One of the most difficult things about finishing any electronics project is finding a great enclosure for it. Up until now the options for North Americans have been very limited – the chassis available are either ugly, expensive, require international shipping or a combination of all three.

We're hoping we can change that!

We've been working with an Italian company who we think make one of the world's most attractive and affordable chassis for the DIY-er, and will soon be placing an order to get those most suitable for diyAudio style projects into our Los Angeles warehouse so they can be shipped quickly and economically to anywhere in North America.

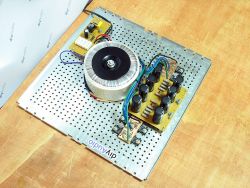

Here is what we are proposing as the base models:

Additional configuration options:

Why buy a chassis from diyAudio?

Chassis Pricing:

Additional options:

Shipping:

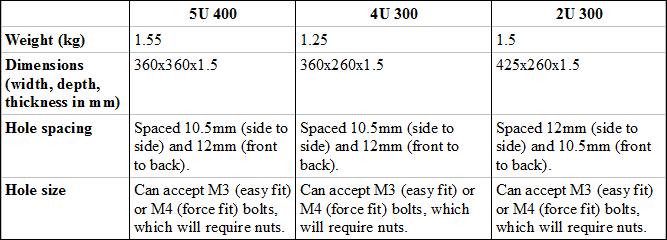

Specifications

Chassis

Note: The 5U 400 heatsinks on each side are made from two pieces which are joined with a steel frame that compresses them together along the flush edges to create a strong bond between the two. There is no sign of “give”, slipping or sliding when assembled and they feel as rigid as a single heatsink. We have not measured significant temperature differences between the two pieces in use. The 5U 400 with the PTH option has the holes centered and symmetric, so there are 11 holes in each heatsink for a total of 22 per side and 44 per chassis.

DIY Friendly Base (Optional – fits inside chassis as a second base)

Photographs (please use the thumbnails at the very bottom of this post to zoom in)

2U 300 (No heatsinks)

The 2U Chassis with 10mm solid aluminum faceplate in silver. Shown with a Mezmerize DCB1.

4U 300 (With heatsinks)

The 4U chassis with 10mm solid aluminum faceplate in silver. Shown with a 400VA toroidal transformer.

5U 400 (With heatsinks)

The 5U chassis with 10mm solid aluminum faceplate in black, with the diyAB "Honey Badger" inside (this chassis is overkill for the diyAB).

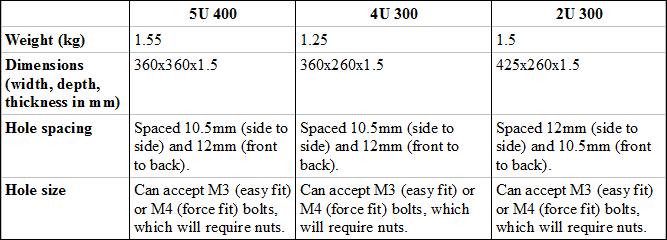

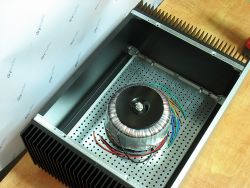

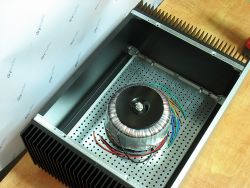

DIY Friendly Base (DFB)

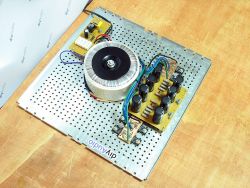

DFB for the 5U 400 with a fully tested FirstWatt / Burning Amp power supply using a 400VA transformer, DA Cap Board, DA Diode Board and DA Soft-start Board (these will all be in the store soon).

Pre-drilled, pre-threaded holes (PTH)

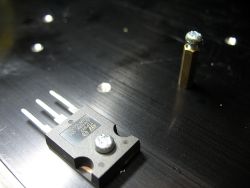

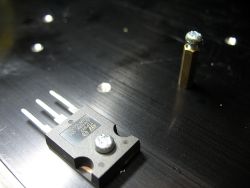

PTH shown with an M3 bolt, an M3 brass standoff and a transistor package similar to what we use in the FW amplifiers.

We need your input!

We'd really like to hear your thoughts on the following options:

General interest: Which chassis and how many would you order?

Color: Whether you would prefer black or silver faceplates. Silver is more forgiving of scratches, we think it's more attractive generally and we'd like to keep things simple, but please let us know if you would much prefer black.

Pre-drilled, pre-tapped holes (PTH): We've spent a great deal of time ensuring that the F4, F5, F5c, Burning Amps, diyAB Amp and (very soon) the F5x, all use the diyAudio Universal PCB & Semiconductor Mounting Specification M3 mounting holes, so one chassis can be used for multiple projects. It's not cheap to pre-tap the holes, but for the uninitiated tapping is scarey and time consuming. Would you pay $49 to have the UMS holes professionally pre-drilled and pre-tapped into all the heatsinks in your chassis?

These boards currently in the store will work with the pre-tapped holes:

DIY Friendly Base (DFB): The DFB is pre-drilled with a grid of holes suitable for mounting your power supply and non-heatsink boards directly with M3 bolts without having to drill it. The new PSU, Soft-Start and Speaker Protection boards we'll have in our store shortly have all been designed to fit the 10.5mm x 12mm hole pattern. Since it doubles the base thickness, it also supports heavy components better. Would you order this for your chassis?

Thanks for your time and feedback. We really hope that we can make this a win/win for all involved and solve one of the most difficult problems in making our own amplifiers and line level components.

We're hoping we can change that!

We've been working with an Italian company who we think make one of the world's most attractive and affordable chassis for the DIY-er, and will soon be placing an order to get those most suitable for diyAudio style projects into our Los Angeles warehouse so they can be shipped quickly and economically to anywhere in North America.

Here is what we are proposing as the base models:

- A 2U, 300mm deep “Slimline Chassis” without heatsinks for line level projects and those with internal heatsinks such as gainclones.

- A 4U, 300mm deep “Jack-Of-All Chassis” with heatsinks that will suit a majority of projects, including the Honey Badger diyAB amp, and the First Watt amps.

- A 5U, 400mm deep “Big *** Chassis” with towering walls of heatsinking to cool demanding class A projects such as F-5 Turbos, Burning Amps, multichannel amps for biamping and home theater, and amps with elaborate power supplies and other components that that require a lot of internal space.

Additional configuration options:

- DIY Friendly Base (DFB) – A pre-drilled additional inside floor panel with holes at regular intervals.

- Pre-Drilled, Pre-Threaded Holes (PTH) - Both heatsinks pre-drilled and pre-tapped with 22 M3 threads per heatsink (a total of 44 threaded holes) as specified in the diyAudio Universal PCB & Semiconductor Mounting Specification (UMS) (so you can use one chassis with any current diyAudio circuit boards designed to be heatsink mounted, as they all fit the UMS. We hope future PCBs made by diyAudio members will use this standard so that chassis can be easily re-used for future projects.

Why buy a chassis from diyAudio?

- The total cost including shipping will in most cases be less than ordering from overseas

- It will arrive faster

- No customs broker fees, clearance fees, surety bonds, storage and demurrage charges, duties to pay or other “surprises”

- If there are any problems or returns you will be dealing with diyAudio in the USA

- All profit will go straight back into improving diyAudio

- You avoid currency conversion fees by paying in USD

- With the PTH option, you'll be able to re-use your heatsinks for any UMS standardized project in the future

Chassis Pricing:

- 2U 300 - $79

- 4U 300 - $199

- 5U 400 - $299

Additional options:

- DIY Friendly Base (DFB) - $19

- Pre-drilled, Pre-Threaded Holes (PTH) (22 M3 threads per side as specified in the UMS, for a total of 44) - $49

Shipping:

- All chassis will be shipped directly from our Shipwire warehouse in Los Angeles.

- Shipping from our warehouse to you is “at cost”.

- Shipping *estimates* per piece (2U/4U/5U)

- West coast ($14/$17/$20)

- East coast ($19/$29/$39)

- Vancouver ($29/$41/$51)

- Toronto ($31/$44/$57)

- Shipping will take an estimated 1-5 days

- Chassis are shipped “flat pack”

Specifications

Chassis

Note: The 5U 400 heatsinks on each side are made from two pieces which are joined with a steel frame that compresses them together along the flush edges to create a strong bond between the two. There is no sign of “give”, slipping or sliding when assembled and they feel as rigid as a single heatsink. We have not measured significant temperature differences between the two pieces in use. The 5U 400 with the PTH option has the holes centered and symmetric, so there are 11 holes in each heatsink for a total of 22 per side and 44 per chassis.

DIY Friendly Base (Optional – fits inside chassis as a second base)

Photographs (please use the thumbnails at the very bottom of this post to zoom in)

2U 300 (No heatsinks)

The 2U Chassis with 10mm solid aluminum faceplate in silver. Shown with a Mezmerize DCB1.

4U 300 (With heatsinks)

The 4U chassis with 10mm solid aluminum faceplate in silver. Shown with a 400VA toroidal transformer.

5U 400 (With heatsinks)

The 5U chassis with 10mm solid aluminum faceplate in black, with the diyAB "Honey Badger" inside (this chassis is overkill for the diyAB).

DIY Friendly Base (DFB)

DFB for the 5U 400 with a fully tested FirstWatt / Burning Amp power supply using a 400VA transformer, DA Cap Board, DA Diode Board and DA Soft-start Board (these will all be in the store soon).

Pre-drilled, pre-threaded holes (PTH)

PTH shown with an M3 bolt, an M3 brass standoff and a transistor package similar to what we use in the FW amplifiers.

We need your input!

We'd really like to hear your thoughts on the following options:

General interest: Which chassis and how many would you order?

Color: Whether you would prefer black or silver faceplates. Silver is more forgiving of scratches, we think it's more attractive generally and we'd like to keep things simple, but please let us know if you would much prefer black.

Pre-drilled, pre-tapped holes (PTH): We've spent a great deal of time ensuring that the F4, F5, F5c, Burning Amps, diyAB Amp and (very soon) the F5x, all use the diyAudio Universal PCB & Semiconductor Mounting Specification M3 mounting holes, so one chassis can be used for multiple projects. It's not cheap to pre-tap the holes, but for the uninitiated tapping is scarey and time consuming. Would you pay $49 to have the UMS holes professionally pre-drilled and pre-tapped into all the heatsinks in your chassis?

These boards currently in the store will work with the pre-tapped holes:

- Burning Amp BA-1

- Burning Amp BA-2

- Burning Amp BA-3 (Single ended or Complementary)

- Burning Amp BA-3 Balanced (Single ended or Complementary)

- F-4 clone

- F-5 clone

- F-5c (Also when used as an F-5 Turbo)

- F-5x (EUVL Balanced F-5 boards)

- diyAB "Honey Badger" 150w/ch class AB amp

DIY Friendly Base (DFB): The DFB is pre-drilled with a grid of holes suitable for mounting your power supply and non-heatsink boards directly with M3 bolts without having to drill it. The new PSU, Soft-Start and Speaker Protection boards we'll have in our store shortly have all been designed to fit the 10.5mm x 12mm hole pattern. Since it doubles the base thickness, it also supports heavy components better. Would you order this for your chassis?

Thanks for your time and feedback. We really hope that we can make this a win/win for all involved and solve one of the most difficult problems in making our own amplifiers and line level components.

Attachments

-

2u-1.jpg425.4 KB · Views: 458

2u-1.jpg425.4 KB · Views: 458 -

5u-2.JPG361.5 KB · Views: 505

5u-2.JPG361.5 KB · Views: 505 -

5u-1.JPG346.4 KB · Views: 476

5u-1.JPG346.4 KB · Views: 476 -

4u-4.jpg406.9 KB · Views: 522

4u-4.jpg406.9 KB · Views: 522 -

4u-3.jpg514.4 KB · Views: 516

4u-3.jpg514.4 KB · Views: 516 -

4u-2.jpg420.1 KB · Views: 412

4u-2.jpg420.1 KB · Views: 412 -

4u-1.jpg424.8 KB · Views: 411

4u-1.jpg424.8 KB · Views: 411 -

2u-4.jpg447.9 KB · Views: 491

2u-4.jpg447.9 KB · Views: 491 -

2u-3.jpg470.6 KB · Views: 522

2u-3.jpg470.6 KB · Views: 522 -

2u-2.jpg463.8 KB · Views: 386

2u-2.jpg463.8 KB · Views: 386 -

pth-5.jpg389.7 KB · Views: 343

pth-5.jpg389.7 KB · Views: 343 -

pth-4.jpg396.1 KB · Views: 323

pth-4.jpg396.1 KB · Views: 323 -

pth-3.jpg347.7 KB · Views: 282

pth-3.jpg347.7 KB · Views: 282 -

pth-2.jpg431.5 KB · Views: 291

pth-2.jpg431.5 KB · Views: 291 -

pth-1.jpg436.2 KB · Views: 387

pth-1.jpg436.2 KB · Views: 387 -

dfb-3.jpg593.1 KB · Views: 452

dfb-3.jpg593.1 KB · Views: 452 -

dfb-2.jpg533 KB · Views: 462

dfb-2.jpg533 KB · Views: 462 -

dfb-1.jpg580.6 KB · Views: 658

dfb-1.jpg580.6 KB · Views: 658 -

5u-3.JPG566.9 KB · Views: 739

5u-3.JPG566.9 KB · Views: 739

Last edited:

Some tube friendly chassis and something [smaller] earmarked for phono/line/dac applications would be welcome. 😀

Jason,

Congradulations to you and Mark for putting this together finally.

I also second Dave that an aluminium case is a much better choice than sheet steel. And the extra cost is well justified.

On top of that, it is important for anyone considering these cases to have data regarding heat sink performance. And by that I mean actual measured data, and not manufacturer's numbers. The reason behind this will be explained in details in an article on Class A case design by your truely in Linear Audio Vol. 3.

(Hope Jan will forgive me for leaking the news upfront.)

Patrick

Congradulations to you and Mark for putting this together finally.

I also second Dave that an aluminium case is a much better choice than sheet steel. And the extra cost is well justified.

On top of that, it is important for anyone considering these cases to have data regarding heat sink performance. And by that I mean actual measured data, and not manufacturer's numbers. The reason behind this will be explained in details in an article on Class A case design by your truely in Linear Audio Vol. 3.

(Hope Jan will forgive me for leaking the news upfront.)

Patrick

Last edited by a moderator:

I agree with both David and Euvl. Aluminum is ideal and getting a proper heatsink is one of the most difficult aspects for the class A crowd. I would think an all clear or clear with black sinks should be an option, but i am being peculiar at this point.

Really awesome work, guys!

I'm sure I'd order a couple of the big ones, with pre-tapped holes, and the bottom plate. Either color is fine. All aluminum would be nice, but perhaps that's not possible.

Probably a small chassis as well.

I'm sure I'd order a couple of the big ones, with pre-tapped holes, and the bottom plate. Either color is fine. All aluminum would be nice, but perhaps that's not possible.

Probably a small chassis as well.

Congratulations!

This is a great idea!

My suggestion would be to offer the 3U heatsinked version as well, as it is adequate to a wide variety of projects and aestetically pleasing.

Also, I woud suggest that you reduce a bit the countersinking of the tapped holes.

Quoting from ESP - Heatsink design and transistor mounting :

"It is vitally important that any recess or countersinking is only large enough to prevent metal "stretch" - overly large recesses will do more harm than good, either by reducing the available surface area, and/ or allowing the transistor flange to be distorted."

This is a great idea!

My suggestion would be to offer the 3U heatsinked version as well, as it is adequate to a wide variety of projects and aestetically pleasing.

Also, I woud suggest that you reduce a bit the countersinking of the tapped holes.

Quoting from ESP - Heatsink design and transistor mounting :

"It is vitally important that any recess or countersinking is only large enough to prevent metal "stretch" - overly large recesses will do more harm than good, either by reducing the available surface area, and/ or allowing the transistor flange to be distorted."

I'd like to make a recommendation for something sized more suitably for a project like the Shigaclone transport. I'm not sure any of the current sizes would be ideal. Maybe an enclosure more along the lines of what Bel Canto uses for its digital products, in one or two heights.

Jason and Mark:

This is terrific news for those of us in North America -- thank you! I've purchased seven enclosures from HiFi2000 and really appreciate both their construction and cosmetics (I admit to being a sucker for the 10mm front panels); HiFi2000 makes really nice boxes. My experience with purchasing directly from HiFi2000 has been a little problematic, not because of any malice on their part but because their command of English isn't very good, making it easy to miscommunicate (and who wants the wrong box showing up?). Coupled with the cost of shipping heavy enclosures from Bologna, Italy, the shipping times and the customs duties, dealing with HiFi2000 was not an inexpensive solution; even so, I thought it was worth it. But buying from diyaudio would be a whole lot better.

I have a few suggestions:

Finally, when do you anticipate product availability?

Regards,

Scott

This is terrific news for those of us in North America -- thank you! I've purchased seven enclosures from HiFi2000 and really appreciate both their construction and cosmetics (I admit to being a sucker for the 10mm front panels); HiFi2000 makes really nice boxes. My experience with purchasing directly from HiFi2000 has been a little problematic, not because of any malice on their part but because their command of English isn't very good, making it easy to miscommunicate (and who wants the wrong box showing up?). Coupled with the cost of shipping heavy enclosures from Bologna, Italy, the shipping times and the customs duties, dealing with HiFi2000 was not an inexpensive solution; even so, I thought it was worth it. But buying from diyaudio would be a whole lot better.

I have a few suggestions:

1. HiFi2000 offers a small chassis called the Galaxy Maggiorato, which looks like a half-width Slimline chassis and is well-suited as a power supply or chip amp enclosure; the photo below shows the power supply of my Aleph P1.7 in a Galaxy Maggiorato chassis to the left, the preamp in a Slimline chassis to the right. I suggest diyaudio add these small boxes to the list.

2. There are optional handles for the two Pesante Dissipante boxes you are planning on offering; Hifi2000 offers a couple of different designs and the back side of the front panels are pre-drilled to accommodate them. I strongly prefer the look of the milled handles, but confess to not having any personal experience with them. Given the weight of these enclosures fully-loaded, handles might be nice.

3. Similarly, please consider offering the optional HiFi2000 feet.

4. The top and bottom panels that HiFi2000 supplies with their enclosures are partially-vented -- they have slim vents running along both sides. It might be helpful if a fully-vented panel was available for the Pesante Dissipante enclosures, at least as a top panel (F5 Turbos will be difficult to heatsink).

5. Can HiFi2000 also supply a stiffer panel for the bottom of the Pesante Dissipante boxes? I'd happily spring for a 3, 4 or 5mm aluminum bottom panel if it would be significantly stiffer than those that HiFi2000 ordinarily includes. One of the few complaints I read about these enclosures is that the connection between the bottom panels and heat sinks may need to be strengthened if the amp is very heavy; a heavier-duty bottom panel would help.

6. This is less of a suggestion and more a request, but is there any chance that HiFi2000 could use a different, more efficient heatsink? Even with the 5U/400mm option, those of us considering higher-powered F5 Turbos will likely be forced to build monoblocks unless bigger heatsinks are available. As proud as I am of my audio projects, two side-by-side 5U/400mm enclosures will be a little ostentatious.

2. There are optional handles for the two Pesante Dissipante boxes you are planning on offering; Hifi2000 offers a couple of different designs and the back side of the front panels are pre-drilled to accommodate them. I strongly prefer the look of the milled handles, but confess to not having any personal experience with them. Given the weight of these enclosures fully-loaded, handles might be nice.

3. Similarly, please consider offering the optional HiFi2000 feet.

4. The top and bottom panels that HiFi2000 supplies with their enclosures are partially-vented -- they have slim vents running along both sides. It might be helpful if a fully-vented panel was available for the Pesante Dissipante enclosures, at least as a top panel (F5 Turbos will be difficult to heatsink).

5. Can HiFi2000 also supply a stiffer panel for the bottom of the Pesante Dissipante boxes? I'd happily spring for a 3, 4 or 5mm aluminum bottom panel if it would be significantly stiffer than those that HiFi2000 ordinarily includes. One of the few complaints I read about these enclosures is that the connection between the bottom panels and heat sinks may need to be strengthened if the amp is very heavy; a heavier-duty bottom panel would help.

6. This is less of a suggestion and more a request, but is there any chance that HiFi2000 could use a different, more efficient heatsink? Even with the 5U/400mm option, those of us considering higher-powered F5 Turbos will likely be forced to build monoblocks unless bigger heatsinks are available. As proud as I am of my audio projects, two side-by-side 5U/400mm enclosures will be a little ostentatious.

Finally, when do you anticipate product availability?

Regards,

Scott

Attachments

The one thing I'd do is make the store more prominent on the diyaudio home page. I visit the home page more than my employer would like and I forget the store is there. There's more boards there than I realized.

Anyway, other than that +1 on a smaller chassis (half wide) for smaller projects.

Anyway, other than that +1 on a smaller chassis (half wide) for smaller projects.

I was planning to place an order from Italy during the Summer for Fall/Winter projects. I'll gladly buy from the DIYaudio store instead. If you guys make it available, I'll order:

2 x 2U 300

1 x 5U 400

2 x 2U 300

1 x 5U 400

regarding screws for outputs - it's clever to use max possible dia - M3.5 or whatever is in non-metric size

Store can scavenge and sell small packages of these , but in greater quality (hardness?) than usual metal store generic ones .

either torx or wrench heads

same for big washers and spring washers

Store can scavenge and sell small packages of these , but in greater quality (hardness?) than usual metal store generic ones .

either torx or wrench heads

same for big washers and spring washers

Wow...I never knew there was a diyaudio store. I love the idea of making enclosures available, as they are about the hardest things to source, and far beyond my means to fabricate.

I've been using Hammond RM series enclosures. To my taste the Hammond look very good. Not sure if I would switch, but it would be great to have the option.

As to size and finishes, I like 1U and I like black powder coat. "Silver" is also OK with me. On the other hand, I've never seen black anodized aluminum that looked any good. And I used to manufacture commercial units in black anodized aluminum. Yuck.

The DIY Friendly Base is something I would probably want if I were to buy an enclosure.

Thanks for doing this.

I've been using Hammond RM series enclosures. To my taste the Hammond look very good. Not sure if I would switch, but it would be great to have the option.

As to size and finishes, I like 1U and I like black powder coat. "Silver" is also OK with me. On the other hand, I've never seen black anodized aluminum that looked any good. And I used to manufacture commercial units in black anodized aluminum. Yuck.

The DIY Friendly Base is something I would probably want if I were to buy an enclosure.

Thanks for doing this.

Silver ...!!!

I'm sure both colors will have to be in stock , they are both good looking case's ..

I'm sure both colors will have to be in stock , they are both good looking case's ..

- Status

- Not open for further replies.

- Home

- Site

- Site Announcements

- The diyAudio Store (USA) soon to stock chassis – requesting your feedback!