Hi Folks,

I've been ramping up the shop to cut precision cutouts in baffles.

And something that I didn't know until recently, PE has a nice selection of pre made DAYTON Cabinets, with removable fronts and grills. [extra parts available also]

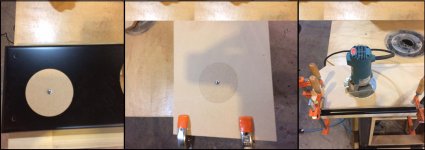

Sharing this pic that might help others, because cutting pre-finished material does has a few challenges.

The idea here is to cut the thru-holes first, I use a drill press with a wing cutter.

Secondly, made a two piece adapter ring, the speaker could be used, but for this project, no speaker drivers -- only measurements from the manufacture.

Third, slip the template over the centering adapter, clamp, removed centering ring, and router cut the lip for the speaker flange. I prefer to make the

lip cut the last step, less (or no) tear out, and the bit will last longer.

To set the router height, cut/rip small strip of wood to the desired height.

Top Bearing Bits, there are several on Amazon, starting at 3/8" diameter.

Although there are 1/2" - 5/8" top bearing bits for $12 (Yonico).

Wing cutters, collected about a dozen, found a sale on lathe 1/4" x 1/4" x 4" replacement cutters. They can be easily ground down, and/or turned/flipped to cut holes, or circles. Safety tip, slow speed only!!

PE baffles, 1" mdf, so there's going to be some nasty dust to consider when cutting.

http://www.parts-express.com/Search.aspx?keyword=Dayton Cabinets&sitesearch=true

I've been ramping up the shop to cut precision cutouts in baffles.

And something that I didn't know until recently, PE has a nice selection of pre made DAYTON Cabinets, with removable fronts and grills. [extra parts available also]

Sharing this pic that might help others, because cutting pre-finished material does has a few challenges.

The idea here is to cut the thru-holes first, I use a drill press with a wing cutter.

Secondly, made a two piece adapter ring, the speaker could be used, but for this project, no speaker drivers -- only measurements from the manufacture.

Third, slip the template over the centering adapter, clamp, removed centering ring, and router cut the lip for the speaker flange. I prefer to make the

lip cut the last step, less (or no) tear out, and the bit will last longer.

To set the router height, cut/rip small strip of wood to the desired height.

Top Bearing Bits, there are several on Amazon, starting at 3/8" diameter.

Although there are 1/2" - 5/8" top bearing bits for $12 (Yonico).

Wing cutters, collected about a dozen, found a sale on lathe 1/4" x 1/4" x 4" replacement cutters. They can be easily ground down, and/or turned/flipped to cut holes, or circles. Safety tip, slow speed only!!

PE baffles, 1" mdf, so there's going to be some nasty dust to consider when cutting.

http://www.parts-express.com/Search.aspx?keyword=Dayton Cabinets&sitesearch=true

Attachments

Last edited:

Couple of thoughts to add here.

Shown in pic one is the Stanley 04-419 large circle cutter, best to flip it around and use the 1/2" side in the stock - pre drill hole 1/2". This is the best that I have found.

That said, use a steel shaft in ALL circle cutting bits/tools. Using a drill bit as a center pivot can cause wobble problems.

* Stanley 04-419 ebay only.

Shown in pic one is the Stanley 04-419 large circle cutter, best to flip it around and use the 1/2" side in the stock - pre drill hole 1/2". This is the best that I have found.

That said, use a steel shaft in ALL circle cutting bits/tools. Using a drill bit as a center pivot can cause wobble problems.

* Stanley 04-419 ebay only.

Attachments

The wood fill plugs and templates are working nicely, glad that worked and it was worth the effort.

Here's another construction tip for cutting 45 degree miters.

The sled shown is very lightweight, easy to store but tends to lift when entering the wood.

Solution: used old speaker magnets as weights, but they also have magnetic pull.

BTW, if someone needs PE cabinet baffles cut, send a PM.

Shipping is always expensive, but there's a flat-rate box here:

https://store.usps.com/store/browse/productDetailSingleSku.jsp?productId=P_GB_FRB

[table saw an old Dewalt 746 - they didn't make many]

Here's another construction tip for cutting 45 degree miters.

The sled shown is very lightweight, easy to store but tends to lift when entering the wood.

Solution: used old speaker magnets as weights, but they also have magnetic pull.

BTW, if someone needs PE cabinet baffles cut, send a PM.

Shipping is always expensive, but there's a flat-rate box here:

https://store.usps.com/store/browse/productDetailSingleSku.jsp?productId=P_GB_FRB

[table saw an old Dewalt 746 - they didn't make many]

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.