Hi All I'm starting a new thread because I think my title 110dB 3way may have been a little confusing to most.

I wanted to talk a little about the what and why about what I did on this project and hopefully get a little feedback on where I did good and where I could have improved.

The completed box.

Design criteria.

Optimal listening hight for people seated in sofa's or love seats.

All components very linear beyond intended xover range, high power handling, high output low distortion. Good polar pattern.

Able to deliver Full Scale Cinema SPL at reasonable listening distance. (85dB 3rd octave Banded Pink with 20dB of headroom The lower octaves helped with Bass management)

Components:

Peerless 830667 (SLS213)

SEAS MCA15RCY

Vifa DX25TG05-04

A couple of Ideas I tried out:

Sealed boxes for quickness

I decided to go push pull with the woofers to reduce even harmonic distortion.

I wanted to make the drivers time coherent to themselves as far as arrival time. What I ended up deciding on trying was moving the drivers until the impulse arrival was the same in the range of the drivers Xover frequencies, even the reverse firing driver.

I was aware that there may be some diffraction problems and had not really looked into it much (Later I read Sigfried Linkwitz's article about it) but decided to make the Box about as Baffle less as possible. My thoughts were I could probably make a Nice (Anti?) Baffle wall with some 6lb yellow board.

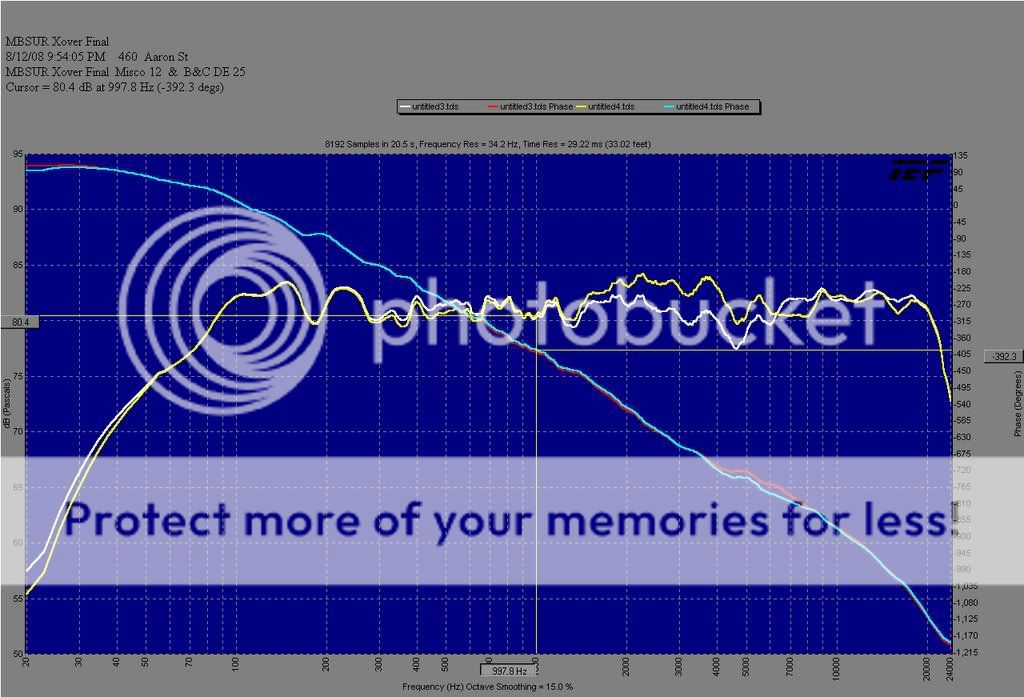

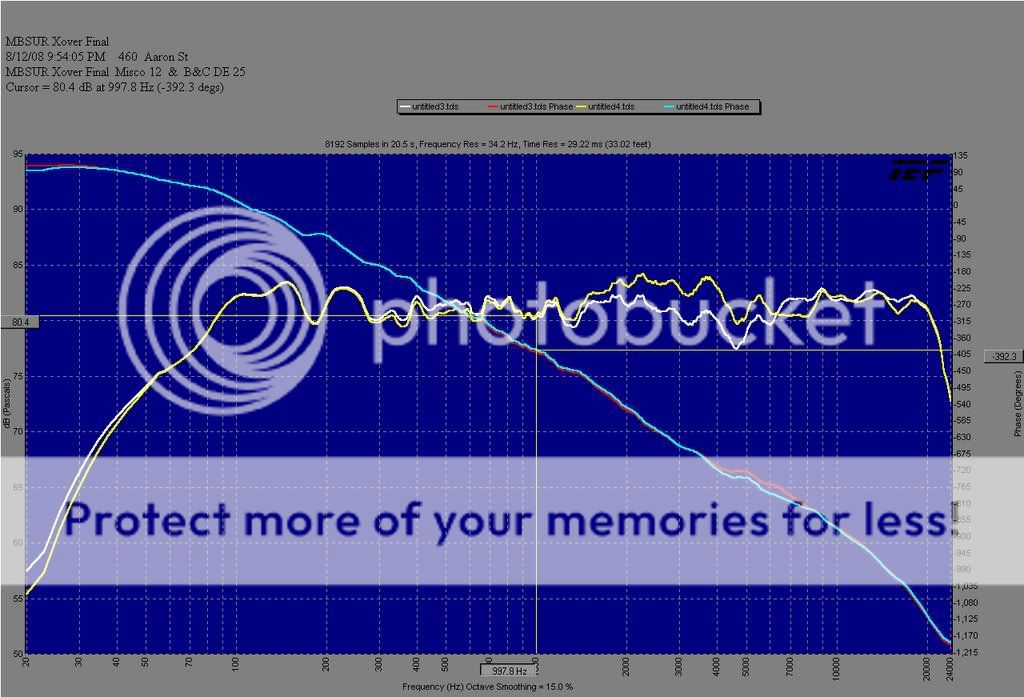

Xover:

Originally I had designed a passive Xover for this speaker. I think they were 12dB/12dB-12dB/24dB LR at 300Hz and 2KhZ.

Because of the impedances involved W=4ohm M=8ohm T=4ohm, I ended up having some incredibly huge components in the Xover, and the Mid needed a Zoeble, to help correct for some upper mid boost caused by the interaction between the Xover and mid driver Voice Coil.

Anyhow I was never fully satisfied with the Xover, its parts were all very expensive (No Electrolytic Caps thank you).

Anyhow I left on in the back burner for a while but was going to bite the bullet and make this passive Xover Monstrosity.

Then I got a hold of the 3 channel ICE amps with a nice 96kHz DSP engine, and decided to take the easy way out.

All Xover LR 24dB 300 and 2000

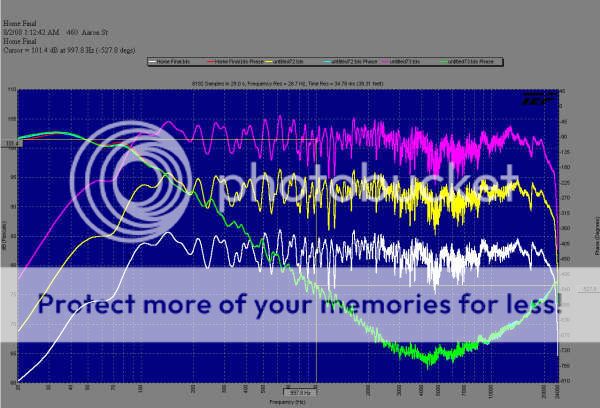

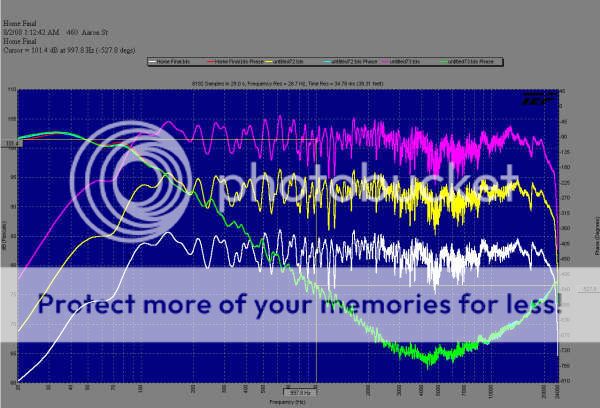

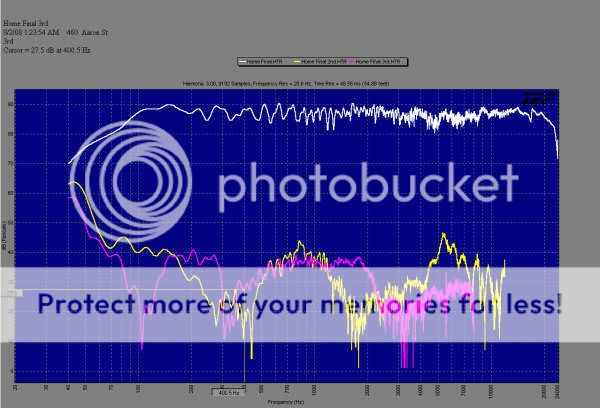

Anyhow I ended up here:

I decided to investigate diffraction, by making a tweeter diffraction damper.

This is the result of damping or absorbing the diffraction.

This is not my final EQ setting (since I have 16 filters per channel available I was able to to a bit of tweeking that no one in their right mind would do with a passive filter).

I'm am interested in discussing the merits, and pitfalls of a ~baffle less design and using, material like fiberglass to Damp or prevent any would be diffracted energies.

A quick note on SQ of this box, Balanced is an understatement.

They are very fast.

Its so clean I don't really realize how loud it is until I go to another room.

I've been listening to my Elton John Tumble Weed Connection SACD, the transients from the percussion and cowbells are unreal.

Since its a dual layer I can switch to Standard CD mode, its amazing how squashed and noisy the symbols and sibalant sounds are in general.

They really expose how bad I pods sound.

Cheers Guys!!!

Antone-

I wanted to talk a little about the what and why about what I did on this project and hopefully get a little feedback on where I did good and where I could have improved.

An externally hosted image should be here but it was not working when we last tested it.

The completed box.

Design criteria.

Optimal listening hight for people seated in sofa's or love seats.

All components very linear beyond intended xover range, high power handling, high output low distortion. Good polar pattern.

Able to deliver Full Scale Cinema SPL at reasonable listening distance. (85dB 3rd octave Banded Pink with 20dB of headroom The lower octaves helped with Bass management)

Components:

Peerless 830667 (SLS213)

SEAS MCA15RCY

Vifa DX25TG05-04

A couple of Ideas I tried out:

Sealed boxes for quickness

I decided to go push pull with the woofers to reduce even harmonic distortion.

I wanted to make the drivers time coherent to themselves as far as arrival time. What I ended up deciding on trying was moving the drivers until the impulse arrival was the same in the range of the drivers Xover frequencies, even the reverse firing driver.

I was aware that there may be some diffraction problems and had not really looked into it much (Later I read Sigfried Linkwitz's article about it) but decided to make the Box about as Baffle less as possible. My thoughts were I could probably make a Nice (Anti?) Baffle wall with some 6lb yellow board.

Xover:

Originally I had designed a passive Xover for this speaker. I think they were 12dB/12dB-12dB/24dB LR at 300Hz and 2KhZ.

Because of the impedances involved W=4ohm M=8ohm T=4ohm, I ended up having some incredibly huge components in the Xover, and the Mid needed a Zoeble, to help correct for some upper mid boost caused by the interaction between the Xover and mid driver Voice Coil.

Anyhow I was never fully satisfied with the Xover, its parts were all very expensive (No Electrolytic Caps thank you).

Anyhow I left on in the back burner for a while but was going to bite the bullet and make this passive Xover Monstrosity.

Then I got a hold of the 3 channel ICE amps with a nice 96kHz DSP engine, and decided to take the easy way out.

All Xover LR 24dB 300 and 2000

An externally hosted image should be here but it was not working when we last tested it.

Anyhow I ended up here:

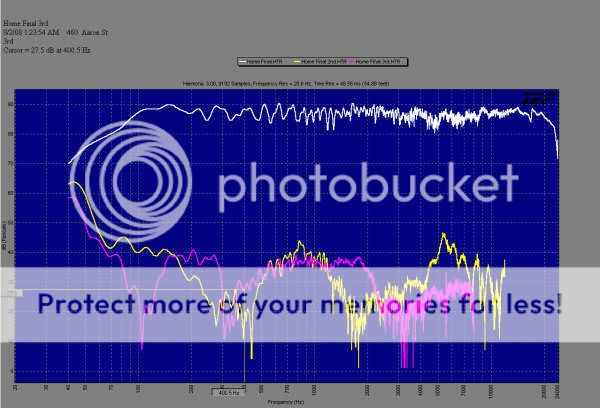

I decided to investigate diffraction, by making a tweeter diffraction damper.

An externally hosted image should be here but it was not working when we last tested it.

This is the result of damping or absorbing the diffraction.

This is not my final EQ setting (since I have 16 filters per channel available I was able to to a bit of tweeking that no one in their right mind would do with a passive filter).

I'm am interested in discussing the merits, and pitfalls of a ~baffle less design and using, material like fiberglass to Damp or prevent any would be diffracted energies.

A quick note on SQ of this box, Balanced is an understatement.

They are very fast.

Its so clean I don't really realize how loud it is until I go to another room.

I've been listening to my Elton John Tumble Weed Connection SACD, the transients from the percussion and cowbells are unreal.

Since its a dual layer I can switch to Standard CD mode, its amazing how squashed and noisy the symbols and sibalant sounds are in general.

They really expose how bad I pods sound.

Cheers Guys!!!

Antone-

Yes...

So Far I'm liking them a lot.

I really haven't compared them to a nice Clean AB or A-AB amp for a while.

I did my passive design with an "AB" brand amplifier

I think they could improve on their DSP interface, navigation is a little funny. But better than Motorola's from what I hear.

As Far as I know the ICE modules are the only way to go for Class D amplifiers.

The only thing I don't like is the use of 16 gauge wires for their output connectors. Especially on the 1kw modules.

Antone-

So Far I'm liking them a lot.

I really haven't compared them to a nice Clean AB or A-AB amp for a while.

I did my passive design with an "AB" brand amplifier

I think they could improve on their DSP interface, navigation is a little funny. But better than Motorola's from what I hear.

As Far as I know the ICE modules are the only way to go for Class D amplifiers.

The only thing I don't like is the use of 16 gauge wires for their output connectors. Especially on the 1kw modules.

Antone-

sumsound said:No one have any thoughts on using damping material to stop diffraction?

No, but I can tell you that "stuffing"/filling tweeter and mid screwholes with black wax is VERY effective

Wool felt at first guess.sumsound said:No one have any thoughts on using damping material to stop diffraction?

Felt is good, but it should be incorporated in xo design/measurements...even felt on cabinet sides and back will help

Try to throw a blanket over one speakers side/top and back and then listen to both, and you will hear the difference

So yes, the whole speaker should be wrapped in felt

Try to throw a blanket over one speakers side/top and back and then listen to both, and you will hear the difference

So yes, the whole speaker should be wrapped in felt

I used a 1" Fiber glass.

Its the black stuff I've seen used behind the screen, and on the baffel wall in places like skywalker, and ILM.

I think its a pipe wrap of sorts for large pipe? OR maybe HVAC?

I think Fiber glass is more effective than wool felt, but haven't confirmed.

I want to try some of the compressed fiberglass board (yellow board). You can wrap it with some nice fabrics and the final product can look very good.

Antone-

Its the black stuff I've seen used behind the screen, and on the baffel wall in places like skywalker, and ILM.

I think its a pipe wrap of sorts for large pipe? OR maybe HVAC?

I think Fiber glass is more effective than wool felt, but haven't confirmed.

I want to try some of the compressed fiberglass board (yellow board). You can wrap it with some nice fabrics and the final product can look very good.

Antone-

Wavebourn said:Linoleum.

I have a feeling, its not so good as a damping material. Probably a little reflective.

That will make the finishing of the current speakers much easier; no paint.tinitus said:

So yes, the whole speaker should be wrapped in felt

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Studio Quality DIY 3 Way