diyAudio Universal Power Supply Circuit Board v3 illustrated build guide. (October 2013)

(Any photo with a link directly below will go to full-size file of the photo)

This build guide will show a typical use of the diyAudio PSU v3 circuit board. This specific build will be suitable for any of the Pass/Firstwatt amps that use a +/-25V supply. If you need a higher voltage make sure you use capacitors of a suitable voltage rating for your project. You may always have a higher voltage rating, but do not use a cap with a lower voltage rating than your rails.

Useful Links

BOM - https://www.diyaudio.com/forums/images/diy/store/board-documentation/P-PSU-1V30/P-PSU-1V30-bom.xls

Schematic - https://www.diyaudio.com/forums/ima...mentation/P-PSU-1V30/P-PSU-1V30-schematic.pdf

PSU18 - My Photo Gallery

((Do not connect 2-leg TO-220 diodes as shown. See photos in 'heatsink' section.))

PSU36 - My Photo Gallery

Fully stuffed

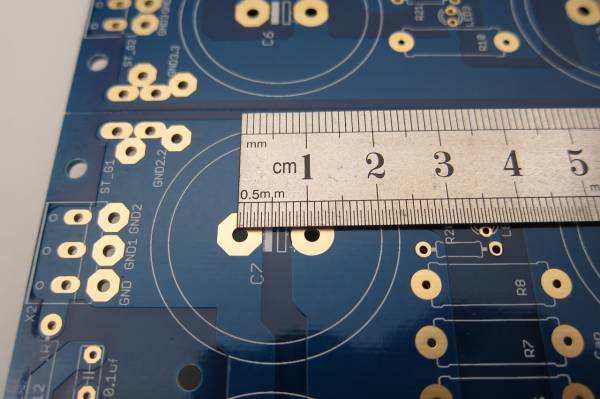

PCB scale

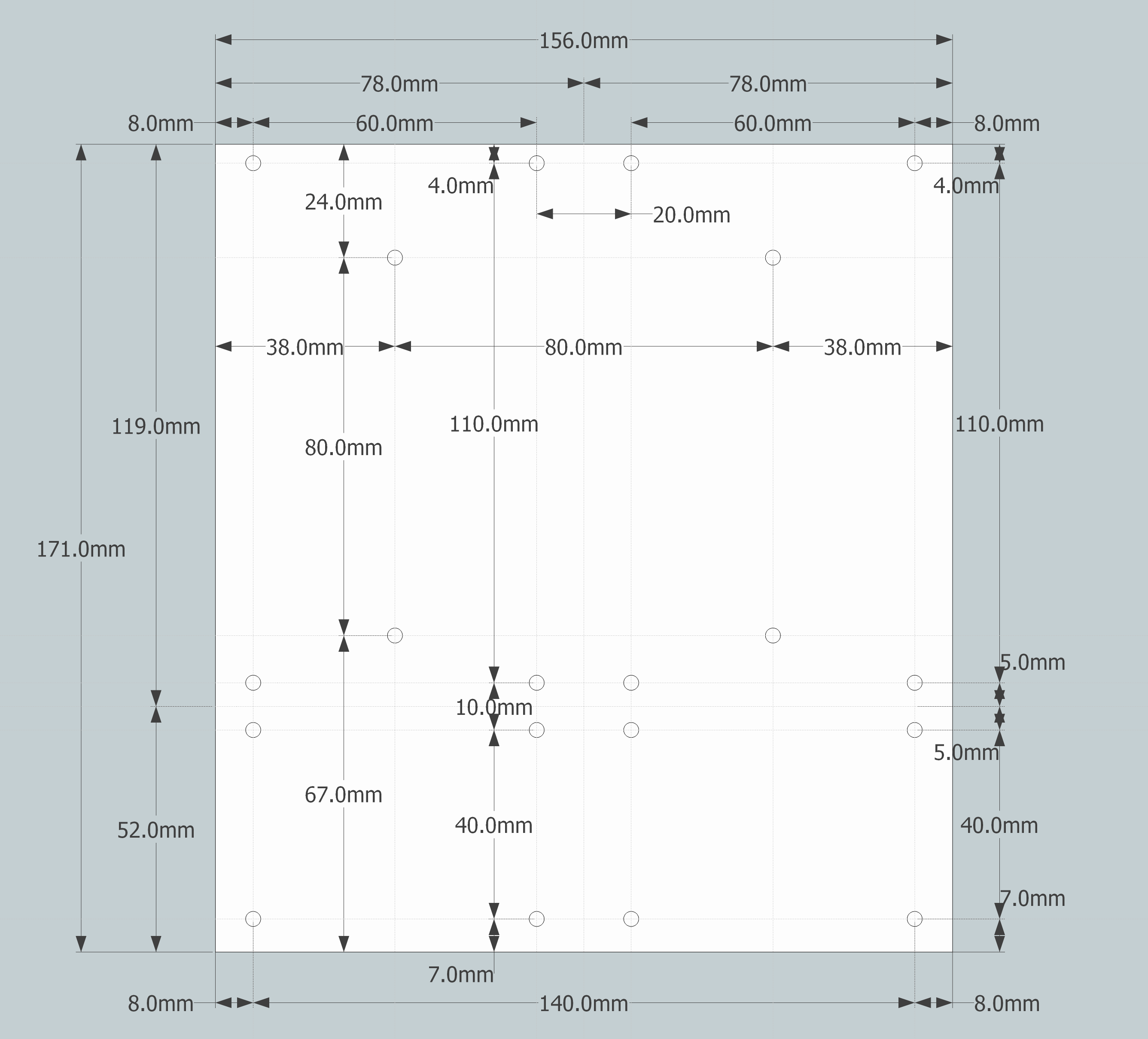

Dimensions -

PCB dimensions

PSU14 - My Photo Gallery

The heatsinks are one inch post spacing. Look at the BOM for a specific part suggestion and find something similar that you can use. The sinks I used in this guide are of the same outer profile, so they fit the pads perfectly, but are quite a bit taller. A number of parts will be available that will work.

IMG_2134 - My Photo Gallery

This board can accept capacitors of up to 35mm diameter.

Equally important is the lead spacing - the caps should be 10mm 'snap in'. 10mm radial leads will work as well, but usually the bigger diameter caps have the 'snap in' leads.

For more information on dimensions of the specific parts, please consult the BOM for suggested parts, and cross-reference from that part's datasheet. http://www.diyaudio.com/forums/images/diy/store/board-documentation/P-PSU-1V30/P-PSU-1V30-bom.xls

Board features -

The bridge diode section of the board can utilize either TO-247/TO-3P (larger) package devices or TO-220 (smaller). If heat dissipation / heatsinking is not an issue, you could also use conventional axial-leaded diodes. (Not shown.)

IMG_2135 - My Photo Gallery

If you would like to use snubbers on the rectifier diodes you will find that there is room for them on the top of the PCB, and inside the heatsinks.

IMG_2141 - My Photo Gallery

If you don't find enough room there, or would like to try a different snubber layout, there is plenty of place to connect on the bottom of the PCB, as you will always have one of the d=sets of diode pads empty - you can only use one type of diode at a time, for example if you are using the TO-220, the TO-247 pads will be empty and you may make connections there.

IMG_2142 - My Photo Gallery

For designs that require one, there is also room for a snubber on the output. (Per rail)

Also worth noting, in this photo you can see the multiple solder pads for the output - the row towards the edge is for the euroblock connectors, and the inner row, with the larger pads, for wire. There is also a place for a blade terminal. (Near the board edge, on the outside. To be better illustrated in a later photo.)

Building / Stuffing

PSU41 - My Photo Gallery

This photo shows all the parts that will be used in this guide.

Starting at top and circling clockwise -

Capacitors and 'euroblock' connectors

(8) filter or 'pi' resistors

Diode heatsinks and diodes (TO-220 package shown)

(2) bleeder resistors

LED and LED resistors

AMP terminal blades

As this board has the scoring to let you separate it if you so choose, you need to notice that there is no connection from the diodes to the first capacitors nor across GND. These must be connected.

The PCB has no connection from diodes to capacitor.

The PCB also has no connection to make GND.

Since I am planning on keeping this PCB intact for the amp I am building, I need to make a connection form the diodes to the capacitor bank, and a connection to establish ground.

You can see all the links here (diode links not soldered in this photo)

GND links. The pads on most of this PCB are all through-plated and big enough to solder from the top if you choose.

PSU28 - My Photo Gallery

In general stuffing should be from the smaller devices to the bigger devices, so the resistors and such should be first. The filter resistors are on the outside, then the LED and LED resistors (the small brown one) and inboard are the bleeder resistors.

The silkscreen markings at the LED pads are slightly obscured, and the break in the circle, indicating where the flat of the LED should go (cathode, negative, short leg) is a little bit confusing. The legs of the LED go as shown. You can also see another link at the top of the PCB where I joined GND together.

The blades are actually taller than the euroblocks, so don't solder them first!

PSU27 - My Photo Gallery

The output edge shown with all the connectors in place

Capacitors -

As mentioned before, this PCB can accept caps with 10mm lead spacing and up to 35mm diameter. This photo shows 35mm caps next to 30mm. You will also commonly find some appropriate values in 25mm diameter.

PSU32 - My Photo Gallery

The addition of the large solder pads has obscured the markings on the PCB and the ' + ' mark is somewhat hard to make out. In each case the Positive side is marked with the open rectangle and the negative the white or filled-in rectangle. Remember that electrolytic capacitors are usually only marked on the Negative side.

PSU9 - My Photo Gallery

Note capacitor direction - you can see the negative markings on each capacitor.

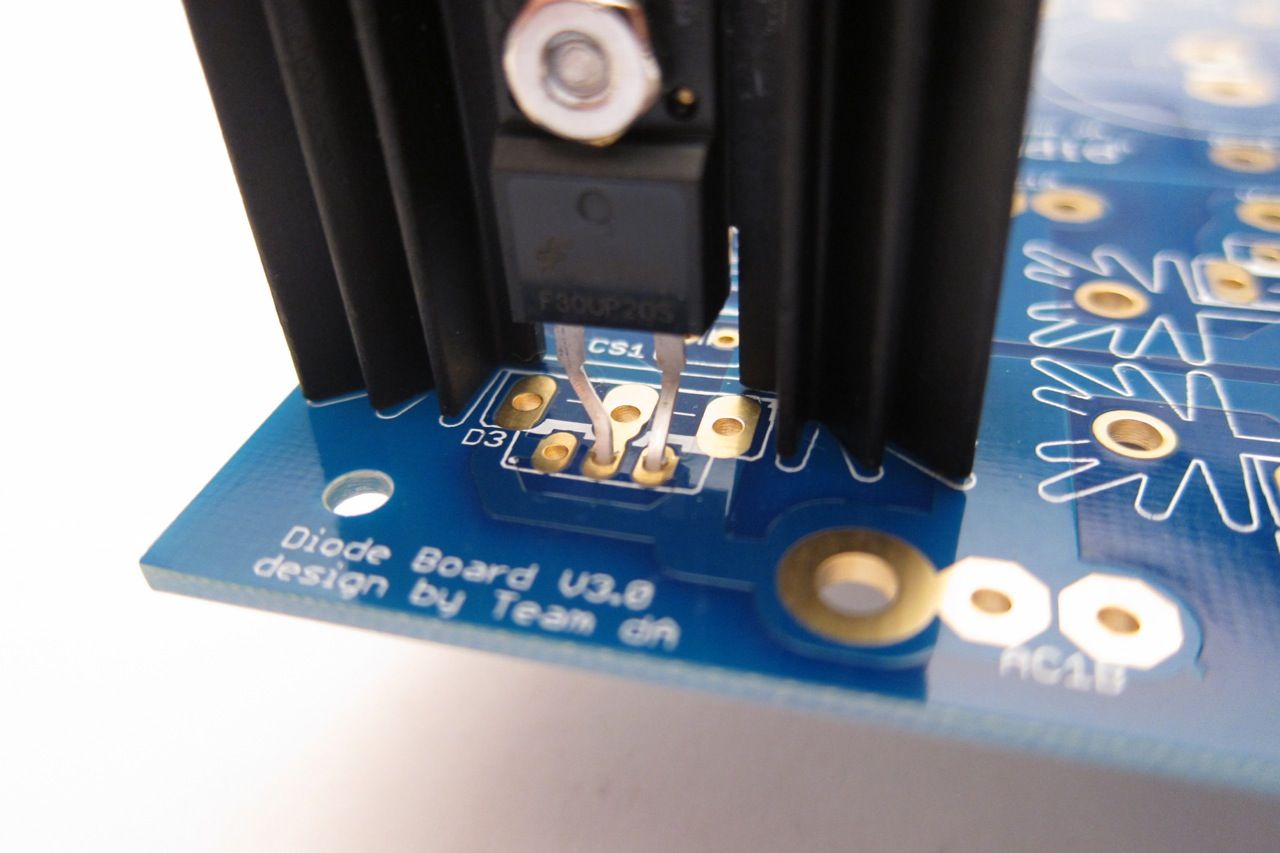

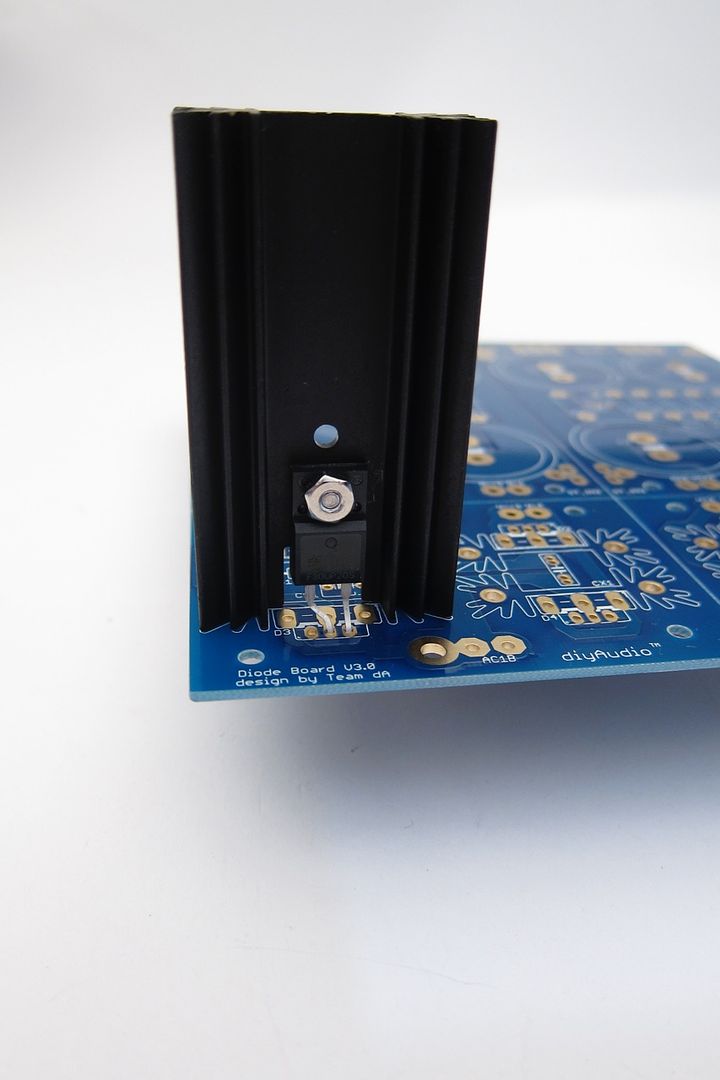

Heatsinks -

The heatsinks used in this guide were chosen as they were of proper dimension to fit the PCB, and in-stock at the time I ordered them. They are a little tall, but as Nelson Pass says, there is no such thing as too much heatsink… I do suggest you try to get something that will fit a TO-247/TO-3P package as it will also mount the TO-220, whereas the slightly narrower inner profile of this heatsink will only mount the smaller diode. Regardless, it's quite easy to get really nice, suitable diodes in whichever package - you want 20A, 200V minimum diodes.

A little grease is helpful on the full-pack devices. Secure to the heatsink with a nut and screw. This is a 4-40 screw, about the same size as M3.

Please Read - If you use a conventional TO-220 diode or TO-247/TO-3P it's a very good idea to use an insulator between the device and the heatsink. But it's not necessary - although if you choose not to the heatsinks will probably be live. The heatsinks themselves solder to the PCB and are in holes that have no electrical connection, and aluminum anodize is actually not very conductive, but I would still suggest using an insulator. (Or a full-pack TO-220)

Feel free to snap off the diode section and use bridges. They work and sound great!

NOTE - I strongly suggest not separating the capacitor board if at all possible. With it intact, you can run multiple jumpers (as shown) to tie GND together and have a low-impedance, and therefore quiet GND. Splitting it will complicate making a quiet circuit. FYI.

Example wiring.

(Any photo with a link directly below will go to full-size file of the photo)

This build guide will show a typical use of the diyAudio PSU v3 circuit board. This specific build will be suitable for any of the Pass/Firstwatt amps that use a +/-25V supply. If you need a higher voltage make sure you use capacitors of a suitable voltage rating for your project. You may always have a higher voltage rating, but do not use a cap with a lower voltage rating than your rails.

Useful Links

BOM - https://www.diyaudio.com/forums/images/diy/store/board-documentation/P-PSU-1V30/P-PSU-1V30-bom.xls

Schematic - https://www.diyaudio.com/forums/ima...mentation/P-PSU-1V30/P-PSU-1V30-schematic.pdf

PSU18 - My Photo Gallery

((Do not connect 2-leg TO-220 diodes as shown. See photos in 'heatsink' section.))

PSU36 - My Photo Gallery

Fully stuffed

PCB scale

Dimensions -

PCB dimensions

PSU14 - My Photo Gallery

The heatsinks are one inch post spacing. Look at the BOM for a specific part suggestion and find something similar that you can use. The sinks I used in this guide are of the same outer profile, so they fit the pads perfectly, but are quite a bit taller. A number of parts will be available that will work.

IMG_2134 - My Photo Gallery

This board can accept capacitors of up to 35mm diameter.

Equally important is the lead spacing - the caps should be 10mm 'snap in'. 10mm radial leads will work as well, but usually the bigger diameter caps have the 'snap in' leads.

For more information on dimensions of the specific parts, please consult the BOM for suggested parts, and cross-reference from that part's datasheet. http://www.diyaudio.com/forums/images/diy/store/board-documentation/P-PSU-1V30/P-PSU-1V30-bom.xls

Board features -

The bridge diode section of the board can utilize either TO-247/TO-3P (larger) package devices or TO-220 (smaller). If heat dissipation / heatsinking is not an issue, you could also use conventional axial-leaded diodes. (Not shown.)

IMG_2135 - My Photo Gallery

If you would like to use snubbers on the rectifier diodes you will find that there is room for them on the top of the PCB, and inside the heatsinks.

IMG_2141 - My Photo Gallery

If you don't find enough room there, or would like to try a different snubber layout, there is plenty of place to connect on the bottom of the PCB, as you will always have one of the d=sets of diode pads empty - you can only use one type of diode at a time, for example if you are using the TO-220, the TO-247 pads will be empty and you may make connections there.

IMG_2142 - My Photo Gallery

For designs that require one, there is also room for a snubber on the output. (Per rail)

Also worth noting, in this photo you can see the multiple solder pads for the output - the row towards the edge is for the euroblock connectors, and the inner row, with the larger pads, for wire. There is also a place for a blade terminal. (Near the board edge, on the outside. To be better illustrated in a later photo.)

Building / Stuffing

PSU41 - My Photo Gallery

This photo shows all the parts that will be used in this guide.

Starting at top and circling clockwise -

Capacitors and 'euroblock' connectors

(8) filter or 'pi' resistors

Diode heatsinks and diodes (TO-220 package shown)

(2) bleeder resistors

LED and LED resistors

AMP terminal blades

As this board has the scoring to let you separate it if you so choose, you need to notice that there is no connection from the diodes to the first capacitors nor across GND. These must be connected.

The PCB has no connection from diodes to capacitor.

The PCB also has no connection to make GND.

Since I am planning on keeping this PCB intact for the amp I am building, I need to make a connection form the diodes to the capacitor bank, and a connection to establish ground.

You can see all the links here (diode links not soldered in this photo)

GND links. The pads on most of this PCB are all through-plated and big enough to solder from the top if you choose.

PSU28 - My Photo Gallery

In general stuffing should be from the smaller devices to the bigger devices, so the resistors and such should be first. The filter resistors are on the outside, then the LED and LED resistors (the small brown one) and inboard are the bleeder resistors.

The silkscreen markings at the LED pads are slightly obscured, and the break in the circle, indicating where the flat of the LED should go (cathode, negative, short leg) is a little bit confusing. The legs of the LED go as shown. You can also see another link at the top of the PCB where I joined GND together.

The blades are actually taller than the euroblocks, so don't solder them first!

PSU27 - My Photo Gallery

The output edge shown with all the connectors in place

Capacitors -

As mentioned before, this PCB can accept caps with 10mm lead spacing and up to 35mm diameter. This photo shows 35mm caps next to 30mm. You will also commonly find some appropriate values in 25mm diameter.

PSU32 - My Photo Gallery

The addition of the large solder pads has obscured the markings on the PCB and the ' + ' mark is somewhat hard to make out. In each case the Positive side is marked with the open rectangle and the negative the white or filled-in rectangle. Remember that electrolytic capacitors are usually only marked on the Negative side.

PSU9 - My Photo Gallery

Note capacitor direction - you can see the negative markings on each capacitor.

Heatsinks -

The heatsinks used in this guide were chosen as they were of proper dimension to fit the PCB, and in-stock at the time I ordered them. They are a little tall, but as Nelson Pass says, there is no such thing as too much heatsink… I do suggest you try to get something that will fit a TO-247/TO-3P package as it will also mount the TO-220, whereas the slightly narrower inner profile of this heatsink will only mount the smaller diode. Regardless, it's quite easy to get really nice, suitable diodes in whichever package - you want 20A, 200V minimum diodes.

A little grease is helpful on the full-pack devices. Secure to the heatsink with a nut and screw. This is a 4-40 screw, about the same size as M3.

Please Read - If you use a conventional TO-220 diode or TO-247/TO-3P it's a very good idea to use an insulator between the device and the heatsink. But it's not necessary - although if you choose not to the heatsinks will probably be live. The heatsinks themselves solder to the PCB and are in holes that have no electrical connection, and aluminum anodize is actually not very conductive, but I would still suggest using an insulator. (Or a full-pack TO-220)

Feel free to snap off the diode section and use bridges. They work and sound great!

NOTE - I strongly suggest not separating the capacitor board if at all possible. With it intact, you can run multiple jumpers (as shown) to tie GND together and have a low-impedance, and therefore quiet GND. Splitting it will complicate making a quiet circuit. FYI.

Example wiring.

Last edited by a moderator:

Excellent photos! Thank you so much for producing this guide!

Can you tell me why you are using both blade connectors and the euro style connectors on the output edge?

Why too is one board linked to the other (GND2.2 to GND2.3, ST_IN2 to ST_IN3)?

Can you tell me why you are using both blade connectors and the euro style connectors on the output edge?

Why too is one board linked to the other (GND2.2 to GND2.3, ST_IN2 to ST_IN3)?

Can you tell me why you are using both blade connectors and the euro style connectors on the output edge?

To illustrate where they go. 🙂

Why too is one board linked to the other (GND2.2 to GND2.3, ST_IN2 to ST_IN3)?

As the PCB is made to be split if you wish to do so, there is no connection across the two sides of the bipolar PSU - and in order to use it as a bipolar (POS/GND/NEG) supply you need to tie the sides together - this makes GND. As I'm not planning on splitting this particular PCB I joined them in the spots shown.

My apologies but I still have questions...

I guess I've once again not formulated my question well...

You show both manners of making a connection euro style and blade style not because they would both be used at the same time thus typically built with both, but because you wished to save on file space/pictures right?

You have tied one board to the other not because it is necessary (I hope not because I did not tie my boards GND planes together accept that they meet at the star ground) but because, because...you wanted to? Do the (I hope) "extra" connections make the grounding scheme more effective?

I ask because I have to be sure in my mind why everything is done. I'm just that new and just that curious. I mean no disrespect at all!

I guess I've once again not formulated my question well...

You show both manners of making a connection euro style and blade style not because they would both be used at the same time thus typically built with both, but because you wished to save on file space/pictures right?

You have tied one board to the other not because it is necessary (I hope not because I did not tie my boards GND planes together accept that they meet at the star ground) but because, because...you wanted to? Do the (I hope) "extra" connections make the grounding scheme more effective?

I ask because I have to be sure in my mind why everything is done. I'm just that new and just that curious. I mean no disrespect at all!

You show both manners of making a connection euro style and blade style not because they would both be used at the same time thus typically built with both, but because you wished to save on file space/pictures right?

Essentially yes, however it never hurts to have as many connections points as you can have, especially on GND. On GND this board has place for 6 wires in the blocks, 6 wires soldered in the pads behing them, and the 2 blades - there is no reason not to use the PCB as the starground - you have the connection points... and that's really useful.

It is extremely necessary. If you don't have the GND tied together there is no GND, and as the PSU is what usually defines the GND point in an amp, you need them together.You have tied one board to the other not because it is necessary

See - you did tie them together. Just not on the PCB. 🙂(I hope not because I did not tie my boards GND planes together accept that they meet at the star ground)

There are no stupid question, the entire point of these forums is to have a place where you can ask those exact questions! 😀 😀 😀I ask because I have to be sure in my mind why everything is done. I'm just that new and just that curious.

Last edited:

Is it necessary to use all the jumper pads - V- -1 to D- -1 and V-1 to D-1? Same for using 3 jumpers for st_in2 and st_in3. Or use all the ground pads on the other side of the board instead of the st_in2/3.

If not all are needed, I'm guessing it didn't matter which pads we use.

Thanks

If not all are needed, I'm guessing it didn't matter which pads we use.

Thanks

Doesn't matter - other than you want a really good connections between the two - hence why I used so many of the available pads.

That's the answer I was hoping for. If using a star ground, should we jumper or connect each to the star point through a thermistor?

Sorry I wasn't clear. Should I jumper the grounds and then connect one wire to the star ground? Our not jumper them and use two wires to the star ground.

grounding the star

Thanks 6L6, you are extremely patient with these questions.

As someone recently IN the confused state rif's question made sense to me; it is what I did!

I ran separate wires (4 actually) from the GNDs (euroblocks) of the power boards to the star ground point.

To get the thermistor into the act the star ground is physically short/shy of the GND bolt on the chassis, the thermistor is what connects the star ground TO the grounding bolt on the chassis.

How do you create a star ground short/shy of the ground bolt, in the air? I used a piece of copper suspended/insulated from the chassis. To connect ground wires to the copper I used bronze bolts going into euro barrier stips; the open ends then can receive all the many ground wires from everywhere on the PCBs. Ugly perhaps but thats why there is a case around all the working parts😉

I see and understand now one could take all the ground wires to the power board and then take a large single wire out from the power board through a thermistor and to a bolt on the chassis. 'Just didn't think of it at the time.

Thanks 6L6, you are extremely patient with these questions.

As someone recently IN the confused state rif's question made sense to me; it is what I did!

I ran separate wires (4 actually) from the GNDs (euroblocks) of the power boards to the star ground point.

To get the thermistor into the act the star ground is physically short/shy of the GND bolt on the chassis, the thermistor is what connects the star ground TO the grounding bolt on the chassis.

How do you create a star ground short/shy of the ground bolt, in the air? I used a piece of copper suspended/insulated from the chassis. To connect ground wires to the copper I used bronze bolts going into euro barrier stips; the open ends then can receive all the many ground wires from everywhere on the PCBs. Ugly perhaps but thats why there is a case around all the working parts😉

I see and understand now one could take all the ground wires to the power board and then take a large single wire out from the power board through a thermistor and to a bolt on the chassis. 'Just didn't think of it at the time.

Attachments

There are at least 14 places you can connect a wire to the GND portion of this PCB. Connect all your grounds there, and it is a starground. 🙂

Also, the Faston "blade" connectors were mostly added to facilitate Stacking TWO boards if required to allow a LOT of caps

Last edited:

Power supply for F4 and F5T

I'm planning on building this power supply for an F4, but would also like to be able to use it for an F5T ( V1 or V2, different trafo of course ), should the inclination arise. I've already purchased capacitors rated for 50V, and am about to buy everything else. As the F5T power supply calls for MUR3020's as rectifiers, is there any drawback to using these from the get-go, knowing the supply will first be used for an F4? Should any other values, other than capacitors, be changed to facilitate this?

I'm planning on building this power supply for an F4, but would also like to be able to use it for an F5T ( V1 or V2, different trafo of course ), should the inclination arise. I've already purchased capacitors rated for 50V, and am about to buy everything else. As the F5T power supply calls for MUR3020's as rectifiers, is there any drawback to using these from the get-go, knowing the supply will first be used for an F4? Should any other values, other than capacitors, be changed to facilitate this?

No real difference, other than you need much more capacitance for an F5T. Look for the biggest (35mm diameter) caps you can find.

I would use the dual rectifiers as shown in the F4, not the single of the F5T.

If you build a good supply with 50V caps it will be fine for either amp.

I would use the dual rectifiers as shown in the F4, not the single of the F5T.

If you build a good supply with 50V caps it will be fine for either amp.

Possible for Phono MM or for 45VDC ore some more ?

Is that design possible for my aged Phono MM and Pre needing 2x +/- 24V (hk Citation 17).

Other idea is to take it for my Citation Amp wich needs 2x +/- 47-49V,

Possible?

Is that design possible for my aged Phono MM and Pre needing 2x +/- 24V (hk Citation 17).

Other idea is to take it for my Citation Amp wich needs 2x +/- 47-49V,

Possible?

- Home

- Amplifiers

- Power Supplies

- diyAudio Power Supply Circuit Board v3 illustrated build guide