Congratulations!

With these big panels, I'm sure you can do a lot lower than 70hz.

Wachara C.

You are right, they do go lower than 70 Hz, but I have my subwoofer (4-18" woofers in an infinite baffle) set for 70Hz. I may play with that crossover point though.🙂

You are right, they do go lower than 70 Hz, but I have my subwoofer (4-18" woofers in an infinite baffle) set for 70Hz. I may play with that crossover point though.🙂

Many important considerations in the choice of the crossover point. Claiming several decades of experience, here are some.

1. With a steep crossover and a pretty clean system downstream of the crossover, no directionality confusions with music even as high as 140 Hz... when tested blind*.

2. Somewhere around 80 Hz and below your sources start demanding substantial power. So you want to keep sounds needing power in the subs so your ESL system isn't challenged too much. Don't try pushing the ESLs into a range where cone drivers are OK. (The old Janzen speakers with a 1000 Hz crossover were quite ESL in their sound quality.)

Ben

*when tested with subs visible, people will swear they can "hear" directionality of music influenced down to 5 Hz.

Last edited:

I suspect that is why THX sets the crossover to 80 HZ.

When spoken, some sentences that make no sense in writing make sense, if only to the speaker. If you know what I mean?

Ben

Last edited:

You are right, they do go lower than 70 Hz, but I have my subwoofer (4-18" woofers in an infinite baffle) set for 70Hz. I may play with that crossover point though.🙂

Congratulations on a beautiful project. The frames on the panels are particularly nice - but then, so is your garage/workshop! Love that workbench and vice.

Have you considered H-baffle subs to continue the dipolar theme, or would that be too intrusive in the room?

Thanks. Yes, I'm a little bit short of space for some H-baffle subs but I may give them a try in the future. I alreade have 4 12" woofers that would work well for them.

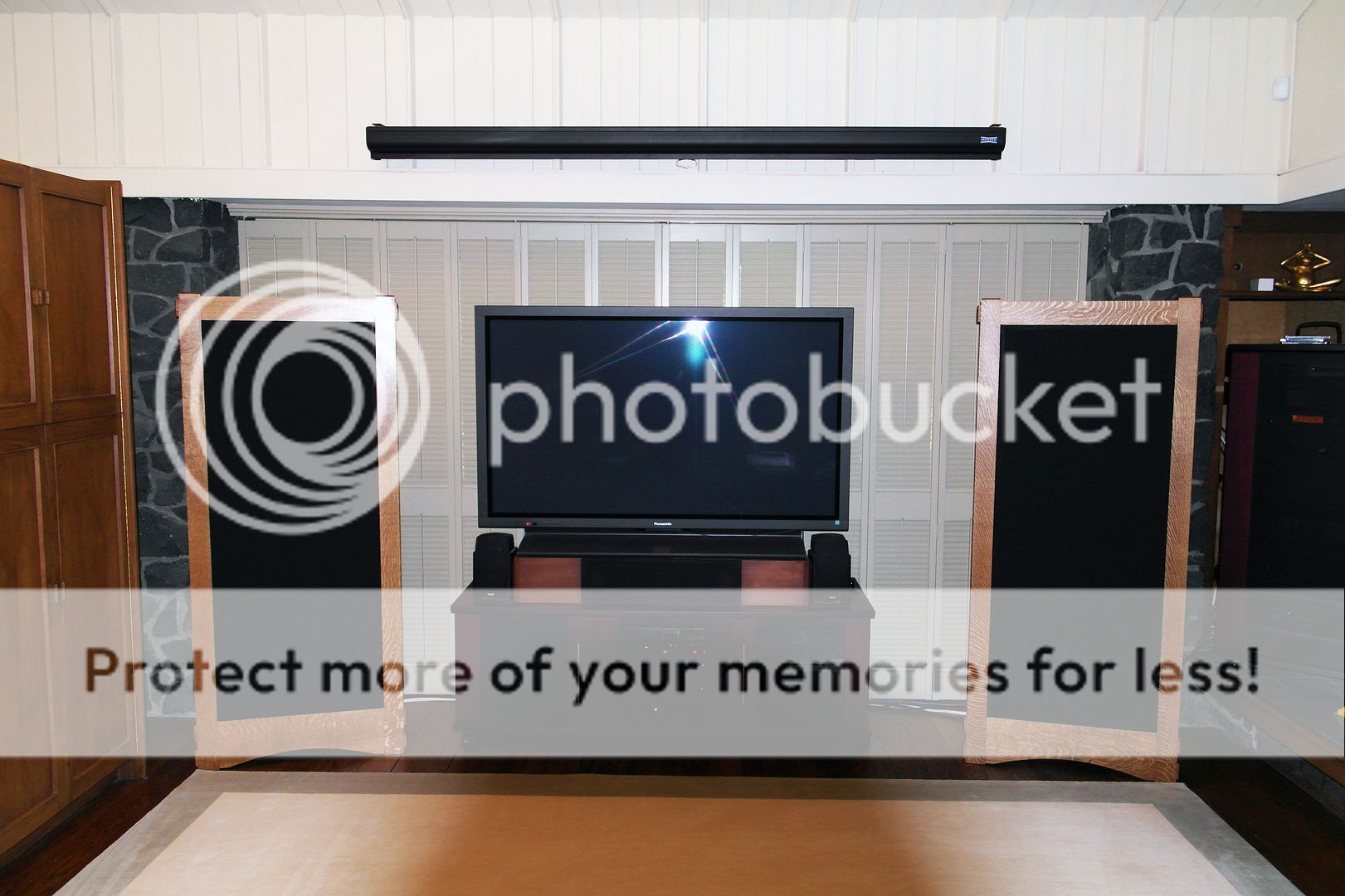

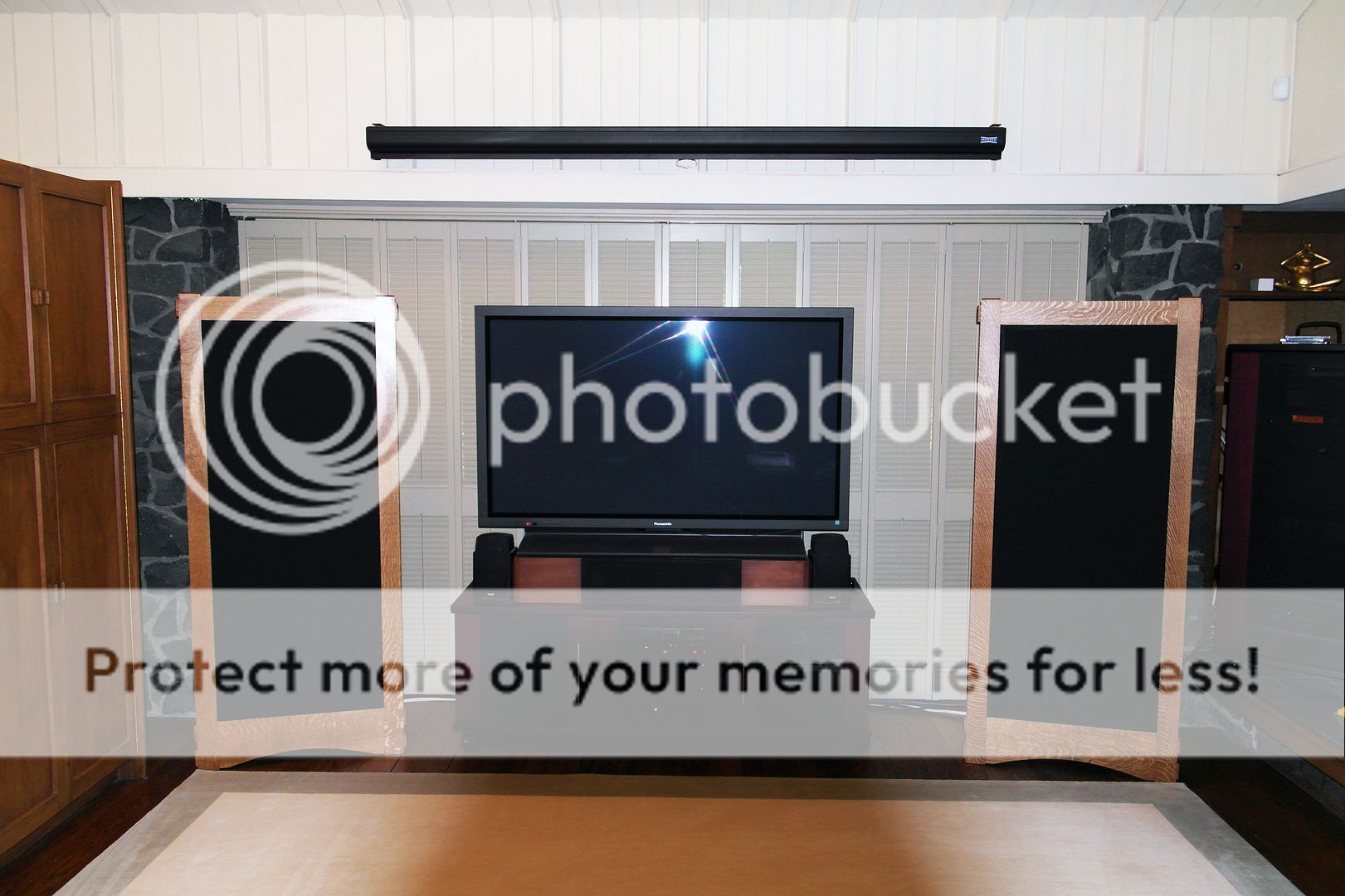

Here's a shot of the speakers in my AV room with all the electronics. My next project will be to build a nice center cabinet to hold all the equipment in one place and, more importantly to match the quarter sawn white oak speakers.

Here's a shot of the speakers in my AV room with all the electronics. My next project will be to build a nice center cabinet to hold all the equipment in one place and, more importantly to match the quarter sawn white oak speakers.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Some More Questions On ELS Design

![ELS1-1[1].jpg](/community/data/attachments/280/280521-0a1de576f37d268002288cf8f438623f.jpg?hash=Ch3ldvN9Jo)

![els1[1].jpg](/community/data/attachments/280/280533-ca6c5a1b1dbf5e0abc26da86866af0f3.jpg?hash=ymxaGx2_Xg)

![ELS2-1[1].jpg](/community/data/attachments/280/280538-bc06e4654eb1674651cd59b17efe0ffa.jpg?hash=vAbkZU6xZ0)

![ELS4[1].jpg](/community/data/attachments/280/280546-46cb46a30a1dfe5028c7dc820082e3b0.jpg?hash=RstGowod_l)

![IMG_0500[1].jpg](/community/data/attachments/280/280555-fdde6d22e27b2c4400b144428ea97255.jpg?hash=_d5tIuJ7LE)