My first post here (and one that I've posted elsewhere because I in a quandary about what to do)....

A few months ago, I purchased a nice clean base plate for my operationally sound, but cosmetically-challenged Garrard 301.

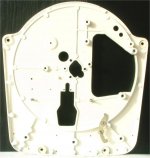

This weekend I decided to spend a few hours and carefully swap base plates. I hadn't proceeded too far when I noticed that a brass piece is riveted to the base plate. Having never dealt with rivets before I'm a bit stumped. I emailed someone I knew in England and he provided me with a photo of what I probably should have gotten when I purchased the better condition base plate. The photo shows the underside of a stripped base plate, bare except for one piece (near the ON/OFF works) that is riveted on.

On the base plate I want to use, the previous owner cut the rivet and kept the brass piece (part of the rivet is still in the hole).

So, to my questions...has anyone had experience removing this riveted piece, and if so, what's a good method to remove and install it on another base plate? Also, in what order would a person remove the rivet i.e. after all the other parts have been removed, or while the parts are there (making it easier to disconnect the spring)? Understandably, I don't want to mess anything up!

I have posted these questions on other sites and have received a couple of responses, but as of yet no one who's actually done this has responded. I couldn't figure out how to post pictures on this site, but I have good photos that clearly illustrate what I'm talking about, if anyone is interested. Thanks!

Nick

A few months ago, I purchased a nice clean base plate for my operationally sound, but cosmetically-challenged Garrard 301.

This weekend I decided to spend a few hours and carefully swap base plates. I hadn't proceeded too far when I noticed that a brass piece is riveted to the base plate. Having never dealt with rivets before I'm a bit stumped. I emailed someone I knew in England and he provided me with a photo of what I probably should have gotten when I purchased the better condition base plate. The photo shows the underside of a stripped base plate, bare except for one piece (near the ON/OFF works) that is riveted on.

On the base plate I want to use, the previous owner cut the rivet and kept the brass piece (part of the rivet is still in the hole).

So, to my questions...has anyone had experience removing this riveted piece, and if so, what's a good method to remove and install it on another base plate? Also, in what order would a person remove the rivet i.e. after all the other parts have been removed, or while the parts are there (making it easier to disconnect the spring)? Understandably, I don't want to mess anything up!

I have posted these questions on other sites and have received a couple of responses, but as of yet no one who's actually done this has responded. I couldn't figure out how to post pictures on this site, but I have good photos that clearly illustrate what I'm talking about, if anyone is interested. Thanks!

Nick

Attachments

More pictures, please!

My old eyes cannot see clearly what you mean.

I have used many 301s and still run a 401.

In general, rivets are removed by drilling them out.

If they are cinched (like eyelets in a leatherbelt) an oversize drill is used to take off the the exposed face and the rest drops out - or can be pushed.

If it is a blind hole and/or a solid rivet you need to drill through them in ever increasing sizes until the rivet falls apart. That can be quite tricky!

Anyway, I am guessing until I can see a clearer picture.

My old eyes cannot see clearly what you mean.

I have used many 301s and still run a 401.

In general, rivets are removed by drilling them out.

If they are cinched (like eyelets in a leatherbelt) an oversize drill is used to take off the the exposed face and the rest drops out - or can be pushed.

If it is a blind hole and/or a solid rivet you need to drill through them in ever increasing sizes until the rivet falls apart. That can be quite tricky!

Anyway, I am guessing until I can see a clearer picture.

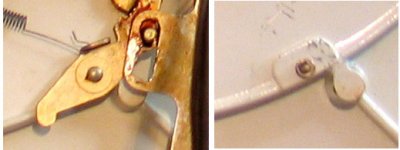

OK, I have chopped and joined the important bits from your images.

I presume the one on the left is your existing one and you wish to strip off all the mechanicals and add them to the refurbished one on the right.

Presumably the seller removed all the bits he could and repainted it, but left the rivet in there because he couldn't extract it! Now it is YOUR problem!

I suspect that the scuff marks around the rivet are where you / he tried to lever it out?

This is not so easy unless you have the correct tools and, I guess, since you had to ask the question, you don't have a workshop well kitted out!

The base plate is made from cast aluminium (do you miss out the "i" in "Gods Own Country" or is that just the heathens south of the border?

It is very soft - softer than the brass rivet. I can't tell from the photo what is inside that rivet - just distorted metal or some kind of pin?

In any case it has to be drilled out. To stop it getting all chewed up you must use a pillar drill (drill press) and firmly and accurately clamp the target below it. Then drill out with increasing size drills in 0.2mm (or 1/64") increments. Even so, the drill bit is going to grab the rivet and spin it round. Much better would be a mill which will chop the rivet to bits.

This is NOT easy to do well, and I would recommend you take it into a machine shop and find someone who will do it for a few Molsens.

Rivets are not designed to be removed. They are put in with a pneumatic tool and can only be drilled out. If you can get to both sides this is easy, but with blind holes like this it is difficult.

For the one shown on the left I would file the domed top flat with a needle file, carefully punch the exact centre with a centre-punch, then progressively drill it out, as described.

This one is a crude bearing - the plate rotates - so there is probably a brass washer underneath attached to the rivet.

Since this is only part of the on/off switch it doesn't need to be too precise.

Putting all the bits int the new base plate will involve tapping holes and fitting screws.

It can all be done but will require some mechanical skills - are you a quick learner?

For a quick look at all the different types of rivet, look

here

Cliff

Sorry there is no magic solution.

I presume the one on the left is your existing one and you wish to strip off all the mechanicals and add them to the refurbished one on the right.

Presumably the seller removed all the bits he could and repainted it, but left the rivet in there because he couldn't extract it! Now it is YOUR problem!

I suspect that the scuff marks around the rivet are where you / he tried to lever it out?

This is not so easy unless you have the correct tools and, I guess, since you had to ask the question, you don't have a workshop well kitted out!

The base plate is made from cast aluminium (do you miss out the "i" in "Gods Own Country" or is that just the heathens south of the border?

It is very soft - softer than the brass rivet. I can't tell from the photo what is inside that rivet - just distorted metal or some kind of pin?

In any case it has to be drilled out. To stop it getting all chewed up you must use a pillar drill (drill press) and firmly and accurately clamp the target below it. Then drill out with increasing size drills in 0.2mm (or 1/64") increments. Even so, the drill bit is going to grab the rivet and spin it round. Much better would be a mill which will chop the rivet to bits.

This is NOT easy to do well, and I would recommend you take it into a machine shop and find someone who will do it for a few Molsens.

Rivets are not designed to be removed. They are put in with a pneumatic tool and can only be drilled out. If you can get to both sides this is easy, but with blind holes like this it is difficult.

For the one shown on the left I would file the domed top flat with a needle file, carefully punch the exact centre with a centre-punch, then progressively drill it out, as described.

This one is a crude bearing - the plate rotates - so there is probably a brass washer underneath attached to the rivet.

Since this is only part of the on/off switch it doesn't need to be too precise.

Putting all the bits int the new base plate will involve tapping holes and fitting screws.

It can all be done but will require some mechanical skills - are you a quick learner?

For a quick look at all the different types of rivet, look

here

Cliff

Sorry there is no magic solution.

Attachments

Thanks, Cliff, for such a thorough reply to my question.

I'm glad I waited to do this; messing up the table would have pained me greatly. I didn't pay a great deal for the replacement base plate, so I'm not out a lot of money and I have learned from the experience—I'll explore other options now.

If you're ever in Calgary, I'll buy you a Big Rock Traditional Ale. You too, Dan.

Nick

I'm glad I waited to do this; messing up the table would have pained me greatly. I didn't pay a great deal for the replacement base plate, so I'm not out a lot of money and I have learned from the experience—I'll explore other options now.

If you're ever in Calgary, I'll buy you a Big Rock Traditional Ale. You too, Dan.

Nick

how to remove/reinstall...

Hi Nick

I have 301's and have removed rivets by wrapping masking tape in some places on the chassis for protection and afterwards bolting it down on a wooden plank with some holes and spacers underneath to clear the sticking out bits. The plank was then clamped on my mill and the rivets were precision milled out.

Those which fasten the switch legends, can be re-used by drilling or milling with a 2 or 2.5mm 4-flute cutter and tapping them out from underneath with a 2mm drift and a light plastic mallet.

In the following post, I'll show a completely stripped and re-painted 301.

Good luck

bulgin

Hi Nick

I have 301's and have removed rivets by wrapping masking tape in some places on the chassis for protection and afterwards bolting it down on a wooden plank with some holes and spacers underneath to clear the sticking out bits. The plank was then clamped on my mill and the rivets were precision milled out.

Those which fasten the switch legends, can be re-used by drilling or milling with a 2 or 2.5mm 4-flute cutter and tapping them out from underneath with a 2mm drift and a light plastic mallet.

In the following post, I'll show a completely stripped and re-painted 301.

Good luck

bulgin

how to remove/reinstall...

Hi

This grease bearing 301 is a recent addition to the stable and was stripped completely and re-painted using an air brush. The legend plates around the controls were removed by drilling the rivets underneath, tapping them out with a small drift. Once they were out, they were chucked in my lathe and the heads re-polished like new.

Regards

bulgin

Hi

This grease bearing 301 is a recent addition to the stable and was stripped completely and re-painted using an air brush. The legend plates around the controls were removed by drilling the rivets underneath, tapping them out with a small drift. Once they were out, they were chucked in my lathe and the heads re-polished like new.

Regards

bulgin

Attachments

Bravo, bulgin...what a beautiful-looking 301!

One thing I was wondering about: at hardware shops, I've looked at the kind of tools available to reinstall the rivet; there isn't much room on the plate because of the ridge...how does one install a new rivet in such a confined area?

thanks.

Nick

One thing I was wondering about: at hardware shops, I've looked at the kind of tools available to reinstall the rivet; there isn't much room on the plate because of the ridge...how does one install a new rivet in such a confined area?

thanks.

Nick

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- how to remove/reinstall rivet on Garrard 301?