i have about 3kgs of copper wire that i took out from your japanese iso traffo,

if you want, i can give them back to you as i do not have any use for those at this time...

Okay if you don't need them just give those to me and i will use them later on sir.

One thing about those aluminum is they can't be soldered so twisting or crimping is needed. I found another toroid power trafo with oxidized connection causing loose contact.

hi sir i have here a 2"CL stack to 3.25" and i am planing to utilize the available materials as of the moment a kilo of #16, 1.2 kg of #14 and 3kg of #18 can i use #14 and #18 copper for secondary to be wound separately but same voltage then have it paralleled. the result that i wanted to have was #16 for primary 1150VA and (55-0-55 8A + 55-0-55 3A) that is 55-0-55 11A? will this be advisable?

thank you very much

thank you very much

hi sir i have here a 2"CL stack to 3.25" and i am planing to utilize the available materials as of the moment a kilo of #16, 1.2 kg of #14 and 3kg of #18 can i use #14 and #18 copper for secondary to be wound separately but same voltage then have it paralleled. the result that i wanted to have was #16 for primary 1150VA and (55-0-55 8A + 55-0-55 3A) that is 55-0-55 11A? will this be advisable?

thank you very much

not a good idea....two strands of #18 is equivalent to a #15 single wire...although #12 could have been accommodated as well...

i built a traffo in the 80's using the same core are yours, i used #16 primary and #13 secondary....

Okay if you don't need them just give those to me and i will use them later on sir.

One thing about those aluminum is they can't be soldered so twisting or crimping is needed. I found another toroid power trafo with oxidized connection causing loose contact.

noted....will text you when i go to Dau...

thank you so much for the reply

i suppose to reply yesterday but unfortunately heavy rain caused us brownout till midnight

i got 1.1kg from my classmate for free.

now i will try some comment from others on last traffo i built suggesting only 1:1.5 core ratio. then 2"CL x 3" and use #17 for primary and #14 secondary 900VA @1.5 t/v for my SR200 stereo.

thanks

Godbless

i suppose to reply yesterday but unfortunately heavy rain caused us brownout till midnight

i got 1.1kg from my classmate for free.

now i will try some comment from others on last traffo i built suggesting only 1:1.5 core ratio. then 2"CL x 3" and use #17 for primary and #14 secondary 900VA @1.5 t/v for my SR200 stereo.

thanks

Godbless

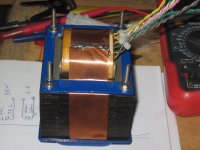

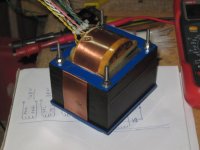

sir tony here's my last built trafo after asked some ideas to you,

i used 1mm pcb's as bobbin accdg to the supplier its fibre made.

also mylar in separating pri and secondary

thanks

regards

i used 1mm pcb's as bobbin accdg to the supplier its fibre made.

also mylar in separating pri and secondary

thanks

regards

Attachments

I just finish repairing a 502 trafo. Found out that aluminyo contacts must be properly twisted or joined due to oxidation.

Sir tony wish u a happy bday! Hope to see u soon. Dami ako nakuha na tube sa baguio. 2boxes of used and brand new from an old tech given free to my brother.

Sir tony wish u a happy bday! Hope to see u soon. Dami ako nakuha na tube sa baguio. 2boxes of used and brand new from an old tech given free to my brother.

sir tony here's my last built trafo after asked some ideas to you,

i used 1mm pcb's as bobbin accdg to the supplier its fibre made.

also mylar in separating pri and secondary

thanks

regards

looks good......

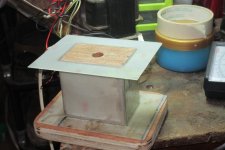

The lams that I asked about

Here are the pics of the lams. I included a pic where I scraped off some of the coating to show the metal underneath.

The thickness is .08mm. My caliper is kind of cruddy, but it's usually fairly close.

Here are the pics of the lams. I included a pic where I scraped off some of the coating to show the metal underneath.

The thickness is .08mm. My caliper is kind of cruddy, but it's usually fairly close.

Attachments

lams

Sorry about that.... I will have to post them one at a time due to the file size limit. I had to reduce the size of them to get them to upload. I've made them about 70 percent of the original size....

Sorry about that.... I will have to post them one at a time due to the file size limit. I had to reduce the size of them to get them to upload. I've made them about 70 percent of the original size....

Attachments

- Home

- Amplifiers

- Power Supplies

- Tony's latest traffo DIY build