Hello,

the Sony CDP-X5000 / CDP-XA7ES / CDP-XA50ES use the same transport (or base unit) BU-12. For the disc a brushless motor is used. The good news, it can be easily disassembled for maintenace.

The bad news, Sony did it not so well.

I found that the rotor had a little play, so I wanted to check if I could swap the bearings.

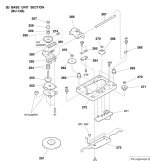

First obstacle: The three philips-screws #1 (KTP3x8 See the attached photos)

Even though part #255 Base Assy, Slide is made of plastic, the screws are completely stuck.

Applying tiny drops of oil (must be suited for plastics) and waiting about a week did the trick -

still i had to use a flat screwdriver with a 2mm tip, all Philips screwdrivers i tried, slipped.

In the base plate of the bsl board is a small bearing. When the CDP-X5000 was introduced, somebody wrote that the bearings were made from ruby.

Well, it is something looking like glass. It is glued/pressed into a brass shell, I assume the blue color is the glue. The rotor sits on it with a rounded cone.

The good news is that the bearing and the cone do not show any sign of wear. The glass has to bear vertical forces.

The bronze bearings align the rotor horizontally, when thy wear out, this should have no effect on the "glass" bearing. BTW, it is greased.

But the main bronze bearings in the slide assembly #255 provide a problem.

There are two of them pressed into it. You don´t seem them in the schematics.

Inner Ø is 6mm, Outer Ø10mm, Height 5mm.

Swapping bearings is normally an easy job. But with the BU-12 it is different. To remove them, one has to PULL them out -

normally you push them out with a stamp.

There is a rim between the two bearings they cannot be pushed further into the slide assembly.

I guess there is a tool needed to grab beneath them. Also the slide assembly is made of plastic so no strong force can be used.

Any ideas how to pull them out?

Something that these three players also share is the Vacuum Tube Display.

It can be only be partially switched off with the remote, at least with the CDP-X5000.

Any idea how to modify the circuit, to switch the display off completely?

I would like to treat the display more gentle by this mod for the next decades.

The often-used filaments have already become darker...

All the best,

Salar

the Sony CDP-X5000 / CDP-XA7ES / CDP-XA50ES use the same transport (or base unit) BU-12. For the disc a brushless motor is used. The good news, it can be easily disassembled for maintenace.

The bad news, Sony did it not so well.

I found that the rotor had a little play, so I wanted to check if I could swap the bearings.

First obstacle: The three philips-screws #1 (KTP3x8 See the attached photos)

Even though part #255 Base Assy, Slide is made of plastic, the screws are completely stuck.

Applying tiny drops of oil (must be suited for plastics) and waiting about a week did the trick -

still i had to use a flat screwdriver with a 2mm tip, all Philips screwdrivers i tried, slipped.

In the base plate of the bsl board is a small bearing. When the CDP-X5000 was introduced, somebody wrote that the bearings were made from ruby.

Well, it is something looking like glass. It is glued/pressed into a brass shell, I assume the blue color is the glue. The rotor sits on it with a rounded cone.

The good news is that the bearing and the cone do not show any sign of wear. The glass has to bear vertical forces.

The bronze bearings align the rotor horizontally, when thy wear out, this should have no effect on the "glass" bearing. BTW, it is greased.

But the main bronze bearings in the slide assembly #255 provide a problem.

There are two of them pressed into it. You don´t seem them in the schematics.

Inner Ø is 6mm, Outer Ø10mm, Height 5mm.

Swapping bearings is normally an easy job. But with the BU-12 it is different. To remove them, one has to PULL them out -

normally you push them out with a stamp.

There is a rim between the two bearings they cannot be pushed further into the slide assembly.

I guess there is a tool needed to grab beneath them. Also the slide assembly is made of plastic so no strong force can be used.

Any ideas how to pull them out?

Something that these three players also share is the Vacuum Tube Display.

It can be only be partially switched off with the remote, at least with the CDP-X5000.

Any idea how to modify the circuit, to switch the display off completely?

I would like to treat the display more gentle by this mod for the next decades.

The often-used filaments have already become darker...

All the best,

Salar

Attachments

Last edited:

I would have no confidence in removing those bearings. Attempts to remove them may result in the plastic part breaking without warning. The outside might be textured and the bearing pushed in hot melting the plastic for a tight fit, or glue used.

Freezing the bearing or the whole assembly might help, but shrinking the bearing relative to the plastic.

Can you look inside with a light to see if you notice any residual material like glue?

Brute force trim the tips off of two sheet metal screws so the remaining part of the screw just fits inside the bearing and screw them in until they have a solid grip then pull out.

Leave the bearings in place and drill out the center until a replacement bearing fits inside the old bearing.

Freezing the bearing or the whole assembly might help, but shrinking the bearing relative to the plastic.

Can you look inside with a light to see if you notice any residual material like glue?

Brute force trim the tips off of two sheet metal screws so the remaining part of the screw just fits inside the bearing and screw them in until they have a solid grip then pull out.

Leave the bearings in place and drill out the center until a replacement bearing fits inside the old bearing.

hello Mike!

Thanks a lot for your reply. It does not look like the bearings were hot melted, i.e. in an injection molding process. You are correct, chances are high that they may break. A friend who has a milling company gave the advice to tap a thread into the bearing and gentle pull it out using a screw and a spacer that fits the outer diameter. Standard bearings have tolerances around 0,02mm, nothing we can achieve at home so I guess drilling a hole is not a good solution....

I cannot see any signs of wear on the shaft, only little black debris on a cotton bud after I wiped it.I never thoght about play of the shaft until we solved this temperature-related problem in diyaudio.

http://www.diyaudio.com/forums/digital-source/163691-sony-x5000-troubleshooting-24.html

So maybe the play is normal. If any other owner of a X5000 or XA-50ES or XA-7ES oberves play, it is probably normal. But not easy to observe because the base unit is not stiff. But with the base unit in my hand I was able to bend the shaft to the side until it could not move. Don´t know wether this is normal for standard tolerances. Observing reflections the polished brass disk pulley, I cannot see vibrations...

All the best, Salar

Thanks a lot for your reply. It does not look like the bearings were hot melted, i.e. in an injection molding process. You are correct, chances are high that they may break. A friend who has a milling company gave the advice to tap a thread into the bearing and gentle pull it out using a screw and a spacer that fits the outer diameter. Standard bearings have tolerances around 0,02mm, nothing we can achieve at home so I guess drilling a hole is not a good solution....

I cannot see any signs of wear on the shaft, only little black debris on a cotton bud after I wiped it.I never thoght about play of the shaft until we solved this temperature-related problem in diyaudio.

http://www.diyaudio.com/forums/digital-source/163691-sony-x5000-troubleshooting-24.html

So maybe the play is normal. If any other owner of a X5000 or XA-50ES or XA-7ES oberves play, it is probably normal. But not easy to observe because the base unit is not stiff. But with the base unit in my hand I was able to bend the shaft to the side until it could not move. Don´t know wether this is normal for standard tolerances. Observing reflections the polished brass disk pulley, I cannot see vibrations...

All the best, Salar

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.