One of my bucket list items is to build an outdoor stereo system - i.e. a pair of reinforced concrete straight horns.

The tentative driver I’ve selected is a B&C 12NW76

BL = 25.5 Tesla-meters

Xmax = 8 mm

SD = 522 cm^2

MMS = 77 grams

Qts = 0.16

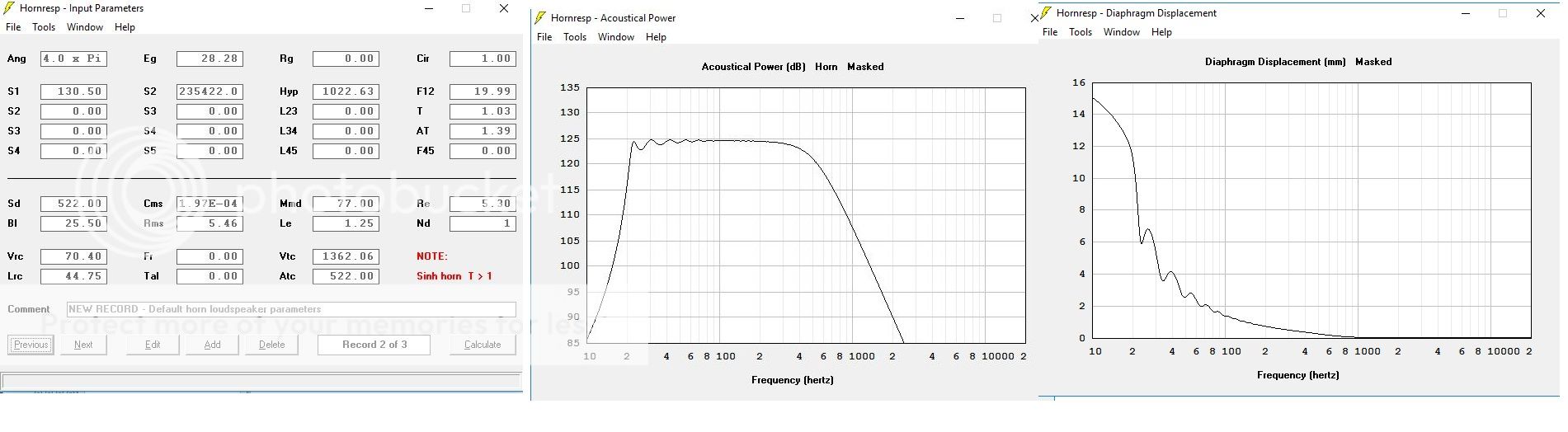

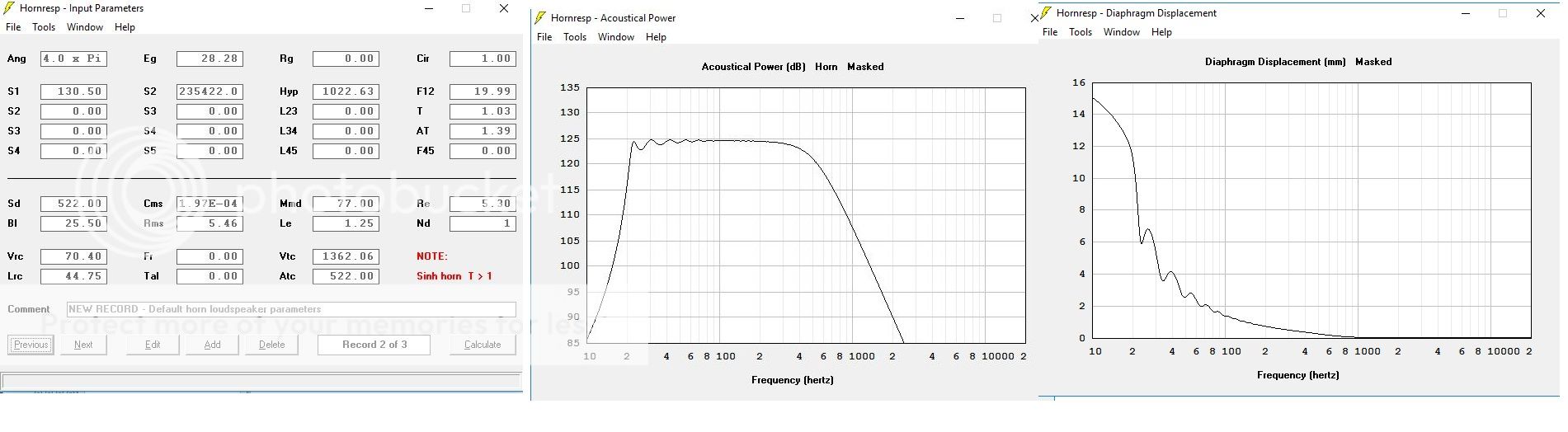

Using a single driver per horn (20 Hz & 160 Hz cutoff frequencies) Hornresp (see above) recommends a 33.5 foot long hyperbolic-exponential horn, with a mouth that’s roughly 16 feet x 16 feet (assuming square mouth). The flair parameter is 1.03, and the horn will supposedly crank out 125 dB down to 20 Hz, without exceeding the 8 mm Xmax. This is good – I can live with that.

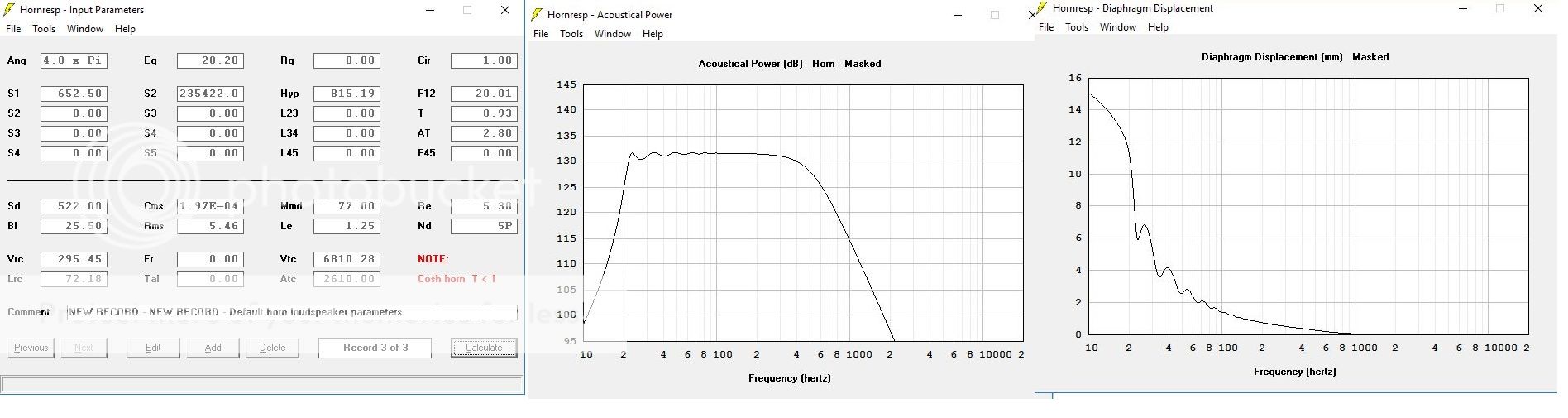

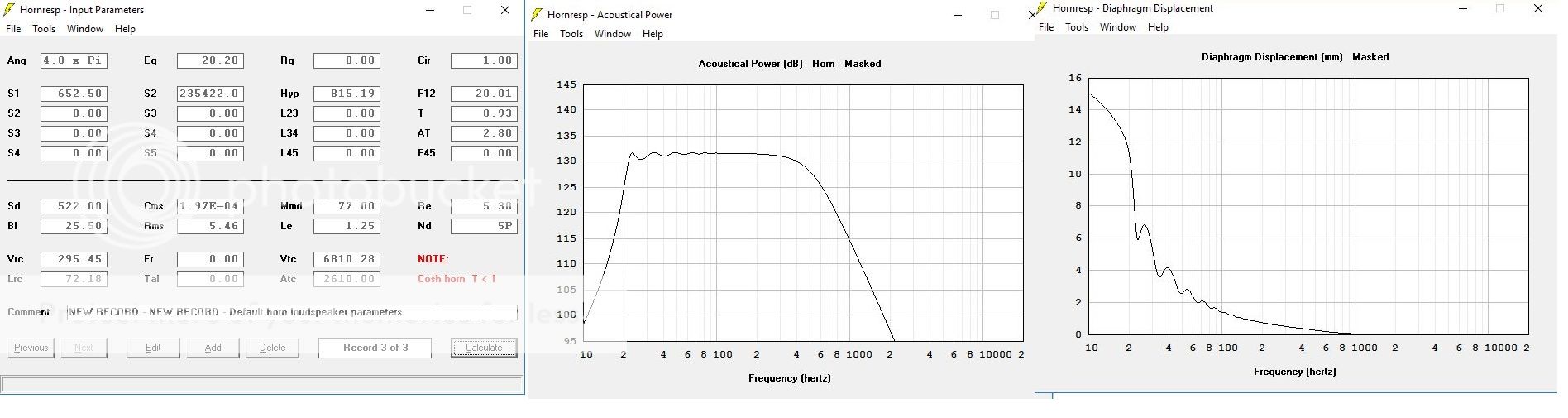

But I was tinkering with adding additional drivers (the same B&C 12NW76) – for (qty 5 total) per horn (see above). My thought was a square chamber, with drivers on five of the six sides, all feeding the horn’s throat/chamber. In this configuration (with the same 20 Hz & 160 Hz cutoff frequencies), Hornresp recommends shortening the horn down to 26.7 ft, and increasing the throat area by a factor of five, while keeping the same mouth area - this makes perfect sense to me. What I don’t understand is why the recommended flair parameter changes from 1.03 to 0.93 by simply adding more of the same drivers? Nonetheless, increasing the drivers to (qty 5 total), will increase horn output to about 132 dB, without exceeding the 8 mm Xmax. I can live with that.

Conceptually, am I on the right track here? I've selected a driver with a low Qts, low MMS, and high BL - which is what the old design texts say to do. . . .

The tentative driver I’ve selected is a B&C 12NW76

BL = 25.5 Tesla-meters

Xmax = 8 mm

SD = 522 cm^2

MMS = 77 grams

Qts = 0.16

Using a single driver per horn (20 Hz & 160 Hz cutoff frequencies) Hornresp (see above) recommends a 33.5 foot long hyperbolic-exponential horn, with a mouth that’s roughly 16 feet x 16 feet (assuming square mouth). The flair parameter is 1.03, and the horn will supposedly crank out 125 dB down to 20 Hz, without exceeding the 8 mm Xmax. This is good – I can live with that.

But I was tinkering with adding additional drivers (the same B&C 12NW76) – for (qty 5 total) per horn (see above). My thought was a square chamber, with drivers on five of the six sides, all feeding the horn’s throat/chamber. In this configuration (with the same 20 Hz & 160 Hz cutoff frequencies), Hornresp recommends shortening the horn down to 26.7 ft, and increasing the throat area by a factor of five, while keeping the same mouth area - this makes perfect sense to me. What I don’t understand is why the recommended flair parameter changes from 1.03 to 0.93 by simply adding more of the same drivers? Nonetheless, increasing the drivers to (qty 5 total), will increase horn output to about 132 dB, without exceeding the 8 mm Xmax. I can live with that.

Conceptually, am I on the right track here? I've selected a driver with a low Qts, low MMS, and high BL - which is what the old design texts say to do. . . .

Last edited:

What I don’t understand is why the recommended flair parameter changes from 1.03 to 0.93 by simply adding more of the same drivers?

The horn throat area S1 automatically changes in the calculations because of the changed driver configuration. The calculated value of T is a function of throat area.

Conceptually, am I on the right track here?

You could probably get away with assuming 2 Pi rather than 4 Pi radiation, which would reduce the overall size of the horn somewhat.

Entropy455,1)One of my bucket list items is to build an outdoor stereo system - i.e. a pair of reinforced concrete straight horns. The flair parameter is 1.03, and the horn will supposedly crank out 125 dB down to 20 Hz, without exceeding the 8 mm Xmax. This is good – I can live with that.

2)What I don’t understand is why the recommended flair parameter changes from 1.03 to 0.93 by simply adding more of the same drivers?

3)Nonetheless, increasing the drivers to (qty 5 total), will increase horn output to about 132 dB, without exceeding the 8 mm Xmax. I can live with that.

4)Conceptually, am I on the right track here? I've selected a driver with a low Qts, low MMS, and high BL - which is what the old design texts say to do. . . .

There are a welter of paths that lead to entropy, you appear to be on several ;^).

A single driver tapped horn of only 15.5 cubic feet will exceed the SPL of your design, though won't have much response below 32 Hz, generally not a concern unless you want to reproduce earthquakes, mortar blasts, or Osprey helicopter wash at original levels.

1) Concrete is a cheap, but very work intensive medium to work with, the reinforcement needed to keep it intact should not be underestimated. Building a stem wall a fraction of the size of the horn you propose stands out in my memory as a more negative use of time than two of the four airplane crashes I have experienced. Your mileage may vary..

2) When "thinking big", relatively small changes effect differences "down wind". A flair parameter difference of less than 10% is like not shaving for 90 minutes, who cares?

3) It is good to be able to live with the laws of physics, life becomes intolerable otherwise

4) Whether you are on the right track depends on what your goal concept is, building a concrete "statement", or producing a given SPL to a given frequency with minimal effort and maximal effect.

For better or worse, am far too familiar with using maximal effort to produce effects that few notice, much less appreciate, so I do appreciate where you are coming from, and wish you the best, whatever "track" you get stuck in/on.

Cheers,

Art

Conceptually, am I on the right track here? I've selected a driver with a low Qts, low MMS, and high BL - which is what the old design texts say to do. . . .

While the driver you chose obviously works you can forget about what the ancient texts say about low q, low mms, high bl drivers. That's just a first best guess at getting a decent driver to work in an ancient midrange horn.

If you want to know the truly best specs for your intended application, use Leach's math, specifically the System Design - From Specifications tool. That will design your horn and driver all at once in one fell swoop.

At that point the issue becomes finding a driver with the same specs that Leach's math suggests - in the case of the Labhorn, Tom Danley had to have one specially made by Eminence, hence the new Lab 12 driver specifically designed for the Labhorn.

That doesn't mean that you can't get fantastic results from wildly inappropriate drivers, but the point here is that the optimal driver specs for a low tuned bass horn very likely are not going to have low q, low mms or high bl.

The "new" LAB 12 was designed around the turn of the century, I was late to the party and got my first units July of 2003, my first purchase of a horn driver with such a low FS and super stiff, heavy cone.At that point the issue becomes finding a driver with the same specs that Leach's math suggests - in the case of the Labhorn, Tom Danley had to have one specially made by Eminence, hence the new Lab 12 driver specifically designed for the Labhorn.

That doesn't mean that you can't get fantastic results from wildly inappropriate drivers, but the point here is that the optimal driver specs for a low tuned bass horn very likely are not going to have low q, low mms or high bl.

Prior to that, Tom Danley's servo-motor belt drive units had far more displacement potential than professional drivers, though by the mid 1990s they had been rendered obsolete by drivers such as AuraSound's 1808, the 1997 spec sheet copy below. Funny, (in retrospect) I was so caught up in driver "sensitivity" specifications back then that I paid little attention to their displacement- the AuraSound 1808 had considerably more than a pair of LAB 12", though the LAB 12 had more displacement per dollar.

I had mostly forgot about how advanced the 1808 was until 2015 when I started scanning old documents to eliminate hundreds of pounds of paper before moving cross country. Although the 1808 has great displacement capability, the mms is/was too low for low distortion in high compression ratio applications, something that does not show up in simulations, but can also result in ripped or kinked cones when pushed to Xmax.

Eminence has not made much advancement in LF horn drivers since the introduction of the LAB 12, but B&C and many smaller companies have, sold off my last (spare) LAB 12 last year.

I was contacted by PM several years ago on this forum by a man who wrote he had purchased the old Aura neo magnet structures, and was planning to re-issue drivers. I was unable to get a response back, and could find no web presence of his enterprise, a shame, as the 1808 magnet structure is still one of the best designs.

Art

Attachments

Last edited:

The "new" LAB 12 was designed around the turn of the century ...

Yes, of course, I meant it was new (created for) for that application. There are other options available now with much higher power handling.

I had mostly forgot about how advanced the 1808 was until 2015 when I started scanning old documents to eliminate hundreds of pounds of paper before moving cross country. Although the 1808 has great displacement capability, the mms is/was too low for low distortion in high compression ratio applications, something that does not show up in simulations, but can also result in ripped or kinked cones when pushed to Xmax.

I remember when those came out. 18" drivers with huge Xmax and very low Qes. But yes, light cones.

Didn't someone try filling the cones with foam at one point in an attempt to stiffen them up for heavy duty use?

Bjorno, I have been looking over your calculations. Please remember that I am still a beginner/novice at using Hornresp. I omitted adding dampening material to the driver’s box, because until about five minutes ago, I didn’t know how to do it. . . I am trying to draw conclusions from what you’ve posted. Please let me know if I’m interpreting your intent correctly?

A large horn mouth equates to a high electro-mechanical energy conversion (horn efficiency), however the horn’s off-axis response suffers at higher frequencies.

A smaller mouth horn is capable of extending to lower frequencies, and achieving decent sound pressure levels – and with what appears to be superior off-axis response – however the electrical input power requirements are higher, due to the decreased horn efficiency. Are the colored graphs and off-axis plots you posted from Hornresp, or are they from another software?

Please remember that I am not constrained by space. I’ve got 5 acres of land, surrounded by 700 acres of vacant State land to the north – thus I won’t have any complaints about the sound. I’m not the slightest bit discouraged at the thought of constructing 16, or even 20 foot diameter horns. They are going to be outdoors. I am just trying to understand why you would recommend such a drastic reduction in mouth area. Doesn’t this increase harmonic distortion? If you could type out a brief explanation as to the rationale behind your suggestion/calculations, it would be greatly appreciated!

Just-a-Guy, I’m a bit confused. Are you suggesting that a Lab-12 driver is better suited for a full-size strait 20 Hz exponential horn, than a driver with a lower MMS, lower Qts, and higher BL? Which driver would you specifically recommend for my application?

A large horn mouth equates to a high electro-mechanical energy conversion (horn efficiency), however the horn’s off-axis response suffers at higher frequencies.

A smaller mouth horn is capable of extending to lower frequencies, and achieving decent sound pressure levels – and with what appears to be superior off-axis response – however the electrical input power requirements are higher, due to the decreased horn efficiency. Are the colored graphs and off-axis plots you posted from Hornresp, or are they from another software?

Please remember that I am not constrained by space. I’ve got 5 acres of land, surrounded by 700 acres of vacant State land to the north – thus I won’t have any complaints about the sound. I’m not the slightest bit discouraged at the thought of constructing 16, or even 20 foot diameter horns. They are going to be outdoors. I am just trying to understand why you would recommend such a drastic reduction in mouth area. Doesn’t this increase harmonic distortion? If you could type out a brief explanation as to the rationale behind your suggestion/calculations, it would be greatly appreciated!

Just-a-Guy, I’m a bit confused. Are you suggesting that a Lab-12 driver is better suited for a full-size strait 20 Hz exponential horn, than a driver with a lower MMS, lower Qts, and higher BL? Which driver would you specifically recommend for my application?

Last edited:

From the engineering papers I’ve read regarding horn design, the throat of a horn is as close to a purely resistive load on the driver, as one could ever hope to obtain. In an equivalent spring-mass system, the horn’s throat impedance is simply a damper – in which case you need raw & blunt applied-force to overcome the damper (i.e. a high BL). You specifically do not need extra mass (MMS), nor do you need additional spring-K (high Vas), to overcome the damper. The ideal horn driver has a low Qts, mainly due to the high BL, and low MMS. Or am I completely out-to-lunch on my understanding of horn driver selection???

Just-a-Guy, I’m a bit confused. Are you suggesting that a Lab-12 driver is better suited for a full-size strait 20 Hz exponential horn, than a driver with a lower MMS, lower Qts, and higher BL? Which driver would you specifically recommend for my application?

No, not at all. I'm suggesting that the Lab 12 was designed specifically for the purpose of being an "ideal" driver for the Labhorn. (Ideal is in quotes because it was changed a bit from the mathematical ideal for a few reasons.)

The Lab 12 doesn't have particularly low qts, low mms or high bl. So how can it be ideal? We'll get to that...

From the engineering papers I’ve read regarding horn design, the throat of a horn is as close to a purely resistive load on the driver, as one could ever hope to obtain. In an equivalent spring-mass system, the horn’s throat impedance is simply a damper – in which case you need raw & blunt applied-force to overcome the damper (i.e. a high BL). You specifically do not need extra mass (MMS), nor do you need additional spring-K (high Vas), to overcome the damper. The ideal horn driver has a low Qts, mainly due to the high BL, and low MMS. Or am I completely out-to-lunch on my understanding of horn driver selection???

A well designed ideal full size horn is mostly resistive, most horns are far from ideal or full sized. Your project has a chance to be both.

Leach's math from the "On the specification of moving coil drivers for low frequency horn loudspeakers" paper is considered one of the best horn models available for full size ideal reactance annulled horns. And as the name implies, this paper allows you to specify the ideal parameters for both the driver and the horn. This paper is the basis for the Hornresp System Design tool, both the "with driver" and the "from specifications" parts of the tool.

If you run the System Design - From Specifications tool you will find that it doesn't routinely spit out low qts, low mms, high bl specs all the time. It will give radically different ideal driver specs based on the goals (bandwidth, number of drivers, etc).

Danley used Leach's math to design the Labhorn and the Lab 12 driver. You could use it to find the ideal driver parameters and horn dimensions for your project. Or you could use wildly inappropriate drivers instead, it's up to you. You can get good results even with bad driver choices.

As far as a recommendation for an ideal driver - I'm not going to make one. A single 12 inch driver with 8 mm xmax coupled to a $20000 concrete horn the size of a small house is not my idea of a good design. I would design it much differently, but then again, that's what makes us all individuals.

Your concrete horn is going to crack (probably in the first year) and even if it didn't, it can be easily beaten in every performance metric by a system costing several times less and a fraction of the size.

Because I like horns this is interesting to talk about but I'd seriously recommend not going forward with this as planned. There are much cheaper and better ways to get a system that will perform much better.

Your concrete horn is going to crack (probably in the first year) and even if it didn't, it can be easily beaten in every performance metric by a system costing several times less and a fraction of the size.

Because I like horns this is interesting to talk about but I'd seriously recommend not going forward with this as planned. There are much cheaper and better ways to get a system that will perform much better.

Just-a-guy - this is the second time you’ve implied the B&C 12NW76 driver as being wildly inappropriate. Can you please explain why? I’ve been tinkering with the design tool as you’ve suggested, and the driver does not seem wildly inappropriate.

Regarding your hesitation to build horns from concrete - I can summarize ACI-318 for you in one simple blurb: “Concrete is strong in compression and weak in tension, thus install your rebar wherever the concrete is in tension.” Note: this is why 10 story concrete parking garages remain standing safely after magnitude 7.0 earthquakes. . . I can assure you that my horns will not catastrophically fail (or degrade) from cracking.

Concrete is about 100 bucks a yard. I figure I’ll need roughly 30 yards of 3000 psi mix, about 1.5 tons of Grade-40 Number 4 rebar – give or take – depending on the final size of the mouth. About 300 bucks for a pumper-truck rental, and another 1500 in plywood, form ties, and 2x6 boards – making this roughly a 6000 dollar project (less the cost of the construction permit, which I’m sure the county will require). I already own a dozer, excavator, and a forklift – thus my dirt-work costs are practically non-existent.

Nonetheless, I am always open to new ideas. Which type of system would you recommend that I construct – that will outperform a pair of 20-Hz straight exponential horns, in every performance metric - costing several times less, and at a fraction of the size?

Regarding your hesitation to build horns from concrete - I can summarize ACI-318 for you in one simple blurb: “Concrete is strong in compression and weak in tension, thus install your rebar wherever the concrete is in tension.” Note: this is why 10 story concrete parking garages remain standing safely after magnitude 7.0 earthquakes. . . I can assure you that my horns will not catastrophically fail (or degrade) from cracking.

Concrete is about 100 bucks a yard. I figure I’ll need roughly 30 yards of 3000 psi mix, about 1.5 tons of Grade-40 Number 4 rebar – give or take – depending on the final size of the mouth. About 300 bucks for a pumper-truck rental, and another 1500 in plywood, form ties, and 2x6 boards – making this roughly a 6000 dollar project (less the cost of the construction permit, which I’m sure the county will require). I already own a dozer, excavator, and a forklift – thus my dirt-work costs are practically non-existent.

Nonetheless, I am always open to new ideas. Which type of system would you recommend that I construct – that will outperform a pair of 20-Hz straight exponential horns, in every performance metric - costing several times less, and at a fraction of the size?

Has anyone actually heard (with their own ears) a pair of outdoor full-size 20-Hz straight exponential horns? Or even seen a picture of one? I personally have not – in either case.

The only person I’ve ever talked with who claims to have heard a set, is a design engineer at Radian. He said that when you remove the ceiling & walls from the equation, the nodes completely go away, and then the magic happens. You must stand back from the horn mouth at least 1.5 wavelengths, so that the horns may properly load the air. The sound is full & intense, and disappears into the abyss just as quickly & completely as it was formed. There’s no need to construct tube-traps, or Helmholtz resonators - to absorb standing waves & residual energy. No room rattles, no loud spots, no nulls - it’s just pure sound.

That conversation was my inspiration for this project. . . . I intend to use Radian drivers for the highs.

The only person I’ve ever talked with who claims to have heard a set, is a design engineer at Radian. He said that when you remove the ceiling & walls from the equation, the nodes completely go away, and then the magic happens. You must stand back from the horn mouth at least 1.5 wavelengths, so that the horns may properly load the air. The sound is full & intense, and disappears into the abyss just as quickly & completely as it was formed. There’s no need to construct tube-traps, or Helmholtz resonators - to absorb standing waves & residual energy. No room rattles, no loud spots, no nulls - it’s just pure sound.

That conversation was my inspiration for this project. . . . I intend to use Radian drivers for the highs.

Are the colored graphs and off-axis plots you posted from Hornresp, or are they from another software?

All the charts shown in bjorno's post are from Hornresp.

I often felt that the sound of a Klipsch bass folded corner horn filled a room with clean wonderful unboxy sound like nothing else (and made an oddly excellent match to clean ESL speakers)....when you remove the ceiling & walls from the equation, the nodes completely go away, and then the magic happens. .....

That conversation was my inspiration for this project. . . . I intend to use Radian drivers for the highs.

Granted, it is wonderful to be able to play notes an octave lower than any feasible horn can go. Feels terrific. But the plain truth is that ordinary music rarely goes below maybe 35 Hz, no kidding, and no big loss if your sub can get no lower. Now-a-days, easy to add a sub to handle music south of 35 Hz to supplement the horn, as a buddy of mine was doing in 1967; concept may sound peculiar to you, but two Klipschorns and two sub-subs sure sounded great (and he built his house around his speakers).

How do you time-align a 15 foot long horn with the rest of your speakers?

Ben

Last edited:

There's a Scandinavian Guy that built a wood outdoor horn. Maybe 8 to 10 tears ago.Has anyone actually heard (with their own ears) a pair of outdoor full-size 20-Hz straight exponential horns? Or even seen a picture of one? I personally have not – in either case................

Just-a-guy - this is the second time you’ve implied the B&C 12NW76 driver as being wildly inappropriate.

I never said the driver you chose was inappropriate. I implied it might be inappropriate based on horn math.

Regarding your hesitation to build horns from concrete - I can summarize ACI-318 for you in one simple blurb: “Concrete is strong in compression and weak in tension, thus install your rebar wherever the concrete is in tension.” Note: this is why 10 story concrete parking garages remain standing safely after magnitude 7.0 earthquakes. . . I can assure you that my horns will not catastrophically fail (or degrade) from cracking.

Parking garages have cracked concrete. If you want to spend your time patching concrete that's up to you. This is not how I would do it.

Concrete is about 100 bucks a yard. I figure I’ll need roughly 30 yards of 3000 psi mix, about 1.5 tons of Grade-40 Number 4 rebar – give or take – depending on the final size of the mouth. About 300 bucks for a pumper-truck rental, and another 1500 in plywood, form ties, and 2x6 boards – making this roughly a 6000 dollar project (less the cost of the construction permit, which I’m sure the county will require). I already own a dozer, excavator, and a forklift – thus my dirt-work costs are practically non-existent.

Baltic birch is about $55 a sheet. Glue is about $20 a gallon. Paint, duratex or truck bedliner isn't much either, depending on which product you use. You could build this out of wood for a couple thousand dollars max. And it would be a lot less work and take a lot less time.

Nonetheless, I am always open to new ideas. Which type of system would you recommend that I construct – that will outperform a pair of 20-Hz straight exponential horns, in every performance metric - costing several times less, and at a fraction of the size?

First, straight vs folded has no practical significant at subwoofer frequencies.

Second, the horn itself isn't a huge problem, I see more problems with your choice of a single 12 inch driver. For a 20 hz full size horn I would likely not use less than eight 18s. That balances the driver cost and the horn cost and allows for orders of magnitude better performance.

Third, let's just run the sim, as I've recommended to you twice already and see what the sim says. This is a 30 second attempt so it's not optimized in any way. I chose a low compression ratio and a relatively small rear chamber to keep excursion in check, 2 pi space and Sd = eight 18 inch drivers and a 20 - 100 hz passband. I let the simulator fill in all the blanks for horn and driver specs.

An externally hosted image should be here but it was not working when we last tested it.

I didn't run your sim but I'm pretty sure this horn is a lot smaller than yours and will go a lot louder with a lot less distortion. And it's just a 30 second first pass, it could be better in a lot of ways.

For construction, I'd build it as 8 modular baltic birch folded horns.

And it would beat your design in every conceivable performance metric.

Has anyone actually heard (with their own ears) a pair of outdoor full-size 20-Hz straight exponential horns? Or even seen a picture of one? I personally have not – in either case.

The only person I’ve ever talked with who claims to have heard a set, is a design engineer at Radian. He said that when you remove the ceiling & walls from the equation, the nodes completely go away, and then the magic happens. You must stand back from the horn mouth at least 1.5 wavelengths, so that the horns may properly load the air. The sound is full & intense, and disappears into the abyss just as quickly & completely as it was formed. There’s no need to construct tube-traps, or Helmholtz resonators - to absorb standing waves & residual energy. No room rattles, no loud spots, no nulls - it’s just pure sound.

That conversation was my inspiration for this project. . . . I intend to use Radian drivers for the highs.

Again, straight vs folded horns have no practical distinction at subwoofer frequencies.

And the audible characteristics of the outside environment applies to any system. The only thing horns will do better than a Bose wave radio is efficiency. You make it sound like you want to build this massive thing outside instead of properly treating a room - I think that's a dubious motivation. If this is all about the audible experience it's better to do it properly indoors. Then you can experience it whenever you want. How often are you going to be sitting outside for critical listening sessions?

Besides, listening outside isn't all that great. Rooms create a spaciousness effect that you can't get outside (unless you are setting up a 7.1 system outside, which at this point wouldn't surprise me).

You suggested that I construct a different system that will outperform a pair of 20-Hz straight exponential horns, in every performance metric - costing several times less, and at a fraction of the size. And your recommendation was that I build a pair of 20-Hz straight exponential horns. . . I love it! You’ve recommended (qty 8) 18s in the throat to bat – I love that too! As the whole point of this thread (original post) was how to properly incorporate multiple drivers into a bass-horn design. . . .

I have a few conceptual questions though. Background: I’ve built dozens of sound systems over the past 25 years – primarily bass-reflex enclosures. For right or wrong, here’s a few of my observations:

18s sound like 18s. Even with a mega-motor structure, the higher MMS degrades the transient response, and fidelity suffers. And 18s with a lighter cone sound better (tighter bass – primarily due to the faster transient response) – however these drivers are often Fs-limited in how low you can tune a bass-reflex enclosure - which kinda defeats the purpose when you’re trying to fill the bottom end. I’ve played around with the 15” long-throw woofers – big rubber surrounds, low FS, workable VAS, with a giant Xmas -and these speakers sound like mud also. Don’t get me wrong – they can reproduce bass, but they simply don’t sound good. They sound rubbery compared to an accordion-surround driver. And yes, I was feeding them plenty of clean power (MT-5000, active crossover, heavy-gauge leads).

21 inch drivers – I’ll never buy one. Practically every review says they sound like mud (for the reasons stated above).

12 inch drivers can chew the low-end out with clean authority. However you need a wall of them to fill a large room – which adds an additional set of problems in itself. Actual VAS values can vary quite a bit - even with speakers from the same assembly line, manufactured on the same day. When you have a wall of slightly out-of-alignment speakers, you can hear it. And sizing each enclosure for the specific driver (while pure in the realm of high-fidelity) is a cumbersome work practice in my book. It also causes problems if you ever need to replace a driver. Additionally, it has been my experience that the really good sounding 12” drivers have a higher Fs anyway (primarily due to the high BL & lower MMS), and cannot tune very low anyway.

This is what’s attracting me to horns – the idea that a speakers Fs is not a major design obstacle. The resistive load of the throat provides significant damping at FS, essentially minimizing the effect. The drivers that are suggested for bass horn applications (high BL, low MMS, low Qts), are good mid-bass drivers at best – in a bass reflex application.

Here's my question just-a-guy, will 18s still sound like 18s, in a horn application? Your simulation recommends an MMD of 323 grams. That’s nearing 21” driver territory. . . .

I have a few conceptual questions though. Background: I’ve built dozens of sound systems over the past 25 years – primarily bass-reflex enclosures. For right or wrong, here’s a few of my observations:

18s sound like 18s. Even with a mega-motor structure, the higher MMS degrades the transient response, and fidelity suffers. And 18s with a lighter cone sound better (tighter bass – primarily due to the faster transient response) – however these drivers are often Fs-limited in how low you can tune a bass-reflex enclosure - which kinda defeats the purpose when you’re trying to fill the bottom end. I’ve played around with the 15” long-throw woofers – big rubber surrounds, low FS, workable VAS, with a giant Xmas -and these speakers sound like mud also. Don’t get me wrong – they can reproduce bass, but they simply don’t sound good. They sound rubbery compared to an accordion-surround driver. And yes, I was feeding them plenty of clean power (MT-5000, active crossover, heavy-gauge leads).

21 inch drivers – I’ll never buy one. Practically every review says they sound like mud (for the reasons stated above).

12 inch drivers can chew the low-end out with clean authority. However you need a wall of them to fill a large room – which adds an additional set of problems in itself. Actual VAS values can vary quite a bit - even with speakers from the same assembly line, manufactured on the same day. When you have a wall of slightly out-of-alignment speakers, you can hear it. And sizing each enclosure for the specific driver (while pure in the realm of high-fidelity) is a cumbersome work practice in my book. It also causes problems if you ever need to replace a driver. Additionally, it has been my experience that the really good sounding 12” drivers have a higher Fs anyway (primarily due to the high BL & lower MMS), and cannot tune very low anyway.

This is what’s attracting me to horns – the idea that a speakers Fs is not a major design obstacle. The resistive load of the throat provides significant damping at FS, essentially minimizing the effect. The drivers that are suggested for bass horn applications (high BL, low MMS, low Qts), are good mid-bass drivers at best – in a bass reflex application.

Here's my question just-a-guy, will 18s still sound like 18s, in a horn application? Your simulation recommends an MMD of 323 grams. That’s nearing 21” driver territory. . . .

Here’s a much more significant design question issue. It’s the concept of half-space, vs full space. I understand the basic idea – in that if you put a horn along the ground (half-space), that the ground itself acts as an extension of the horn – where you can theoretically half the size of the horn mouth, and still achieve a reasonable SPL. Problem – one of the engineering design papers I read was able to mathematically show that the ideal horn mouth circumference – for both full-space, and for half-space loading - is equal to approximately the lower cutoff frequency wavelength of the horn – which is the full-space horn mouth area in both regards. This engineering reference clearly shows that using half-space to reduce the size of the horn mouth, while effective in its ability to reproduce the desired SPL, will cause appreciable increases in horn harmonic distortion.

Question: how significant is this introduced harmonic distortion phenomena (to what the ear hears?)

I’m trying to picture myself cutting the mouth of a trombone to half its original size, resting it up against the wall, then playing it and expecting it to sound just as good. . . . Will it really?

Question: how significant is this introduced harmonic distortion phenomena (to what the ear hears?)

I’m trying to picture myself cutting the mouth of a trombone to half its original size, resting it up against the wall, then playing it and expecting it to sound just as good. . . . Will it really?

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Concrete Bass Horn Design Question