Hello all,

here are two pictures of my wide range ribbons. The ribbons are 70mm wide and made of 11um thick aluminium kitchen foil. Backing film is clear packing tape, because it happened to be thinner than 1mil Kapton tape.

Amplification is done by diy direct drive class A SE Mosfet amps and MiniDSP.

The question is about aluminium ribbon damping.

My limited experience is that pure aluminum has a lot of resonances and the best way to damp the resonances is to use plastic backing material and to divide the ribbon to narrow vertical slices.

However there are still annoying resonances in the upper midrange.

Based on internet info I have understood that Apogee Full Range speakers had 50mm wide pure aluminium midrange ribbons with about 15um foil thickness and without any Kapton backing? How did they manage to succeed with pure aluminium without severe resonances?

Is ordinary kitchen foil totally wrong alloy to be used in a ribbon transducer or should I try to treat it somehow e.g. annealing?

BR,

Hannu

here are two pictures of my wide range ribbons. The ribbons are 70mm wide and made of 11um thick aluminium kitchen foil. Backing film is clear packing tape, because it happened to be thinner than 1mil Kapton tape.

Amplification is done by diy direct drive class A SE Mosfet amps and MiniDSP.

The question is about aluminium ribbon damping.

My limited experience is that pure aluminum has a lot of resonances and the best way to damp the resonances is to use plastic backing material and to divide the ribbon to narrow vertical slices.

However there are still annoying resonances in the upper midrange.

Based on internet info I have understood that Apogee Full Range speakers had 50mm wide pure aluminium midrange ribbons with about 15um foil thickness and without any Kapton backing? How did they manage to succeed with pure aluminium without severe resonances?

Is ordinary kitchen foil totally wrong alloy to be used in a ribbon transducer or should I try to treat it somehow e.g. annealing?

BR,

Hannu

Attachments

you might experiment with embossed bumps on your foil rather than folding the foil. you can make the bumps any size you like. You will need a sheet of perforated metal or plastic with the hole size and pattern you want for the foil. rubbing the foil over the perforated surface will generate bumps in the foil. Best regards Moray James.

Thanks for your reply Moray James.

Here are some samples of different style corrugations I have tried. Almost all are pure aluminium without any backing material.

The diamond pattern is closest to your suggestion of embossed bumps.

Maybe I should try diamond pattern with plastic film backing.

And yes, all the different corrugations sound different from each other.

Here are some samples of different style corrugations I have tried. Almost all are pure aluminium without any backing material.

The diamond pattern is closest to your suggestion of embossed bumps.

Maybe I should try diamond pattern with plastic film backing.

And yes, all the different corrugations sound different from each other.

Attachments

I received a question about more detailed construction info.

So here are a couple more pictures.

The ribbon frame is made of 30mm square steel tube. Some horizontal structural braces are welded behind the frame.

The bottom baseplate is screwed to steel frame (steel tubes have welded nuts inside).

Neodymium magnets are 50mm x 25mm x 3mm. Magnets don't need any glue to hold in place.

Ribbon frame height is of course from floor to ceiling.

So here are a couple more pictures.

The ribbon frame is made of 30mm square steel tube. Some horizontal structural braces are welded behind the frame.

The bottom baseplate is screwed to steel frame (steel tubes have welded nuts inside).

Neodymium magnets are 50mm x 25mm x 3mm. Magnets don't need any glue to hold in place.

Ribbon frame height is of course from floor to ceiling.

Attachments

Any chance you could create a "Making a Ribbon Loudpseaker for Dummies" tutorial?

I have enthusiasm but, better, a friend with a factory that can makes lots of things.

He has tools, CNC devices, space, etc.

What we need is cookbook instructions/suggestions/etc/description of parts to buy (that are available)

Regards

I have enthusiasm but, better, a friend with a factory that can makes lots of things.

He has tools, CNC devices, space, etc.

What we need is cookbook instructions/suggestions/etc/description of parts to buy (that are available)

Regards

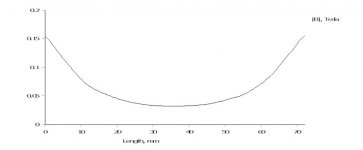

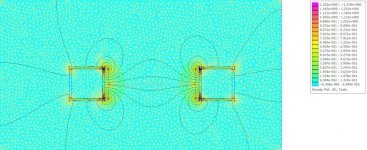

I guess I should point out that my ribbons are pushing the limits of ribbon design. 70mm wide ribbon combined with reasonably priced neodymium magnets leads to low efficiency due to low magnetic flux density.

I have attached couple FEMM modelling pictures to show the low flux.

This doesn't matter in my active system with my listening levels.

Ribbon high pass filter is LR4 at 140Hz.

A more standard wide range ribbon design would be 50mm wide ribbon with 200Hz LR4 high pass filter. It has higher efficiency if built with the same magnets I'm using. (My previous ribbons were like that.)

And for anyone reading this thread, please feel free to criticize my opinions. I'm no expert in this area and I would love to learn more.

I have attached couple FEMM modelling pictures to show the low flux.

This doesn't matter in my active system with my listening levels.

Ribbon high pass filter is LR4 at 140Hz.

A more standard wide range ribbon design would be 50mm wide ribbon with 200Hz LR4 high pass filter. It has higher efficiency if built with the same magnets I'm using. (My previous ribbons were like that.)

And for anyone reading this thread, please feel free to criticize my opinions. I'm no expert in this area and I would love to learn more.

Attachments

pink noise playback at low level will reveal any problem with ribbon resonances (use high pass filter for small and medium sized ribbons) ... even flat ribbons/magnetostatics are sometimes not free from this kind of distortion , a rattling sound , very easy to hear with pink noise

not if there is ANY kind of flat foil driver out there that can do pink noise (smaller bandwith like 1/3octave does not help) without distortion artifacts

by playing music most of this artifacts are masked if the transducer is well constructed

I think a precisely corrugated 1-strip ribbon (your ribbons are too much warped, locally and globally) of 20mm width in a homogenous field will not produce hearable distortions with pink noise applied , but the mechanical suspension at both ends can play a major role here

on the net you will find several sources for downloading of pink noise as a test signal , just make sure you get WAV file format

good luck

not if there is ANY kind of flat foil driver out there that can do pink noise (smaller bandwith like 1/3octave does not help) without distortion artifacts

by playing music most of this artifacts are masked if the transducer is well constructed

I think a precisely corrugated 1-strip ribbon (your ribbons are too much warped, locally and globally) of 20mm width in a homogenous field will not produce hearable distortions with pink noise applied , but the mechanical suspension at both ends can play a major role here

on the net you will find several sources for downloading of pink noise as a test signal , just make sure you get WAV file format

good luck

go here an look at what Apogee did with there ribbons...it a brace page 4...goodluck

http://www.apogeespeakers.com/manuals/stage_midtweeter_replacement.pdf

http://www.apogeespeakers.com/manuals/stage_midtweeter_replacement.pdf

Thanks Marveloudio for pointing out the pink noise test. I will definitely do that.

You also pointed out that precisely corrugated 1-strip ribbon shold be the way to go. I would love to learn how to succeed with that for the simple reason that 1-strip pure aluminium ribbon is easier to diy than multitrack Kapton backed ribbon.

Thanks Tyu for the Apogee ribbon replacement link. That instruction has two interesting details:

1: Correct ribbon tension

2. The use of a glued flexible plastic ribbon support close to center of the ribbon length

I would like to hear comments how much these two details affect to ribbon resonances?

Or are they there just to protect the ribbon from over excursion and prevent low frequency flutter that sometimes occurs when using low order HP crossover slopes?

You also pointed out that precisely corrugated 1-strip ribbon shold be the way to go. I would love to learn how to succeed with that for the simple reason that 1-strip pure aluminium ribbon is easier to diy than multitrack Kapton backed ribbon.

Thanks Tyu for the Apogee ribbon replacement link. That instruction has two interesting details:

1: Correct ribbon tension

2. The use of a glued flexible plastic ribbon support close to center of the ribbon length

I would like to hear comments how much these two details affect to ribbon resonances?

Or are they there just to protect the ribbon from over excursion and prevent low frequency flutter that sometimes occurs when using low order HP crossover slopes?

You might find the following of interest.

US5243150

EP0404488

US4473723

rgds

James

US5243150

A ribbon transducer has the ends of its ribbon held by end fixings which incorporate damping member. The end fixing may include a resilient support member fixed to the ribbon, with the ribbon overlying a pad of damping material and having its outer end held clamped, or alternatively left free.

EP0404488

A ribbon transducer has its ribbon (10) which is held at each end made capable of lateral movement for adjustment purposes by providing a plurality of traverse cross-suspension elements (12) to which the ribbon is secured, with each of these cross-suspension elements being capable of transverse displacement, for example by rotation of mounting pillars (14a, 14b).

US4473723

A specially designed ribbon for a ribbon loudspeaker is disclosed which prevents ribbon snaking associated with prior art corregated ribbon. The elimination of snaking enables the use of extremely small gaps between the side edges of the ribbon and the magnetic pole pieces which in turn greatly reduce transient distortion of high fidelity sound. Relatively large amplitude corregations are formed within suspended terminal ribbon portions and substantially smaller amplitude corregations are formed within the suspended centralized ribbon portion.

rgds

James

Thanks Tvi for the links.One of the patents is about ribbon end damping.

This picture shows Apogee Full Range midrange ribbon end clamping:

http://i818.photobucket.com/albums/zz101/sap_bucket/Apogee Fullrange/Apogee_FullRange_Fig5.jpg

The ribbon end clamping doesn't have any special damping. To me it sounds like it should be possible to make a good ribbon without any special ribbon end damping.

However this picture shows, if I see correctly, several foam pads along the length of the ribbon:

http://i818.photobucket.com/albums/zz101/sap_bucket/Apogee Fullrange/Apogee_FullRange_Fig3.jpg

Does anyone have a better picture of those foam pads?

Or perhaps comments about them?

This picture shows Apogee Full Range midrange ribbon end clamping:

http://i818.photobucket.com/albums/zz101/sap_bucket/Apogee Fullrange/Apogee_FullRange_Fig5.jpg

The ribbon end clamping doesn't have any special damping. To me it sounds like it should be possible to make a good ribbon without any special ribbon end damping.

However this picture shows, if I see correctly, several foam pads along the length of the ribbon:

http://i818.photobucket.com/albums/zz101/sap_bucket/Apogee Fullrange/Apogee_FullRange_Fig3.jpg

Does anyone have a better picture of those foam pads?

Or perhaps comments about them?

Last night I took Marveloudio advice and did pink noise testing. The ribbon under test was pure aluminium ribbon without plastic backing and with corrugation style closest to Apogee Full Range and Scintilla corrugation pictures found from the web.

The extra noise caused by ribbon resonances was very easy to hear. In my case it was a bit like wind blowing into metallic pipe.

I started by adding foam pads here and there along the length or ribbon, but their effect was marginal. I even tried foam pads glued with silicone to the ribbon, but no help.

Then I tested increasing ribbon tension. Increasing tension decreased noise frequency and also decreased noise amplitude. The end result was a bit more pleasant sound than with my plastic backed multitrack ribbon. Before adding the tension the fine pitch corrugation pure aluminium ribbon was my worst sounding ribbon.

What a learning experience!

The extra noise caused by ribbon resonances was very easy to hear. In my case it was a bit like wind blowing into metallic pipe.

I started by adding foam pads here and there along the length or ribbon, but their effect was marginal. I even tried foam pads glued with silicone to the ribbon, but no help.

Then I tested increasing ribbon tension. Increasing tension decreased noise frequency and also decreased noise amplitude. The end result was a bit more pleasant sound than with my plastic backed multitrack ribbon. Before adding the tension the fine pitch corrugation pure aluminium ribbon was my worst sounding ribbon.

What a learning experience!

Hi Hanski. A few of the electrostatic threads spoke of using a felt sheet suspended immediately behind the speaker to damp resonances. I think in some cases, it was glued to the rear stator. I know there is no rear stator here but perhaps carefully chosen material might offer some damping if attached to the frame?

Your ribbon is too wide , better to break up into two ribbon drive units using the same 4 elements . The resonances you guys are suffering from is because you are corrugating the full length , corrugating is ok If you plan to run for bass or frequency below 1k , flat ribbon with Mylar backing will have less Resonance issues , corrugating the ends only for suspension and household foil has no memory doesn't do well in retaining tension ..

Thanks guys for the responses,

I know I don't have the required experience/intelligence to design a good ribbon.

So my best bet is try to copy an existing design. I would be very happy achieve even small part of the performance of the original Apogee speakers.

Here are two pictures of Apogee Full Range and Apogee Scintilla midrange ribbons. My understanding is that they are about 50mm wide and 15um and 12um thick pure aluminium:

http://www.abload.de/img/dscn0263w14.jpg

https://lh4.googleusercontent.com/-tyv5nLBuGyk/T8Kme36aiSI/AAAAAAAAFTY/Vu01k-rmwBA/s640/IMG_1614.JPG

Based on the pictures, would it be bold to guess that they both have been run through the same corrugation machine?

I know I don't have the required experience/intelligence to design a good ribbon.

So my best bet is try to copy an existing design. I would be very happy achieve even small part of the performance of the original Apogee speakers.

Here are two pictures of Apogee Full Range and Apogee Scintilla midrange ribbons. My understanding is that they are about 50mm wide and 15um and 12um thick pure aluminium:

http://www.abload.de/img/dscn0263w14.jpg

https://lh4.googleusercontent.com/-tyv5nLBuGyk/T8Kme36aiSI/AAAAAAAAFTY/Vu01k-rmwBA/s640/IMG_1614.JPG

Based on the pictures, would it be bold to guess that they both have been run through the same corrugation machine?

I could try to duplicate Apogee corrugation if I knew how many corrugations/pleats they used per inch or cm.

Would somebody be so kind and measure how many corrugations per cm/inch does Apogee Scintilla or Full Range have?

I have attached a picture of my finest pitch corrugation (the pure aluminium one).

I guess one difference is that my corrugation is triangle wave and Apogee used sine wave style corrugation? Any comments to this?

And the amplifier is diy single ended Mosfet source follower without feedback.

My 70mm wide single trace ribbon is about 0.125 Ohm and amplifier bias current is 10A with 8V supply voltage.

My 70mm wide 4 trace ribbon is about 2 Ohm and used amplifier bias current was then 4A with 18V supply voltage.

Would somebody be so kind and measure how many corrugations per cm/inch does Apogee Scintilla or Full Range have?

I have attached a picture of my finest pitch corrugation (the pure aluminium one).

I guess one difference is that my corrugation is triangle wave and Apogee used sine wave style corrugation? Any comments to this?

And the amplifier is diy single ended Mosfet source follower without feedback.

My 70mm wide single trace ribbon is about 0.125 Ohm and amplifier bias current is 10A with 8V supply voltage.

My 70mm wide 4 trace ribbon is about 2 Ohm and used amplifier bias current was then 4A with 18V supply voltage.

Attachments

Why don't you use resistors to get the impedance to where you want it. I use resistors to get to 4, 8, 16 ohms, so you can use any amp and the different outputs on your amps as well! Have built many full range planars and I never corrugate my aluminium foil, stuck on 12um mylar C. Have built from A4 size up to 7' x 2' and am in the process of building 2 headphone designs. Resonance is usually caused by a loose diaphragm, which must be very tight like a drum skin.

I have built some A4 size full range planars with 5.25 x 9 inch diaphragm which sounded good, so I don't see the point of building ribbon tweeters, which need other mid range etc. and complicated crossovers. When you can build a full range one !! You can make the resistance what you want with resistors in series or if too much tape in parallel.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Suggestions for aluminium ribbon damping?