Im going to build an Armageddon clone and after looking at all the information out there, Ive been unable to find an adequate answer to way a 500VA transformer is so important.

The larger the VA, the better the regulation but does the difference affect the performance in any meaningful way? Plitron lists 160VA at 8%, 300@ 6%, 400 @ 5% and 500 @ 4%.

So the is a gain of 2% (300 vs 500) worth the extra weight, cash and light dimming?

amt

The larger the VA, the better the regulation but does the difference affect the performance in any meaningful way? Plitron lists 160VA at 8%, 300@ 6%, 400 @ 5% and 500 @ 4%.

So the is a gain of 2% (300 vs 500) worth the extra weight, cash and light dimming?

amt

I'm not sure how good the mains is in the US, but here in the UK, the 50hz is rock solid, so the regulation does nothing. How it filters out high frequency crap and allows for more DC before saturation are important, and bigger is better.

Very happy with my Geddon clone, it beat all the Linn PSU's and the Hercules when used with thicker oil to provide some drag and load up than crappy motor to reduce cogging.

Very happy with my Geddon clone, it beat all the Linn PSU's and the Hercules when used with thicker oil to provide some drag and load up than crappy motor to reduce cogging.

Regulation (i.e. how much your transformer drops voltage when you take more current from it) is either enough for your circuit at your minimum mains voltage or not. If enough, then improving it will make no difference. If not enough, then improving it will make a big difference.

There is a separate meaning for regulation for constant voltage transformers - how well the transformer compensates for mains voltage variations. This meaning does not apply to normal mains transformers as used in electronics PSUs.

There is a separate meaning for regulation for constant voltage transformers - how well the transformer compensates for mains voltage variations. This meaning does not apply to normal mains transformers as used in electronics PSUs.

Not sure how good the grid is here but after looking more closely at what regulation refers to, I would think that a 5 watt motor is close to an absolute minimal load on a 300VA or bigger transformer. If this is the case, I would think that a small drop in regulation shouldnt decrease performance. As to the filtering of noise Im still unclear.

sq225917, I looked at your nice build on Flickr and it looks exactly like what I would like to do. Im guessing a varistor at half the voltage would work for 115V mains?

amt

sq225917, I looked at your nice build on Flickr and it looks exactly like what I would like to do. Im guessing a varistor at half the voltage would work for 115V mains?

amt

check out this thread:

http://www.diyaudio.com/forums/anal...ve-vs-sine-wave-oscillator-motor-control.html

I don't understand the kind of filtering by only a transformer use.

http://www.diyaudio.com/forums/anal...ve-vs-sine-wave-oscillator-motor-control.html

I don't understand the kind of filtering by only a transformer use.

I'm really puzzled by the use of a massive transformer for a few watt motor. I was about to build a geddon clone with a 36va Stancor transformer that I had in a parts box, but got the Valhalla working with some minimal troubleshooting. (Actually, zero troubleshooting since it's hard to troubleshoot something that works.) Any impedance difference between my small 36va transformer and a massive 500kva toroid will be swamped by the 3.3K series resistor.

Can anyone explain why the huge transformers?

thx,

Jim

Can anyone explain why the huge transformers?

thx,

Jim

From what a Naim rep explained in a Stereophile article, the size has to do with

proper creation of the sinewaves that arent "gutless". (apparently, wimpy sine waves are to had with smaller transformers)

Naim ARO tonearm & Armageddon turntable power supply | Stereophile.com

amt

proper creation of the sinewaves that arent "gutless". (apparently, wimpy sine waves are to had with smaller transformers)

Naim ARO tonearm & Armageddon turntable power supply | Stereophile.com

amt

They say they use a transformer to filter out high frequencies. These would anyway be filtered out by the mechanical inertia of the motor and platter. I suspect marketing rather than engineering. A big transformer might give higher starting torque so faster spin-up.

My guess (I could be wrong) is that a crystal oscillator will have far less jitter than the mains frequency. Crystal frequency depends on a high Q resonator. Mains frequency depends on the instantaneous balance between load (set by who has switched on what) and supply (set by how high they have turned up the knob at the power stations); it is adjusted so the average is about 50/60Hz and the total number of cycles per day is about right so synchronous clocks remain about right.

My guess (I could be wrong) is that a crystal oscillator will have far less jitter than the mains frequency. Crystal frequency depends on a high Q resonator. Mains frequency depends on the instantaneous balance between load (set by who has switched on what) and supply (set by how high they have turned up the knob at the power stations); it is adjusted so the average is about 50/60Hz and the total number of cycles per day is about right so synchronous clocks remain about right.

I don't remember "guts" or "gutless" being a parameter from my power electronics classes. But I'm guessing guts is being used to describe the low impedance of the transformer and the fact that it won't sag a bit when it's being used to power a few watt motor. However, that's made irrelevant by the series resistor.... the size has to do with

proper creation of the sinewaves that arent "gutless". (apparently, wimpy sine waves are to had with smaller transformers)

amt

It was probably a typical nuanced engineering decision - "Hey Bill, I think I figured out what to do with that pallet of toroids in the warehouse..."

Jim,

Comparing a 35VA geddon against the Valhalla would be quite interesting.

Ive not seen the resistor in the circuit sq225917 is using. What is its purpose?

In addition, the motor is 50hz and Im now wondering where to locate a 60hz pulley. Might have to turn one I guess.

amt

Comparing a 35VA geddon against the Valhalla would be quite interesting.

Ive not seen the resistor in the circuit sq225917 is using. What is its purpose?

In addition, the motor is 50hz and Im now wondering where to locate a 60hz pulley. Might have to turn one I guess.

amt

I haven't seen the circuit that sq225917 uses, but was basing my comment off of Neil McBride's site and the schematic on this site:

Armageddon Clone

They use a resistor in series with the transformer to drop the voltage supplied to the motor.

Armageddon Clone

They use a resistor in series with the transformer to drop the voltage supplied to the motor.

Why use a resistor and not just utilize a transformer with appropriate secondaries? Why use 55-0-55 with resistance and not 50-0-50? Does the

transformers impedance come into play?

I was considering this:

Antek - AN-4450

Here is sq225917 version:

YYYYYY | Flickr - Photo Sharing!

amt

transformers impedance come into play?

I was considering this:

Antek - AN-4450

Here is sq225917 version:

YYYYYY | Flickr - Photo Sharing!

amt

I don't use a resistor in mine I run the motor on a full fat 110 volts. Some people like to drop the voltage on one phase as they think it quietens the motor, some like to drop both because they think less torque = less noise. I just did the sensible thing, kept on tweaking the nominal value of the capacitor until I hit the value with the lowest vibration for my motor and then I dropped thick oil in the bearing, the added drag helps collapse the field in the motor and reduces/all but eliminates the effects of cogging. YMMV, i know my current deck has better measured speed stability than my SME had, that's good enough for me.

what about a simple 12v power supply using a transformer then bridge rectifiers to create 12vdc then modding a dc/ac inverter as the inverter must have a 50hz/60hz frequency generator in there somewhere so might just be a simple case of swapping out the frequency generator for something more suitable.

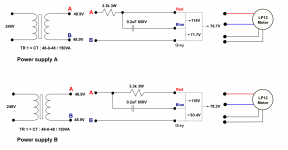

Hi, I am reopening this thread with some questions. Please refer to the attached drawing. I have a 240 VAC center tapped transformer rated at 150VA with 48-0-48 output. I have done up the boards for Supply A and B but the motor just don't spin without a little push. My question are:

1) do i need a higher VA transformer?

2) how to get the motor spin with this current transformer?

3) how do i get it spin with the mains supply and then switch it over to the transformer?

If a bigger VA transformer is necessary then i will have to order another one.

Thank you.

1) do i need a higher VA transformer?

2) how to get the motor spin with this current transformer?

3) how do i get it spin with the mains supply and then switch it over to the transformer?

If a bigger VA transformer is necessary then i will have to order another one.

Thank you.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Armageddon clone VA size vs. regulation