I wish to build a 26-36" ribbon like the one here:

"The tall neodymium ribbon". Part 1

I havent built anything like this before so I wish to go ahead with a 1000 dollar project. I am very good at fabricating but I need some tech info.

1-Do I have to use a side by side magnet assembly as he did or can I use a single row of really strong magnets on each side? Can I use a 3 x 1 x 1/2 instead of side by side 3 x 1/2 x 1/4 essentially combining the side by side magnets?

2-Will the use of thicker magnets make it more efficient? For example, Will a 3 x 1 x 1 increase efficiency over a 3 x 1 x 1/2?

3-Can someone explain the orientation of the magnets by poles...IE pos to pos and neg to neg with the magnets pushing away from each other?

4-On this site:

Applied Magnets & WindMax Wind Turbines

most magnets are described as 'magnetized through thickness'. Is this what I need?

I have already made corrigated ribbons using his proceedure for my 5" ribbon tweeters and they sound and measure better than the originals.

I will post pictures and results as I proceed.

Thanks.

"The tall neodymium ribbon". Part 1

I havent built anything like this before so I wish to go ahead with a 1000 dollar project. I am very good at fabricating but I need some tech info.

1-Do I have to use a side by side magnet assembly as he did or can I use a single row of really strong magnets on each side? Can I use a 3 x 1 x 1/2 instead of side by side 3 x 1/2 x 1/4 essentially combining the side by side magnets?

2-Will the use of thicker magnets make it more efficient? For example, Will a 3 x 1 x 1 increase efficiency over a 3 x 1 x 1/2?

3-Can someone explain the orientation of the magnets by poles...IE pos to pos and neg to neg with the magnets pushing away from each other?

4-On this site:

Applied Magnets & WindMax Wind Turbines

most magnets are described as 'magnetized through thickness'. Is this what I need?

I have already made corrigated ribbons using his proceedure for my 5" ribbon tweeters and they sound and measure better than the originals.

I will post pictures and results as I proceed.

Thanks.

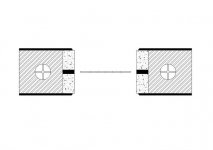

most magnets are described as 'magnetized through thickness'. Is this what I need?

from two construction pictures, I would say yes, magged through thickness

Attachments

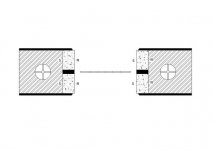

3-Can someone explain the orientation of the magnets by poles...IE pos to pos and neg to neg with the magnets pushing away from each other?

I have marked north and south poles in the picture

I suppose its how it should be

Attachments

Will the use of thicker magnets make it more efficient? For example, Will a 3 x 1 x 1 increase efficiency over a 3 x 1 x 1/2?

it will be more efficient, yes

Dahlberg's magnets looks like 2" x 1/2" x 1/4"

so the only magnets you should use are 2" x 1/2" x 1/2"

ofcourse they can be longer

but may get so strong they are difficult to handle

note that each side of the magnet system should be assembled to one unit before placing the magnets

though Dahlberg seem to use a neat trick, so that he can rotate each side, to ease the mounting of magnets

but I can tell, be very very careful here

they will clash together at any chance given, and with exstreme force

but could be a very dangerous trick

make no mistake, or your fingers could be crushed, completely beyond saving

it is a very dangerous thing

and even if using very thick and strong iron, the force of the magnets will bend it

hence notice the small brass tubes Dahlberg is using

I will estimate that the combined magnet force could lift a small car

Is there any measurements of the frequency response and sensitivity available for "The tall neodymium ribbon". I did not see any on the website - may be I have missed it?

Bruno

Is there any measurements of the frequency response and sensitivity available for "The tall neodymium ribbon". I did not see any on the website - may be I have missed it?

Bruno

DahlbergAudioDesign

Thanks for the measurements. I reproduced the FEMM simulation.

See attached file.

The picture below shows the predicted magnetic field strength in the gap (range is -0.27 to 0.19).

There might be some differences with the simulation shown on the website since I don't have all the details (e.g magnet strength).

Something to keep in mind: the FEMM simulation is only 2D. In the third dimension, we have a long magnetic system. When the magnetic system gets longer, then the field strength decreases. In my ribbon system, with only one magnet pair (Length = 4 cm), the measured B in the middle of the gap is 0.51, with 3 magnets (3x4cm = 12 cm), the measured B is 0.48 and with 5 magnets (5 x 4cm = 20 cm), the measured B is 0.42. Note that I wrote "measured" not "computed".

Attachments

When the magnetic system gets longer, then the field strength decreases.

Hi, brunob, do you know why that is?

Does FEMM calculate the field strength for infinite length in the 3rd dimension?

Thanks,

Kenneth

Hi, brunob, do you know why that is?

I don't have a an explanation but I have an observation. When assembling one side of a long magnetic system, placing the first magnet is easy. The second one has be pushed against the first because there is a strong repulsion. I think that this repulsion could be connected to the magnetic field decrease in the ribbon gap for longer ribbon systems.

For a small 20 cm ribbon system, I measured already a 21% decrease of the magnetic field when compared to 4 cm long one. I wonder what the decrease would be for a 1 meter tall ribbon?

Does FEMM calculate the field strength for infinite length in the 3rd dimension?

I don't know.

Bruno

Last edited:

Spinmaster,

Check this thread out on this forum. It tells you everything you need to know in great detail with lots of pictures. Valvetude has done a fabulous job.

A 60" Ribbon w/TL Loaded Extremis Hybrid .

So far the magnets4less folks have the best price. If you find a better price please post it on your site. Remember when you glue several dozen strong magnets with opposite polarity and are going to join them with a small gap the combined pull is TREMENDOUS. Be very careful.

Good Luck Tad

Check this thread out on this forum. It tells you everything you need to know in great detail with lots of pictures. Valvetude has done a fabulous job.

A 60" Ribbon w/TL Loaded Extremis Hybrid .

So far the magnets4less folks have the best price. If you find a better price please post it on your site. Remember when you glue several dozen strong magnets with opposite polarity and are going to join them with a small gap the combined pull is TREMENDOUS. Be very careful.

Good Luck Tad

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- DIY ribbon info requested (constructing a ribbon unit)