Just after some advice. I currently have a sub using a Peerless XLS driver. I had the box built by a cabinet maker who had the driver hole recessed so the driver was recessed into the hole. I've decided to go for a Rythmik 12" sub and have to alter the driver hole as the Rythmik is a little bigger. Without a template and not doing it free hand how do I open up the driver hole but just a little. I have a router.

If it includes the rebate as well, the best is to create a new centre to swivel a circle jig (like the Jasper Jig... Soundlabs sells them or you can make one). Add a piece of MDF, glued or screwed behind the baffle, and drill a new perpendicular swivel hole on centre (see the pic).

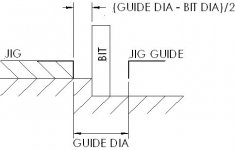

If it's just the inner diameter then you can make a jig out of some MDF, clamp it on the box and use the router with a jig guide.

If it's just the inner diameter then you can make a jig out of some MDF, clamp it on the box and use the router with a jig guide.

Attachments

yer they look nice my self would maybe like a different colour but still look good

yer i was thinking to get around the rebate bit was to cut the round hole "with jasper circle jig" and have the frame on the out side and then a 3m black perspex"plastic sheet" or something cut with the not fully round shapes so it would look rebate or what ever the proper term is

yer i was thinking to get around the rebate bit was to cut the round hole "with jasper circle jig" and have the frame on the out side and then a 3m black perspex"plastic sheet" or something cut with the not fully round shapes so it would look rebate or what ever the proper term is

Hi Larksp,

no.

The rebate is routed separately from the driver opening.

You need to cut the rebate first. It's easier to rebate when both sides of the router are supported by the uncut MDF.

Then route out the opening.

This will usually need two different jigs. A large one for the rebate and a smaller one for the opening.

no.

The rebate is routed separately from the driver opening.

You need to cut the rebate first. It's easier to rebate when both sides of the router are supported by the uncut MDF.

Then route out the opening.

This will usually need two different jigs. A large one for the rebate and a smaller one for the opening.

Use your Jasper jig for the hole through the box and the jig for the driver's rebate.

I mark out the template with the driver size and shape oversized by the (jig guide outside dia - router bit size)/2.

I'm using a 20mm router jig guide and a 8mm bit so the MDF jig is (20-8)/2 overize all the way around.... 6mm. I use a block with a nail at 6mm from the edge and trace around the driver which gives me the jig shape and correct size for the jig cut out. Cut with a jigsaw, add the jig guide (black thing) onto the router, do a practice run and away you go.

You just have to make sure the jig is clamped tightly onto the box so it can't move and the clamps don't get in the way of the router.

I mark out the template with the driver size and shape oversized by the (jig guide outside dia - router bit size)/2.

I'm using a 20mm router jig guide and a 8mm bit so the MDF jig is (20-8)/2 overize all the way around.... 6mm. I use a block with a nail at 6mm from the edge and trace around the driver which gives me the jig shape and correct size for the jig cut out. Cut with a jigsaw, add the jig guide (black thing) onto the router, do a practice run and away you go.

You just have to make sure the jig is clamped tightly onto the box so it can't move and the clamps don't get in the way of the router.

larksp said:so u have drew out a template in mdf then use a router black thing that then would leave enough for the rebate part

how did u make a "near perfect" jig, without a use of router to start with?

gychang

I'm pretty hot with a jigsaw.  I cut so the scribed line disappears so the end result is within 0.5mm which is plenty close for a rebate. Even at 1mm it's still very good.

I cut so the scribed line disappears so the end result is within 0.5mm which is plenty close for a rebate. Even at 1mm it's still very good.

I have done in the past, as you have mentioned, used a router to do the radius and then finish with a jigsaw but I found the jigsaw for the complete cutout was suitable. One thing I learned is don't sand the cut on the template too much as MDF disappears quickly and now just remove any loose material only. Any small imperfections in the jigsaw cut will not show up as it's a 20mm diameter guide so will not follow any small nicks or cuts.

One other thing is that a lot of these HDS baskets are not as per the Peerless drawings and are not completely symmetrical or the flats parallel so additional clearance can be required and useful.

I cut so the scribed line disappears so the end result is within 0.5mm which is plenty close for a rebate. Even at 1mm it's still very good.

I cut so the scribed line disappears so the end result is within 0.5mm which is plenty close for a rebate. Even at 1mm it's still very good.I have done in the past, as you have mentioned, used a router to do the radius and then finish with a jigsaw but I found the jigsaw for the complete cutout was suitable. One thing I learned is don't sand the cut on the template too much as MDF disappears quickly and now just remove any loose material only. Any small imperfections in the jigsaw cut will not show up as it's a 20mm diameter guide so will not follow any small nicks or cuts.

One other thing is that a lot of these HDS baskets are not as per the Peerless drawings and are not completely symmetrical or the flats parallel so additional clearance can be required and useful.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Routing advice