..impressions..

.. v-bro thanks for the info links

though i'm a bit unfortunate with my net access as i use the firms internet wich is very "restricted due to company policy" (#@^$*).

..so this weekend was dedicated to listening to the stereo couple perform ...

..ofcource i could not find the same electronics to match so i tried to match the output and i think i came quite close..

the other device uses higher polarization voltage and less step-up ratio using 4 iron trafos 110-9v wired the usual way.

disspite the differenses in graph coating, membrane tension and some hv losses (1st panel discharges rappidly when hv turned of)

due to wood conductivity and invisible leftover graphite (2nd panel was constructed with more carrefull and cleaner graph application) i was able to get a good stereo image and enjoy weekend.

i interchanged panels and electronics to hear what did what.

i got the impresion that toroids have a bit deeper bass and the highs are a bit less than the iron trafos who give more live highs..

irons tend to distort less at volume end.. maybe due to more core

mass .?. i will soon try to add another pair to make 3x110v output out of 6 total trafos and maybe gain some more efficiency to begin with..

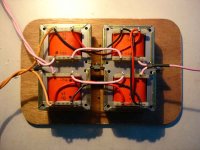

..here u can see the transformers 4pack used..

.. v-bro thanks for the info links

though i'm a bit unfortunate with my net access as i use the firms internet wich is very "restricted due to company policy" (#@^$*).

..so this weekend was dedicated to listening to the stereo couple perform ...

..ofcource i could not find the same electronics to match so i tried to match the output and i think i came quite close..

the other device uses higher polarization voltage and less step-up ratio using 4 iron trafos 110-9v wired the usual way.

disspite the differenses in graph coating, membrane tension and some hv losses (1st panel discharges rappidly when hv turned of)

due to wood conductivity and invisible leftover graphite (2nd panel was constructed with more carrefull and cleaner graph application) i was able to get a good stereo image and enjoy weekend.

i interchanged panels and electronics to hear what did what.

i got the impresion that toroids have a bit deeper bass and the highs are a bit less than the iron trafos who give more live highs..

irons tend to distort less at volume end.. maybe due to more core

mass .?. i will soon try to add another pair to make 3x110v output out of 6 total trafos and maybe gain some more efficiency to begin with..

..here u can see the transformers 4pack used..

Attachments

now lets speculate..

... each panel when taped like a drum sounds very different because of different film used.. they were heat treated for tension and each film got its specific tension ..

..1st one sounds (drums) to high and that note is realy heard in the music content.. thats the only irritating thing with 1st panel.. i must refilm this one..it does this more with the toroids.

..2nd panel drums a low note near some 40hz and gives the impression of deeper bass highlighting a region were most bass is gone... i guess something like ported woofer with its port tuned to a frequensy.. but not exactly.

..mind that these are impressions not measurements so lots of other things may be going on.

the thing in the circle is a diy air ionizer for hv

an elecricians screwdriver with neon lamp is used to find hot-voltage spots and probable leak paths..

... each panel when taped like a drum sounds very different because of different film used.. they were heat treated for tension and each film got its specific tension ..

..1st one sounds (drums) to high and that note is realy heard in the music content.. thats the only irritating thing with 1st panel.. i must refilm this one..it does this more with the toroids.

..2nd panel drums a low note near some 40hz and gives the impression of deeper bass highlighting a region were most bass is gone... i guess something like ported woofer with its port tuned to a frequensy.. but not exactly.

..mind that these are impressions not measurements so lots of other things may be going on.

the thing in the circle is a diy air ionizer for hv

an elecricians screwdriver with neon lamp is used to find hot-voltage spots and probable leak paths..

Attachments

ah.. someome may have noticed the way the 4pack is bolted together.. i tell you when i tried them upright my amp made horrible screaming sound and went into protection.. a 12v lamp in series litup full power at idle.. i guess serius amp oscilations..

..i have to admit that i put them like this from the very first try with the thought of shearing magnetic fields and acting more like a single core tranny and i did get music ..then drawing some scetches shows they should be on top of each other(not tested yet) instead of bottom to bottom..i guess this way the magnetic fields repel each other and get confined in the iron path of each tranny ..anyways this way they sound very nice.. more guessing will be done as soon as i experiment with tranny topology ..

..i have to admit that i put them like this from the very first try with the thought of shearing magnetic fields and acting more like a single core tranny and i did get music ..then drawing some scetches shows they should be on top of each other(not tested yet) instead of bottom to bottom..i guess this way the magnetic fields repel each other and get confined in the iron path of each tranny ..anyways this way they sound very nice.. more guessing will be done as soon as i experiment with tranny topology ..

Attachments

Making two slightly different to test is a good idea, but if you need trannys to make two the same and want low cost look at this:

http://www.diyaudio.com/forums/showthread.php?s=&threadid=88032

I think they should be on top of eachother indeed when they should act more as "one".

I read on the Dutch esl-club site that graphite is not very advised for diy-use. They say it loses conductivity after a while due to particles that come loose from the membrane. Another down-side to this effect would be that the cluttered graphite can cause leaking voltages at the corners.

They advise to diy with "green soap" or "methylcellulose".

Here's some translations from the http://www.esl.hifi.nl site:

Membranes:

PE/PP (polyethylene/polypropene, shrinks w. heat):

-thickness: from 10uM (0.01mM) and up.

-to weak for ESL.

PTFE (teflon):

-thickness: from 10uM (0.01mM) and up.

-expensive.

-to weak for ESL.

Kapton (also used for ribbons):

-thickness: 25 to 50 uM

-expensive.

-hardly available.

PA (polyacetate, also used as a wrap for flowers)

-strong, but to thick.

-tares quickly under high tension.

-sensitive to uv and air, not durable.

Polyesther ("mylar"):

-thickness from 1 uM (0.001mM) to 50uM.

-most durable.

-for ESL usage thickness between 4 and 18 uM advised.

The author uses ICI polyesther film under the brandname "Melinex"(GB), 12uM thickness. I E-mailed the author to ask if I may post his adress for others to order (he says he has enough to make

about 1500 fullrange ESLs, but he said this in 2001...).

Awaiting his reply........

Coatings:

1:Graphite:

-10Kohms up to several hundreds of Kohms.

-dangerous, because it glows and can cause membranes to burn.

-not easy to get equally spread resistance.

-most of the times not durable.

-corona effects.

-messy to work with.

-any stain can cause voltage-leaks or even shorts.

2:Green soap:

-several hundred Mohms to Gohms.

-easy to apply by a brush.

-reliable, though dust can stick to the surface.

3:Methylcellulose (wallpaperglue):

-several hundreds of Kohms till infinity.

-only reported being reliable.

4:Exotic types like:

-hairgel, brand unknown...

-ceramic powders like SiC (siliciumcarbide), ferro (III) oxide, iridiumoxide, indiumoxide. Often mixed with graphite.

-water containing salts.

The author doesn't have much experience with these exotic types of coatings....

http://www.diyaudio.com/forums/showthread.php?s=&threadid=88032

I think they should be on top of eachother indeed when they should act more as "one".

I read on the Dutch esl-club site that graphite is not very advised for diy-use. They say it loses conductivity after a while due to particles that come loose from the membrane. Another down-side to this effect would be that the cluttered graphite can cause leaking voltages at the corners.

They advise to diy with "green soap" or "methylcellulose".

Here's some translations from the http://www.esl.hifi.nl site:

Membranes:

PE/PP (polyethylene/polypropene, shrinks w. heat):

-thickness: from 10uM (0.01mM) and up.

-to weak for ESL.

PTFE (teflon):

-thickness: from 10uM (0.01mM) and up.

-expensive.

-to weak for ESL.

Kapton (also used for ribbons):

-thickness: 25 to 50 uM

-expensive.

-hardly available.

PA (polyacetate, also used as a wrap for flowers)

-strong, but to thick.

-tares quickly under high tension.

-sensitive to uv and air, not durable.

Polyesther ("mylar"):

-thickness from 1 uM (0.001mM) to 50uM.

-most durable.

-for ESL usage thickness between 4 and 18 uM advised.

The author uses ICI polyesther film under the brandname "Melinex"(GB), 12uM thickness. I E-mailed the author to ask if I may post his adress for others to order (he says he has enough to make

about 1500 fullrange ESLs, but he said this in 2001...).

Awaiting his reply........

Coatings:

1:Graphite:

-10Kohms up to several hundreds of Kohms.

-dangerous, because it glows and can cause membranes to burn.

-not easy to get equally spread resistance.

-most of the times not durable.

-corona effects.

-messy to work with.

-any stain can cause voltage-leaks or even shorts.

2:Green soap:

-several hundred Mohms to Gohms.

-easy to apply by a brush.

-reliable, though dust can stick to the surface.

3:Methylcellulose (wallpaperglue):

-several hundreds of Kohms till infinity.

-only reported being reliable.

4:Exotic types like:

-hairgel, brand unknown...

-ceramic powders like SiC (siliciumcarbide), ferro (III) oxide, iridiumoxide, indiumoxide. Often mixed with graphite.

-water containing salts.

The author doesn't have much experience with these exotic types of coatings....

... wonderfull info v-bro ..thanks again

the duch site is absolutely right about graphite... thats exactly the problems i'm experiensing with it... (only i'll have to get to the site from some net-caffe place )

)

regardless of how hard you rub it or wash it away some particles will brake free and scatter around the frame eventualy forming

leakage paths..

..when i had the hissing effect due to exess graph i blowed it away with compressed air and had the hissing minimized..

i discovered a can of "plastik 70" at work and i will try a graphed membrane masked and sprayed with that stuff to see if it can hold the graphite in place..isolate it.. and make music.

..i think i will buy me that roll of 1500m 12ì 12"wide packaging film wich i kind of remember it said it was "polyester" wich is the right stuff for esl's ...and worked for me successfully ... they sell it for about 27 euros ..and will last for a lifetime of experimenting and building. .

..for today i'll try the 6pack setup and listen carrefully

the duch site is absolutely right about graphite... thats exactly the problems i'm experiensing with it... (only i'll have to get to the site from some net-caffe place

)

)regardless of how hard you rub it or wash it away some particles will brake free and scatter around the frame eventualy forming

leakage paths..

..when i had the hissing effect due to exess graph i blowed it away with compressed air and had the hissing minimized..

i discovered a can of "plastik 70" at work and i will try a graphed membrane masked and sprayed with that stuff to see if it can hold the graphite in place..isolate it.. and make music.

..i think i will buy me that roll of 1500m 12ì 12"wide packaging film wich i kind of remember it said it was "polyester" wich is the right stuff for esl's ...and worked for me successfully ... they sell it for about 27 euros ..and will last for a lifetime of experimenting and building. .

..for today i'll try the 6pack setup and listen carrefully

Attachments

... hm.

...well .. 6packs, 8packs etc are not recomended with cheap trannys .. their insulation isn't enough

.mine dispite being higher quality than usual with a thick paper layer between pri & sec , the final pair made hissing noise at volume end and i think i heard music come out of it.. but would not dear get my ear closer. . the output was fuzzier . a more sharp distortion at v-end also. .

..this time i used only one hv bias cirquit wich took of sensitivity from other speaker,, bias was not equal in both panels, dont know how much but evident with neon screwdriver, maybe due to hv-cable distance from hv source to panel + different losses.

..overall outcome could be judged as less in quality and safety.. i think i will settle with toroids 2pack but will try a 6v->220v 4pack cheap irons for additional experience..

..there is the possibility that panel materials do not allow higher operating voltages and losses become biger than output gain..

...well .. 6packs, 8packs etc are not recomended with cheap trannys .. their insulation isn't enough

.mine dispite being higher quality than usual with a thick paper layer between pri & sec , the final pair made hissing noise at volume end and i think i heard music come out of it.. but would not dear get my ear closer. . the output was fuzzier . a more sharp distortion at v-end also. .

..this time i used only one hv bias cirquit wich took of sensitivity from other speaker,, bias was not equal in both panels, dont know how much but evident with neon screwdriver, maybe due to hv-cable distance from hv source to panel + different losses.

..overall outcome could be judged as less in quality and safety.. i think i will settle with toroids 2pack but will try a 6v->220v 4pack cheap irons for additional experience..

..there is the possibility that panel materials do not allow higher operating voltages and losses become biger than output gain..

Attachments

I_Forgot said:Licron seems to work. It provides high enough resistance for low distortion at low frequencies and seems to be permanent. I've only got about a year on it so far but others have reported much longer times.

I_F

The licron does look good on paper. I was shocked at the $55 pricetag.

How much coverage do you get out of a 10 oz can? Do you have a feel for how much mass the stuff adds to the mylar? Is the resin carrier pretty thin? It would be a shame to use 3.8 uM film then load it up with 8 uM of coating.

I've been using Dupont Zelec thinned down to get a fairly high surface resistivity, but DuPont no longer makes the stuff.

Also what is green soap? (the only green soap I know of is palmolive dish soap, and irish spring bath soap), neither strikes me as a particularly good or permanent polyester coating.

Sheldon

I have only preliminary results from Licron so far, but my impression is that a fairly heavy coating is necessary to ensure uniform conductivity. Perhaps my meter isn't sensitive enough to detect the conductivity when really thin coatings are applied. I've been trying to apply just enough to make the conductivity detectable with my old digital multimeter. I think its maximum resistance reading is 10 MOhms; I may have a meter that can go higher than that so I'll have to check that out. In any case, when I sprayed enough Licron on ~4 micron thick mylar so that I could measure the resistance between probes placed about an inch apart, the result felt like significant mass has been added to the diaphragm. The very limp almost-not-there feeling of the mylar was gone.

The coating is also a bit ugly, if that's a concern. It leaves a blotchy almost opaque white cloudiness that might look okay if it could be applied uniformly, but I haven't found a way to accomplish that yet. I haven't entirely given up on it, but it's certainly not a "just spray it on and you get ideal results" sort of situation. Has anyone else found a better way to apply Licron?

Few

The coating is also a bit ugly, if that's a concern. It leaves a blotchy almost opaque white cloudiness that might look okay if it could be applied uniformly, but I haven't found a way to accomplish that yet. I haven't entirely given up on it, but it's certainly not a "just spray it on and you get ideal results" sort of situation. Has anyone else found a better way to apply Licron?

Few

I don't know what the name for green soap is in English, but this is where you can get it:

http://www.orangepackage.com/spiceupyourday/q100.htm

And this is what it looks like...

http://www.orangepackage.com/spiceupyourday/q100.htm

And this is what it looks like...

Attachments

Few said:I have only preliminary results from Licron so far, but my impression is that a fairly heavy coating is necessary to ensure uniform conductivity.

One of the problems of Licron might be the relatively large sized particles which makes it unpossible to get a really thin layer with uniform resistance (the latter being quite low for operation in full range esls. For most antistatic applications a layer of say 10 micron is acceptable, but in esls..... judge yourself.

You're not the first person who has encountered this problem (see comments on the audiocircuit)

Best regards,

How heavy would "graphite 33" (with 50% thinner) and a layer of "plastic 70" (also adulterated?) be?

On the site they mention aluminum coated mylar can be etched to desired resistance... only it would burn round the connections to the membrane after a while...

Another site mentions the use of hobby-glue (adulterated, sprayed on)...

Most links say the thinner membranes sound to harsh, thickness is desired above 10uM...

And you can somehow trim HV-supply transformer with a potentiometer (voltage devider)...

I'll get back on other tweaks and info as soon as I have more time...

On the site they mention aluminum coated mylar can be etched to desired resistance... only it would burn round the connections to the membrane after a while...

Another site mentions the use of hobby-glue (adulterated, sprayed on)...

Most links say the thinner membranes sound to harsh, thickness is desired above 10uM...

And you can somehow trim HV-supply transformer with a potentiometer (voltage devider)...

I'll get back on other tweaks and info as soon as I have more time...

QUOTE****On the site they mention aluminum coated mylar can be etched to desired resistance... only it would burn round the connections to the membrane after a while...

Another site mentions the use of hobby-glue (adulterated, sprayed on)...

Most links say the thinner membranes sound to harsh, thickness is desired above 10uM...

QUOTE****

Hi,

Etching the aluminium removes it completely. There is no way to control the resistance in that way. Besides this there are some other disadvantages of etching the Mylar, out of scope here.

Thinner sheets of Mylar will improve high frequency reproduction and detail. They won't sound harsh unless the ESL is designed to work with a very thick membrane only (never seen or heard of this)

Replacing ESLs with thinner membranes is performed by some commercial guys as a sound improving tweak. In most applications, the 6 micron tensilized Mylar (R) ( or even 4 micron!) is strong enough. No need to use the 12 micron package wrap.

You can put some plastik spray on the Mylar to cover the graphite, but the adhesion of the plastik spray will be heavily compromised. It is difficult to predict the added mass. It is possible to measure though. My EC-coating measures around 10 mg/100cm2 which is a nice value.

There are different recipes around of coatings you can make yourself. For example mixtures of methylcellulose and sodiumlaurylsulphate or soap, hobby glue in ethanol. They all are hygroscopic compounds, their performance will vary with humidity as a consequence. There can be other problems like biodegradation, migration effects, contact erosion of metals etc. Whether these problems are relevant to you depends on your needs.

The EC-coating has been used for more than 3 years in more than 100 ESLs around the world. No failures so far. It is specially designed for the use in ESLs.

Another site mentions the use of hobby-glue (adulterated, sprayed on)...

Most links say the thinner membranes sound to harsh, thickness is desired above 10uM...

QUOTE****

Hi,

Etching the aluminium removes it completely. There is no way to control the resistance in that way. Besides this there are some other disadvantages of etching the Mylar, out of scope here.

Thinner sheets of Mylar will improve high frequency reproduction and detail. They won't sound harsh unless the ESL is designed to work with a very thick membrane only (never seen or heard of this)

Replacing ESLs with thinner membranes is performed by some commercial guys as a sound improving tweak. In most applications, the 6 micron tensilized Mylar (R) ( or even 4 micron!) is strong enough. No need to use the 12 micron package wrap.

You can put some plastik spray on the Mylar to cover the graphite, but the adhesion of the plastik spray will be heavily compromised. It is difficult to predict the added mass. It is possible to measure though. My EC-coating measures around 10 mg/100cm2 which is a nice value.

There are different recipes around of coatings you can make yourself. For example mixtures of methylcellulose and sodiumlaurylsulphate or soap, hobby glue in ethanol. They all are hygroscopic compounds, their performance will vary with humidity as a consequence. There can be other problems like biodegradation, migration effects, contact erosion of metals etc. Whether these problems are relevant to you depends on your needs.

The EC-coating has been used for more than 3 years in more than 100 ESLs around the world. No failures so far. It is specially designed for the use in ESLs.

My email: mj-dijkstra@zonnet.nl

I will try to send you a mail first.

Best regards, Martin-Jan Dijkstra

I will try to send you a mail first.

Best regards, Martin-Jan Dijkstra

MJ Dijkstra said:

Hi,

Etching the aluminium removes it completely. There is no way to control the resistance in that way. Besides this there are some other disadvantages of etching the Mylar, out of scope here.

Thinner sheets of Mylar will improve high frequency reproduction and detail. They won't sound harsh unless the ESL is designed to work with a very thick membrane only (never seen or heard of this)

Replacing ESLs with thinner membranes is performed by some commercial guys as a sound improving tweak. In most applications, the 6 micron tensilized Mylar (R) ( or even 4 micron!) is strong enough. No need to use the 12 micron package wrap.

You can put some plastik spray on the Mylar to cover the graphite, but the adhesion of the plastik spray will be heavily compromised. It is difficult to predict the added mass. It is possible to measure though. My EC-coating measures around 10 mg/100cm2 which is a nice value.

There are different recipes around of coatings you can make yourself. For example mixtures of methylcellulose and sodiumlaurylsulphate or soap, hobby glue in ethanol. They all are hygroscopic compounds, their performance will vary with humidity as a consequence. There can be other problems like biodegradation, migration effects, contact erosion of metals etc. Whether these problems are relevant to you depends on your needs.

The EC-coating has been used for more than 3 years in more than 100 ESLs around the world. No failures so far. It is specially designed for the use in ESLs.

I've etched my share of circuit boards, and I can vouch for the fact that the etching process is not uniform, and in this case would be super hard to stop at the right instance when the surface resistivity is high, but still continuous. You’d have better luck building your own vacuum sputtering system.

All the casual recipes I’ve read about have real issues with longevity uniformity and adhesion. Soap and wallpaper paste are hardly ideal for the job. There are a lot of conductive coatings out there for making and treating packaging to b static dissipative, it shouldn’t be too hard to select or adapt one of those for ESL use.

Your EC coating sounds useful, do you sell it?

I know ER audio sells two different flavors of coatings as well.

Sheldon

I think the http://www.esl.hifi.nl (or google on: "esl club") site is loaded with good-and bad information. The information consists mostly out of (expert-and amateur) reported experience. I noticed two remarks that go straight against eachother..

Much like on forums you have to filter the information by yourself.

Was the book by E.Fikier ever published in English language? (maybe you know Martin-Jan).

Or is the info available on the net somewhere by now?

Much like on forums you have to filter the information by yourself.

Was the book by E.Fikier ever published in English language? (maybe you know Martin-Jan).

Or is the info available on the net somewhere by now?

To Sheldon:

Yes, I do sell the EC-coating. It costs 20 euro per bottle (=100 gram = +/- 100 ml). The coating fluid must be stored in a refrigerator and has to be used within a period of around 5 months (exact expiration date is printed on the bottle). More information is at the audiocircuit or will be send on request.

To V-bro;

The text of the book (in dutch only) is somewhere on the web (with permission of the author, the book is not for sale anymore). I thought it is in the archive of the ESL-forum.

The book gives some basic information and there are 3 projects described. The book was published 13 years ago and in the meanwhile constructionmethods have been improved so I can recommend to take a look at the projects described on the clubsite.

Unfortunately there are some small mistakes in the book (projects). The information about how to segment electrically and how to put the wires around the nails show wrong pictures which can lead to construction faults.

Kind regards, Martinjan Dijkstra

Yes, I do sell the EC-coating. It costs 20 euro per bottle (=100 gram = +/- 100 ml). The coating fluid must be stored in a refrigerator and has to be used within a period of around 5 months (exact expiration date is printed on the bottle). More information is at the audiocircuit or will be send on request.

To V-bro;

The text of the book (in dutch only) is somewhere on the web (with permission of the author, the book is not for sale anymore). I thought it is in the archive of the ESL-forum.

The book gives some basic information and there are 3 projects described. The book was published 13 years ago and in the meanwhile constructionmethods have been improved so I can recommend to take a look at the projects described on the clubsite.

Unfortunately there are some small mistakes in the book (projects). The information about how to segment electrically and how to put the wires around the nails show wrong pictures which can lead to construction faults.

Kind regards, Martinjan Dijkstra

MJ, I guess you've received my mail in the meanwhile? Please let me know if and where I can pick up a bottle.

Though one thing I have to get first is the membrane...

Would you know any links to those good diy info or projects MJ?

Don't bother if you don't have the time, but thank you in advance.

Though one thing I have to get first is the membrane...

Would you know any links to those good diy info or projects MJ?

Don't bother if you don't have the time, but thank you in advance.

Hi,

Didn't receive any mail yet. Better try directly?

It's : mj-dijkstra@zonnet.nl

You may also take the the phone: 030-2898893 or 06-13053454

Best regards, MartinJan

Didn't receive any mail yet. Better try directly?

It's : mj-dijkstra@zonnet.nl

You may also take the the phone: 030-2898893 or 06-13053454

Best regards, MartinJan

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- ..didn't know how they sound till i made me one..