Thought I'd share pictures of me Aleph30 in progress. The chassis is complete and I'm now focusing on the electronics.

The main chassis plate was built through frontpanel express and bent into a box on a sheet metal brake.

The heatsinks are the large ones from Conrad heatsinks.

This was a lot of fun to assemble, and a great excuse for me to buy the drill press I always wanted. I'm happy with all the drilling and tapping of the screw holes. This was my first attempt to tap screw holes and everything worked out well.

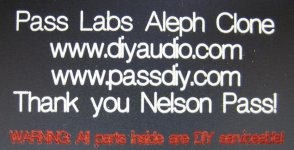

You might like the Service warning on the back.

-David

The main chassis plate was built through frontpanel express and bent into a box on a sheet metal brake.

The heatsinks are the large ones from Conrad heatsinks.

This was a lot of fun to assemble, and a great excuse for me to buy the drill press I always wanted. I'm happy with all the drilling and tapping of the screw holes. This was my first attempt to tap screw holes and everything worked out well.

You might like the Service warning on the back.

-David

Attachments

It warms my heart to no end that Nelson likes the chassis.

A HUGE thank you to Nelson, and everyone on this forum who have been kind enough to answer my questions. It is an honor to share the collective wisdom and ideas in this forum.

Thank you all from the bottom of my heart.

-David

A HUGE thank you to Nelson, and everyone on this forum who have been kind enough to answer my questions. It is an honor to share the collective wisdom and ideas in this forum.

Thank you all from the bottom of my heart.

-David

Frontpanel express charged $187USD including shipping. Not inexpensive, but the outcome is professional looking. I noticed a lot of builders use aluminum plates and aluminum square stock. Thought this might be an easy approach, and it was.

All said and done, it costs less to buy a good used Aleph30... but that would't be as much fun.

-David

All said and done, it costs less to buy a good used Aleph30... but that would't be as much fun.

-David

BrianDonegan said:Sweet chassis! What did you use for trafos?

The transformers are from Antek in Canada they are 21+21 at 400va. The price was $84 for the pair. The owner was very nice to deal with, and he shipped as promised. If you buy more than one from him directly an eBay, he will shave a few bucks off the asking price.

Seemed like a good deal.

-David

chipco3434 said:Did you get a price on two by any chance?

For 2 panels of the same design, FrontPanel express reduces the price on this configuration by about 10% on the order.

Download their CAD program for free, mock-up a panel, and the CAD tool costs out a quote and estimates delivery time.

I removed a series of mounting holes not needed in the file I used for a Trafo housing. This reduced the cost by $25. The attached file costs $141 shipping included.

http://www.frontpanelexpress.com/

-David

I had a local precision fab shop bend up to chassis's. The cost was around $100 for the labor. The panels are 2mm thick and it takes a large sheetmetal brake for a 14ga panel.

Attached is an image of a bare chassis and the heatsinks being tapped with 1/4" holes 3/16" deep.

-David

Attached is an image of a bare chassis and the heatsinks being tapped with 1/4" holes 3/16" deep.

-David

Attachments

The transformers are from Antek in Canada they are 21+21 at 400va.

Cool. I spoke to him last week. He said he would have 18V trafos in in a few weeks, which is what I was planing on using.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- My 1st Aleph Amp