Thanks for the advice. I'm really looking for a box for the fe 127 I have so, might be better to look elsewhere from the mk3,

Fran

Fran, if you've not already found another target for the 127s, I'd likely be able to give them a quick try-out in FH3s before Dave - perhaps by the end of this week.

As posted elsewhere, I spent a few hours this past weekend with the 126e the FH3, and was reminded of all the things I love about the Fostex. My wife's father's day present to me was to play in her garden to avoid complaining about the music.

Chrisb,

Are gardens really safe from you? 🙂

it's taken the 2 of us get it this far, and it never ends - but mrs B deserves most of the credit for the gardens - I tend to concentrate on inside the house

after 24 yrs there isn't a square foot inside or out that hasn't been renovated, painted, updated at least twice - some rooms 4 times

Chris, that would be great.......

Fran.

refresh my memory as to type of amp you'd be using them with - I have 4 different flavors of tube amp ( 2A3, EL84 P/P triode and pentode, and EL34 SET) as well as a Denon HT receiver and Trends T-amp available

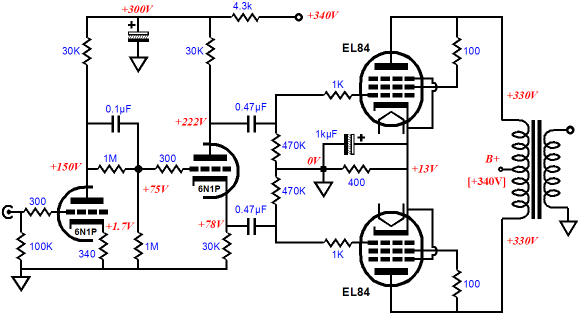

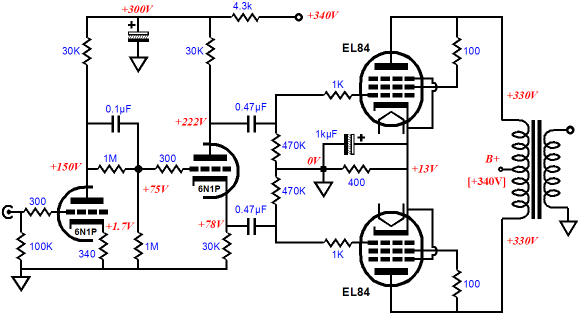

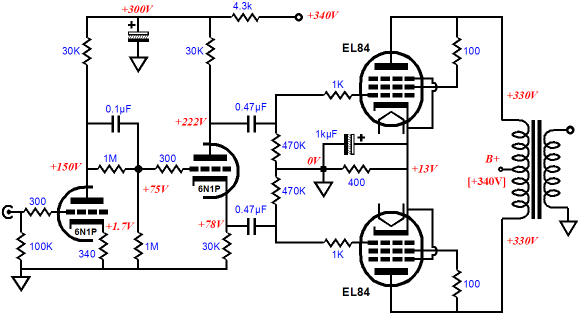

Most likely this one:

tubecad el84 triode PP

And maybe a Pass delite when I get back to doing another bit of work on it....

Fran

tubecad el84 triode PP

And maybe a Pass delite when I get back to doing another bit of work on it....

Fran

Most likely this one:

tubecad el84 triode PP

And maybe a Pass delite when I get back to doing another bit of work on it....

Fran

Same topology as TubeLab SimplePP but wired in triode.

dave

well then, the triode "El Cheapo" variant will probably do for starters

Fran:

a quick update on suitability of FE127 in FH3, including yet another anecdote speaking to the matter of (degrees of) synergy;

yes they'll "work", as with other drivers known or modeled to work in this design, will likely need some fiddling with damping,

today's story:

I have 2 pairs of this enclosure presently on hand - one fully finished and originally fitted with EnAbl'd FE126E, and the other prototype "mules" - with removable mounting plates to test a range of driver candidates.

Unfortunately, one of the FE126s was damaged while removing to swap for FE127s for this test (so it's your fault I was clumsy {smilie here - still not working!} ), so we'll have to rely on my taste memory of the 126e from last week's session.

As to the "synergy" - as it happens the amp that was sitting on the rack was Eddie Vaughn EL34 SET (with Raytheon 5842 drivers and Shuguang Treasure 6CA7 outputs) - by no token a mushy or incoherent amp. So I warmed her up and played for about 10 minutes to confirm that "nice, but something's not quite right" - dynamics / soundstage depth/ bass articulation and weight .

So I dug out the EL84 P/P ( El Cheapo variant - running in class A and acutally less power than the SET) NOS GE 12AT7/ JJ EL84 - much closer to the topology in your post. Simply - put considerably better - so it's not always about the watts, son.

I'm long on record as being a big fan of the FE127, and have certainly been happy with it in a wide range of enclosures over the past 5-6 years, so familiarity could well a factor.

I'll be listening to a couple of other drivers in the mules over the weekend, and will post my impressions.

cheers

a quick update on suitability of FE127 in FH3, including yet another anecdote speaking to the matter of (degrees of) synergy;

yes they'll "work", as with other drivers known or modeled to work in this design, will likely need some fiddling with damping,

today's story:

I have 2 pairs of this enclosure presently on hand - one fully finished and originally fitted with EnAbl'd FE126E, and the other prototype "mules" - with removable mounting plates to test a range of driver candidates.

Unfortunately, one of the FE126s was damaged while removing to swap for FE127s for this test (so it's your fault I was clumsy {smilie here - still not working!} ), so we'll have to rely on my taste memory of the 126e from last week's session.

As to the "synergy" - as it happens the amp that was sitting on the rack was Eddie Vaughn EL34 SET (with Raytheon 5842 drivers and Shuguang Treasure 6CA7 outputs) - by no token a mushy or incoherent amp. So I warmed her up and played for about 10 minutes to confirm that "nice, but something's not quite right" - dynamics / soundstage depth/ bass articulation and weight .

So I dug out the EL84 P/P ( El Cheapo variant - running in class A and acutally less power than the SET) NOS GE 12AT7/ JJ EL84 - much closer to the topology in your post. Simply - put considerably better - so it's not always about the watts, son.

I'm long on record as being a big fan of the FE127, and have certainly been happy with it in a wide range of enclosures over the past 5-6 years, so familiarity could well a factor.

I'll be listening to a couple of other drivers in the mules over the weekend, and will post my impressions.

cheers

I'll be listening to a couple of other drivers in the mules over the weekend, and will post my impressions.

Have you tried the hemp 4.5's yet?

jeff

Have you tried the hemp 4.5's yet?

jeff

nope - Alpair 7 and TB W5-1611 are up next (Sunday afternoon - Saturday night is reserved for cheezie Netflix movies)

How is bass with the 127s?

Many thanks for the testing!!

In the FH3s, more weight ( and maybe extension?), but not the same "speed" / dynamic snap as with 126s, soundstage dimension is smaller in spread and more recessed, but at the same time with along with greater finesse and shading / texture of low level detail.

As noted earlier, I'm probably too familiar with the sound of both drivers in a range of enclosure types. For the present, my suggestion would be the same old "room/system dependent" - hopefully more testing upstairs later Sunday afternoon upstairs.

OK, thanks Chris, that sounds very positive for the 127s. Perhaps another bit of playing with lining might also make a difference.

I think this might well be my next cabinet to try.....

Fran

I think this might well be my next cabinet to try.....

Fran

Hi Dave... would you please send me a pair of the new Alpair 7 with the eNabling added?

Phil

Santa Fe

Phil

Santa Fe

OK, thanks Chris, that sounds very positive for the 127s. Perhaps another bit of playing with lining might also make a difference.

I think this might well be my next cabinet to try.....

Fran

Sunday afternoon now - and had another couple of hours with the 2 pairs of enclosures and rolling some drivers - this time in the much larger upstairs space (LR/DR/kitchen well over 450sq ft and lots of corners, etc.) . The gist of it is that with any driver, I found the FH3 cramped/congested in the small downstairs office / listening cave ( L-shaped 8ft wide x 23 ft long), but they blossom in larger space.

FE127E works quite well, as does Alpair7 and TB W5-1611. I'm fairly familiar with the first 2, but this is my first exposure to the latter - very nice for a Russian tractor .

Alpair7 in F.H. Mk1

I shoved 40 grams of fluff into the cavity behind the driver. I think it was a good guess. Befor the Alpair 7 , the box had a Fostex sigma 108... Poor thing, never did like that box all that much. But the Alpair now that is a different story!

I have not heard a bunch of Alpairs only two, mine and Ramon's. Ramon lives in Santa Fe town only a few miles from me. Ramon installed his 7 in an O.B.! It sounds really good! It has a high enough QTS do do just fine. I have been an OB fan for a number of years and like how they fill up the room. Maybe not the best sound stage but that has become less important to me as I get older.

Cleanliness is how, in a word, I hear the Alpair 7. The eNabled Alpair takes it beyond. The dots let the sound get out of it's own way. It keeps the air molecules from getting stuck on the surface of the cone. Micro turbulation if you will. Aircraft wings use a similar idea to help wings work. Free flight aircraft use turbulators to help keep the airflow attached to the wing at higher angles of attack. It has to do with boundary layer control.

So the question for me is.... would I do this to my Feastrex 5Dnf drivers?

Answer... A year ago... No... Today... YES! I now think all cones should have enAbleing built in when they are made.

So, Dave... Wanna enable a 5Dnf?

I shoved 40 grams of fluff into the cavity behind the driver. I think it was a good guess. Befor the Alpair 7 , the box had a Fostex sigma 108... Poor thing, never did like that box all that much. But the Alpair now that is a different story!

I have not heard a bunch of Alpairs only two, mine and Ramon's. Ramon lives in Santa Fe town only a few miles from me. Ramon installed his 7 in an O.B.! It sounds really good! It has a high enough QTS do do just fine. I have been an OB fan for a number of years and like how they fill up the room. Maybe not the best sound stage but that has become less important to me as I get older.

Cleanliness is how, in a word, I hear the Alpair 7. The eNabled Alpair takes it beyond. The dots let the sound get out of it's own way. It keeps the air molecules from getting stuck on the surface of the cone. Micro turbulation if you will. Aircraft wings use a similar idea to help wings work. Free flight aircraft use turbulators to help keep the airflow attached to the wing at higher angles of attack. It has to do with boundary layer control.

So the question for me is.... would I do this to my Feastrex 5Dnf drivers?

Answer... A year ago... No... Today... YES! I now think all cones should have enAbleing built in when they are made.

So, Dave... Wanna enable a 5Dnf?

- Home

- More Vendors...

- Planet 10 hifi

- Frugel-Horn Mk3 flat-paks