Hi folks!

This is an 'in theory' thread - I would be interested in people's thoughts on the following. I have just bought another pair of Quad II amps. As per usual, the original ERIE resistors on the tag boards are pretty much all out of spec now.

I am curious what happens physically to resistors for them to change value? I read somewhere that it's mainly due to the ingress of moisture over the decades. Would this be accurate? What actually changes within the resistor?

Assuming one wanted to keep their equipment as authentic as is practically possible (and please, let's keep any arguements about new components being superior out of this, for the time being. I'm well aware that they are), could one bake the resistors to drive out this moisture? Hi-Fi Collective mention the following baking process on their website for NOS Allen Bradley resistors:

"...Allen Bradley resistors are carbon composite, being made of an organic material they do have the tendency to absorb water from the atmosphere. This absorption can increase the actual resistance of the component, hence the slightly higher than normal tolerance published on this page. To fix this simply remove the water from the component and seal it. The best method is to place the resistor/s on a baking tray set, your oven to 80 degrees centigrade and leave in the oven for 8 hours. The secret is to remove the mositure slowly if you rush it it will become noisy in circuit. Once cooked seal the body of the component in Shellack (preferably the flakes) to stock any further water absorption. At the end of this procedure you will have a much lower noise, more closely tolerance resistors. Special thanks to Colin Cornish for this excellent tip."

I assume one could also use this method with the Quad II ERIE resistors, but instead of using melted shellac (which sounds really messy) use a modern spray acrylic conformal coating to seal the resistors against moisture ingress all over again, so they'd keep their values. Something like the following:

HPA200H - ELECTROLUBE - COATING, CONFORMAL, AEROSOL, 200ML | Farnell United Kingdom

Once again, YES I am fully aware that modern resistors are superior in every respect, and it's not expensive to replace them in an amp like the Quad II. But as a mini project in itself, it would be kind of fun to bring these resistors back to their original spec if possible, instead of throwing them away. In fact, I might just give it a go anyway and see how they measure after baking... & hope they don't accidentally end up in Mum's Christmas Cake

Cheers,

- John

This is an 'in theory' thread - I would be interested in people's thoughts on the following. I have just bought another pair of Quad II amps. As per usual, the original ERIE resistors on the tag boards are pretty much all out of spec now.

I am curious what happens physically to resistors for them to change value? I read somewhere that it's mainly due to the ingress of moisture over the decades. Would this be accurate? What actually changes within the resistor?

Assuming one wanted to keep their equipment as authentic as is practically possible (and please, let's keep any arguements about new components being superior out of this, for the time being. I'm well aware that they are), could one bake the resistors to drive out this moisture? Hi-Fi Collective mention the following baking process on their website for NOS Allen Bradley resistors:

"...Allen Bradley resistors are carbon composite, being made of an organic material they do have the tendency to absorb water from the atmosphere. This absorption can increase the actual resistance of the component, hence the slightly higher than normal tolerance published on this page. To fix this simply remove the water from the component and seal it. The best method is to place the resistor/s on a baking tray set, your oven to 80 degrees centigrade and leave in the oven for 8 hours. The secret is to remove the mositure slowly if you rush it it will become noisy in circuit. Once cooked seal the body of the component in Shellack (preferably the flakes) to stock any further water absorption. At the end of this procedure you will have a much lower noise, more closely tolerance resistors. Special thanks to Colin Cornish for this excellent tip."

I assume one could also use this method with the Quad II ERIE resistors, but instead of using melted shellac (which sounds really messy) use a modern spray acrylic conformal coating to seal the resistors against moisture ingress all over again, so they'd keep their values. Something like the following:

HPA200H - ELECTROLUBE - COATING, CONFORMAL, AEROSOL, 200ML | Farnell United Kingdom

Once again, YES I am fully aware that modern resistors are superior in every respect, and it's not expensive to replace them in an amp like the Quad II. But as a mini project in itself, it would be kind of fun to bring these resistors back to their original spec if possible, instead of throwing them away. In fact, I might just give it a go anyway and see how they measure after baking... & hope they don't accidentally end up in Mum's Christmas Cake

Cheers,

- John

Last edited:

Like a car restoration - do you want a totally original restoration or a functional restoration. Or something in-between.

If the carbon composite has changed its characteristics in time it is unlikely that any amount of cleaning will restore their correct values.

If the resistors have deteriorated then the capacitors will certainly have preceded them.

So again - either LIKE for LIKE, LIKE for BETTER or LIKE for SIMILAR.

If the carbon composite has changed its characteristics in time it is unlikely that any amount of cleaning will restore their correct values.

If the resistors have deteriorated then the capacitors will certainly have preceded them.

So again - either LIKE for LIKE, LIKE for BETTER or LIKE for SIMILAR.

I have never before heard of baking old carbon comp resistors to restore them. If moisture is the problem then it might work. I suspect there is more to it than that. As I understand it, they are basically a mixture of powdered graphite and clay. It astonishes me that a wide range of resistance values (10R - 10M) can be made in such a simple way, and that they are as stable as they are - changing over decades rather than the days one might expect.

Give it a try. Tell us how you get on.

Give it a try. Tell us how you get on.

Like a car restoration - do you want a totally original restoration or a functional restoration. Or something in-between.

If the carbon composite has changed its characteristics in time it is unlikely that any amount of cleaning will restore their correct values.

If the resistors have deteriorated then the capacitors will certainly have preceded them.

So again - either LIKE for LIKE, LIKE for BETTER or LIKE for SIMILAR.

It's not cleaning, it's baking. I'm very intrigued as to what actually causes something as seemingly 'simple' as a resistor to change over the years. And if this process can be reversed.

And I am more than aware of all the (often heated!) arguments vis-a-vis keeping them as museum pieces vs using modern components so they can be used.

I actually have two pairs of Quads - the first has been restored by myself using modern components, albeit to the same values as the original circuit. For this second pair I'd love to keep it as stock as possible, though there is no doubt that I'll be replacing ALL electrolytics & the PIO caps. It would just be nice to keep the original tagboard resistors if there's a cunning way of doing that.

It's for fun more than anything - a little project to see if old resistors can be baked back to their original working conditions... Then sealed to prevent them drifting again.

Last edited:

I have never before heard of baking old carbon comp resistors to restore them. If moisture is the problem then it might work. I suspect there is more to it than that. As I understand it, they are basically a mixture of powdered graphite and clay. It astonishes me that a wide range of resistance values (10R - 10M) can be made in such a simple way, and that they are as stable as they are - changing over decades rather than the days one might expect.

Give it a try. Tell us how you get on.

I think I'm going to try it. Nothing ventured nothing gained. I already have modern replacement resistors to hand anyways, so nothing to lose in trying this out. Will just have to be careful desoldering the old resistors. Will have to use some desoldering braid I think.

I too am astonished how these resistors were originally made! And if it is something as simple as moisture ingress, it would be nice to see if baking can revive them. Though I would have thought with the temperatures within a Quad II they'd be constantly being baked anyway

Last edited:

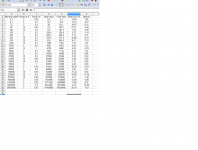

I have measured two dozens carb comp resistors from my scrap box.

They are of all origins, vintages, sizes and values are comprised between 4.7 ohm and 56 megohm.

I have begun to bake them. I will report this evening after some hours @100°C in the oven (accelerated process )

)

They are of all origins, vintages, sizes and values are comprised between 4.7 ohm and 56 megohm.

I have begun to bake them. I will report this evening after some hours @100°C in the oven (accelerated process

I have measured two dozens carb comp resistors from my scrap box.

They are of all origins, vintages, sizes and values are comprised between 4.7 ohm and 56 megohm.

I have begun to bake them. I will report this evening after some hours @100°C in the oven (accelerated process)

This'll be interesting - look forward to hearing about your results

P.S. They do say on the net (cannot find the link now - arghh!) not to go above 80°C, as it can result in a noisier resistor...

John

Noisier in not a concern here: I don't intend to actually use them.This'll be interesting - look forward to hearing about your results

P.S. They do say on the net (cannot find the link now - arghh!) not to go above 80°C, as it can result in a noisier resistor...

John

I am just interested in the values.

I have baked them for three hours @100°C + some minutes to allow for warm-up time.

It isn't a lab oven, just a regular kitchen one, so accuracy is certainly not exemplary, but we are looking for trends here, not excellence in metrology.

The results are.... well, mixed: supporters of the method will find some "proofs", but opponents will as well.

Of course, the sample is too small to draw any serious conclusion.

One thing is certain: even a relatively modest thermal event as this one is sufficient to significantly alter the values.

I' ll post a pic of the samples later

Attachments

I thought the topic was about carb comp resistors?Elvee: You need to clean out your parts bin! These are not even carbon film, but carbon composition resistors. Menace of servic techies everywhere! E

../..

I'm well aware that they are[/U]), could one bake the resistors to drive out this moisture? Hi-Fi Collective mention the following baking process on their website for NOS Allen Bradley resistors:

"...Allen Bradley resistors are carbon composite, being made of an organic material they do have the tendency to absorb water from the atmosphere.

Or maybe the OP is mistaken?

What vintage is the Quad? I cant recall carb comp beeing used after the mid/late 60's (tube time). And I cant believe that Quad would have ever used them

Low value Rs (<100 Ohm), like in your picture, sometimes where wirewound, differnt animal, but you can not tell from the outside

The reason I mentioned the temperatur (dis)coefficient of carbon resistors was an experience I had in a hospital, consulting, where the techs where using CF resistors to repair lifesafety equipment. Scarey! E

Low value Rs (<100 Ohm), like in your picture, sometimes where wirewound, differnt animal, but you can not tell from the outside

The reason I mentioned the temperatur (dis)coefficient of carbon resistors was an experience I had in a hospital, consulting, where the techs where using CF resistors to repair lifesafety equipment. Scarey! E

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- Saving vintage resistors (in theory!) in Quad II amps