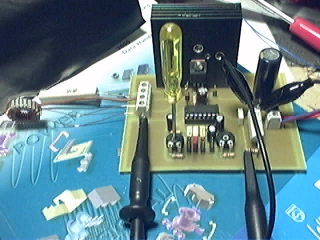

I'm publishing that because somebody asked me how to measure inductance values and saturation currents, which are critical parameters in any switching inductor. What I'm going to show in the following pictures is my clumsy measurement fixture. Don't laugh, it was mostly an unexpected weekend project, but it has proven to be very useful in the past years.

First, this is the PCB design, it has been corrected to show the patches that I applied to the first PCB:

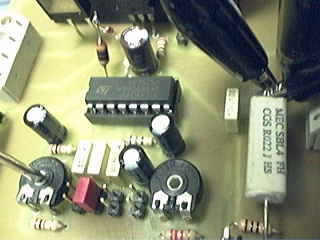

Don't ask me for a schematic because I don't have any, but with the previous picture, SG3525A datasheet and the following part list, it can be figured out quite easily:

Quantity Type/Value Ref Designators

==============================================

9 JUMPERS J1,J2,J3,J4,TP1,TP2,TP3

3 CONNECTORS K1,K2,K3

1 3.3u C1

1 1n C2

1 10n C3

1 100n C4

1 1u C5

1 10u C6

1 >2200u 25V low ESR C7

1 100u 25V C8

1 10n (depends on R7 ESL) C9

1 10uH >0.2A (in series w/1N4148) L1

2 4k7 R1,R2

1 68 R3

1 2k2 R4

2 22 R5,R6

1 0.022ohm non-inductive R7

1 100 (depends on R7 ESL) R8

1 4K7 P1

1 47k P2

1 60V 60A <0.020 ohm N-CH switching MOSFET Q1

1 MUR820 or similar D1

1 SG3525A IC1

And that's the EPS file, that can be printed with Adobe Photoshop in order to etch the PCB (if somebody actually dares to try...):

http://www.diyaudio.com/forums/atta...98665168-measuring-inductors-test_pwm_eps.zip

A very low value current-sense resistor is required for R7. Also, R8 and C9 form a low-pass filter that cancels the effects of R7 leakage inductance, thus their values have to be tuned depending on the particular resistor model employed (mine is from SBL4 series from Meggit Electronic Components and the values shown compensate it quite well).

A heavy duty low-ESR high ripple current SMPS capacitor is required for C7, mine is a Panasonic 2200uF 25V rated at >6A rms ripple at <45ºC and >10Khz, and featuring 0.022ohm ESR.

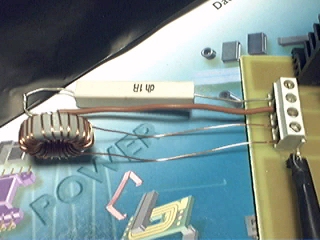

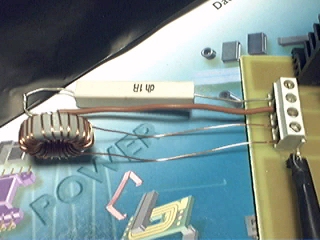

A dummy resistor of suitable value (connected as the PCB text shows) is required to dissipate the energy stored in the inductor during the switching pulses, 1 ohm 6W suits well measurements up to 40A, altough higher values are required to get reasonable reset times when the currents involved are very low. To measure inductors supposed to have very high saturation currents, it's preferable to temporarily double the number of turns, so that inductance gets multiplied by 4 and saturation current gets halved. The I(sat)^2*L product will still be the same, as it depends almost only on the size of the core and the length of the air gap (for ferrites), allowing to predict turn counts and saturation currents for other inductance values quite easily.

In order to use the circuit, duty cycle has to be adjusted below 0 (to prevent switching, achieved by turning the pot. full anti-clock-wise), then the test inductor has to be connected and power has to be applied (a 15V >1.5A well regulated supply is recommended). Then, the duty cycle has to be slowly increased (by turning the pot. clock-wise) while looking carefully at the current and voltage waveforms in the oscilloscope (that in turn will tell almost anything about the inductor). The waveforms should look like the following ones (there will be some ringing after transients because I was too lazy to add damping). Note the scales:

Before trying to further increase the duty cycle in order to find out the saturation current, the frequency has to be adjusted low enough to allow the inductor to fully reset before the next pulse begins, and it's recommended to switch power off while changing the timing capacitor jumpers. The following picture illustrates proper inductor reseting, see how inductor voltage has completely fallen to the 15V supply voltage level before each new pulse starts.

Using a higher value dummy resistor will provide faster resetting but at the expense of a higher voltage spike, so care has to be taken to not destroy the switching MOSFET due to excess avalanche dissipation (it has never happened to me, though).

In order to calculate inductance, the first thing that has to be kept in mind is that its value is not constant, it's a non-linear parameter and it's always current dependent, particularly for iron-powder cores or anything involving iron (only air cored inductors are believed to be truly linear, but they create high densities of flux lines up to quite far in space, so any close ferrous object will make a measurable difference). Being aware of that, the average inductance between two instants t0 and t1 is calculated by dividing the voltage applied to the coil (that must be as constant as possible) by the current slope:

L(t0..t1) = V / ( (I(t1) - I(t0)) / (t1-t0) )

or:

L(t0..t1) = V * (t1-t0) / (I(t1) - I(t0))

Note that at high currents the voltage drops across the sense resistor, the switching MOSFET and the capacitor have to be taken into account because the voltage applied to the inductor is no longer 15V during most of the time. I usually take an average of the initial and final values, something like 14.5V

In the previous example, we could assume that the inductor starts to saturate when the voltage drop across R7 exceeds 120mV, so the Isat would be:

.12/.022=5.4A

Note that iron-powder cores produce very progressive saturation knees, while gapped ferrites tend to be quite abrupt, particularly with small gap lengths.

Also, according to the waveforms, the current takes 23.3uS to rise from 0A to 5.4A, so average inductance in that region would be (using the previous formulas):

L= 15V * 23.3u / 5.4A = 65uH

That's all. BTW: I wound that inductor to be rated at 68uH 5A so it's quite close to spec 🙂

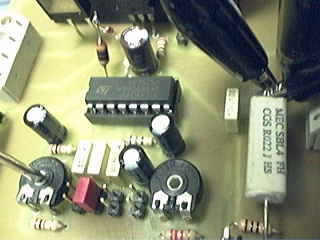

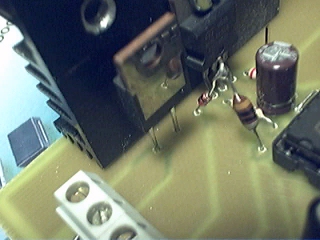

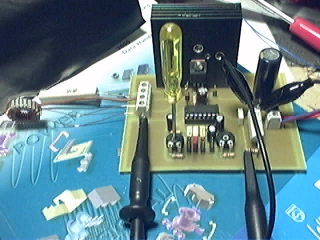

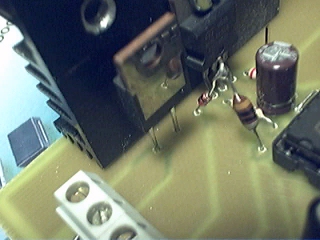

Finally, these are some pictures showing the previously described measurement setup:

Enjoy!

First, this is the PCB design, it has been corrected to show the patches that I applied to the first PCB:

Don't ask me for a schematic because I don't have any, but with the previous picture, SG3525A datasheet and the following part list, it can be figured out quite easily:

Quantity Type/Value Ref Designators

==============================================

9 JUMPERS J1,J2,J3,J4,TP1,TP2,TP3

3 CONNECTORS K1,K2,K3

1 3.3u C1

1 1n C2

1 10n C3

1 100n C4

1 1u C5

1 10u C6

1 >2200u 25V low ESR C7

1 100u 25V C8

1 10n (depends on R7 ESL) C9

1 10uH >0.2A (in series w/1N4148) L1

2 4k7 R1,R2

1 68 R3

1 2k2 R4

2 22 R5,R6

1 0.022ohm non-inductive R7

1 100 (depends on R7 ESL) R8

1 4K7 P1

1 47k P2

1 60V 60A <0.020 ohm N-CH switching MOSFET Q1

1 MUR820 or similar D1

1 SG3525A IC1

And that's the EPS file, that can be printed with Adobe Photoshop in order to etch the PCB (if somebody actually dares to try...):

http://www.diyaudio.com/forums/atta...98665168-measuring-inductors-test_pwm_eps.zip

A very low value current-sense resistor is required for R7. Also, R8 and C9 form a low-pass filter that cancels the effects of R7 leakage inductance, thus their values have to be tuned depending on the particular resistor model employed (mine is from SBL4 series from Meggit Electronic Components and the values shown compensate it quite well).

A heavy duty low-ESR high ripple current SMPS capacitor is required for C7, mine is a Panasonic 2200uF 25V rated at >6A rms ripple at <45ºC and >10Khz, and featuring 0.022ohm ESR.

A dummy resistor of suitable value (connected as the PCB text shows) is required to dissipate the energy stored in the inductor during the switching pulses, 1 ohm 6W suits well measurements up to 40A, altough higher values are required to get reasonable reset times when the currents involved are very low. To measure inductors supposed to have very high saturation currents, it's preferable to temporarily double the number of turns, so that inductance gets multiplied by 4 and saturation current gets halved. The I(sat)^2*L product will still be the same, as it depends almost only on the size of the core and the length of the air gap (for ferrites), allowing to predict turn counts and saturation currents for other inductance values quite easily.

In order to use the circuit, duty cycle has to be adjusted below 0 (to prevent switching, achieved by turning the pot. full anti-clock-wise), then the test inductor has to be connected and power has to be applied (a 15V >1.5A well regulated supply is recommended). Then, the duty cycle has to be slowly increased (by turning the pot. clock-wise) while looking carefully at the current and voltage waveforms in the oscilloscope (that in turn will tell almost anything about the inductor). The waveforms should look like the following ones (there will be some ringing after transients because I was too lazy to add damping). Note the scales:

Before trying to further increase the duty cycle in order to find out the saturation current, the frequency has to be adjusted low enough to allow the inductor to fully reset before the next pulse begins, and it's recommended to switch power off while changing the timing capacitor jumpers. The following picture illustrates proper inductor reseting, see how inductor voltage has completely fallen to the 15V supply voltage level before each new pulse starts.

Using a higher value dummy resistor will provide faster resetting but at the expense of a higher voltage spike, so care has to be taken to not destroy the switching MOSFET due to excess avalanche dissipation (it has never happened to me, though).

In order to calculate inductance, the first thing that has to be kept in mind is that its value is not constant, it's a non-linear parameter and it's always current dependent, particularly for iron-powder cores or anything involving iron (only air cored inductors are believed to be truly linear, but they create high densities of flux lines up to quite far in space, so any close ferrous object will make a measurable difference). Being aware of that, the average inductance between two instants t0 and t1 is calculated by dividing the voltage applied to the coil (that must be as constant as possible) by the current slope:

L(t0..t1) = V / ( (I(t1) - I(t0)) / (t1-t0) )

or:

L(t0..t1) = V * (t1-t0) / (I(t1) - I(t0))

Note that at high currents the voltage drops across the sense resistor, the switching MOSFET and the capacitor have to be taken into account because the voltage applied to the inductor is no longer 15V during most of the time. I usually take an average of the initial and final values, something like 14.5V

In the previous example, we could assume that the inductor starts to saturate when the voltage drop across R7 exceeds 120mV, so the Isat would be:

.12/.022=5.4A

Note that iron-powder cores produce very progressive saturation knees, while gapped ferrites tend to be quite abrupt, particularly with small gap lengths.

Also, according to the waveforms, the current takes 23.3uS to rise from 0A to 5.4A, so average inductance in that region would be (using the previous formulas):

L= 15V * 23.3u / 5.4A = 65uH

That's all. BTW: I wound that inductor to be rated at 68uH 5A so it's quite close to spec 🙂

Finally, these are some pictures showing the previously described measurement setup:

Enjoy!

Last edited:

Nordic said:Great, now I just need plans for a $50 scope....

My local supplier has just brought in a new line basic scope with probe for about US$110

If you want to measure cores BH Loop characteristic:

http://www.edn.com/contents/images/6294161.pdf

If you want to measure impedance:

http://www.arrl.org/qex/2005/Steber.pdf

http://www.edn.com/contents/images/6294161.pdf

If you want to measure impedance:

http://www.arrl.org/qex/2005/Steber.pdf

Nice Eva!

I use the same approach meassuring inductors with help of my own circuit and an oscilloscope.

But I use much bigger capacitor bank which I charge through the inductor so I can meassure up to couple of ten amperes! 😀

Adjustable duty on cycle and frequency.

Upper left with 3 pair of TO220 tranies I incorparated also an additional adjustable CCS switched on/off with the same 555 circuit as for the short circuit trany upper right.

Attached a picture of my circuit. 🙂

Cheers Michael

I use the same approach meassuring inductors with help of my own circuit and an oscilloscope.

But I use much bigger capacitor bank which I charge through the inductor so I can meassure up to couple of ten amperes! 😀

Adjustable duty on cycle and frequency.

Upper left with 3 pair of TO220 tranies I incorparated also an additional adjustable CCS switched on/off with the same 555 circuit as for the short circuit trany upper right.

Attached a picture of my circuit. 🙂

Cheers Michael

Attachments

Update:

I finally blew my ancient STP60N05-14 MOSFET after years of abuse, so I replaced it with a IRFZ48V (72A .010 ohms) wich handles high peak currents much better.

I added a "double barreled" ferrite bead in series with the gate, and then the old 22 ohm resistor in parallel with a 11DQ06 schottky for faster turn-off. The ferrite bead suppresses RF ringing and actually speeds up turn on and turn off transients (due to resonance with gate capacitance), although a small delay is introduced (not a problem). See picture:

The main PCB tracks were reinforced with solder to reduce parasitistic voltage drop and get a more precise measurement. See picture:

Finally, I also added to 4700uF 35V capacitors to get less voltage drop when dealing with low voltage high current inductors (50A measurements are more precise now). See picture:

Another small modification was to solder the sense resistor (.022ohm 4W non-inductive) sitting on the PCB rather than lifted. Leakage inductance was reduced as a result.

I finally blew my ancient STP60N05-14 MOSFET after years of abuse, so I replaced it with a IRFZ48V (72A .010 ohms) wich handles high peak currents much better.

I added a "double barreled" ferrite bead in series with the gate, and then the old 22 ohm resistor in parallel with a 11DQ06 schottky for faster turn-off. The ferrite bead suppresses RF ringing and actually speeds up turn on and turn off transients (due to resonance with gate capacitance), although a small delay is introduced (not a problem). See picture:

An externally hosted image should be here but it was not working when we last tested it.

The main PCB tracks were reinforced with solder to reduce parasitistic voltage drop and get a more precise measurement. See picture:

An externally hosted image should be here but it was not working when we last tested it.

Finally, I also added to 4700uF 35V capacitors to get less voltage drop when dealing with low voltage high current inductors (50A measurements are more precise now). See picture:

An externally hosted image should be here but it was not working when we last tested it.

Another small modification was to solder the sense resistor (.022ohm 4W non-inductive) sitting on the PCB rather than lifted. Leakage inductance was reduced as a result.

If anybody is interested on improving the measuring setup, I have found out following lately:

If you want to get clean non-resonant traces to scope, the first thing to do is to throw away those alligator clip equipped scope 1:10 probes.

I have found out that there is amazing difference between proper non-resonant high-bandwidth setup and ordinary 1:10 probes. Making the probe is very simple, just use normal 50 ohm coax, add 1 k series resistor at the measuring end. I tried 0603 SMD-resistor and conventional 1/4 W resistor, but that there was very little difference between SMD and THT resistors, at least on the 300 MHz bandwidth I used.

When 50 ohm termination is enabled on the scope, this makes extremely high bandwidth non-resonating measuring setup with 1:21 attenuation. If your scope doesn't have built-in termination, then use an 50 ohm in-line terminator (don't use that T-branch, however). The coax shield should be soldered to DUT GND as near of the measuring point as possible.

This is not actually my idea, but it is mentioned in the book "High-speed digital design" by Graham & Johnson.

I have used this to measure the ripple of SMPS by adding a 1 µF AC coupling capacitor, for the first time I have been able to see properly the ESR notch in ripple voltage, which has almost always been masked by ringing introduced by standard 1:10 probes.

How good is this probe? I had doubts about this but once I tried to measure 22 MHz digital oscillator, my doubts were gone:

here is a scope screenshot from standard probe:

Note the ~1V undershoots in falling edges. And here is the setup described above:

This home-made probe makes extremely clean traces, no

undershoots or ringing.

Regards,

Janne

If you want to get clean non-resonant traces to scope, the first thing to do is to throw away those alligator clip equipped scope 1:10 probes.

I have found out that there is amazing difference between proper non-resonant high-bandwidth setup and ordinary 1:10 probes. Making the probe is very simple, just use normal 50 ohm coax, add 1 k series resistor at the measuring end. I tried 0603 SMD-resistor and conventional 1/4 W resistor, but that there was very little difference between SMD and THT resistors, at least on the 300 MHz bandwidth I used.

When 50 ohm termination is enabled on the scope, this makes extremely high bandwidth non-resonating measuring setup with 1:21 attenuation. If your scope doesn't have built-in termination, then use an 50 ohm in-line terminator (don't use that T-branch, however). The coax shield should be soldered to DUT GND as near of the measuring point as possible.

This is not actually my idea, but it is mentioned in the book "High-speed digital design" by Graham & Johnson.

I have used this to measure the ripple of SMPS by adding a 1 µF AC coupling capacitor, for the first time I have been able to see properly the ESR notch in ripple voltage, which has almost always been masked by ringing introduced by standard 1:10 probes.

How good is this probe? I had doubts about this but once I tried to measure 22 MHz digital oscillator, my doubts were gone:

here is a scope screenshot from standard probe:

An externally hosted image should be here but it was not working when we last tested it.

Note the ~1V undershoots in falling edges. And here is the setup described above:

An externally hosted image should be here but it was not working when we last tested it.

This home-made probe makes extremely clean traces, no

undershoots or ringing.

Regards,

Janne

any one still have the scheme

Hi Veze,

thanks for your PM I will respond to it here.

Check out the link Sch3mat1c gave, my circuit is actually very similar, except that I have added the generator on the board but you could instead use a function generator as well controlling the switching FET.

Notice that this circuit is fed with a negative voltage from ground, so if you use a PSU with only positive voltage feed and where the ground is connected to the mains ground make sure you know what you do because the oscilloscope ground is directly connected to mains ground and you can destroy your equipment if improperly connected, or use a full transformer to isolate the oscilloscope from mains ground.

If any more questions just post here and I will check back, good luck!

Michael

I'm going to resurrect this thread i need some help.

Do anyone here still have the PCB files for this file or an equivalent version ?

Thanks in advance.!

Do anyone here still have the PCB files for this file or an equivalent version ?

Thanks in advance.!

Its easy to get fooled by cheap LC meters.

I designed a SMPS and had to have a certain leakage inductance.

My multi-meter said the inductor was 120uH and my USB LC meter said it was 60uH.

When I measured it using a resonant circuit, sig gen and scope it was in fact only 10uH which is why my SMPS over current kept tripping out.

I designed a SMPS and had to have a certain leakage inductance.

My multi-meter said the inductor was 120uH and my USB LC meter said it was 60uH.

When I measured it using a resonant circuit, sig gen and scope it was in fact only 10uH which is why my SMPS over current kept tripping out.

Its easy to get fooled by cheap LC meters.

I designed a SMPS and had to have a certain leakage inductance.

My multi-meter said the inductor was 120uH and my USB LC meter said it was 60uH.

When I measured it using a resonant circuit, sig gen and scope it was in fact only 10uH which is why my SMPS over current kept tripping out.

Very true, what brand of meter was that ?

I do however understand a inductor meter cant provide parameters like Saturation currents ect.. that why i need the schematic or PCB that eva posted. or something similar.

i could try and build one.. what i need a PWM signal adjustable ,frequency adjust, some compensation network, what rating transformer ? a simple mosfet..

Very true, what brand of meter was that ?

I do however understand a inductor meter cant provide parameters like Saturation currents ect.. that why i need the schematic or PCB that eva posted. or something similar.

i could try and build one.. what i need a PWM signal adjustable ,frequency adjust, some compensation network, what rating transformer ? a simple mosfet..

It was a £25 Farnell LCR meter.

Very true, what brand of meter was that ?

I do however understand a inductor meter cant provide parameters like Saturation currents ect.. that why i need the schematic or PCB that eva posted. or something similar.

i could try and build one.. what i need a PWM signal adjustable ,frequency adjust, some compensation network, what rating transformer ? a simple mosfet..

You can make an accurate L meter with a scope and signal generator.

You need a resistor, capacitor and the inductor under test.

Wire them all in series.

Shift the sig gen up and and down until you get least ac across LC and this is the resonant frequency.

Then L = 1 / ( 4 PI PI F F C)

You can make an accurate L meter with a scope and signal generator.

You need a resistor, capacitor and the inductor under test.

Wire them all in series.

Shift the sig gen up and and down until you get least ac across LC and this is the resonant frequency.

Then L = 1 / ( 4 PI PI F F C)

Thanks for the tip i actually have a meter already ive referenced the reading to a off the self inductor and its about -/+ 10% accuracy.

But i need the circuit at the start of this thread see with this circuit i can go beyond just reading inductance i get get useful parameter like current, core saturation, frequency ect..

i think it should be simple enough looking at the SG apps notes there is a sample circuit i can just use to create a frequency sweep (limited to 300kz single ended, 150kz + 150khz push pull per phase) the problem im having is the other components around it like compensation, reset resistor, supply voltage.. uhmm

- Status

- Not open for further replies.

- Home

- Amplifiers

- Power Supplies

- Measuring inductors