My harman Kardon HK990 amplifier suddenly dead. I suspect one of the transformers -the one which power preamp section- has failed because thermal FUSE is open. The transformer has a thermal FUSE that opens at 125ºC

I want to know if is possible to replace the fuse. I have read that sometimes fuse is inside the transformer and it is very difficult to change it. I have read too that I MUST DISCAR the transformer because it may not BE SECURE...

What to do? Discard the transformer? Open it and try to chage the fuse????

I want to know if is possible to replace the fuse. I have read that sometimes fuse is inside the transformer and it is very difficult to change it. I have read too that I MUST DISCAR the transformer because it may not BE SECURE...

What to do? Discard the transformer? Open it and try to chage the fuse????

The 'fuse' is generally buried in the primary winding of the transformer. This would require the rewinding of the transformer to ensure there is no internal short that caused it to fail in the first place.

I have seen many units that have taps with and without the fuse in the circuit, though I would not recommend using the unfused tap, especially if the fuse has opened already.

I'd suggest replacing the transformer if the internal fuse has failed.

I have seen many units that have taps with and without the fuse in the circuit, though I would not recommend using the unfused tap, especially if the fuse has opened already.

I'd suggest replacing the transformer if the internal fuse has failed.

Those fuses can fail from repeated thermal cycling rather than a fault condition, though as jk already mentioned you need to determine if there is a fault such as a winding or downstream component short causing excessive current.

If you can determine there is no fault, or you want to monitor the circuit when you next power it up to check operation, you can replace the thermal fuse and hope for the best that it's the only problem.

It is usually not difficult at all to change one, you simply take the plastic wrap off the primary winding, the fuse is usually right there at the top because it was machine wound all the way then the fuse added after that. Solder a replacement in, wrap a few layers of tape around it or put insulating material behind it, then put the outer tape back around the primary windings.

Of course replacing the transformer is the more common way and if the transformer is PCB mounted it could be difficult to access the fuse if other components are blocking your tools, but if the primary reads open on a multimeter you might as well try, OR substitute a different transformer mounted elsewhere and just jumper wire it into the circuit (also cut the secondary winding or trace from it on the dead transformer so your new transformer isn't loaded down by it.

If you can determine there is no fault, or you want to monitor the circuit when you next power it up to check operation, you can replace the thermal fuse and hope for the best that it's the only problem.

It is usually not difficult at all to change one, you simply take the plastic wrap off the primary winding, the fuse is usually right there at the top because it was machine wound all the way then the fuse added after that. Solder a replacement in, wrap a few layers of tape around it or put insulating material behind it, then put the outer tape back around the primary windings.

Of course replacing the transformer is the more common way and if the transformer is PCB mounted it could be difficult to access the fuse if other components are blocking your tools, but if the primary reads open on a multimeter you might as well try, OR substitute a different transformer mounted elsewhere and just jumper wire it into the circuit (also cut the secondary winding or trace from it on the dead transformer so your new transformer isn't loaded down by it.

thermal fuses can be shunted by twisting its leads (if you can pry them) then insulating the leads from the transformer body. then, tracing the primary voltage and inserting the replacement fuse on one of the power lines-don't try to change the burnt fuse - simply short it out and insulate then fuse 'out'. be careful since you are working on the power supply.

I was able to change thermal fuse and put a new thermal fuse. Idid not see anything elese wrong. HK990 is working OK since them...

Harman KArdon repair service offered me the original NEW transformer. Total price is about 60 euros. Question is:

If everything is WORKING OK ¿What I have to do? Change the entire transformer or leave the actual, that is working OK?

There are two oppisite ideas:

a) If thermal fuse OPENS, transforme MUST be changed because transformers is not safe

b) Thermal fuse is here for protecting transformer, so, if fuse changed and everything OK, no need to change the entire transformer.

I thing this was a simple overheat, and notunig else. I did not see anything burned....

WHAT TO DO??????????

Harman KArdon repair service offered me the original NEW transformer. Total price is about 60 euros. Question is:

If everything is WORKING OK ¿What I have to do? Change the entire transformer or leave the actual, that is working OK?

There are two oppisite ideas:

a) If thermal fuse OPENS, transforme MUST be changed because transformers is not safe

b) Thermal fuse is here for protecting transformer, so, if fuse changed and everything OK, no need to change the entire transformer.

I thing this was a simple overheat, and notunig else. I did not see anything burned....

WHAT TO DO??????????

This is Diyaudio. I think everyone will agree with me when I say, toss it.WHAT TO DO??????????

Assuming you inspected the windings and did not see any damage to the insulating coating nor heat damage elsewhere, AND that the replacement thermal fuse was rated for an appropriate trip temperature, I would not buy a new transformer.

Unless the last user of the amp was operating it in an abnormal environment with high ambient air temperature, very high load, or a shorted output (or very low impedance speaker load), odds are the thermal fuse blew merely because it had been subject to too many thermal cycles. Thermal fuses of this type will fail eventually even if the temperature never exceeded their trip point temperature rating.

So in summary, I would use the amp as is, keeping an eye on it and not leaving it unattended for a little while to be sure there is no undetected fault still present that is causing excessive power loss and strain on the transformer, AND I would measure the output voltages (again?) to make sure the voltage looks correct, to rule out the possibility of there being a shorted winding. However, thermal expansion can change the mechanical aspect of contact conduction, I would measure voltage both when it is cold, then wait for it to heat up then measure again.

Unless the last user of the amp was operating it in an abnormal environment with high ambient air temperature, very high load, or a shorted output (or very low impedance speaker load), odds are the thermal fuse blew merely because it had been subject to too many thermal cycles. Thermal fuses of this type will fail eventually even if the temperature never exceeded their trip point temperature rating.

So in summary, I would use the amp as is, keeping an eye on it and not leaving it unattended for a little while to be sure there is no undetected fault still present that is causing excessive power loss and strain on the transformer, AND I would measure the output voltages (again?) to make sure the voltage looks correct, to rule out the possibility of there being a shorted winding. However, thermal expansion can change the mechanical aspect of contact conduction, I would measure voltage both when it is cold, then wait for it to heat up then measure again.

Thermal fuses are relatively robust and I would not expect one to blow unless the transformer was seriously overheated. Usually they are rated for a temperature just below the point where the wire insulation in the hottest part of the transformer will fail. Properly designed transformers place the fuse in a location where the highest temperature is likely and not near the surface. They do occasionally fail due to other causes, but as AndrewT mentioned there is usually a reason. I'd check all associated supply components carefully and really think about replacing that transformer - they generally do not blow under electrical overload, but as a result of over temperature.

^ With all due respect, no, thermal fuses aren't robust. They will always fail after a number of years even if the target temperature was never reached.

Thermal cycling (or time?) will make thermal fuses fail. I've replaced far too many to count where there was no overheating condition, only that the thermal fuse failed itself.

Granted, caution is necessary to be sure it didn't fail for the designed reason it was there, which is quite possible. Even so, on many circuits where I found a thermal fuse the fault, replacing it with no other changes resulted in years more operation of a device with no other changes.

So... don't believe any of us, test the circuit because the fuse is a potential fault point in and of itself, or it could be an indicator of another fault point.

Thermal cycling (or time?) will make thermal fuses fail. I've replaced far too many to count where there was no overheating condition, only that the thermal fuse failed itself.

Granted, caution is necessary to be sure it didn't fail for the designed reason it was there, which is quite possible. Even so, on many circuits where I found a thermal fuse the fault, replacing it with no other changes resulted in years more operation of a device with no other changes.

So... don't believe any of us, test the circuit because the fuse is a potential fault point in and of itself, or it could be an indicator of another fault point.

If there is a problem in a transformer it gets hot. The issue is if the transformer failed due to a weak fuse or if it is running hot. A temperature reading will show you the core temperature.

On high power transformers you can pick a rise of 50, 80, 115 or 150 C. The lower the rise the greater the cost. If you are cheap you do pay more for actual electrical draw. If maintenance is an issue you spend more money.

For a small transformer 20 C is the most I would expect to see. If there is an internal short it will go way beyond that.

Any failure of components past the transformer should cause the AC line fuse to blow. A bad transformer will overheat even without a load.

On high power transformers you can pick a rise of 50, 80, 115 or 150 C. The lower the rise the greater the cost. If you are cheap you do pay more for actual electrical draw. If maintenance is an issue you spend more money.

For a small transformer 20 C is the most I would expect to see. If there is an internal short it will go way beyond that.

Any failure of components past the transformer should cause the AC line fuse to blow. A bad transformer will overheat even without a load.

Last edited:

^ With all due respect, no, thermal fuses aren't robust. They will always fail after a number of years even if the target temperature was never reached.

Thermal cycling (or time?) will make thermal fuses fail. I've replaced far too many to count where there was no overheating condition, only that the thermal fuse failed itself.

Granted, caution is necessary to be sure it didn't fail for the designed reason it was there, which is quite possible. Even so, on many circuits where I found a thermal fuse the fault, replacing it with no other changes resulted in years more operation of a device with no other changes.

So... don't believe any of us, test the circuit because the fuse is a potential fault point in and of itself, or it could be an indicator of another fault point.

Not my experience at all with tens of thousands of power transformers involved... (Consumer audio product) Of course the transformers in question were competently designed and used good quality Japanese thermal fuses.

Also most of the devices here at home have thermally fused transformers - the only failures I have seen in some 20 yrs involved a partially shorted rectifier, and the thermal fuse in a hairdryer I misapplied for heat shrink tubing. (And even that one ran for a couple of years before it failed.)

Otherwise I completely agree with the cautions suggested.

Hi,

Thermal fuse will also failed for high current. They are sizing by current that they can handle and the temperature.

IMLE should not be sized by current rating, but practices may differ. Usually a separate fuse or fusible resistors would (should) be fitted to deal with other component failures, or inadvertent short circuit so that the transformer itself is not compromised, but I will admit this is not always or perhaps even usually done. As a cost cutting measure I can see it being done since repair cost and long term customer satisfaction are not usually part of the design equation for cheap consumer electronics, as a design matter it is nothing other than a poor design practice.

If there is a problem in a transformer it gets hot. The issue is if the transformer failed due to a weak fuse or if it is running hot. A temperature reading will show you the core temperature.

On high power transformers you can pick a rise of 50, 80, 115 or 150 C. The lower the rise the greater the cost. If you are cheap you do pay more for actual electrical draw. If maintenance is an issue you spend more money.

For a small transformer 20 C is the most I would expect to see. If there is an internal short it will go way beyond that.

Any failure of components past the transformer should cause the AC line fuse to blow. A bad transformer will overheat even without a load.

If there is a problem causing it to run hot, that's power loss... it won't be outputting the correct voltage at current which can be detected with a multimeter easier and more accurately (since we don't actually know what the (amp) designer's target rise over ambient temp is for the transformer).

The other factor is you have to have the amp closed up to get the running state temperature reading and in that situation, internal chassis temp could easily exceed 20C rise over ambient without fan cooling.

Failure of components past the transformer might or might not cause a fuse to blow. Take for example a leaky transistor. It may not cause enough current flow to blow the AC fuse, particularly in a linear PSU powered amp as the fuse may be sized sufficient to withstand power on surge current due to the transformer and bulk capacitors after it, if it doesn't have a fairly restrictive current limiting built in.

Last edited:

Not my experience at all with tens of thousands of power transformers involved... (Consumer audio product) Of course the transformers in question were competently designed and used good quality Japanese thermal fuses.

Also most of the devices here at home have thermally fused transformers - the only failures I have seen in some 20 yrs involved a partially shorted rectifier, and the thermal fuse in a hairdryer I misapplied for heat shrink tubing. (And even that one ran for a couple of years before it failed.)

Otherwise I completely agree with the cautions suggested.

The key thing might be whether it is an ideal, perfectly manufactured, quality Japanese thermal fuse and the transformer isn't a bit undersized for the load. Certain transformers or other devices may have their own particular high fault rate components.

The test is simple enough, replace a failed thermal fuse and reproduce the operating state the device was in when it failed. If the replacement thermal fuse does not trip with nothing else changed...

This is a very interesting question with OPPOSITE opinions.

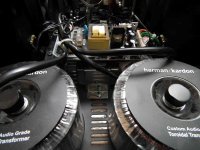

I have uploaded images from the transformer and its situation

HK990 has FOUR transformers: Two big toroids, in top is the smallest standby transformer, and under it and the central board is THE PREVIOUS section transformer, who fuse failed. this thermal fuse is set to 125 ºC as seen in picture.

The transformer is in very bad place, between the large heatsinks of the HK990 (very high biased: 170W idle power), as you can see. I think the transformer has been oerheated by its enviroment time after time... the transformer is relatively small...

After fuse changed, I put the amplifier over aluminium pieces for standing 3 cm over ground, for easier air circulating.

I think this tranformer has a bad situation, and repeated EXTERNAL overheating MAY caused thermal fuse to open... with the images, perhaps question will be clearer... ¿WHAT DO YOU THINK?

¿replace the entire transformer or keep working actual with new FUSE?????????

I have uploaded images from the transformer and its situation

HK990 has FOUR transformers: Two big toroids, in top is the smallest standby transformer, and under it and the central board is THE PREVIOUS section transformer, who fuse failed. this thermal fuse is set to 125 ºC as seen in picture.

The transformer is in very bad place, between the large heatsinks of the HK990 (very high biased: 170W idle power), as you can see. I think the transformer has been oerheated by its enviroment time after time... the transformer is relatively small...

After fuse changed, I put the amplifier over aluminium pieces for standing 3 cm over ground, for easier air circulating.

I think this tranformer has a bad situation, and repeated EXTERNAL overheating MAY caused thermal fuse to open... with the images, perhaps question will be clearer... ¿WHAT DO YOU THINK?

¿replace the entire transformer or keep working actual with new FUSE?????????

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Power Supplies

- THERMALLY FUSED TRANSFORMER