in an unhealthy manner when Q11, Q12

heat up. I regularly add small heat sinks to these in order to combat this

problem."

..

"But even with new LEDs in my opinion the LED current is too high and

so I usually replace R16 and R18 with 10k in both channels. The standard

resistors of 3k3 are deteriorated most times and are in no way 1 watt parts

as seen on the board. Check R8 also."

Thanks for confirmation.

I have attached small heatsinks in upside-down way on each of heating transistor.

And I don't like how idling current behaves.

Issue is with Q11 and Q12, that they still heating up, but now slowly, and it makes idle current rising very slowly, and in total it takes 30 minutes till idle current reaches point when it stabilize.

So to place Q11,12 on small heatsinks, is not a right solution, in my opinion.

It was even better without heatsinks (Q11,12) as idle current stabilized within couple of minutes as soon as them heated to max temperature.

I will try to extend with 3way flat wire legs and attach them on output transistor backs. As Alex N. suggested at a very beginning.

Only FET is left without heatsink, not sure if there any "clip" type heatsink available in the market that could fit to help FET deal with heat.

I have attached small heatsinks in upside-down way on each of heating transistor.

And I don't like how idling current behaves.

Issue is with Q11 and Q12, that they still heating up, but now slowly, and it makes idle current rising very slowly, and in total it takes 30 minutes till idle current reaches point when it stabilize.

So to place Q11,12 on small heatsinks, is not a right solution, in my opinion.

It was even better without heatsinks (Q11,12) as idle current stabilized within couple of minutes as soon as them heated to max temperature.

I will try to extend with 3way flat wire legs and attach them on output transistor backs. As Alex N. suggested at a very beginning.

Only FET is left without heatsink, not sure if there any "clip" type heatsink available in the market that could fit to help FET deal with heat.

Attachments

Hello all,

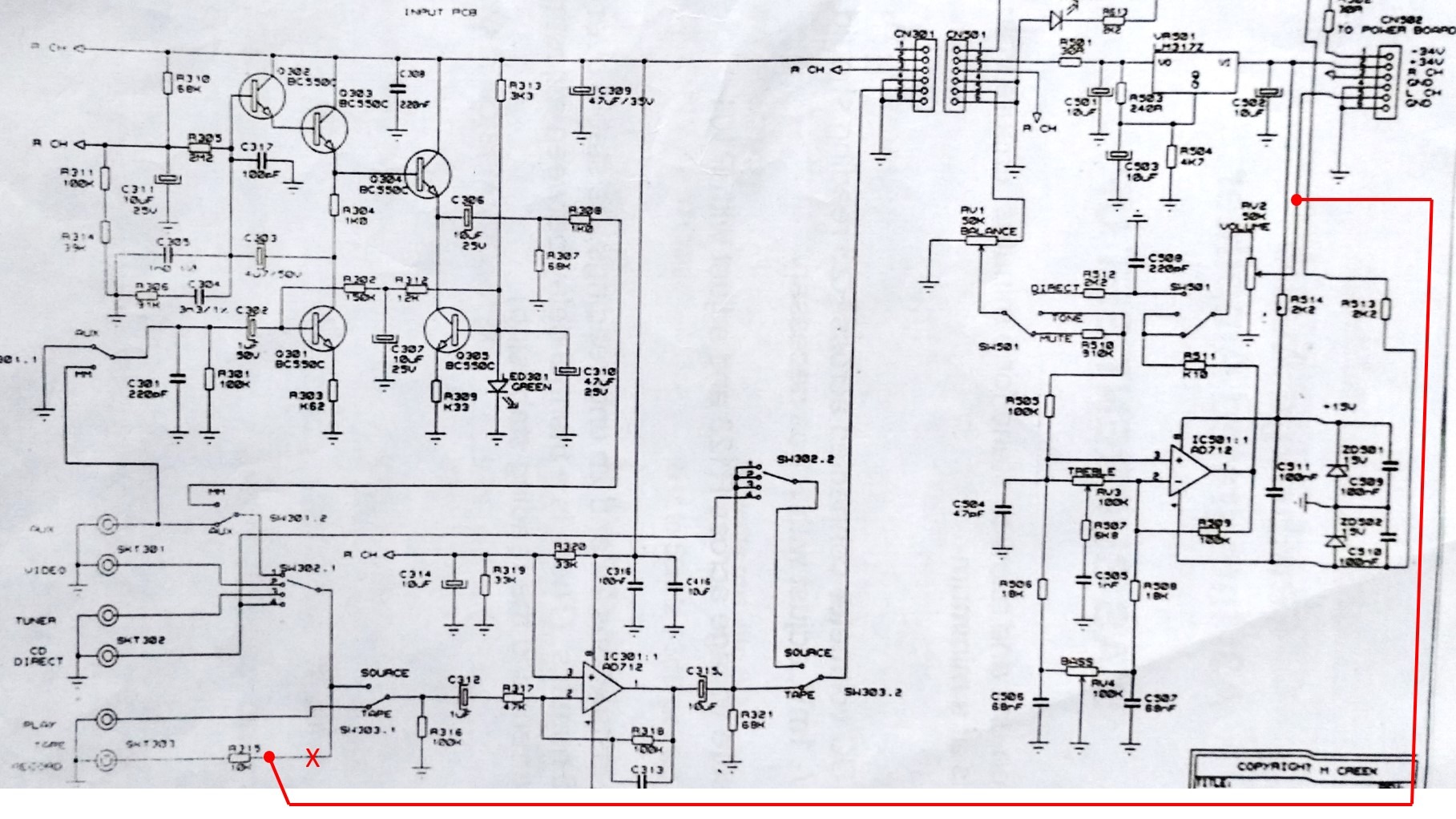

I've been following this thread for years and have used it to help repair my A3i many moons ago, and I thank the contributors for their priceless info, especially Alex, of course. I have never contributed as I am not clever enough, but I would like to make a modification to the amp and wondered if anyone has already done this before and also some feedback on whether it's a good idea or not. I have never used (and unlikely to ever use) the tape outputs, but would like pre-amp outputs to feed a sub which has stereo line inputs. Cutting to the chase here's what I want to do:

Basically, isolate the tape outputs from the inputs (where the red cross is in the image) and the feed the Volume pot output to the tape output via the 10K resistor. Any thoughts? Cheers guys

I've been following this thread for years and have used it to help repair my A3i many moons ago, and I thank the contributors for their priceless info, especially Alex, of course. I have never contributed as I am not clever enough, but I would like to make a modification to the amp and wondered if anyone has already done this before and also some feedback on whether it's a good idea or not. I have never used (and unlikely to ever use) the tape outputs, but would like pre-amp outputs to feed a sub which has stereo line inputs. Cutting to the chase here's what I want to do:

Basically, isolate the tape outputs from the inputs (where the red cross is in the image) and the feed the Volume pot output to the tape output via the 10K resistor. Any thoughts? Cheers guys

It will work as you imagine but be aware that the input impedance of the sub inputs will appear in parallel with the wiper of the volume control (plus that series 10k). If the impedance is low, it will have the effect of altering the law of the control meaning the subjective level vs rotation of the control will be altered. The pot is shown as 50k which is moderately high and so will accentuate that effect.

All you can do is try it.

All you can do is try it.

Wow, that was quick, thank you Mooly. Yes, I understand what you're saying, and yes, I'll give it a go. Maybe I can try increasing the value of the resistor before the tape output if the sound level feels massively wrong relative to the rotation of the volume knob. Below is the input side of the sub, showing 100pF caps down to ground and 10K resistor in line with the Left and Right signal before they are shorted together to make a single input for the sub's pre-amp. Like you say, I'll try it. Cheers

Attachments

- Home

- Amplifiers

- Solid State

- Cambridge Audio A3i repairs and mods