HEY,

Can anyone please tell me what is the formula for finding priamary and secondory turns for a small ferrite core transformer where 220vac will be the input of priamary side and 12vac will be the output of secondory side...or can we use the EP/ES=NP/NS formula??

please help me...

Can anyone please tell me what is the formula for finding priamary and secondory turns for a small ferrite core transformer where 220vac will be the input of priamary side and 12vac will be the output of secondory side...or can we use the EP/ES=NP/NS formula??

please help me...

HEY,

Can anyone please tell me what is the formula for finding priamary and secondory turns for a small ferrite core transformer where 220vac will be the input of priamary side and 12vac will be the output of secondory side...or can we use the EP/ES=NP/NS formula??

please help me...

ferrite core, means you are looking at smps, out of scope of this thread...

This thread covers a lot of the basics of transformers'

http://www.diyaudio.com/forums/planars-exotics/161485-step-up-transformer-design.html#post2088330

It is a long thread but as lots of very good info as it explains basics of core saturation and how to go about finding such parameters.

As well as finding the turns count of the windings and ratio of a unknown transformer.

Here is a link to a calculator that might help you.

http://www.diyaudio.com/forums/planars-exotics/161485-step-up-transformer-design.html#post2089815

This one is a good one as well but I think it assumes a square wave input and I have not tried raw calculations to check it yet,

TRANSFORMERS

You need to know the core size and type of material in order to determine the number of primary turns as per frequency and primary voltage in order to design it for no saturation of the core.

There many good threads on transformer design in this forum but I don't have a compiled list for them as they can be found very easily using the search function.

Here is the calculator that I think you are looking for and it also shows the formulas as well,

Maximum Flux Density Calculator

There a few more transformer calculators that can be found on this page,

http://www.daycounter.com/SiteMap.phtml

I hope this helps you !!

jer

http://www.diyaudio.com/forums/planars-exotics/161485-step-up-transformer-design.html#post2088330

It is a long thread but as lots of very good info as it explains basics of core saturation and how to go about finding such parameters.

As well as finding the turns count of the windings and ratio of a unknown transformer.

Here is a link to a calculator that might help you.

http://www.diyaudio.com/forums/planars-exotics/161485-step-up-transformer-design.html#post2089815

This one is a good one as well but I think it assumes a square wave input and I have not tried raw calculations to check it yet,

TRANSFORMERS

You need to know the core size and type of material in order to determine the number of primary turns as per frequency and primary voltage in order to design it for no saturation of the core.

There many good threads on transformer design in this forum but I don't have a compiled list for them as they can be found very easily using the search function.

Here is the calculator that I think you are looking for and it also shows the formulas as well,

Maximum Flux Density Calculator

There a few more transformer calculators that can be found on this page,

http://www.daycounter.com/SiteMap.phtml

I hope this helps you !!

jer

Last edited:

I think this is not good

This will be 300VA trafo that I'm going to make or maybe not.

I'm just not so confidence is this okay or not

I thing ask some suggestion here is a good way

I just use what I see around he..he... ,

,

latter

I found better "things" to use as

inter layer windings insulation

also found good trafo as a reference

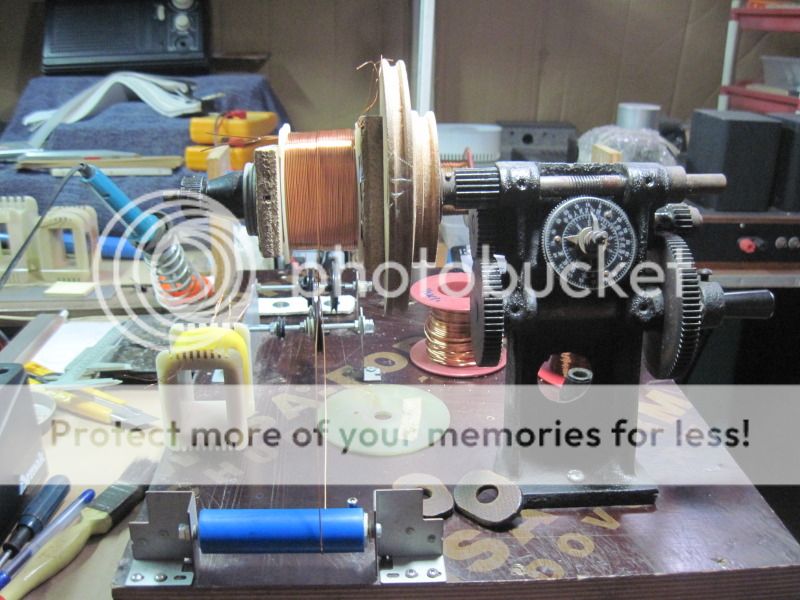

here 2 pictures

what do you think, give it a try or

I must start again with better way?

Any comment greatly appreciated

This will be 300VA trafo that I'm going to make or maybe not.

I'm just not so confidence is this okay or not

I thing ask some suggestion here is a good way

I just use what I see around he..he...

latter

I found better "things" to use as

inter layer windings insulation

also found good trafo as a reference

here 2 pictures

what do you think, give it a try or

I must start again with better way?

Any comment greatly appreciated

Attachments

Tony is right, look at this page: Jan's transformer article p4

Has excellent advices to follow.

Here is a 4-digit counter that I have recently built, code, eagle files, attiny2313.

metal

Has excellent advices to follow.

Here is a 4-digit counter that I have recently built, code, eagle files, attiny2313.

metal

Attachments

Last edited:

this is what i use for mandrels:

An externally hosted image should be here but it was not working when we last tested it.

Thanks for quick reply from Tony & Metal

Very good suggestion & advice

Now I change my mind

I'm planning to make bigger trafo (about 600VA) but after look at

http://www.diyaudio.com/forums/power-supplies/191730-my-latest-traffo-build-28.html

then more question appear in my head

I will make bobbin for this one but the form is rectangle not square as Tony suggest.

Please tell me what the disadvantages with rectangle shape?

I want trafo that not so high that can be fit in the shorter case

Rectangle because I will use :

1 1/4 inch (32mm) center tongue stacked 6.5 inch (16.5mm)

The thickness of the laminated plate is 0.5mm & I will go bellow 1T

The bobbin I will made with "fiber" PCB

Every 1 stack complete winding, brushed with clear insulating enamel

then I have a choice to use paper or plastic for insulating.

The paper is "brown wrapping paper" &

the plastic is that what use as "laminating paper" it is can stand up to 150°C

& I guess its good to be used

but allmost Tony's trafo use paper insulator...

Again please tell me what to use here?

For finishing I'm not dip it into the insulating enamel because the winding is already insulated before & for the laminated plate just do with brush

So I'm on the right track or I must find bigger core size?

Very good suggestion & advice

Now I change my mind

I'm planning to make bigger trafo (about 600VA) but after look at

http://www.diyaudio.com/forums/power-supplies/191730-my-latest-traffo-build-28.html

then more question appear in my head

I will make bobbin for this one but the form is rectangle not square as Tony suggest.

Please tell me what the disadvantages with rectangle shape?

I want trafo that not so high that can be fit in the shorter case

Rectangle because I will use :

1 1/4 inch (32mm) center tongue stacked 6.5 inch (16.5mm)

The thickness of the laminated plate is 0.5mm & I will go bellow 1T

The bobbin I will made with "fiber" PCB

Every 1 stack complete winding, brushed with clear insulating enamel

then I have a choice to use paper or plastic for insulating.

The paper is "brown wrapping paper" &

the plastic is that what use as "laminating paper" it is can stand up to 150°C

& I guess its good to be used

but allmost Tony's trafo use paper insulator...

Again please tell me what to use here?

For finishing I'm not dip it into the insulating enamel because the winding is already insulated before & for the laminated plate just do with brush

So I'm on the right track or I must find bigger core size?

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Power Supplies

- Iron Core Transformer Formula

@Shams, posting in all caps is against forum rules....please do not do it again...

@Shams, posting in all caps is against forum rules....please do not do it again...