Howdy 🙂,

I recently purchased a set of Extremis 6.8's (thanx herm), and set out to find a transmission line design for them..no luck. I was kind of surprised about this, as the spec's seemed to indicate they would be a match made in heaven. Not to be deterred, I got access to MJK's Mathcad vault, and fired up the Mathcad worksheet, and AutoCad, and between dealing with a pair of sick grand babies, went to work . After a few emails to Martin asking questions on how to enter the data manually (Martin provides fantastic support for his worksheets), I got things rolling and came up with this design...

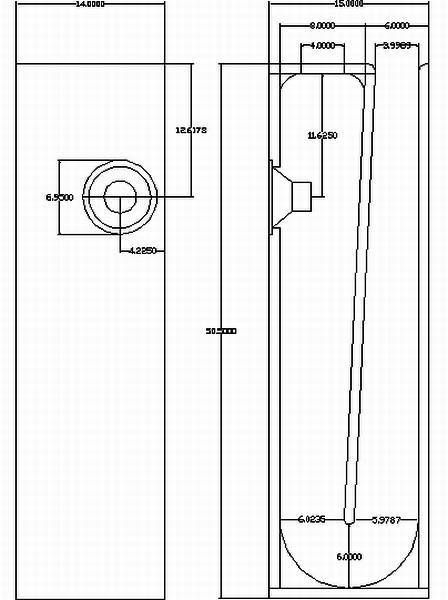

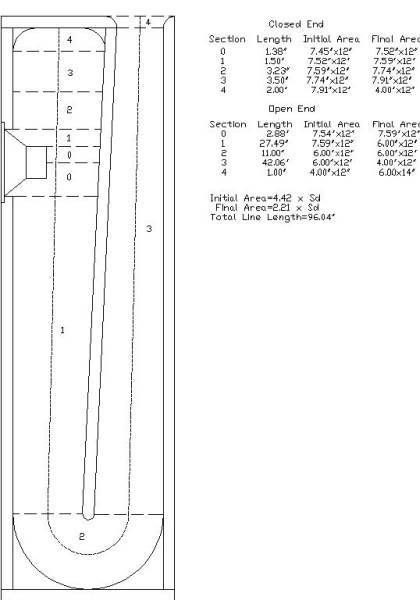

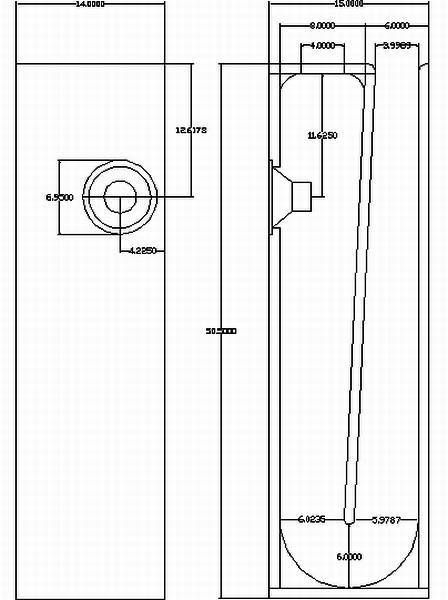

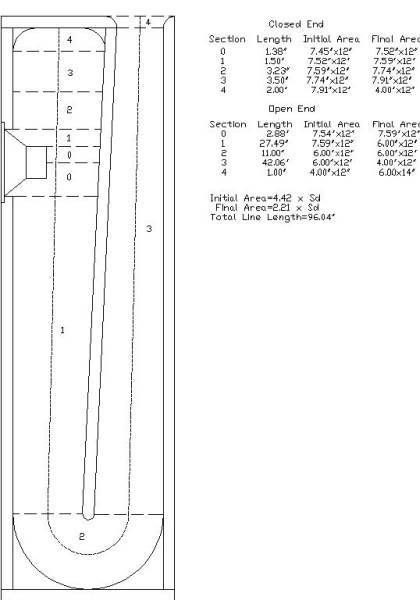

I plan to run a dipole ribbon off the side with the driver, so the final baffle shape hasn't been worked out. Here is the “sections” outline that I used to model it in MJK's “Offset-TL” worksheet...

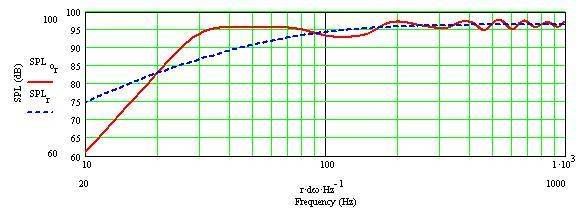

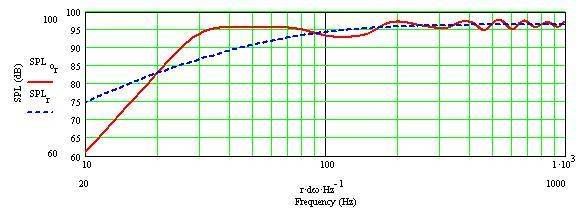

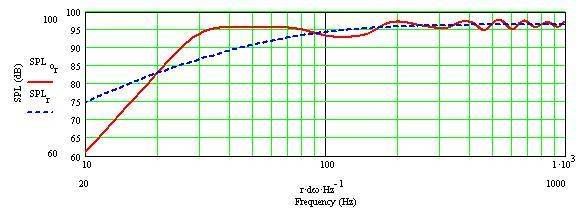

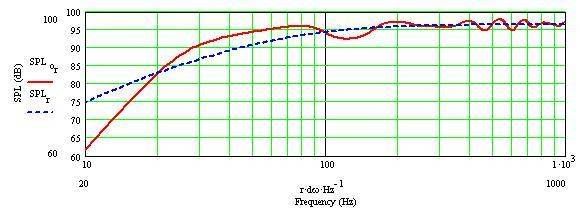

Here is the projected freq. Response...

And the impedance curve...

I put together a PDF file that I copied all the Mathcad worksheet fields into (excluding baffle step..my dinosaur of a PC can't handle that section) and posted it here ( it's 300k, so it's to big for an attachment). It has been a l-o-n-g time since I built a pair of speakers, I have no experience with TL's (except falling in love listening to them), and I was hoping that the more learned of the members here could give it a once over. I would really like to know if I have overlooked anything, and your general impression of the design before I draft up the cut sheet for them.

Edit: I forgot to mention the spl graph was with a 10W input, it is a 86dB/1W driver after all 😉.

Thanx,

Casey

I recently purchased a set of Extremis 6.8's (thanx herm), and set out to find a transmission line design for them..no luck. I was kind of surprised about this, as the spec's seemed to indicate they would be a match made in heaven. Not to be deterred, I got access to MJK's Mathcad vault, and fired up the Mathcad worksheet, and AutoCad, and between dealing with a pair of sick grand babies, went to work . After a few emails to Martin asking questions on how to enter the data manually (Martin provides fantastic support for his worksheets), I got things rolling and came up with this design...

I plan to run a dipole ribbon off the side with the driver, so the final baffle shape hasn't been worked out. Here is the “sections” outline that I used to model it in MJK's “Offset-TL” worksheet...

Here is the projected freq. Response...

And the impedance curve...

I put together a PDF file that I copied all the Mathcad worksheet fields into (excluding baffle step..my dinosaur of a PC can't handle that section) and posted it here ( it's 300k, so it's to big for an attachment). It has been a l-o-n-g time since I built a pair of speakers, I have no experience with TL's (except falling in love listening to them), and I was hoping that the more learned of the members here could give it a once over. I would really like to know if I have overlooked anything, and your general impression of the design before I draft up the cut sheet for them.

Edit: I forgot to mention the spl graph was with a 10W input, it is a 86dB/1W driver after all 😉.

Thanx,

Casey

Casey,

Exactly what I would do if using a dipole ribbon, if your front faced drawing shows the free standing left frontal speaker.

Otherwise in my opinion, it’s a good-looking Tl plan and well done simulations I find no reasons to remark upon.

Are you kidding? 🙂

🙂

b

I plan to run a dipole ribbon off the side with the driver

Exactly what I would do if using a dipole ribbon, if your front faced drawing shows the free standing left frontal speaker.

Otherwise in my opinion, it’s a good-looking Tl plan and well done simulations I find no reasons to remark upon.

It has been a l-o-n-g time since I built a pair of speakers

Are you kidding?

🙂

🙂 b

Hi bjorno-

It is.

Good news 🙂, thank you for taking the time to review the simulation.

Afraid not..it's been about 25 years 🙁 .

-Casey

...if your front faced drawing shows the free standing left frontal speaker.

It is.

Otherwise in my opinion, it’s a good-looking Tl plan and well done simulations I find no reasons to remark upon.

Good news 🙂, thank you for taking the time to review the simulation.

Are you kidding?

Afraid not..it's been about 25 years 🙁 .

-Casey

Afraid not..it's been about 25 years

That’s about the years ago I tested this concept for the first time.

It’s still my favourite design though I’m nowadays using a mid driver between the tweeter and the bas driver.

What about your choice of ribbon driver? I’m also curious of the proposed crossover.

b

What about your choice of ribbon driver? I’m also curious of the proposed crossover.

The ribbon will be a DIY design I've been playing with (on paper anyway). As for the crossover, this will be an active setup with a 200W

tube buffered BPA200 driving the Extremis, and a tube SE driving the ribbon. The crossover point will ultimately be determined by the ribbon's performance, but I am shooting for 300hz. One of the reasons I chose the Extremis is the low distortion in the midrange, this gives me a little flexibility if I need to crossover higher. The slope will also be picked based on the ribbon. I would idealy like to use a dual slope with an initial rolloff of 6dB/octave. I believe this would give me the most seemless transition between the 2 drivers.

As a "stopgap" until I can build the ribbon and required amps, I am considering converting my Paradigm Titans to dipole and using them in place of the ribbons.

-Casey

An intersesting observation, and a couple questions:

Changing the Mathcad model of the line to ignore the last 1" flare, the response below 100 hz gets slightly less flat (a small hump). It's very slight, but noticible.

I'm planning on using 1" mdf, is this thick enough to eliminate any bracing of the 12" wide center Baffle ? Any other material recommendations ?

-Casey

Changing the Mathcad model of the line to ignore the last 1" flare, the response below 100 hz gets slightly less flat (a small hump). It's very slight, but noticible.

I'm planning on using 1" mdf, is this thick enough to eliminate any bracing of the 12" wide center Baffle ? Any other material recommendations ?

-Casey

Casey, I'd be very interested in how this turns out. I have a pair of Extremis gathering dust. They need a good home.

I have a pair of Titans in the garage along with a small powered woofer. They are fine for casual listening but when I do a side by side with others, I find them quite light in the top end.

I look forward to the results of your ribbons. How long does it take to diy them?

I have a pair of Titans in the garage along with a small powered woofer. They are fine for casual listening but when I do a side by side with others, I find them quite light in the top end.

I look forward to the results of your ribbons. How long does it take to diy them?

Hi Cal-

It will be a while yet before I know just how good it all works out..I have to finish my TT project, and build the amps for them (these will need considerably more than the Fisher 800 I'm using can muster) before I make these. In the mean time I'm trying to get the "plan" in place so that I know my goal. As I find (make) the time, I will be drafting up a set of detailed plans, and will be posting them here. Perhaps you can build them before me, and let me know how they sound 😀. I'm only half kidding here, unless someone points out a flaw in my thinking (always a possibility), and the model is way off (not very likely based on results others have gotten from MJK's worksheets), provided you have the power behind them, these should rattle the rafters with bass..not to mention the very clean mids.

Yep..modded with better caps and sound deadening, they sound way better than they should at the price, but that last octave just-aint-there. I think I can get my hands on a pair of the old (80's) Radio Shack (Panasonic) ribbons from my brother to take over the 10k, and up, duties.

Good question. The last pair I made (15 years ago) took a couple of weekends. If you haven't already, I would highly recommend reading the ribbon thread started by dhenryp linked here, it's long, but covers just about all you need to know about building ribbons with inexpensive rare earth magnets.

-Casey

Casey, I'd be very interested in how this turns out. I have a pair of Extremis gathering dust. They need a good home.

It will be a while yet before I know just how good it all works out..I have to finish my TT project, and build the amps for them (these will need considerably more than the Fisher 800 I'm using can muster) before I make these. In the mean time I'm trying to get the "plan" in place so that I know my goal. As I find (make) the time, I will be drafting up a set of detailed plans, and will be posting them here. Perhaps you can build them before me, and let me know how they sound 😀. I'm only half kidding here, unless someone points out a flaw in my thinking (always a possibility), and the model is way off (not very likely based on results others have gotten from MJK's worksheets), provided you have the power behind them, these should rattle the rafters with bass..not to mention the very clean mids.

I have a pair of Titans in the garage along with a small powered woofer. They are fine for casual listening but when I do a side by side with others, I find them quite light in the top end.

Yep..modded with better caps and sound deadening, they sound way better than they should at the price, but that last octave just-aint-there. I think I can get my hands on a pair of the old (80's) Radio Shack (Panasonic) ribbons from my brother to take over the 10k, and up, duties.

I look forward to the results of your ribbons. How long does it take to diy them?

Good question. The last pair I made (15 years ago) took a couple of weekends. If you haven't already, I would highly recommend reading the ribbon thread started by dhenryp linked here, it's long, but covers just about all you need to know about building ribbons with inexpensive rare earth magnets.

-Casey

Doh!!

Finalizing the drafts/cutsheet,I realized my 48 1/2" front/back/side pieces won't work out so well cutting from a 48" wide sheet.. like I said it's been awhile 🙁

Ran a quick sim this morning to see if an inch shorter would make any difference (1/2"x2)..it didn't seem to. I'll redraft and sim a "construction friendly" version soon.

-Casey

Finalizing the drafts/cutsheet,I realized my 48 1/2" front/back/side pieces won't work out so well cutting from a 48" wide sheet.. like I said it's been awhile 🙁

Ran a quick sim this morning to see if an inch shorter would make any difference (1/2"x2)..it didn't seem to. I'll redraft and sim a "construction friendly" version soon.

-Casey

Ed-

Sweet!! 1" mdf was my first choice. My cabinet maker brother threw up the flag on me.

Thank you,

Casey

A sheet of mdf is an option.... it comes 49" wide x 97" long.

Sweet!! 1" mdf was my first choice. My cabinet maker brother threw up the flag on me.

Thank you,

Casey

Hi Valveitude !

Try to add some damping in the line... seeing the impedance curve : i would add some length to the line...

yann

Try to add some damping in the line... seeing the impedance curve : i would add some length to the line...

yann

Hi ypasco,

You might wan't to review the PDF I linked to in the first post 😉.

-Casey

Try to add some damping in the line... seeing the impedance curve : i would add some length to the line...

You might wan't to review the PDF I linked to in the first post 😉.

-Casey

thank you !

it sounds interesting.

I was just wondering why the transmission line was not tuned on the loudpeaker resonant frequency charged by the volume of air enclosed in the line. I think by this way, you could reduce the excusrion a bit more in low frequencies.

great project.

Yann

it sounds interesting.

I was just wondering why the transmission line was not tuned on the loudpeaker resonant frequency charged by the volume of air enclosed in the line. I think by this way, you could reduce the excusrion a bit more in low frequencies.

great project.

Yann

Hi Yann,

But it is 🙂. A reducing line shortens the length required for the target freq. The target length for 1/4 wave line tuned to 30hz (the Extremis's resonance) with a 2:1 taper is 97", mine is 96"..close enuf.

I was hoping for a better dampening at resonance as well, but with 25mm p-p excursion of the Extremis, I think I can live with it. Modeling different lines with this driver showed that this line gave the best overall performance.

Thanx.

-Casey

I was just wondering why the transmission line was not tuned on the loudpeaker resonant frequency charged by the volume of air enclosed in the line.

But it is 🙂. A reducing line shortens the length required for the target freq. The target length for 1/4 wave line tuned to 30hz (the Extremis's resonance) with a 2:1 taper is 97", mine is 96"..close enuf.

I think by this way, you could reduce the excusrion a bit more in low frequencies.

I was hoping for a better dampening at resonance as well, but with 25mm p-p excursion of the Extremis, I think I can live with it. Modeling different lines with this driver showed that this line gave the best overall performance.

great project.

Thanx.

-Casey

I almost feel guilty making suggestions without doing the simulations myself. You've given us lots to think about with your turntable adventure. Thanks so much.

But (is there always one?), in the spirit of continuing education, consider a smaller terminus. Maintain the closed end area and make the port smaller. This increase in loading may allow you to shorten the line or give you a lower tuning (your choice). A flat response may not be the best in combination with your listening room. Consider the room gain. You may arrive at a boomy response with what you have now. Also, decrease the stuffing. Anything over 0.35 lb/cf (some say less) generally increases the losses in the line, along with muddling the mid range.

When I am doing serious sim's, I open the file in 2 windows. I maintain one for a benchmark. I use the other squeezed into the screen beside it to run through the options. I find if I keep the curser in the margin after changing a parameter, I can scroll down the page to the location (usually the response graph) I want to see first, then click the program into action. HTH

But (is there always one?), in the spirit of continuing education, consider a smaller terminus. Maintain the closed end area and make the port smaller. This increase in loading may allow you to shorten the line or give you a lower tuning (your choice). A flat response may not be the best in combination with your listening room. Consider the room gain. You may arrive at a boomy response with what you have now. Also, decrease the stuffing. Anything over 0.35 lb/cf (some say less) generally increases the losses in the line, along with muddling the mid range.

When I am doing serious sim's, I open the file in 2 windows. I maintain one for a benchmark. I use the other squeezed into the screen beside it to run through the options. I find if I keep the curser in the margin after changing a parameter, I can scroll down the page to the location (usually the response graph) I want to see first, then click the program into action. HTH

Hey Ed,

Well since it's an “almost guilty”, as opposed to “definitely guilty”, go for it 😉.

I'll have to show this to Lorelle..”See honey, I'm really not an old xenophobic barnacle that spends all his available time locked away in his shop..I'm a giver” 😀. Seriously..you are more than welcome.

I'll plug some numbers in to see what happens. To be honest though, a shorter line really isn't desired. My planned ribbon that this will be mated to it is 36” long. I want the driver to be as close to the ribbon center as possible, and the center of the ribbon as close to ear level as possible..I'll probably end up with a baffle extension on top as is. As far as the tuning goes, I found that regardless of the taper (expanding, contracting, or straight), when tuned to 30hz, the impedance curve looked very similar. The longer lines did tamp it down a little more, but at the expense of more rippling in the mid band. In the end, I decided that a smoother mid-band trumped the small decrease in excursion..it is an Extremis after all 🙂.

My current listening room is on the small side. I haven't measured, or calculated it, but my ear tells me it has a peak between 80-160hz. Serendipitously, the predicted response has a “sag” in this region. It may still be an issue however..one of the reasons (there are many) I want to go with separate amps. If needed, I can do “nasty” things like EQ the bottom end, without sullying the signal path to the ribbons.

This is the area where the “art” and the “science” of line design seem to collide the most..to me anyway. Fortunately it is also the area that is the easiest to tune, and the area I spent most of my time playing around with in Martin's worksheet. Reading through the monster “BIB” thread in the fullrange forum, the general consensus seems to be that the “ripples” that show up in the worksheet isn't as annoying in real life as the “choked” sound you get when you stuff to get rid of them. What I have tried to do here is to have it all 😀. As I mentioned, I spent a fair amount of time simming the stuffing scheme, and what I came up with is 1 lb/cu ft. above the driver, .75 lb/cu ft. behind the driver to the second half of the line, and no stuffing in the last half. If you average the stuffing (excluding the area above the driver), you get .375 lb/ cu ft.. I also felt that if the cross section area of the line was bigger than normal (4.4 x Sd), the driver would have more space to “breath” into, offsetting the effect of the stuffing to some degree.

As I was typing the above passage, I decided to test my stuffing scheme theory (such as it is) by simming the line with .35 lb/cu. ft. the whole length instead of my staggered stuffing of 1 lb/sqr ft.->.75 lb/cu ft.->0 lb/cu ft. Here is my scheme...

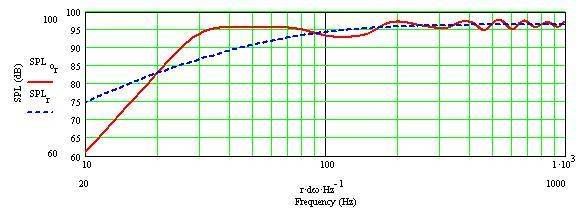

and here is .35 lb/cu ft. the whole length...

[Elvis] Thank ya, thank ya vurry much[/Elvis]

It could still sound like poo, but I'll at least try my plan first..I can always change it.

To be clear, I am not dismissing out of hand anything you have suggested. I just wanted to explain my reasons for going the route I have..thanx for the input.

-Casey

Edit: Changed notation from sqr ft to the correct cu ft.

I almost feel guilty making suggestions without doing the simulations myself.

Well since it's an “almost guilty”, as opposed to “definitely guilty”, go for it 😉.

You've given us lots to think about with your turntable adventure. Thanks so much.

I'll have to show this to Lorelle..”See honey, I'm really not an old xenophobic barnacle that spends all his available time locked away in his shop..I'm a giver” 😀. Seriously..you are more than welcome.

But (is there always one?), in the spirit of continuing education, consider a smaller terminus. Maintain the closed end area and make the port smaller. This increase in loading may allow you to shorten the line or give you a lower tuning (your choice).

I'll plug some numbers in to see what happens. To be honest though, a shorter line really isn't desired. My planned ribbon that this will be mated to it is 36” long. I want the driver to be as close to the ribbon center as possible, and the center of the ribbon as close to ear level as possible..I'll probably end up with a baffle extension on top as is. As far as the tuning goes, I found that regardless of the taper (expanding, contracting, or straight), when tuned to 30hz, the impedance curve looked very similar. The longer lines did tamp it down a little more, but at the expense of more rippling in the mid band. In the end, I decided that a smoother mid-band trumped the small decrease in excursion..it is an Extremis after all 🙂.

A flat response may not be the best in combination with your listening room. Consider the room gain. You may arrive at a boomy response with what you have now.

My current listening room is on the small side. I haven't measured, or calculated it, but my ear tells me it has a peak between 80-160hz. Serendipitously, the predicted response has a “sag” in this region. It may still be an issue however..one of the reasons (there are many) I want to go with separate amps. If needed, I can do “nasty” things like EQ the bottom end, without sullying the signal path to the ribbons.

Also, decrease the stuffing. Anything over 0.35 lb/cf (some say less) generally increases the losses in the line, along with muddling the mid range.

This is the area where the “art” and the “science” of line design seem to collide the most..to me anyway. Fortunately it is also the area that is the easiest to tune, and the area I spent most of my time playing around with in Martin's worksheet. Reading through the monster “BIB” thread in the fullrange forum, the general consensus seems to be that the “ripples” that show up in the worksheet isn't as annoying in real life as the “choked” sound you get when you stuff to get rid of them. What I have tried to do here is to have it all 😀. As I mentioned, I spent a fair amount of time simming the stuffing scheme, and what I came up with is 1 lb/cu ft. above the driver, .75 lb/cu ft. behind the driver to the second half of the line, and no stuffing in the last half. If you average the stuffing (excluding the area above the driver), you get .375 lb/ cu ft.. I also felt that if the cross section area of the line was bigger than normal (4.4 x Sd), the driver would have more space to “breath” into, offsetting the effect of the stuffing to some degree.

As I was typing the above passage, I decided to test my stuffing scheme theory (such as it is) by simming the line with .35 lb/cu. ft. the whole length instead of my staggered stuffing of 1 lb/sqr ft.->.75 lb/cu ft.->0 lb/cu ft. Here is my scheme...

and here is .35 lb/cu ft. the whole length...

[Elvis] Thank ya, thank ya vurry much[/Elvis]

It could still sound like poo, but I'll at least try my plan first..I can always change it.

To be clear, I am not dismissing out of hand anything you have suggested. I just wanted to explain my reasons for going the route I have..thanx for the input.

-Casey

Edit: Changed notation from sqr ft to the correct cu ft.

Greets!

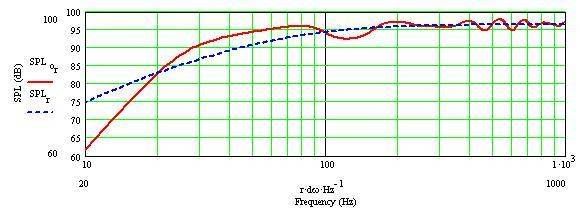

Coming a little late to the 'party' and certainly nothing fundamentally wrong with your alignment, but I hate to give up any acoustic efficiency in the ~40-120 Hz if I can help it, so FWIW here's an alignment I did when these became popular awhile back, but still haven't prototyped it:

L = 56.5"

zdriver = 3"

SO = 173.6"^2

SL = 21.7"^2

stuffing density = 0.2 lb/ft^3 with a 1.0 lb/ft^3 wad just below the driver for the sim, I use acoustic fiberglass, so it will be different

GM

Coming a little late to the 'party' and certainly nothing fundamentally wrong with your alignment, but I hate to give up any acoustic efficiency in the ~40-120 Hz if I can help it, so FWIW here's an alignment I did when these became popular awhile back, but still haven't prototyped it:

L = 56.5"

zdriver = 3"

SO = 173.6"^2

SL = 21.7"^2

stuffing density = 0.2 lb/ft^3 with a 1.0 lb/ft^3 wad just below the driver for the sim, I use acoustic fiberglass, so it will be different

GM

Attachments

Hi GM,

Thanx for stopping by, I was hoping to lure some of the TL "heavy hitters" here 🙂.

A couple of Q's..first, forgive my ignorance of the lingo, but what is "zdriver"? First thought was offset, but if it is , it must be from the edge of the driver (3" is less than the radius). Second, could you give me a little more info on the "wad" of stuffing, specifically, how do I model it in the worksheet? Finally (for the moment), how does the insulation you use differ from the worksheet, and how do I compensate for it in the model?

To be honest, I settled on the 2->1 alignment mainly because it met my physical needs. That is, it placed the driver where I wanted it relative to the floor/ribbon, and the terminus was facing up (minimizing floor coupling). I was already to close the worksheet/cad when you up and lay that spl graph on me..damn. I'm not sure if the flatter 80-200hz is actually beneficial to me or not (my room peaks in that region), but the .2lb cu ft is. Is my concept of "averaging" of the volume->density valid, as far as midrange choking? That is, is 50% of the line filled with .4 cu ft equivelent to a 100% of the line filled at .2 cu ft? I know it models the same (for the midrange).

You've certainly given me something to think about.

-Casey

Thanx for stopping by, I was hoping to lure some of the TL "heavy hitters" here 🙂.

A couple of Q's..first, forgive my ignorance of the lingo, but what is "zdriver"? First thought was offset, but if it is , it must be from the edge of the driver (3" is less than the radius). Second, could you give me a little more info on the "wad" of stuffing, specifically, how do I model it in the worksheet? Finally (for the moment), how does the insulation you use differ from the worksheet, and how do I compensate for it in the model?

To be honest, I settled on the 2->1 alignment mainly because it met my physical needs. That is, it placed the driver where I wanted it relative to the floor/ribbon, and the terminus was facing up (minimizing floor coupling). I was already to close the worksheet/cad when you up and lay that spl graph on me..damn. I'm not sure if the flatter 80-200hz is actually beneficial to me or not (my room peaks in that region), but the .2lb cu ft is. Is my concept of "averaging" of the volume->density valid, as far as midrange choking? That is, is 50% of the line filled with .4 cu ft equivelent to a 100% of the line filled at .2 cu ft? I know it models the same (for the midrange).

You've certainly given me something to think about.

-Casey

valveitude said:But it is 🙂. A reducing line shortens the length required for the target freq. The target length for 1/4 wave line tuned to 30hz (the Extremis's resonance) with a 2:1 taper is 97", mine is 96"..close enuf.

i agree, and i am quite confident with the fact that the extremis will be happy with your line... I was just asking because when i design quarter wave enlosures, i make sure that the tuning frequency of the line is at the driver resonnance frequency

charged by the volume of air insude the line. In your case, the extremis is no longer resonnant at 30...

So i'm wrong in saying more length... but less is right because the frequency is now closer that 40...

your design sounds good to me now... i apologize...

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- An Extremis 6.8 Offset Reducing Taper TL Design