rjon17469 said:[B

BTW, where do you typically go to get cores? [/B]

230W-400W AT/ATX power supplies are "easy" source for ferrites, iron toroids, hw caps, switches, PWM-modulators and so on. You have to figure out specs by yourself, but some simple maths+scope+func.gen. should do that. You can also reverse-engineer transformer specs, calculate operating freq from controller chip R/C combination and note how many turns of wire there is in primary.

Typically you can get broken ones for free when you find right place/person to ask. Dont use small electrolytics from these, they are almost always bad(and the reason why its broken)

For more serious projects I prefer ordering new stuff with specifications.

Hi all,

I see some very initiated posts here, and I have a pair of beginner's questions for you:

Eva wrote:

It is said in an artice on the smps.us web site that PTFE (teflon) tape is approved as isolation material in SMPS transformers. However, such tape is rather thin, with a thickness around 0.1 mm (at least the kind I have). How many layers of this would be required between primary and secondary in order to adhere to formal safety regulations?

Also, from the same article, it appears that the secondary windings should normally be closest to the core in SMPS transformers, with the primary wound on the outside.

Is this just to minimize wire length per turn for the side with the highest current, or is there some other reason?

Cheers,

Marcus

I see some very initiated posts here, and I have a pair of beginner's questions for you:

Eva wrote:

- When winding transformers, pay great attention to output isolation. There should be three layers of isolating tape between primary side and secondary side windings. Magnet wires from different sides should never be in direct contact, there must be either isolating tape, proper plastic tubing or 3mm of air inbetween. There should be 5mm or more clearance between solder pins of different sides.

It is said in an artice on the smps.us web site that PTFE (teflon) tape is approved as isolation material in SMPS transformers. However, such tape is rather thin, with a thickness around 0.1 mm (at least the kind I have). How many layers of this would be required between primary and secondary in order to adhere to formal safety regulations?

Also, from the same article, it appears that the secondary windings should normally be closest to the core in SMPS transformers, with the primary wound on the outside.

Is this just to minimize wire length per turn for the side with the highest current, or is there some other reason?

Cheers,

Marcus

Depends ultimately wich regulations and wich specific class you refer to. In sweden EN6xxx is probably right one to look for, then it depends if it is Class I(basic insulation) or II(double insulation/reinforged insulation) Sorry, I dont have any of those regulations at hand right now...marcus66 said:Hi all,

It is said in an artice on the smps.us web site that PTFE (teflon) tape is approved as isolation material in SMPS transformers. However, such tape is rather thin, with a thickness around 0.1 mm (at least the kind I have). How many layers of this would be required between primary and secondary in order to adhere to formal safety regulations?

Marcus

Same as with EMI-regulations about line harmonics, "hand tools" have real loose spec about them and television much more strict.

davesaudio said:any chance we could see EVA's schematic?

Do you mean the schematic for that small unregulated SMPS?

Sorry, I have no schematic, I laid out that board from memory and then I tuned up component values. Anyway, the layout is rather self explaining and you also have component values so you can easily draw your own schematic.

IMHO, if you don't want to pay full price for HF transformer cores, the only safe surplus source is a core that served as main transformer in another SMPS.

Old or broken ATX supplies are a good source, but I try to avoid the flyback types, since I don't want gaps in my cores.

I'm not sure what value there is to reverse engineer the windings on these cores, since I think you should strip and rewind anyways.

I've successfully stacked two identical E-cores together from ATX supplies, to emulate a larger core. This doubles the cross-section area (which nearly quadruples the power rating). I had to make my own bobbin, since the core center is no longer square, it's rectangular.

My core of choice, an EER-42, is not easy to come by, and is expensive, so I like to recycle whenever possible.

Adrian

Old or broken ATX supplies are a good source, but I try to avoid the flyback types, since I don't want gaps in my cores.

I'm not sure what value there is to reverse engineer the windings on these cores, since I think you should strip and rewind anyways.

I've successfully stacked two identical E-cores together from ATX supplies, to emulate a larger core. This doubles the cross-section area (which nearly quadruples the power rating). I had to make my own bobbin, since the core center is no longer square, it's rectangular.

My core of choice, an EER-42, is not easy to come by, and is expensive, so I like to recycle whenever possible.

Adrian

SMPS housekeeping voltage

Although all SMPS designs seem to derive the low-voltage controller supply from an auxilliary winding on the main XF, I find it more practical to power the controller from a separate, analog transformer power supply.

This can be very tiny since it only needs to supply 50mA or so. Many miniature wall cubes can provide this circuit ready-made.

Just because you've decided to go SMPS, doen't mean you can't still have the supporting circuitry run off analog.

I find this brings a benefit in reducing the complexity of the SMPS controller circuit, by transferring some of the work out-of-circuit, to a reliable venue. Because this also removes the off-mains start-up supply to the controller, You can easily end up removing 7-10 parts from the SMPS.

I'm not a pro at designing these, so the more parts I can remove from the SMPS controller to simplify design, the less troubleshooting I have to do.

The second, and greatest benefit, though, is removing the housekeeping voltage winding from the HF XF core. The extra core window space is welcome, either for additional secondary power, or to make-up for my imperfect and not-so-compact hand winding technique.

Cheers

Adrian

Although all SMPS designs seem to derive the low-voltage controller supply from an auxilliary winding on the main XF, I find it more practical to power the controller from a separate, analog transformer power supply.

This can be very tiny since it only needs to supply 50mA or so. Many miniature wall cubes can provide this circuit ready-made.

Just because you've decided to go SMPS, doen't mean you can't still have the supporting circuitry run off analog.

I find this brings a benefit in reducing the complexity of the SMPS controller circuit, by transferring some of the work out-of-circuit, to a reliable venue. Because this also removes the off-mains start-up supply to the controller, You can easily end up removing 7-10 parts from the SMPS.

I'm not a pro at designing these, so the more parts I can remove from the SMPS controller to simplify design, the less troubleshooting I have to do.

The second, and greatest benefit, though, is removing the housekeeping voltage winding from the HF XF core. The extra core window space is welcome, either for additional secondary power, or to make-up for my imperfect and not-so-compact hand winding technique.

Cheers

Adrian

funberry said:

I'm not sure what value there is to reverse engineer the windings on these cores, since I think you should strip and rewind anyways.

Whats your method of seperating the two halves of the core?

I've tried paint thinner (not strong enough), boiling (cracked the core), and force (cracked the core completely)...

I've heard laquer thinner is strong enough, but I dont want to buy any unless I know it will work.

btw good advice on using a standard transformer for controller power (if you have a source for them).

Hi thomas997

I don't separate the core.

I simply unwind all the original wire till I get to the bobbin, then rewind my wire with the core in place.

I first thought "this is going to be a monk's work", but it isn't; 30-40 minutes, and you're done, because you're dealing with so few turns.

As the core window gets narrower, passing adhesive tape through the windows becomes difficult, so I use a regular paper strip, later impregnated with enamel.

You need to correctly cut to length the wire you'll need for each winding before you wind.

If I want to "parallel" two cores, (square profile), I destroy the bobbin (since I can't use it anyways), usually by melting it in a toaster oven, then pulling the softened plastic off with large tweezers.

You'll be much happier if you let go of the idea of separating the core halves.

But if you insist on dissolving the glue that holds the thing together, you may want to try the following:

Acetone

Paint stripper

Trichloroethylene, trichloroethane

(paint thinner must--by your government's orders--be safe for all whining consummers, therefore, useless.)

let the core (without bobbin) soak in the liquid overnight in a small COVERED container, **outside of your house**.

Warning: ventilation, ventilation, ventilation; protect all children, pets, spouses, etc.

You do this at your own risk--I didn't tell you to do it.

Adrian

I don't separate the core.

I simply unwind all the original wire till I get to the bobbin, then rewind my wire with the core in place.

I first thought "this is going to be a monk's work", but it isn't; 30-40 minutes, and you're done, because you're dealing with so few turns.

As the core window gets narrower, passing adhesive tape through the windows becomes difficult, so I use a regular paper strip, later impregnated with enamel.

You need to correctly cut to length the wire you'll need for each winding before you wind.

If I want to "parallel" two cores, (square profile), I destroy the bobbin (since I can't use it anyways), usually by melting it in a toaster oven, then pulling the softened plastic off with large tweezers.

You'll be much happier if you let go of the idea of separating the core halves.

But if you insist on dissolving the glue that holds the thing together, you may want to try the following:

Acetone

Paint stripper

Trichloroethylene, trichloroethane

(paint thinner must--by your government's orders--be safe for all whining consummers, therefore, useless.)

let the core (without bobbin) soak in the liquid overnight in a small COVERED container, **outside of your house**.

Warning: ventilation, ventilation, ventilation; protect all children, pets, spouses, etc.

You do this at your own risk--I didn't tell you to do it.

Adrian

In most of these chinese PSUs the cores of are just glued with varnish and they will split quite easily if they are heated slowly, and then a small force is applied in hot during enough time (not enough to broke them!).

On the other hand, I've found very powerful adhesives in other PSUs whose cores I couldn't split.

On the other hand, I've found very powerful adhesives in other PSUs whose cores I couldn't split.

BTW

If you should ever find that your application is important enough that you want to spend money for a core, you can try these guys:

http://www.tscinternational.net/tscstoreetd.html

You can get an ETD49 for 76 cents, which is not bad. (you'll need two of those.

That's good for about 700W in full-bridge.

Adrian

If you should ever find that your application is important enough that you want to spend money for a core, you can try these guys:

http://www.tscinternational.net/tscstoreetd.html

You can get an ETD49 for 76 cents, which is not bad. (you'll need two of those.

That's good for about 700W in full-bridge.

Adrian

funberry said:BTW

If you should ever find that your application is important enough that you want to spend money for a core, you can try these guys:

http://www.tscinternational.net/tscstoreetd.html

You can get an ETD49 for 76 cents, which is not bad. (you'll need two of those.

That's good for about 700W in full-bridge.

Adrian

Dammit, cheapest so far what i have seen, but US only? Shipping to here would cost an fortune anyways.

What comes to separating cores, I have used MEK(methyl-ethylene-ketone) and acetone mixed. Let it soak overnight or even several days. Some sorta paint stripper is probably even better, havent tried yet.

Edit: Name of most probably successive paint stripper just popped to my head, Nitromors

Edit: Name of most probably successive paint stripper just popped to my head, Nitromors

I've purchased my ferrite cores from

http://www.bejoken.se , a Malmö/sweden based company

Maybe shipping isn't that expensive to finland?

They charge SEK 11,54 ( approx. 1,30 euros? ) for ETD49 cores, not to expensive if you ask me... If you call/email them, perhaps you can pay them in advance, and have it sent to you by mail? I guess shipping would be 3-5 euros or something like that...

( hehe... they've got ETD59 siemens cores as well... i wonder what they are capable of... )

)

http://www.bejoken.se , a Malmö/sweden based company

Maybe shipping isn't that expensive to finland?

They charge SEK 11,54 ( approx. 1,30 euros? ) for ETD49 cores, not to expensive if you ask me... If you call/email them, perhaps you can pay them in advance, and have it sent to you by mail? I guess shipping would be 3-5 euros or something like that...

( hehe... they've got ETD59 siemens cores as well... i wonder what they are capable of...

)

)(maybe we should start a new "Ferrite Core" thread)

Shipping to Finland might not be a fortune.

The US Post Office has a service called "Global Priority Mail - Flat-rate Envelope (Small)", which costs $5 to anywhere in Europe, and can weigh up to 4 pounds (1.8Kg).

The ETD49core weighs 45g (per half)

The ETD59 weighs 130g.

A few of these could fit nicely in a bubble-lined large envelope.

Maybe a group buy of ferrites for our EU friends?

Adrian

Shipping to Finland might not be a fortune.

The US Post Office has a service called "Global Priority Mail - Flat-rate Envelope (Small)", which costs $5 to anywhere in Europe, and can weigh up to 4 pounds (1.8Kg).

The ETD49core weighs 45g (per half)

The ETD59 weighs 130g.

A few of these could fit nicely in a bubble-lined large envelope.

Maybe a group buy of ferrites for our EU friends?

Adrian

IMHO, I still think if you're struggling with separating a core, you've got the wrong view on this.

To gain access to the center leg, and dissolve the glue there, you need to remove the bobbin, usually by destroying it.

I don't know about you, but to me, the bobbin is worth more than the extra comfort of re-winding the coil unhindered.

How much extra time does it cost to rewind with the core in-place?

And how much extra time, work, materials does it cost to dissolve the glue, and then measure/design/craft/improvise a new bobbin?

Good bobbins are valuable, they are not a trivial item, and if you want to buy one, they're often harder to find than the ferrite.

Adrian

To gain access to the center leg, and dissolve the glue there, you need to remove the bobbin, usually by destroying it.

I don't know about you, but to me, the bobbin is worth more than the extra comfort of re-winding the coil unhindered.

How much extra time does it cost to rewind with the core in-place?

And how much extra time, work, materials does it cost to dissolve the glue, and then measure/design/craft/improvise a new bobbin?

Good bobbins are valuable, they are not a trivial item, and if you want to buy one, they're often harder to find than the ferrite.

Adrian

I have used MEK(methyl-ethylene-ketone)

Methyl Ethyl Ketoene is a very good solvent. You have to work quickly with these things, and keep them very tightly capped, because they evaporate before your eyes.

Paint stripper is a mixture of solvents. I think they include one of each major type, an aromatic, a chlorinated, an ionic, an aliphatic, and maybe a branched chain or an alcohol. You really need a lot of trial-and-error, since some solvents are potentiated in a mixture, others do better alone by themselves.

Keep this stuff away from heat, and keep in mind that wifes have been known to divorce their husbands over keeping stuff like this in the house...

funberry said:IMHO, I still think if you're struggling with separating a core, you've got the wrong view on this.

To gain access to the center leg, and dissolve the glue there, you need to remove the bobbin, usually by destroying it.

I don't know about you, but to me, the bobbin is worth more than the extra comfort of re-winding the coil unhindered.

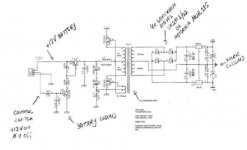

Yeah I didnt even think of it like that... so many wasted cores. The picture is of one I cracked, width is 5.5cm, german brand.

Do you have a source for ETD49 bobbins? Or just an approximate cost?

I bought a couple cores and bobbins that are a bit smaller than the 49s off ebay, cost a lot more than 79 cents though

btw I also got some ferrite toroids, but I dont know if those are of any use at all? They would be much easier to wind, and could be stacked.

Attachments

btw I also got some ferrite toroids, but I dont know if those are of any use at all? They would be much easier to wind, and could be stacked.

Are you sure the toroids are ferrite? There are a lot of powdered iron toroids floating around, and it's not easy to tell them apart. If anyone out there knows how to use simple bench tests to differentiate between ferrite ans powdered Fe, please come forward and say.

You need to calculate the cross-sectional area of the toroid, make sure it's the same as that of the central post of the transformer you're replacing.

Aaaaaaah.... the bobbins.... Now you understand why it's important to preserve them (with the core they're on). This is an even more elusive product than the ferrite. They seem to be about $3 when paying an "authorized disributor's" resale list price. You can't easily find a distibutor that has them, and is willing to sell just two or three.Do you have a source for ETD49 bobbins? Or just an approximate cost?

The bobbin mfr. I know about is Miles-Platts, in England. There are others, but this one is most prolific around ETD cores.

You might work backwards, from Miles-Platts (email them) and find out all the distributors in your area.

Dexter Magnetics in Chicago, carries the Miles-Platts line. They may sell you a small quantity, if you say you're an engineer prototyping a new design.

If other members are interested, maybe we can buy in quantity and spread them around.

The truth of the matter is that ETD cores are one of the most expensive tranformer platforms in SMPS, because of the intricate design of both magnetics, and coil formers. Plain old square "E" cores may be easier to work with.

And then again, you can make that bobbin yourself. Cardboard won't do, because the cummulative force applied to each turn of wire causes deformation of the former. Eventually, even a small deformation of the cardboard bobbin is enough to make it not fit onto the core any more.

A plastic tube, with flanges of epoxy fiberglass PCB material, makes a strong bobbin. (make sure there is no copper on that PCB --shorted turn.

Adrian

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Power Supplies

- Beginning SMPS?