Says who, the Italians ?

Apparently yes. It would appear in your answer that you can die cut any larger gauge alum but we're having these done for us and so this is unarguably something we cannot insist on, unfortunately.

Anyway, we are working to make this as user friendly as possible, one of the very reasons this feedback thread was created so we can address your needs more accurately.

There's not much science in my answer (post77).

There is truth and no exaggeration in my answer.

I am not assuming any exaggeration in your answer but was hoping to find something (in it) to justify the increase in cost this endeavor will take up.

I cannot and will not argue about the intelligence content.

Hope your not getting personal.

Then let it be so. Again, this is just for justifying the extra cost for an all aluminum chassis. Nothing personal in that.

We're trying to hear everything and work on that so it becomes a win/win scenario for everyone in the end.

See below:

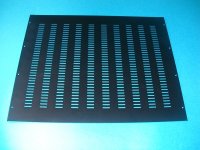

* The standard steel ventilated cover on a chassis (pictured: black)

* A super ventilated steel cover (pictured: black)

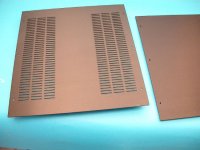

* The standard "4 row" alu ventilated cover (pictured: brown)

* A special edition "6 row" alu ventilated cover that they will do for us if we order alu chassis (pictured: brown)

* The standard steel ventilated cover on a chassis (pictured: black)

* A super ventilated steel cover (pictured: black)

* The standard "4 row" alu ventilated cover (pictured: brown)

* A special edition "6 row" alu ventilated cover that they will do for us if we order alu chassis (pictured: brown)

Attachments

Last edited:

Apparently

Standard bottom of the Modushop cases is 1.2mm steel plate.

They also do punched 2mm aluminum panels.

2mm aluminum has 50% better bending resistance than 1.2mm steel.

( deflection : P*L^3/3*E*I , tensile modulus E (steel) is 3 times E (aluminum) , I = W * T^3/12, W for width and T for thickness )

Last edited:

Standard bottom of the Modushop cases is 1.2mm steel plate.

They also do punched 2mm aluminum panels.

2mm aluminum has 50% better bending resistance than 1.2mm steel.

( deflection : P*L^3/3*E*I , tensile modulus E (steel) is 3 times E (aluminum) , I = W * T^3/12, W for width and T for thickness )

Yes those are their standard panels, but this requests are not their standards anymore so they need to adjust.

It's not just the bending they are concerned of. Plus either they'd do it or not is yet to be known.

Thank you for the formulas, I haven't seen those in many years since my Strength of Materials class in college.

What's wrong with understanding the mechanics/science of the assertion?bloody engineer

And why should you be allowed to make personal remarks about other Members?

we don't need to remember the formulae............ the formulas, I haven't seen those in many years

It's remembering the science behind the formulae that is more important.

A small increase in thickness makes for a big increase in both stiffness and strength.

pixpop:

The HiFi2000 front panels are removable. I've used Front Panel Express on almost all of my projects, and have shipped HiFi2000 10mm front panels to them for processing. Here's an example.

Regards,

Scott

hello. i see you have the wastOfLight ON LED. do you want to know what to do, so you can get standby LED insted?

PM me.

What's wrong with understanding the mechanics/science of the assertion?

And why should you be allowed to make personal remarks about other Members?

I had thought Zen Mod made the response about engineers in jest. For my own experiment I took aluminum panels from the Hammond enclosure I am working with, suspended them between a pair of 12" x 3" x 1 1/2" steel parallels, and stood on them.

I weigh approximately 165 pounds (12 stone or 75 Kilogram). The panels did not bend. I thought about putting a dial gauge on the panels but did not want to risk scratching them. (Or breaking the dial gauge, or falling over it.)

FYI, the aluminum covers are 3mm not 2mm and the steel is 1.25 not 1.2.

Thanks for everybody's feedback. We have added a half width chassis, aluminum chassis (6 rows of vents as pictures above), and a solid aluminum cover as options. Please let us know specifically what you are interested in, and we will put together a final product offering.

Link: diyAudio Chassis Survey

Please let me know if I've missed anything obvious or there are any problems with the survey, here.

Again, many thanks for everyone's feedback and constructive criticism!

Thanks for everybody's feedback. We have added a half width chassis, aluminum chassis (6 rows of vents as pictures above), and a solid aluminum cover as options. Please let us know specifically what you are interested in, and we will put together a final product offering.

Link: diyAudio Chassis Survey

Please let me know if I've missed anything obvious or there are any problems with the survey, here.

Again, many thanks for everyone's feedback and constructive criticism!

Last edited:

we don't need to remember the formulae.

It's remembering the science behind the formulae that is more important.

A small increase in thickness makes for a big increase in both stiffness and strength.

Funny thing is I know that (I'm sure you're not saying I don't). But thanks for reminding me.

BTT: What we're doing now is joining the science and economics of it all. Thanks to this feedback thread which is very helpful and informative.

Cheers

Due to many requests we are probably going to add some more holes to the UMS (Universal Mounting Standard) for the Big A 400mm chassis.

Here is the beginning of many posts describing of what I'm proposing, which invloves a specific board size.

http://www.diyaudio.com/forums/pass-labs/206756-f5-turbo-circuit-boards-128.html#post2968491

Come on over and pile on!

Mark

Here is the beginning of many posts describing of what I'm proposing, which invloves a specific board size.

http://www.diyaudio.com/forums/pass-labs/206756-f5-turbo-circuit-boards-128.html#post2968491

Come on over and pile on!

Mark

Much appreciated...

That you guys are looking to offer these here in the USA. The lack of domestically available options has made this the most daunting part of my DIY experience when building a transistor amplifier. Tube chassis' are a non-issue. A punched out top plate (Front Panel Express) and sturdy wood base (choose your exotic wood and build a simple frame) are all that's actually needed for a beautiful project...

Having built a few class A transistor amps and tapping M3 holes, breaking taps, etc...this is a welcome option.

That you guys are looking to offer these here in the USA. The lack of domestically available options has made this the most daunting part of my DIY experience when building a transistor amplifier. Tube chassis' are a non-issue. A punched out top plate (Front Panel Express) and sturdy wood base (choose your exotic wood and build a simple frame) are all that's actually needed for a beautiful project...

Having built a few class A transistor amps and tapping M3 holes, breaking taps, etc...this is a welcome option.

What a great idea, well done. I bought a chassis from this company for shipment to the UK last year. It took me ages to tap the holes in the heatsinks for the BA-2 boards so to have them pre-drilled is going to save future purchasers a lot of effort.

What about us in Europe? Will the diyaudio specified chassis appear on the MODU website?

Something else which took a while was cutting out the backplate of the chassis for mains sockets, phono plugs and loudspeaker posts. I know individual layouts differ but how about a standard drilled plate for these--one can always add some holes although it may not look that tidy.

Once again thanks for your hard work.

Chris

What about us in Europe? Will the diyaudio specified chassis appear on the MODU website?

Something else which took a while was cutting out the backplate of the chassis for mains sockets, phono plugs and loudspeaker posts. I know individual layouts differ but how about a standard drilled plate for these--one can always add some holes although it may not look that tidy.

Once again thanks for your hard work.

Chris

The bulk of survey responses are now in and we're a day or two away from announcing the final line up and pricing. We are also now very considering offering CNC'd back plates with a power entry module.

Interest in all aluminum chassis is very strong. Unfortunately it is not possible to get the 2U chassis in Aluminum.

They don't make an aluminum version of the 2U chassis (Their name for that chassis is "Pesante"). They do however have a line called "Slim Line" which does come in aluminum, and has heatsink-like sides, and comes in 280mm and 350mm depth.

I've created a new survey just to ask some questions specifically about the 2U, for both those interested in tube and also for non-tube projects. We will try to stock a product for each audience specifically for their needs. If you could spare a few seconds, it will really help us with our choices.

Link: 2U questionnaire for tube and non-tube fanatics

Interest in all aluminum chassis is very strong. Unfortunately it is not possible to get the 2U chassis in Aluminum.

They don't make an aluminum version of the 2U chassis (Their name for that chassis is "Pesante"). They do however have a line called "Slim Line" which does come in aluminum, and has heatsink-like sides, and comes in 280mm and 350mm depth.

I've created a new survey just to ask some questions specifically about the 2U, for both those interested in tube and also for non-tube projects. We will try to stock a product for each audience specifically for their needs. If you could spare a few seconds, it will really help us with our choices.

Link: 2U questionnaire for tube and non-tube fanatics

Last edited:

We are also now very considering offering CNC'd back plates with a power entry module

Yes please!

Hi Jason:

Any chance to buy just the heatsink?

Thanks..

Due to the limitations of our warehousing model, we'll only be offering a limited number of product "options" to start. Based on how things go, we certainly will consider expanding the options available in the future.

Yes please!

It looks like most people would like a CNC'd backplate, but there are a few complications we don't want to trip over in providing such an option, and putting too many holes in smaller chassis is asking for trouble.

We'll definitely at least offer the PEM module hole on the back of larger chassis, and possibly speaker binding post holes and RCA holes if we can agree on where they should go for most flexibility.

Can we get some recommendations for PEM hole dimensions as well as recommendations for good PEM modules themselves? If anyone is game to suggest ideal placement for PEM, RCA and speaker binding posts that will go in the mix too. Thanks

- Status

- Not open for further replies.

- Home

- Site

- Site Announcements

- The diyAudio Store (USA) soon to stock chassis – requesting your feedback!