Hey guys,

When I first suggested the method using Vitrea paint, I was using standard brushes. The results were OK but since the Vitrea paint is thick, the result were not as smooth as a real soldermask.

Recently, I tried a low-cost airbrush (Vitrea paint needs to be thinned a little) and the results are far more smoother. You can find those airbrush in any Walmart or model shop.

Give it a try if you're having troubles getting a smooth finish or if you lack patience as I do.

In the following weeks, I'm going to try various foils found at www.pulsarprofx.com. They have green and white foils for soldermasking and "silkscreening".

http://www.pulsarprofx.com/PCB/a_Pages/4_Products/4b_TRF_Foils/TRF_Foils.html

I'm not very fond of toner transfer system but their results looks promising.

What interests me the most is the fact they also carry a line of transfer foils on which you can print full color images then transfer them on anything (PCB, metal enclosures etc...). May be handy to give a profesionnal look to face/back plate etc.

When I first suggested the method using Vitrea paint, I was using standard brushes. The results were OK but since the Vitrea paint is thick, the result were not as smooth as a real soldermask.

Recently, I tried a low-cost airbrush (Vitrea paint needs to be thinned a little) and the results are far more smoother. You can find those airbrush in any Walmart or model shop.

Give it a try if you're having troubles getting a smooth finish or if you lack patience as I do.

In the following weeks, I'm going to try various foils found at www.pulsarprofx.com. They have green and white foils for soldermasking and "silkscreening".

http://www.pulsarprofx.com/PCB/a_Pages/4_Products/4b_TRF_Foils/TRF_Foils.html

I'm not very fond of toner transfer system but their results looks promising.

What interests me the most is the fact they also carry a line of transfer foils on which you can print full color images then transfer them on anything (PCB, metal enclosures etc...). May be handy to give a profesionnal look to face/back plate etc.

Magura said:

The Vitrea can be applied with an airbrush, I consider that a major benefit.

Magura

OOps ! Sorry Magura

Have a nice day !

hey guys

I find a new metod that is used in industry.

go to:

http://www.pcbhobbyist.com/

This autor uses a DFSM (Dry Film Solder Mask). Can you place the foils directly with pouche office laminator....

I Hope that I help you. Bye

I find a new metod that is used in industry.

go to:

http://www.pcbhobbyist.com/

This autor uses a DFSM (Dry Film Solder Mask). Can you place the foils directly with pouche office laminator....

I Hope that I help you. Bye

Wow, those photoresist film looks interesting. I tried spray photoresist in the past but the results are way too much inconsistent.

masking

Hi,

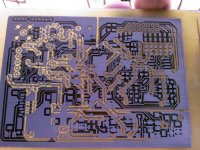

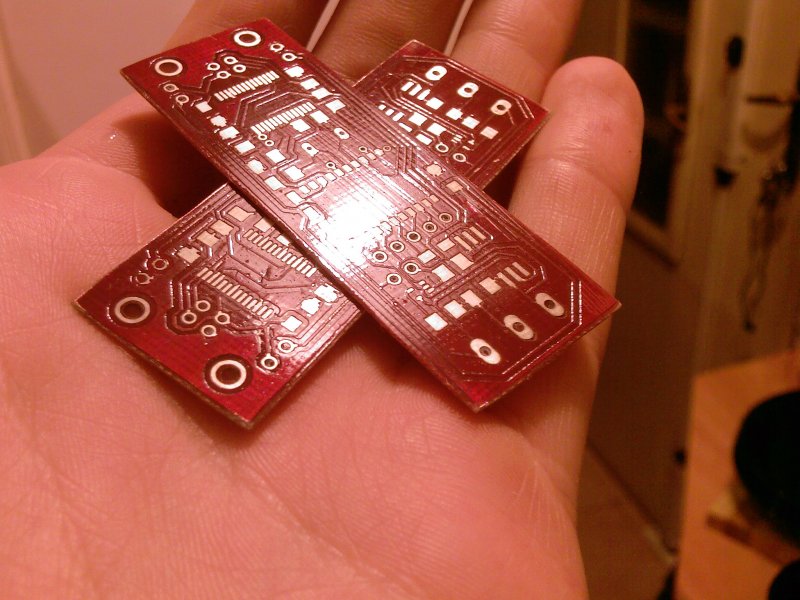

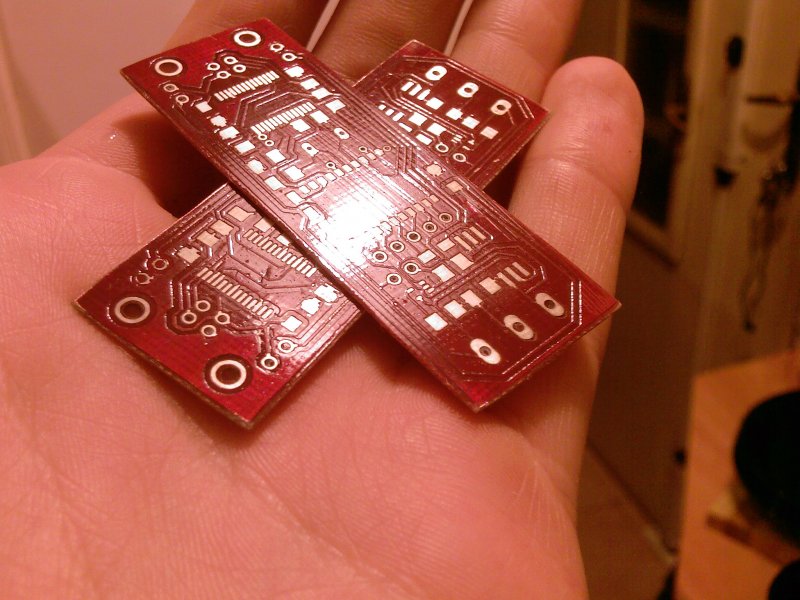

I have found out that Pebeo Vitrea can be easily masked with the toner transfer method.

Masking:

Painting:

Removing the mask after cooking:

Basically it works as a solder mask (doesn't burn away), but I can solder it through if I really-really push the soldering iron into it. Have you also experienced this, or was it only me who didn't bake it enough? (I didn't have a thermometer to measure the temperature with)

Hi,

I have found out that Pebeo Vitrea can be easily masked with the toner transfer method.

Masking:

Painting:

Removing the mask after cooking:

Basically it works as a solder mask (doesn't burn away), but I can solder it through if I really-really push the soldering iron into it. Have you also experienced this, or was it only me who didn't bake it enough? (I didn't have a thermometer to measure the temperature with)

Re: masking

You just need to bake it at 180C, then it will won't melt later, unless you do something real unfortunate.

Magura

lmao said:

Basically it works as a solder mask (doesn't burn away), but I can solder it through if I really-really push the soldering iron into it. Have you also experienced this, or was it only me who didn't bake it enough? (I didn't have a thermometer to measure the temperature with)

You just need to bake it at 180C, then it will won't melt later, unless you do something real unfortunate.

Magura

I have found out that Pebeo Vitrea can be easily masked with the toner transfer method.

Wow ! Good idea

Can you explain wow do you remove paint/toner over pads. Just by heating ?

I had some Techniks Press-N-Peel blue that I tried to use as a mask for the pads before painting with the Vitrea. Was taking too long and the results were poor so I just went at it with a narrow brush and a shaky hand  It bakes up well but the uneven blobs of paint bothered me so I tried to sand them down a bit. Don't do this

It bakes up well but the uneven blobs of paint bothered me so I tried to sand them down a bit. Don't do this  It dulls the gloss and makes it look awful. I think I'll mill another circuit and try the PNP blue again.

It dulls the gloss and makes it look awful. I think I'll mill another circuit and try the PNP blue again.

lmao are you using photo paper?

Jay

lmao are you using photo paper?

Jay

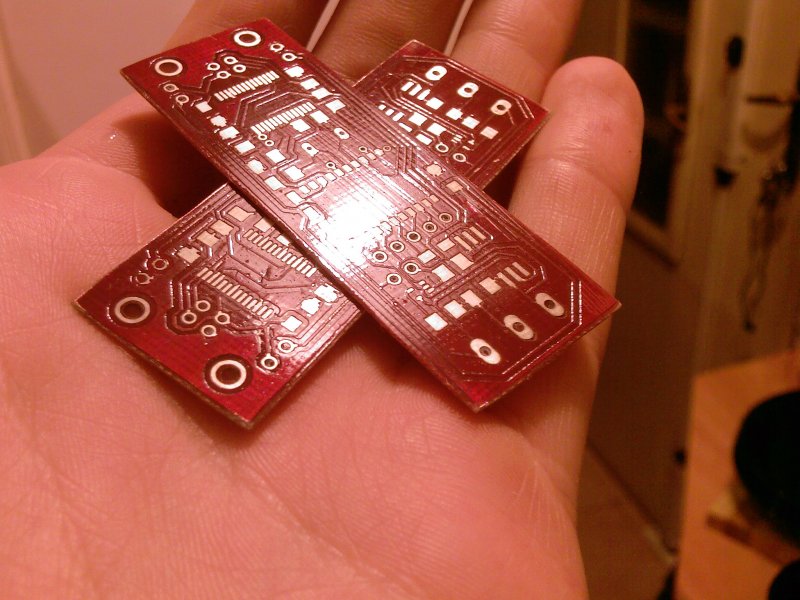

Attachments

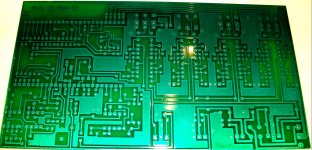

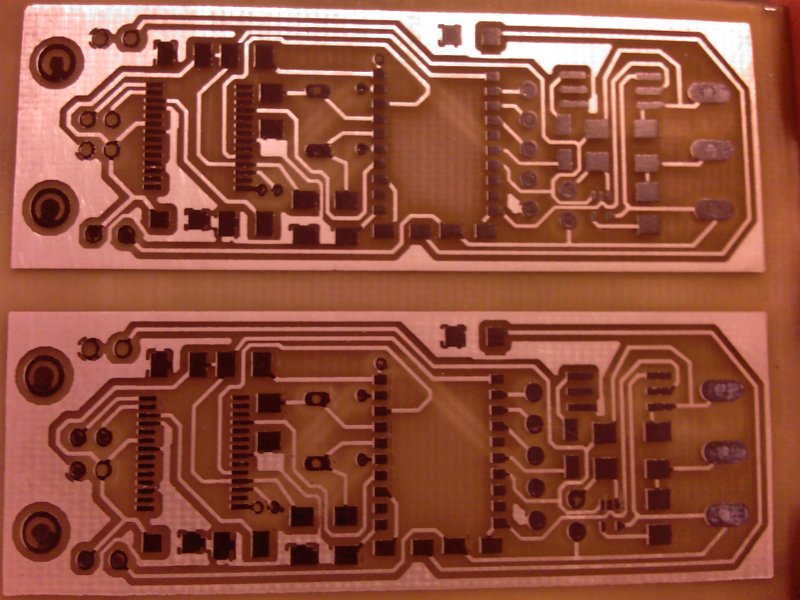

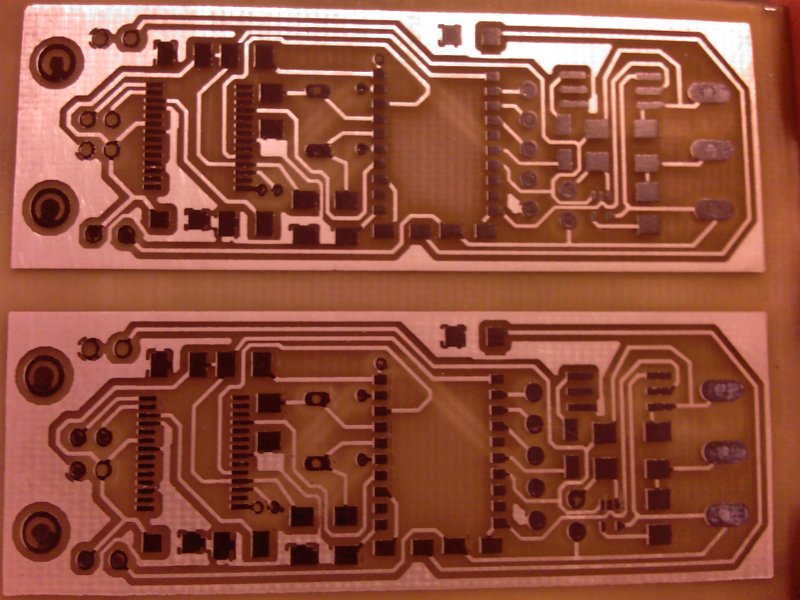

I'm using cheap shiny paper and a simple laminator for the toner transfer. It's possible to achieve a stable 6 mil resolution this way, like in the image I have attached. I think in your case the uneven blobs appeared because you didn't let the paint dry for long enough before baking it (it requires 24 hours).

Attachments

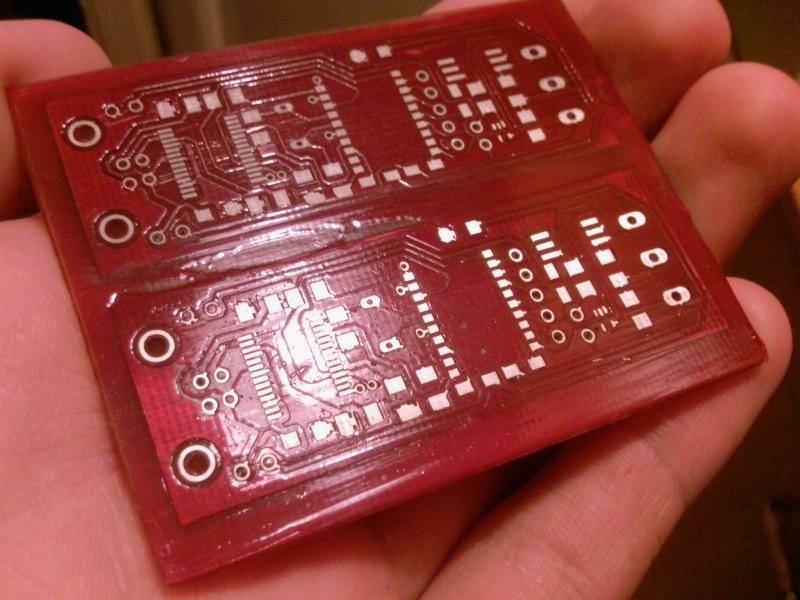

I'm soooooo glad I stumbled upon this topic! I have wondered for the longest time how to make a good looking solder masks on my boards. Magura and lmao, those are some fantastic looking boards! I see that quite a few people have chosen to go with red, I'm thinking I want to try a light blue on my board but I still haven't decided yet. Thanks for the pics and and all the good info!

I can't wait to try this on my latest project, (you can see it here).

I can't wait to try this on my latest project, (you can see it here).

The mask can be removed after baking by rubbing it with paint thinner or acetone.

These didn't alter the Pebeo in any way?

I'm wondering if maybe I didn't have it hot enough. I used a toaster oven to bake this experimental board. I used a glue pen to apply glue to the pads I wanted masked and then I airbrushed the paint onto the board. I tried to clean the glue I used to mask my pads with some Goof Off and it softened up the Vitrea.

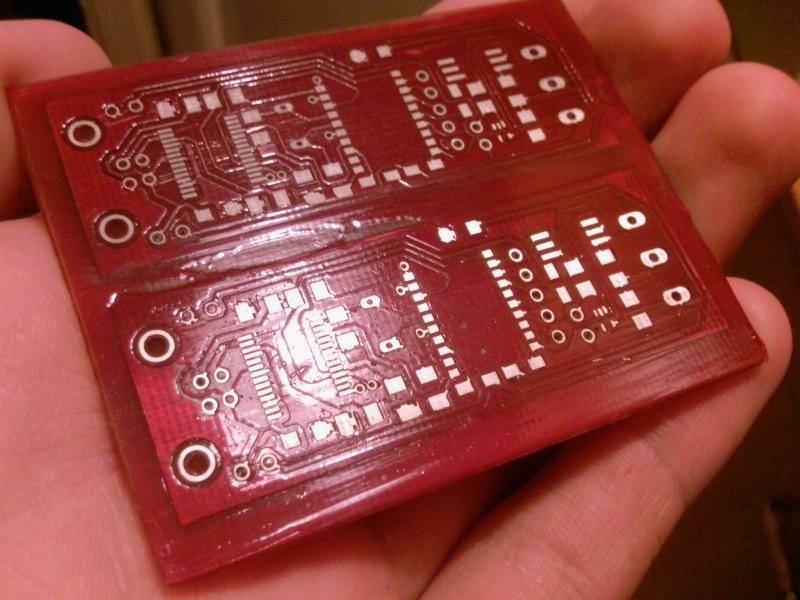

Here's some pics of my semi-successful attempt with this stuff:

Attachments

These didn't alter the Pebeo in any way?

I'm wondering if maybe I didn't have it hot enough. I used a toaster oven to bake this experimental board. I used a glue pen to apply glue to the pads I wanted masked and then I airbrushed the paint onto the board. I tried to clean the glue I used to mask my pads with some Goof Off and it softened up the Vitrea.Now it's still soft and I can practically scratch it off with my fingernail.

Here's some pics of my semi-successful attempt with this stuff:

I think the glue caused the problem. With toner it worked very well. The pads became a little bumpy after baking, and it was easy to remove them. I baked the board again after the acetone treatment.

Hi,

I have found out that Pebeo Vitrea can be easily masked with the toner transfer method.

Basically it works as a solder mask (doesn't burn away), but I can solder it through if I really-really push the soldering iron into it. Have you also experienced this, or was it only me who didn't bake it enough? (I didn't have a thermometer to measure the temperature with)

Hey, this stuff looks awesome! When you remove the masked Vitrea stuff with acetone off the pads, do you use a q-tip or something? I'm just wondering because if you rub the pad with acetone and accidently get the acetone off the pad, does it remove the Vitrea on the actual PCB surrounding the pad? Or would it just remove it wherever you have applied the toner mask?

Mike

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- DIY solder mask