I'll be building a subwwofer at some point in the future. Not for a while yet, but I like to have a design sorted out long in advance. I want to build something unusual, with the priority being on low distortion and wide bandwidth, and it must use one or both of the two woofers I already have (very nice 12" drivers from the unfortunately now defunct McKenzie).

Initially I experimented with motional feedback on a normal sealed sub to achieve this, but I didn't like the way the complexity kept increasing as the system approached a worthwhile improvement. The next choice is a horn. I've not designed a horn of any type before, but the theory doesn't seem too hard to grasp and Hornresp makes it easy to see what might happen!

Anyway, the obvious problem with bass horns is the huge size. This problem can be overcome if the space taken up by the horn is space that would have been taken up by something else anyway, if the horn can somehow be dual function. Luckily, it just so happens that in the room where the sub will be is a bed. Thus the horn must be a bed...

The two woofers have Qt=0.21 and Fs=30Hz, which I gather is fitting for horn loading. They will be connected in parallel, both electrically and acoustically. I roughly calculated the horn parameters and then plugged them into Hornresp and tweaked until the response was reasonably flat and sensitivity still high at 20Hz. It fits well into the size of the bed with some folding, assuming corner loading.

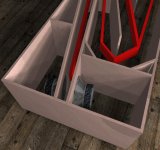

I have also modelled construction using Unreal Ed (UEd > real CAD ) to ensure it is physically practical to construct. Overall dimensions are 1.0*2.2*0.5 metres.

) to ensure it is physically practical to construct. Overall dimensions are 1.0*2.2*0.5 metres.

Since I lack experience with horns, any comments are most welcome. In particular, I was wondering if the narrowness of the throat chamber would be a problem. In order to keep the volume fairly low (Hornresp says nasty bumps happen if it's too large) it is only ~10mm deep (a fair amount of volume is taken up by the baffle cutouts and cone).

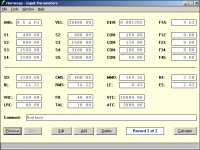

Following are some attachments. First the parameters entered into Hornresp.

Initially I experimented with motional feedback on a normal sealed sub to achieve this, but I didn't like the way the complexity kept increasing as the system approached a worthwhile improvement. The next choice is a horn. I've not designed a horn of any type before, but the theory doesn't seem too hard to grasp and Hornresp makes it easy to see what might happen!

Anyway, the obvious problem with bass horns is the huge size. This problem can be overcome if the space taken up by the horn is space that would have been taken up by something else anyway, if the horn can somehow be dual function. Luckily, it just so happens that in the room where the sub will be is a bed. Thus the horn must be a bed...

The two woofers have Qt=0.21 and Fs=30Hz, which I gather is fitting for horn loading. They will be connected in parallel, both electrically and acoustically. I roughly calculated the horn parameters and then plugged them into Hornresp and tweaked until the response was reasonably flat and sensitivity still high at 20Hz. It fits well into the size of the bed with some folding, assuming corner loading.

I have also modelled construction using Unreal Ed (UEd > real CAD

Since I lack experience with horns, any comments are most welcome. In particular, I was wondering if the narrowness of the throat chamber would be a problem. In order to keep the volume fairly low (Hornresp says nasty bumps happen if it's too large) it is only ~10mm deep (a fair amount of volume is taken up by the baffle cutouts and cone).

Following are some attachments. First the parameters entered into Hornresp.

Attachments

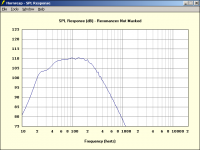

Next the predicted frequency response. It is reasonably flat from 40Hz-250Hz, and still at 100dB@2.83V@20Hz. Room gain will probably lift that up enough to be flat to 20Hz, or a little EQ may be in order (predicted excursion reaches a maximum at 20Hz, but I don't listen too loud and the efficiency is high, so I think it would be ok).

Attachments

This is the final pic. I plan to place it directly onto the carpet, without a panel underneath so that the carpet will help damp the standing waves that will occur between the parallel top and bottom. Do you think this can be done without leakage being too much of a problem? It's a short-pile carpet and the thing will be very heavy, so it should sit very firrmly, but Im not sure.

Attachments

A few comments. Lose the second driver; it only gives you 3dB extra, and if the horn needs that 3dB then the design is botched anyway. Flat to 40 is fine, unless your room is 50 feet long. There won't be any standing waves between the top and bottom, the distance is too short compared to the horn passband. The dimension of the throat chamber doesn't matter much for the flow of low frequencies, but keep it as small as possible, as a 30 Hz fs is rather low for a 20 Hz horn, and the larger the front chamber the more it acts as a HP filter that pushes the box frequency down. Same for the rear chamber with a horn as large as this one.

Is there any disadvantage to using two drivers? Since I already have a pair and don't have any other use for them, I would be inclined to just stick them both in even if it doesn't have any significant advantage, as long as there is no particular disadvantage. Hornresp does suggest that the frequency response will be smoother with two though.

As Bill mentioned, the standing waves won't be a problem, and the rear chambers should be sealed well - so a base plate at least in this area may be in order. Compression ratio is very high, but if the drivers have a stiff cone and not too much power is fed into it, may be ok.

The chambers in front of the drivers seem to be a bit narrow compared to the width at the start of the horn proper - I have some reservations as to whether firing the drivers straight into a solid wall this close will cause problems. I would be more inclined to continue the throat section of the horn right to the back of the box (bed head) and position the drivers on each side facing each other ala LabHorn style.

I like the idea of making use of usually wasted space like this - could have an interesting effect if fed with low frequency sine wave whilst bed is used for alternate functions......

Cheers

Graeme

The chambers in front of the drivers seem to be a bit narrow compared to the width at the start of the horn proper - I have some reservations as to whether firing the drivers straight into a solid wall this close will cause problems. I would be more inclined to continue the throat section of the horn right to the back of the box (bed head) and position the drivers on each side facing each other ala LabHorn style.

I like the idea of making use of usually wasted space like this - could have an interesting effect if fed with low frequency sine wave whilst bed is used for alternate functions......

Cheers

Graeme

I think your real problem is going to be directivity, especially going up to 250hz. You have plenty of volume under the bed to make it 2 horns with the mouths on one side. You'd give up some efficiency, but it sounds like you don't really need it. It would also give you flexibility later if you build them as separate units, and currently to run them in stereo. Loading the room more evenly with 2 is likely to help with the directivity issue. You can also decrease some of the vibration by having the woofers work in opposing directions and net that energy to 0.

Regarding the cat, 100 watts at 40hz will resolve that issue once and for all.

Regarding the cat, 100 watts at 40hz will resolve that issue once and for all.

Is there any disadvantage to using two drivers? Since I already have a pair and don't have any other use for them, I would be inclined to just stick them both in even if it doesn't have any significant advantage, as long as there is no particular disadvantage. Hornresp does suggest that the frequency response will be smoother with two though.

Buy a twin bed and make a stereo pair

Good idea. I've attached a pic of what the would look like. But what happens to the effective length of the horn and throat chamber volume? Does the horn length effectively go all the way to the back, or does the part where the drivers are attached function as if it were the throat chamber? Or somewhere between?Centauri said:...I would be more inclined to continue the throat section of the horn right to the back of the box (bed head) and position the drivers on each side facing each other ala LabHorn style...

That is something I have thought about. I will be crossing it over at around 120Hz, not going all the way to 250. What is the dispersion of horns like at low frequencies? At 120Hz the wavelength is a sizeable 2.8m, so I can't imagine it would be very directional from there down.johninCR said:I think your real problem is going to be directivity, especially going up to 250hz...

Attachments

Horns are more directional than a direct radiator as the horn mouth is the radiating plane and it's larger dimension than the average direct radiator will case the baffle step, and thus the switch to directional versus non-drectional radiation, to occur at a lower frequency. But with a sub bass horn the mouth is usually still too small to have that effect. I would crossover a lot lower than 250 Hz though. Integration will be very difficult otherwise.

Mr Evil said:

But what happens to the effective length of the horn and throat chamber volume? Does the horn length effectively go all the way to the back, or does the part where the drivers are attached function as if it were the throat chamber? Or somewhere between?

Not sure. Quite often, the throat is defined at the edge of the drivers where your red centre line starts, but as the distance from driver centre to end of horn is short compared to wavelengths involved, the horn might be the effective full length. Either way I don't think it would make a big difference to any simulations. Should work well.

Cheers

Graeme

Bass Horn

Resonance may be a problem up high. I divided my pathway in half with a vertical divider internally after the first bend (28 Hz cut-off) to offer better panel support, but I used only 1/2" material on the horn to keep the overall weight down. I would build it as two units if you plan to move it much.

As far as performance, it actually starts to roll off at around 40 Hz. If angled into a corner at about 30 degrees from either wall, it extends the response down to about 35 Hz before rolling off. The 1/8 or corner placement is really necessary to get near cut-off. Enclosure resonance is non-existant below about 80 Hz, but really starts coming on over 100 Hz. The output with twin 10"s is substantial, with a peak of about 125 dB at 90 Hz, maybe 120 dB at 50 if I could stand it that loud. It does keep right up with the LAB, though I think the LAB may be slightly more extended due to the dedicated 12" driver.

The 10" units were found at MCM, now discontinued due to the usual quality control problems from low dollar imports. My drivers are mounted facing each other, and fire into a slot between them of approximately 1" which loads the throat. I made this dual mount, single piece baffle out of solid oak to withstand the forces, which are considerable. John Sheerin actually designed the horn, but at that time didn't have the space/shop to build it. He already had his own horn sub of a different design utulizing a pair of Peerless 10"

Tim

Resonance may be a problem up high. I divided my pathway in half with a vertical divider internally after the first bend (28 Hz cut-off) to offer better panel support, but I used only 1/2" material on the horn to keep the overall weight down. I would build it as two units if you plan to move it much.

As far as performance, it actually starts to roll off at around 40 Hz. If angled into a corner at about 30 degrees from either wall, it extends the response down to about 35 Hz before rolling off. The 1/8 or corner placement is really necessary to get near cut-off. Enclosure resonance is non-existant below about 80 Hz, but really starts coming on over 100 Hz. The output with twin 10"s is substantial, with a peak of about 125 dB at 90 Hz, maybe 120 dB at 50 if I could stand it that loud. It does keep right up with the LAB, though I think the LAB may be slightly more extended due to the dedicated 12" driver.

The 10" units were found at MCM, now discontinued due to the usual quality control problems from low dollar imports. My drivers are mounted facing each other, and fire into a slot between them of approximately 1" which loads the throat. I made this dual mount, single piece baffle out of solid oak to withstand the forces, which are considerable. John Sheerin actually designed the horn, but at that time didn't have the space/shop to build it. He already had his own horn sub of a different design utulizing a pair of Peerless 10"

Tim

Attachments

Nice renderings (thought they were photos at first) ...

Going back to the idea of making them as two separate horns in case you want to sep them later. You could make them similar to the Decware Wicked one sub in which there is a shared mouth. If you later wanted to make them sep it would be easy to modify so they each have their own mouth, so this would be very flexible.

Going back to the idea of making them as two separate horns in case you want to sep them later. You could make them similar to the Decware Wicked one sub in which there is a shared mouth. If you later wanted to make them sep it would be easy to modify so they each have their own mouth, so this would be very flexible.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Bass horn: sleeping on the job