Anyone have any feedback from actual experience using board layout software and then having a board fabricated? I'm looking for something that does auto-routing of traces. I looked at ExpressPCB, DipTrace and Pad2Pad.

I'm guessing my board is going to be no larger than 3 inches square and I only need a few produced. This is new territory for me. Also, I'm not sure about having boards fabricated in China. I was thinking of just staying within the U.S.

Thanks

I'm guessing my board is going to be no larger than 3 inches square and I only need a few produced. This is new territory for me. Also, I'm not sure about having boards fabricated in China. I was thinking of just staying within the U.S.

Thanks

Anyone have any feedback from actual experience using board layout software and then having a board fabricated?

You don't want to do autorouting, trust me. Osh Park is good in the USA, but China is no problem at all.

If you only need to design and fab one type of pcb, post and ask someone here to design it for you.

The cost should be reasonable compared to the steep learning curve.

Last edited:

I agree, you don't want autorouting. What you DO want is ratsnesting. Say you design a schematic circuit that you want to turn into a PCB. A good package will link the schematic connectivity to the PCB part using what is known as a netlist. This may all be behind the scenes, but the upshot is that the PCB part knows what is connected to what. It can raise an error if you try to route a wrong connection, and/or can show the connections between the pins in the PCB part (this is known as a ratsnest for obvious reasons) so you now what to route where. The result is a PCB with no routing errors and no forgotten connections (assuming the schematic is correct of course).

I would not go for any solution that does not support this.

Jan

I would not go for any solution that does not support this.

Jan

Anyone have any feedback from actual experience using board layout software and then having a board fabricated? I'm looking for something that does auto-routing of traces. I looked at ExpressPCB, DipTrace and Pad2Pad.

I'm guessing my board is going to be no larger than 3 inches square and I only need a few produced. This is new territory for me. Also, I'm not sure about having boards fabricated in China. I was thinking of just staying within the U.S.

Thanks

I took the plunge on this a couple of years ago. I found a layout software that I could start using that was free and later I bought the entry level license (one time charge, not yearly like some). This software was Target3001, and I am still using it. With a mild learning curve I was able to get up and running in a short while, and the designers are available by email if you have a special question about the software. There is a pin limit on the free version, but you probably want to start with a modest project anyway. There is a very useful autorouter (actually two of them) built in, and this is helpful to get started. Mostly I lay out tracks by hand because the autorouter isn't better than a human that understand good layout, and it also will not re-position components on the board to help with the layout process nor will it automatically choose thick tracks for power and thin for signal (you could run it in two steps, however). I used the autorouter for the first 12 or 18 months before I realized I could do much better if I just looked at the air-wire "ratsnest" that are there before you actually lay any tracks and fiddled with the layout before manually laying tracks and then optimizing everything from there. I came to the conclusion that 95% of the difficulty was figuring out the best component location and orientation, not laying tracks.

When I am done with the layout, I use Target3001 to produce a set of Gerber files that I send off to PCBway, a fab in China. I live in CA and I can get small runs delivered at my door in about 4-5 days from when I submit the files. They have specials for small runs (<10 pcs) of boards up to 4x4" in size. The price is very reasonable, and most of the total comes from shipping costs (they use DHL). Sadly, it's still cheaper than using a fab in CA. I know other people are very happy with the service and quality from PCBway, and there is even a thread about it somewhere in this web site.

Anyone have any feedback from actual experience using board layout software and then having a board fabricated? I'm looking for something that does auto-routing of traces. I looked at ExpressPCB, DipTrace and Pad2Pad.

I'm guessing my board is going to be no larger than 3 inches square and I only need a few produced. This is new territory for me. Also, I'm not sure about having boards fabricated in China. I was thinking of just staying within the U.S.

Thanks

I was once where you are now. I started out with ExpressPCB and it worked well. Once you draw the schematic with the Express Schematic program that will link to the pcb program and will help you out immensely in the learning phase. It all goes very slow at first, but once learned it will become much easier.

I started with ExpressPCB, which is very user friendly. Unfortunately, you are basically limited to their board manufacturing, and there are cheaper places around.

Recently, I moved to KiCAD. It is not as easy to use, but was fairly quick to learn, is completely free, and allows you to choose your own board house. I've been satisfied with Osh Park for my last several boards.

Recently, I moved to KiCAD. It is not as easy to use, but was fairly quick to learn, is completely free, and allows you to choose your own board house. I've been satisfied with Osh Park for my last several boards.

Everyone,

Thank you for your responses. ExpressPCB software is relatively easy and has the netlist feature that Jan mentioned. Needtubes, you are correct...you can only use their board manufacturing (ExpressPCB).

Charlie, thanks for your detailed response too.

What I find difficult is what size hole to pick for through hole components and other strange details one doesn't think of until he starts with a blank board. Also, routing some basic traces is not for faint of heart.

I'm going to look at the products you all have mentioned and keep going forward. I'm not opposed to doing it myself, but I'm also aware of time vs dollar spent having it done for me. I don't like paying to have things done for me, but with everything else going on, it may be a wise investment.

Thanks again!

Thank you for your responses. ExpressPCB software is relatively easy and has the netlist feature that Jan mentioned. Needtubes, you are correct...you can only use their board manufacturing (ExpressPCB).

Charlie, thanks for your detailed response too.

What I find difficult is what size hole to pick for through hole components and other strange details one doesn't think of until he starts with a blank board. Also, routing some basic traces is not for faint of heart.

I'm going to look at the products you all have mentioned and keep going forward. I'm not opposed to doing it myself, but I'm also aware of time vs dollar spent having it done for me. I don't like paying to have things done for me, but with everything else going on, it may be a wise investment.

Thanks again!

Charlie, thanks for your detailed response too.

What I find difficult is what size hole to pick for through hole components and other strange details one doesn't think of until he starts with a blank board. Also, routing some basic traces is not for faint of heart.

I can only speak for Target3001, but when I am creating the circuit schematic I am not using a "generic" symbol. Instead I use the built-in part database to select e.g. a particular capacitor. This includes of course the capacitance and voltage rating, but also the lead spacing and physical dimensions too. I do this over and over for each part, carefully selecting the one I want to use or one that is very similar.

Then when I do the layout, an outline of the part on the board as well as the thru-holes that are needed to accommodate the leads are automatically made available in the layout view. What is left to do it make the connections between parts.

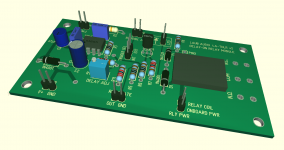

I like Target3001 because it can generate a 3D model view of the PCB with the parts on it. This helps me to figure out if it looks right, could use some adjustment to improve part spacing, etc. I have attached an example of this for a PCB that I recently designed in Target. You can rotate the model in free space to look at both sides using the mouse, and populate and de-populate parts to reveal the PCB underneath them. It's a really cool feature.

It's possible to create a BOM right from Target and place an order for all parts in your project, but unfortunately (for me) the software links to resellers that I do not use, most of which are in Europe. But I like the software so much I don't want to change to somethign else.

I think it is also possible to do circuit simulation in Target, although I have never used that feature. It's quite a powerful and sophisticated package but even a design noob like myself was able to learn it.

When I was getting started, I found online some 'PCB design guideline' pdf files that were helpful for me to learn about track width, track spacing, and so on. At some point you have to jump in and just do it, and you will gain experience and learn as you go. If you are only going to do one PCB, I would suggest that you just ask someone to design it for you, but if you think that you will be doing audio stuff and will design lots of your own PCBs then there is no time like the present to learn the useful skill of PCB design.

Attachments

Last edited:

Everyone,

Thank you for your responses. ExpressPCB software is relatively easy and has the netlist feature that Jan mentioned. Needtubes, you are correct...you can only use their board manufacturing (ExpressPCB).

Thanks again!

The boards from ExpressPCB are as good as anyone else's. It depend's on how you design them.

When I wanted to get beyond ExpressPCB to a different program so as to use other board houses, I would first design the board on ExpressPCB, and then copy it to another program. This worked well and it was not long before I stopped with the ExpressPCB.

Just remember that at the beginning it's best to start at the beginning and simple, and not jump a few steps to advanced.

I've been using KiCad and have had 5 board designs done by Elecrow (china). Zero problems - generally ~$15 including ship to USA for 5 boards (10cm x 10 cm). Great quality. Takes about 2.5 weeks. I use them for my home projects.

Double sided, silk screened, etc. I can't breadboard for less than that.

For "production" - would probably find a US as the diff is less at larger quantities.

The world we live in....

Double sided, silk screened, etc. I can't breadboard for less than that.

For "production" - would probably find a US as the diff is less at larger quantities.

The world we live in....

I've been using Eagle CAD for years. You can add an autorouter but I never had the need. I see they have a free student version now. For quick turn PCB's that are not too expensive I use PCBFABEXPRESS | PCB Fab and Assembly Services. Have also used China mfg and never had a problem except for the delay.

Using TARGET3001 V18 Light

I can absolute agree with CharlieLaub.

I am using Target V18 Light version. With a maximum pin count of 400 pins, i made several layouts, and this count was always sufficient. For my producing layouts i most used Elecrow and PCBWAY in several configurations, single sided and double sided, single and double silkscreens, and also 1oz and 2 oz copper. Never had any problems with the Gerber data created by TARGET.

Even for me was a great help to use the 3D feature of the created layout, which helps me to estimate how good the placement of the parts is.

I can absolute agree with CharlieLaub.

I am using Target V18 Light version. With a maximum pin count of 400 pins, i made several layouts, and this count was always sufficient. For my producing layouts i most used Elecrow and PCBWAY in several configurations, single sided and double sided, single and double silkscreens, and also 1oz and 2 oz copper. Never had any problems with the Gerber data created by TARGET.

Even for me was a great help to use the 3D feature of the created layout, which helps me to estimate how good the placement of the parts is.

Layout program KiCAD 4.0.5 and board manufacturer Eurocircuits. KiCAD takes some getting used to and via stitching is a bit clumsy, but otherwise it is fine.

Eurocircuits is not cheap, but their boards are good and they warn you when there is something fishy with your Gerber files, like pads with solder mask on top of them or metal density gradients that are likely to cause manufacturability problems. You then get the chance to upload corrected data before they make the boards.

Eurocircuits is not cheap, but their boards are good and they warn you when there is something fishy with your Gerber files, like pads with solder mask on top of them or metal density gradients that are likely to cause manufacturability problems. You then get the chance to upload corrected data before they make the boards.

I have designed around 150 pcb's.

I do use auto-routing then go back in and start sorting out the ground.

Smoothing capacitors need a separate ground back to star ground or their charging impulses modulate the ground line.

For valve circuits I use copper pours connected to ground around all the sensitive valve input signal lines.

Keep high AC volts away from audio signals.

Keep mains pcb transformers away from audio signals too.

Keep audio input signals as short as possible.

USe a PCBCAD package with lots of error checking. One error can cause nightmares when you have to start cutting up your pcb tracks to fix it.

I would highly recommend China PCB Prototype & Fabrication Manufacturer - PCB Prototype the Easy Way for cheap and fast pcb's. I haven't had a bad board yet from them.

I do use auto-routing then go back in and start sorting out the ground.

Smoothing capacitors need a separate ground back to star ground or their charging impulses modulate the ground line.

For valve circuits I use copper pours connected to ground around all the sensitive valve input signal lines.

Keep high AC volts away from audio signals.

Keep mains pcb transformers away from audio signals too.

Keep audio input signals as short as possible.

USe a PCBCAD package with lots of error checking. One error can cause nightmares when you have to start cutting up your pcb tracks to fix it.

I would highly recommend China PCB Prototype & Fabrication Manufacturer - PCB Prototype the Easy Way for cheap and fast pcb's. I haven't had a bad board yet from them.

I'm looking to take the leap to designing my own circuit boards too. I'm quite competent with LT Spice schematics now and am wondering if there is software that can use it's .asc files or maybe the netlist?

It would be a bit of pain to have to redo the schematic entry into the PCB layout software.

I should say that my intention is to have my boards manufactured by PCB Way

It would be a bit of pain to have to redo the schematic entry into the PCB layout software.

I should say that my intention is to have my boards manufactured by PCB Way

I have made around 150 pcb's using PCBCAD51.

I use China PCB Prototype & Fabrication Manufacturer - PCB Prototype the Easy Way for cheap pcb's.

I use China PCB Prototype & Fabrication Manufacturer - PCB Prototype the Easy Way for cheap pcb's.

I have made around 150 pcb's using PCBCAD51.

I have contacted Murton Pike Systems, makers of PCBCAD51 asking if their software will run in Linux, or Linux Wine emulation. Lets hope so.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Software Tools

- Circuit board software and manufacturing