It is often reported that the magnetic field in the gap should be as homogeneous as possible. In this context homogeneity means that the strength of the magnetic field in the middle of the ribbon is the same as the strength of the magnetic field in the edge of the ribbon.

To quote the RAAL litterature:

"The magnetic field in RAAL ribbons is homogenous. Regarding the width of the gap, it is designed to have the same strength at the ribbon edges, as well as at the ribbon middle portion. It reduces the stress at the ribbon foil dramatically. The distortion, too. To get the precisely shaped field, through the gap width and depth, we’ve extensively used the FEM and BEM magnetic circuits analysis software. In order to obtain such a field in real magnetic circuit, very strong NdFeB magnets have been precisely machined, prior to magnetization, in very special shape. Making the magnetic field homogenous, sacrifices the strength of it, but efficiency should easily be changed for low stress and low linear and nonlinear distortion. " RAAL Ribbon Tweeters

The "The tall neodymium ribbon". Part 1 uses a design with a deep cavity and multiple magnets in order to obtain an homogeneous magnetic field.

On the other hand, others use wide ribbon with narrow magnets which can weakened the middle. For example http://www.diyaudio.com/forums/planars-exotics/190779-0-6my-aluminium-ribbon-3.html.

In all cases, very good sound is reported.

I have built a 20 cm long tweeter ribbon with a 2.2 cm gap that had only 50% strength in the middle of the gap. I was surprised how good it sounded.

I wonder, if an homogeneous magnetic field is important to get a good sounding ribbon?

Bruno

To quote the RAAL litterature:

"The magnetic field in RAAL ribbons is homogenous. Regarding the width of the gap, it is designed to have the same strength at the ribbon edges, as well as at the ribbon middle portion. It reduces the stress at the ribbon foil dramatically. The distortion, too. To get the precisely shaped field, through the gap width and depth, we’ve extensively used the FEM and BEM magnetic circuits analysis software. In order to obtain such a field in real magnetic circuit, very strong NdFeB magnets have been precisely machined, prior to magnetization, in very special shape. Making the magnetic field homogenous, sacrifices the strength of it, but efficiency should easily be changed for low stress and low linear and nonlinear distortion. " RAAL Ribbon Tweeters

The "The tall neodymium ribbon". Part 1 uses a design with a deep cavity and multiple magnets in order to obtain an homogeneous magnetic field.

On the other hand, others use wide ribbon with narrow magnets which can weakened the middle. For example http://www.diyaudio.com/forums/planars-exotics/190779-0-6my-aluminium-ribbon-3.html.

In all cases, very good sound is reported.

I have built a 20 cm long tweeter ribbon with a 2.2 cm gap that had only 50% strength in the middle of the gap. I was surprised how good it sounded.

I wonder, if an homogeneous magnetic field is important to get a good sounding ribbon?

Bruno

Not necessary for good sound , but i can see where it would make for " better sound " ..

I'm currently looking into this myself as my mid/ribbon is 46mm wide and would love to increase the force in the middle for lower distortion and increased efficiency . The cross bar concept was mentioned by another here , but I'm not in full understanding of how to implement such a setup or if it really works as stated ..

Interested if you continue with this ....................

I'm currently looking into this myself as my mid/ribbon is 46mm wide and would love to increase the force in the middle for lower distortion and increased efficiency . The cross bar concept was mentioned by another here , but I'm not in full understanding of how to implement such a setup or if it really works as stated ..

Interested if you continue with this ....................

Here is Peter's explanation for helper magnets ...

Not sure if you can simulate in Femm .................

Hi A.Wayne

helper magnets idea came from guys at e-magnets.co.uk, they suggested to close the magnetic path between two steel bars (distance setting, so eg. 40mm wide ribbon between 10mm thick neos will require 60mm thick stack of helper neo's) with a stack of magnets as they will help to alleviate field strength drop in the middle of the ribbon length. In effect additional field off helper magnets will add to the field, observe the polarity thou, it has to be reversed in relation to front magnets! I will post a picture tomorrow.

Peter

Not sure if you can simulate in Femm .................

Hi guys,

I'm not sure if you can simulate it, but in reality adding helper magnets did increase sensitivity on the ribbon I added them on. No measurement unfortunately. I'ts easy enough to try though. Another interesting point to consider would be to replace all of the distance blocks with stacks of magnets. that would give you higher sensitivity,and no field decrease in the middle. If you have Gauss meter that would be interesting to measure the effect of adding the magnets. The way I see it is like adding strength to the main magnets.

Peter

I'm not sure if you can simulate it, but in reality adding helper magnets did increase sensitivity on the ribbon I added them on. No measurement unfortunately. I'ts easy enough to try though. Another interesting point to consider would be to replace all of the distance blocks with stacks of magnets. that would give you higher sensitivity,and no field decrease in the middle. If you have Gauss meter that would be interesting to measure the effect of adding the magnets. The way I see it is like adding strength to the main magnets.

Peter

Last edited:

Sorry about the delay,work getting in the way of hobby(nuissance)

Yes ATM I'm only using a stack in the middle, I've got some more magnets coming next week, so will try adding them at both ends, see if it makes a difference worth extra cost.

Cheers

Peter.

A picture would be welcome.

I have a gaussmeter and if I can reproduce your setup I would measure it.

Regarding field strength drop in the middle, in my setup which is 1200 long ribbon (on 1300mm long steel bars 20x50mm, 40mm gap with N42 grade magnets 10x20x40mm) I get 0.15 T in the middle and 0.177 T ends. I have two steel bars at both ends to close magnetic circuit, same size as main bars, 20x50mm mild steel. Unfortunately I had to return the meter before I had a chance to measure the effect with the helper stack.

Regards, Peter.

Regards, Peter.

Attachments

Regarding field strength drop in the middle, in my setup which is 1200 long ribbon (on 1300mm long steel bars 20x50mm, 40mm gap with N42 grade magnets 10x20x40mm) I get 0.15 T in the middle and 0.177 T ends. I have two steel bars at both ends to close magnetic circuit, same size as main bars, 20x50mm mild steel. Unfortunately I had to return the meter before I had a chance to measure the effect with the helper stack.

Regards, Peter.

Whats the difference if not closed ......?

Regarding field strength drop in the middle, in my setup which is 1200 long ribbon (on 1300mm long steel bars 20x50mm, 40mm gap with N42 grade magnets 10x20x40mm) I get 0.15 T in the middle and 0.177 T ends. I have two steel bars at both ends to close magnetic circuit, same size as main bars, 20x50mm mild steel. Unfortunately I had to return the meter before I had a chance to measure the effect with the helper stack.

Regards, Peter.

Thanks for sharing your measurements. This is the first time that I see measurements of a long ribbon!

Two comments:

1) the field in the middle is 85% of the field at the edge - that 's pretty good considering how wide the gap is. My guess it is because of the shape of the magnets - is the gap also 40 mm deep? Must be... Thin deep magnets allow a better field homogeneity.

2) 0.15 T and 0.177 T is a relatively weak magnetic field (I have 0.59 and 0.70 for 1.2cm gap, 20 cm long ribbon, 15x15 x 50mm N48 magnets). My guess it is because of the weakening of the magnet strength due the length of the magnetic system (1300mm). Note that the sensitivity of the ribbon is proportional to the square of the magnetic field

I will do some FEMM simulations and will share.

Bruno

A.Wayne- I've not measured without end bars. Re field strength it is always going to be a compromise between neccessary width of the ribbon for the low end response and sensitivity. I found lower field strength does not matter all thet much because the radiating area increases somwhat compensating loss in sensitivity. But I do think that homogenity IS important.

Thanks for sharing your measurements. This is the first time that I see measurements of a long ribbon!

Two comments:

1) the field in the middle is 85% of the field at the edge - that 's pretty good considering how wide the gap is. My guess it is because of the shape of the magnets - is the gap also 40 mm deep? Must be... Thin deep magnets allow a better field homogeneity.

2) 0.15 T and 0.177 T is a relatively weak magnetic field (I have 0.59 and 0.70 for 1.2cm gap, 20 cm long ribbon, 15x15 x 50mm N48 magnets). My guess it is because of the weakening of the magnet strength due the length of the magnetic system (1300mm). Note that the sensitivity of the ribbon is proportional to the square of the magnetic field

I will do some FEMM simulations and will share.

Bruno

Please do and a few questions ...

1. Is it best to have deep metal plates or shorter give stronger field.

2. Are you saying the longer the ribbon the weaker the field ? so multiple small ones would be more efficient.

My current ribbons are 1800 MM long and the midrange is 44mm wide and anything i can do to increase the efficiency would be appreciated as i know you have to double magnetic weight to increase efficiency by 3 db...

A.Wayne- I've not measured without end bars. Re field strength it is always going to be a compromise between neccessary width of the ribbon for the low end response and sensitivity. I found lower field strength does not matter all thet much because the radiating area increases somwhat compensating loss in sensitivity. But I do think that homogenity IS important.

Interesting as i have never closed mine with metal at the top , i must try and measure. Bruno can you use Femm to see if this makes a difference..

My current ribbons are 1800 MM long and the midrange is 44mm wide and anything i can do to increase the efficiency would be appreciated as i know you have to double magnetic weight to increase efficiency by 3 db...

Doubling the magnetic strength increases sensitivity not by 3 db but 6 db!

Decreasing the ribbon thickness by 2 increases sensitivity by 3 db (and even more in the high frequencies , > 10KHz).

Doubling the ribbon surface increases sensitivity by 3 db.

Having two ribbons on top of another (but not touching) increases increases sensitivity by 3 db (I tried this but I had a high frequency decrease. For midrange , it might be worth a try)

Doubling the thickness of the steel bars that holds the magnets did not improve the strength magnetic field in my system (200 mm long ribbon, 10mm thick steel bar, gap is 15 mm wide and deep, magnets are 15x15x50mm N48)

Hopes this helps,

Bruno

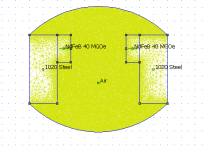

FEMM result of UKPD's ribbon, based on his pictures and description.

A screenshot of the FEMM setup is attached to this post.

FEMM is 2D program and it is not possible to specify the 3rd dimension. In my experience, such a simple simulation gives a useful prediction for small and simple ribbon sytems (< 20 cm long).

The predicted B is 0.22 T in the middle of the gap and 0.52 T on the surface of the magnets.

Measured values: 0.15 T and 0.177 T.

Thus increasing the length strongly decreases the magnetic field but more so on the magnet surface than in the middle of the gap. The good side of this is that the homogeneity of the magnetic field improves with the length of the ribbon.

I looked back at my notes about the measurements I made of my 200 mm long ribbon. I measured also a 50 mm short version with the same gap (15 mm)

length (mm) | B middle (T) | B magnet (T)

50 | 0.58 | 0.74

200 | 0.52 | 0.65

There is here a stronger decrease of the B on the magnet surface than in the gap. The effect is not as strong as UKPD's ribbon, which is about 7 times longer, but the trend is the same.

Bruno

A screenshot of the FEMM setup is attached to this post.

FEMM is 2D program and it is not possible to specify the 3rd dimension. In my experience, such a simple simulation gives a useful prediction for small and simple ribbon sytems (< 20 cm long).

The predicted B is 0.22 T in the middle of the gap and 0.52 T on the surface of the magnets.

Measured values: 0.15 T and 0.177 T.

Thus increasing the length strongly decreases the magnetic field but more so on the magnet surface than in the middle of the gap. The good side of this is that the homogeneity of the magnetic field improves with the length of the ribbon.

I looked back at my notes about the measurements I made of my 200 mm long ribbon. I measured also a 50 mm short version with the same gap (15 mm)

length (mm) | B middle (T) | B magnet (T)

50 | 0.58 | 0.74

200 | 0.52 | 0.65

There is here a stronger decrease of the B on the magnet surface than in the gap. The effect is not as strong as UKPD's ribbon, which is about 7 times longer, but the trend is the same.

Bruno

Attachments

Last edited:

The sad thing with magnetics is that even a very small change in distance results in magnitudes of lost pull. Having access to simulation tools you can get a picture of the circular nature of magnetic force.

What is of true importance is the actual percieved sonic change as the gap, flux, or ribbon gauge change. Try to take acoustic measurements and see if there is something that would change the quality of the music material. Remember that is what we are seeking after all.

I have always wished to construct something with huge wound magnets which could capture even the slightest movement in the ribbon membrane. This of course would require extremely tedious winding of electromagnets. You then could induce tremendous current into the coils and have exacting results.

I really like your setup. It is professional and neat. Tad

What is of true importance is the actual percieved sonic change as the gap, flux, or ribbon gauge change. Try to take acoustic measurements and see if there is something that would change the quality of the music material. Remember that is what we are seeking after all.

I have always wished to construct something with huge wound magnets which could capture even the slightest movement in the ribbon membrane. This of course would require extremely tedious winding of electromagnets. You then could induce tremendous current into the coils and have exacting results.

I really like your setup. It is professional and neat. Tad

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Importance of magnetic field homogeneity for ribbons?