Paul's Lousy 60" Ribbons

Hi All,

First I would like to thank Casey, Dennis, and others here who gave me the incentive to try this.

I borrowed from here, Dahlberg, and Verhagen to build these.

I figured I would be better off just posting my results once I was at a stopping point.

I would not have bothered at all, but I figured others may benefit, or get more incentive themselves to do something like this... These are not at all the beasts that Casey built, but are quite satisfactory given they are a first attempt!

Magnets 125 2"x0.5"x0.25" N45

'L' shaped steel 61" long x 1.25"

Magnets are glued here...

Assembled with 'test' ribbon...

Here is a vid of one while playing:

The ribbons are 4 strips of target brand aluminum foil, 2 are 0.16" wide and 2 are 0.12" wide.

The DC impedance is ~4.5 ohms.

I don't have femm, or even the peripherals to use it, so I don't have measurements for posting yet.

I do have a tone generator, but no spl meter.

I can tell you that connected full range but bass eq'ed out, they are almost unbearably loud at 1 watt.

They are much better than the 1.5" tweets in my JBL Decades!

I am most happy with their sound thus far...

paul

Hi All,

First I would like to thank Casey, Dennis, and others here who gave me the incentive to try this.

I borrowed from here, Dahlberg, and Verhagen to build these.

I figured I would be better off just posting my results once I was at a stopping point.

I would not have bothered at all, but I figured others may benefit, or get more incentive themselves to do something like this... These are not at all the beasts that Casey built, but are quite satisfactory given they are a first attempt!

Magnets 125 2"x0.5"x0.25" N45

'L' shaped steel 61" long x 1.25"

Magnets are glued here...

Assembled with 'test' ribbon...

Here is a vid of one while playing:

The ribbons are 4 strips of target brand aluminum foil, 2 are 0.16" wide and 2 are 0.12" wide.

The DC impedance is ~4.5 ohms.

I don't have femm, or even the peripherals to use it, so I don't have measurements for posting yet.

I do have a tone generator, but no spl meter.

I can tell you that connected full range but bass eq'ed out, they are almost unbearably loud at 1 watt.

They are much better than the 1.5" tweets in my JBL Decades!

I am most happy with their sound thus far...

paul

Congratulations Paul...welcome to the club!!!! A very practical build. You don't have to go as far up the deep slope of diminishing returns as i did (I'm insane by the way) to get excellent results..I'm sure when you get all the little details worked out you will have a superior ribbon to anything you can buy for less than 4 figures..probably a lot more.

Give us some details on your ribbon. What did you laminate the foil to, why the different widths?

Congrats again Paul..ribbons kick a**!!!

Casey

Edit:typo

Give us some details on your ribbon. What did you laminate the foil to, why the different widths?

Congrats again Paul..ribbons kick a**!!!

Casey

Edit:typo

I wish you guys would stop this... I have far too much time on my hands at the moment, and it sends my mind racing to read these threads. Last thing I need is new speakers - I just rewired my Maggies  . Presently, however, my car project ('67 MGB) is the centre of attention, getting some much needed engine work, so the stereo equipment is safe - for now.

. Presently, however, my car project ('67 MGB) is the centre of attention, getting some much needed engine work, so the stereo equipment is safe - for now.

A ribbon experiment, though..... Hmmm....

Thanks for sharing your ideas.

Ed

A ribbon experiment, though..... Hmmm....

Thanks for sharing your ideas.

Ed

valveitude said:Congratulations Paul...welcome to the club!!!! A very practical build.

Thanks!

[/B][/QUOTE](I'm insane by the way) [/B][/QUOTE]

ME TOO.

[/B][/QUOTE]..I'm sure when you get all the little details worked out you will have a superior ribbon to anything you can buy for less than 4 figures..probably a lot more.

[/B][/QUOTE]

I particularly appreciate your information on x-over building, an area I have much to learn about..... I am seeking a capacitor(s) for x-ing between 200 and 400hz. These are not being used nearly as much as they could be connected to 40 year old JBL unit.

[/B][/QUOTE]Give us some details on your ribbon. What did you laminate the foil to, why the different widths? [/B][/QUOTE]

I used the thinnest packaging tape I could find. after the ribbon is cut and cleaned with isopropyl alcohol(as Dahlberg describes in his "A Tall One" tutorial), I lay the tape onto the strips where the are left on the table after being cut with a rag pushing the air out/tape onto the foil as one might use a squeegee.

Dahlberg used celophane and 3M Adhesive, I felt this was too much to try to do for the first time, so I used the tape.

The ribbons come-off the table completely straight as long as I don't stretch the tape as I am applying it [IMPORTANT].

Also, the corrugator I bought puts small breaks in the foil {BAD} so I don't bother doing that at all with these particular ribbons.

The wider 2 strips are on the outside, where they are closer to the magnets, inner 2 are the small ones.

I can only speculate that since they are further from the magnets themselves, they will not 'keep up' with the rest of the ribbon, given equal weight and reduced field area...

So its compensation. I may be entirely wrong, but I got this idea from reading it I forget where...

[/B][/QUOTE] again Paul..ribbons kick a**!!!

Casey [/B][/QUOTE]

Thank you for your kind words

paul

Hey Paul,

If your going with a simple cap x-over, you'll probably have to go up to 800-1k if you play at anything approaching loud. I'm getting away with a cap crossing at 200 because I also have an active 24dB/octave set at 75 hz giving me a gentle roll off for an octave+ to integrate well with the bass driver, and a sharp roll off to protect the ribbon.

As for the ribbon itself might I make a suggestion ? When I started playing with them I was convinced I had to go the "Apogee" route of multiple paths on a film to get a match to the amp. I was chasing my tail and never got satisfactory results...to heavy and tearing during pleating ( sound familiar? ). If you get some film/foil caps to harvest you can get some very thin foil. You didn't state how wide your ribbon is, but if it's around 3/4" these capacitors would be great (the ones I use). A 3/4" x 60" ribbon with this foil will get you right at 1/2 ohm, but weigh about 1/10 as much. Now, as suggested by LineSource, get a roll of small gauge magnet wire and a board, and serpintine the wire back and forth to wind a non-inductive resistor of 3 1/2 ohms. Wire it in series and you have a 4 ohm load to your amp. Only 10% of the power makes it to the ribbon, but your ribbon is now 10 times as efficient do to the less mass..zero net gain/loss (approx.). The advantages of this is 2 fold. 1)The high end will have more extension with improved micro-dynamics (it's a moment of inertia thing), and 2) you can corrogate without tearing...you need to corrogate.

). If you get some film/foil caps to harvest you can get some very thin foil. You didn't state how wide your ribbon is, but if it's around 3/4" these capacitors would be great (the ones I use). A 3/4" x 60" ribbon with this foil will get you right at 1/2 ohm, but weigh about 1/10 as much. Now, as suggested by LineSource, get a roll of small gauge magnet wire and a board, and serpintine the wire back and forth to wind a non-inductive resistor of 3 1/2 ohms. Wire it in series and you have a 4 ohm load to your amp. Only 10% of the power makes it to the ribbon, but your ribbon is now 10 times as efficient do to the less mass..zero net gain/loss (approx.). The advantages of this is 2 fold. 1)The high end will have more extension with improved micro-dynamics (it's a moment of inertia thing), and 2) you can corrogate without tearing...you need to corrogate.

Casey

I am seeking a capacitor(s) for x-ing between 200 and 400hz. These are not being used nearly as much as they could be connected to 40 year old JBL unit.

If your going with a simple cap x-over, you'll probably have to go up to 800-1k if you play at anything approaching loud. I'm getting away with a cap crossing at 200 because I also have an active 24dB/octave set at 75 hz giving me a gentle roll off for an octave+ to integrate well with the bass driver, and a sharp roll off to protect the ribbon.

As for the ribbon itself might I make a suggestion ? When I started playing with them I was convinced I had to go the "Apogee" route of multiple paths on a film to get a match to the amp. I was chasing my tail and never got satisfactory results...to heavy and tearing during pleating ( sound familiar?

Casey

Q&A&Q

Thanks for the help, all suggestions/comments are welcome!

Haha knew I'd forget something or other...

Structure Gap is 0.675" and ribbon width is ~0.62".

What is the total max length harvested from one of these caps?(maybe I missed it)

Wow, so such a small/light conductor still gets you that low?

You can corrugate the foil straight out of the cap, or is there a buffer?

Are you getting good longevity from them once properly x-ed?

Also, can you suggest a magnet wire and gauge? Please forgive my ignorance.

I would assume this is single-conductor wire you are talking about.

It have to be all copper?

K I'll shut-up now

Thanks so much!

Side note,

Miles's trumpet actually HURT to listen to.

Its like having it 7 inches away from my ear!

There is a TON of previously inaudible discovery going on here right now....

paul

valveitude said:Hey Paul,

If your going with a simple cap x-over, you'll probably have to go up to 800-1k if you play at anything approaching loud. I'm getting away with a cap crossing at 200 because I also have an active 24dB/octave set at 75 hz giving me a gentle roll off for an octave+ to integrate well with the bass driver, and a sharp roll off to protect the ribbon.

As for the ribbon itself might I make a suggestion ? When I started playing with them I was convinced I had to go the "Apogee" route of multiple paths on a film to get a match to the amp. I was chasing my tail and never got satisfactory results...to heavy and tearing during pleating ( sound familiar?). If you get some film/foil caps to harvest you can get some very thin foil. You didn't state how wide your ribbon is, but if it's around 3/4" these capacitors would be great (the ones I use). A 3/4" x 60" ribbon with this foil will get you right at 1/2 ohm, but weigh about 1/10 as much. Now, as suggested by LineSource, get a roll of small gauge magnet wire and a board, and serpintine the wire back and forth to wind a non-inductive resistor of 3 1/2 ohms. Wire it in series and you have a 4 ohm load to your amp. Only 10% of the power makes it to the ribbon, but your ribbon is now 10 times as efficient do to the less mass..zero net gain/loss (approx.). The advantages of this is 2 fold. 1)The high end will have more extension with improved micro-dynamics (it's a moment of inertia thing), and 2) you can corrogate without tearing...you need to corrogate.

Casey

Thanks for the help, all suggestions/comments are welcome!

Haha knew I'd forget something or other...

Structure Gap is 0.675" and ribbon width is ~0.62".

What is the total max length harvested from one of these caps?(maybe I missed it)

Wow, so such a small/light conductor still gets you that low?

You can corrugate the foil straight out of the cap, or is there a buffer?

Are you getting good longevity from them once properly x-ed?

Also, can you suggest a magnet wire and gauge? Please forgive my ignorance.

I would assume this is single-conductor wire you are talking about.

It have to be all copper?

K I'll shut-up now

Thanks so much!

Side note,

Miles's trumpet actually HURT to listen to.

Its like having it 7 inches away from my ear!

There is a TON of previously inaudible discovery going on here right now....

paul

What is the total max length harvested from one of these caps?(maybe I missed it)

After you get done roaching a few learning how to harvest the foil, and slicing/crimping it, you will get at least 2 60" ribbons out of each cap. Practice slicing and crimping on your "target" foil.

Wow, so such a small/light conductor still gets you that low?

Cup a dry leaf in your hand and swing your arm..the leaf is supported evenly across its surface and survives. pinch the leaf by the edges and swing it and it tears. The foil in the magnetic field is the same thing..the more homogeneous the field, the more force can be applied.

You can corrugate the foil straight out of the cap, or is there a buffer?

I smooth, and slice the foil before crimping.

Are you getting good longevity from them once properly x-ed?

Other than 1 damaged ribbon from my own stupidity, I have been running them for about 2 months of daily use now with no signs of fatigue. Before i found my "sweet spot" with the crossover I collected a lot of torn foil.

Also, can you suggest a magnet wire and gauge? Please forgive my ignorance.

I would assume this is single-conductor wire you are talking about.

It have to be all copper?

Radio Shack sells a 3-pack of magnet wire. Google for a resistance chart on the smallest gauge, and cut off the length needed for 3 1/2 ohms. Then "serpantine it on a piece of something. I did mine on a piece of mdf...

..not very pretty but it works fine. I have checked it for heat several times and it barely gets warm after extended periods of "crank".

Miles's trumpet actually HURT to listen to.

Its like having it 7 inches away from my ear!

Careful. After getting used to listening to speakers like your JBL's, your brain has learned to associate distortion with volume..remove the distortion and it doesn't seem near as loud. I found that before I got used to just how clean my ribbons were, I would turn it up way too loud..like ears numb when I turned down loud.

There is a TON of previously inaudible discovery going on here right now....

Just wait until you get it right

Casey

A couple more points...

If running a "nude" ribbon like I suggested, you will need to insulate your magnets to prevent fireworks should the ribbon touch..packing tape works well.

Back to the low freq. x-over I get away with. The reason I went to the "lunatic fringe" with my magnet/steel motor was to maximize the flux linearity in an attempt (successful) to reach down to that last octave of midrange without tattering the foil. I'm guessing that yours should be able to reach 400 or so with the right x-over.

Ed,

Idle hands are the devils work shop...

Casey

If running a "nude" ribbon like I suggested, you will need to insulate your magnets to prevent fireworks should the ribbon touch..packing tape works well.

Back to the low freq. x-over I get away with. The reason I went to the "lunatic fringe" with my magnet/steel motor was to maximize the flux linearity in an attempt (successful) to reach down to that last octave of midrange without tattering the foil. I'm guessing that yours should be able to reach 400 or so with the right x-over.

Ed,

I wish you guys would stop this... I have far too much time on my hands at the moment, and it sends my mind racing to read these threads.

Idle hands are the devils work shop...

Casey

Re: Paul's Lousy 60" Ribbons

Hello Paul,

How were you able to get your magnets with such a polished finish ?

poopydoopynoopy said:Hi All,

First I would like to thank Casey, Dennis, and others here who gave me the incentive to try this.

I borrowed from here, Dahlberg, and Verhagen to build these.

I figured I would be better off just posting my results once I was at a stopping point.

I would not have bothered at all, but I figured others may benefit, or get more incentive themselves to do something like this... These are not at all the beasts that Casey built, but are quite satisfactory given they are a first attempt!

Magnets 125 2"x0.5"x0.25" N45

'L' shaped steel 61" long x 1.25"

Magnets are glued here...

Assembled with 'test' ribbon...

Here is a vid of one while playing:

The ribbons are 4 strips of target brand aluminum foil, 2 are 0.16" wide and 2 are 0.12" wide.

The DC impedance is ~4.5 ohms.

I don't have femm, or even the peripherals to use it, so I don't have measurements for posting yet.

I do have a tone generator, but no spl meter.

I can tell you that connected full range but bass eq'ed out, they are almost unbearably loud at 1 watt.

They are much better than the 1.5" tweets in my JBL Decades!

I am most happy with their sound thus far...

paul

Hello Paul,

How were you able to get your magnets with such a polished finish ?

How were you able to get your magnets with such a polished finish ?

They came that way, I am not certtain if it was a special they were running at the time but here is a link to the vendor...

http://www.magnet4less.com/index.php?cPath=1

paul

P.S. Casey the caps are on their way and I am going to be making my way to the Shack soon.

I will report my findings of-course!

Thanks!

They came that way, I am not certtain if it was a special they were running at the time but here is a link to the vendor...

http://www.magnet4less.com/index.php?cPath=1

paul

P.S. Casey the caps are on their way and I am going to be making my way to the Shack soon.

I will report my findings of-course!

Thanks!

a.wayne said:Question ,

Are you guys planning on running a magnetic wire loop( race track ) out side of the speakers mag field to increase impedance ?

a.wayne

I have 4.5 ohm ribbons, they are roughly the same as the tweets that were in the Bookshelfs, so I used that x-over.

I have bought caps and am going to harvest like Casey did, if for nothing else than to compare.

At .5-1ohm which the ribbon will be , I will use magnet wire like suggested previously in this thread. I have 250Watts at my disposal, so its maybe a practical thing to try...

paul

P.S. Casey the caps are on their way...

The best way to harvest these bad boys that I found was to cut off the ends 3/16"" in on both sides (I ue a band saw for this, but a hacksaw, Dremel, whatever you have should be ok..just try to cut square) then slice the fiberglass wrap.

Casey

edit:typo

got some quick clamps on there...

Got the caps, will be buying the rest this week!

Here's a shot of the new & improvised ribbon clamps:

They work goody![wink-wink, nudge-nudge]

paul

valveitude said:

The best way to harvest these bad boys that I found was to cut off the ends 3/16"" in on both sides (I ue a band saw for this, but a hacksaw, Dremel, whatever you have should be ok..just try to cut square) then slice the fiberglass wrap.

Casey

edit:typo

Got the caps, will be buying the rest this week!

Here's a shot of the new & improvised ribbon clamps:

They work goody![wink-wink, nudge-nudge]

paul

baffles are done, stands soon...

Hey!

Been busy as I am sure a lot of you have been...

I got some more work done and wanted to share....

close up of the back I made gap adjustable.

Stained with 'Ebony' minwax no varnish..

side by side..

I like this one too, but I think I need a new camera.

The bases are ~14" square, and will have concrete to help keep them put.

More to follow, Happy New Year,

Happy New Year,

paul

Hey!

Been busy as I am sure a lot of you have been...

I got some more work done and wanted to share....

close up of the back I made gap adjustable.

An externally hosted image should be here but it was not working when we last tested it.

Stained with 'Ebony' minwax no varnish..

An externally hosted image should be here but it was not working when we last tested it.

side by side..

An externally hosted image should be here but it was not working when we last tested it.

I like this one too, but I think I need a new camera.

An externally hosted image should be here but it was not working when we last tested it.

The bases are ~14" square, and will have concrete to help keep them put.

More to follow,

Happy New Year,

Happy New Year,paul

thank you !

I learned this from a Dahlberg page..

the tin foil is temporarily adhered to a 72"W table with bar soap and a little water.

Same way as one tints auto glass.

I have a straight edge at least 72" long clamped at the ends for each cut.

I use carpet layer razors because they stay sharp Forever.

The work table can be glass, but mine is a formica/laminate, (I don't care about mine being etched).

I make the cuts one at a time measuring with calipers as I go. The spaces in-between are eyeballed roughly to 1mm, not more than that...

The four strips in my case came to ~1ohm each. No magnet wire needed.

The backing I use is thin packaging tape which I lay onto the strips still stuck to the table, (cleaned with isopropyl alcohol). The tape is pressed on so as to prevent kinkage but NOT pulled tight. This leaves a ribbon that lies flat at rest and is less likely to shrink to the point that the foil gets kinked.

Once the air is pressed out and the tape is cut at each side with said razor, the ribbon comes off the table and is flipped over for cleaning of the other side.

Done.

I use 5" of packing tape on each end/other side for added strength where they are clamped. I corrugate with a craft store type unit..

I can't really say why I have not tried the single foil conductor yet other than lack of time. I have to get some magnet wire.

I have caps to harvest foil from, just haven't gotten to those yet.

I will do a side-by-side comparison for sure once I am done with the tinkering and building of the baffles. The stands are cemented and are awaiting cover-up panels. I am also still trying to decide what to do with the tops of these things.

I am getting an electronic x-over in the mail today, I expect to cross them at ~400hz.

thanks for your interest and comment,

paul

I learned this from a Dahlberg page..

the tin foil is temporarily adhered to a 72"W table with bar soap and a little water.

Same way as one tints auto glass.

I have a straight edge at least 72" long clamped at the ends for each cut.

I use carpet layer razors because they stay sharp Forever.

The work table can be glass, but mine is a formica/laminate, (I don't care about mine being etched).

I make the cuts one at a time measuring with calipers as I go. The spaces in-between are eyeballed roughly to 1mm, not more than that...

The four strips in my case came to ~1ohm each. No magnet wire needed.

The backing I use is thin packaging tape which I lay onto the strips still stuck to the table, (cleaned with isopropyl alcohol). The tape is pressed on so as to prevent kinkage but NOT pulled tight. This leaves a ribbon that lies flat at rest and is less likely to shrink to the point that the foil gets kinked.

Once the air is pressed out and the tape is cut at each side with said razor, the ribbon comes off the table and is flipped over for cleaning of the other side.

Done.

I use 5" of packing tape on each end/other side for added strength where they are clamped. I corrugate with a craft store type unit..

I can't really say why I have not tried the single foil conductor yet other than lack of time. I have to get some magnet wire.

I have caps to harvest foil from, just haven't gotten to those yet.

I will do a side-by-side comparison for sure once I am done with the tinkering and building of the baffles. The stands are cemented and are awaiting cover-up panels. I am also still trying to decide what to do with the tops of these things.

I am getting an electronic x-over in the mail today, I expect to cross them at ~400hz.

thanks for your interest and comment,

paul

poopydoopynoopy said:thank you !

The four strips in my case came to ~1ohm each. No magnet wire needed.

I use 5" of packing tape on each end/other side for added strength where they are clamped. I corrugate with a craft store type unit..

thanks for your interest and comment,

paul

Hello Paul ,

Thanks for taking the time to respond , i have 2 more questions regarding your above comments ......

are you saying each strip was 1 ohm or the combined imp of all 4 made it 1 ohm .. How did you achieve this ? or else, how are you combining the 4 strips electrically .....

what do you mean by corrugated with a" craftstore" type ?

Regards ,

a.wayne said:

are you saying each strip was 1 ohm or the combined imp of all 4 made it 1 ohm ..

How did you achieve this ?

how are you combining the 4 strips electrically .....

what do you mean by corrugated with a" craftstore" type ?

Regards ,

1 ohm/strip x 4 strips = 4 ohms. strips are connected in series (using 16awg wire in my case) and half-wave current should travel in same direction through all four strips. If you are building these I suggest you do some research on this, what I did.

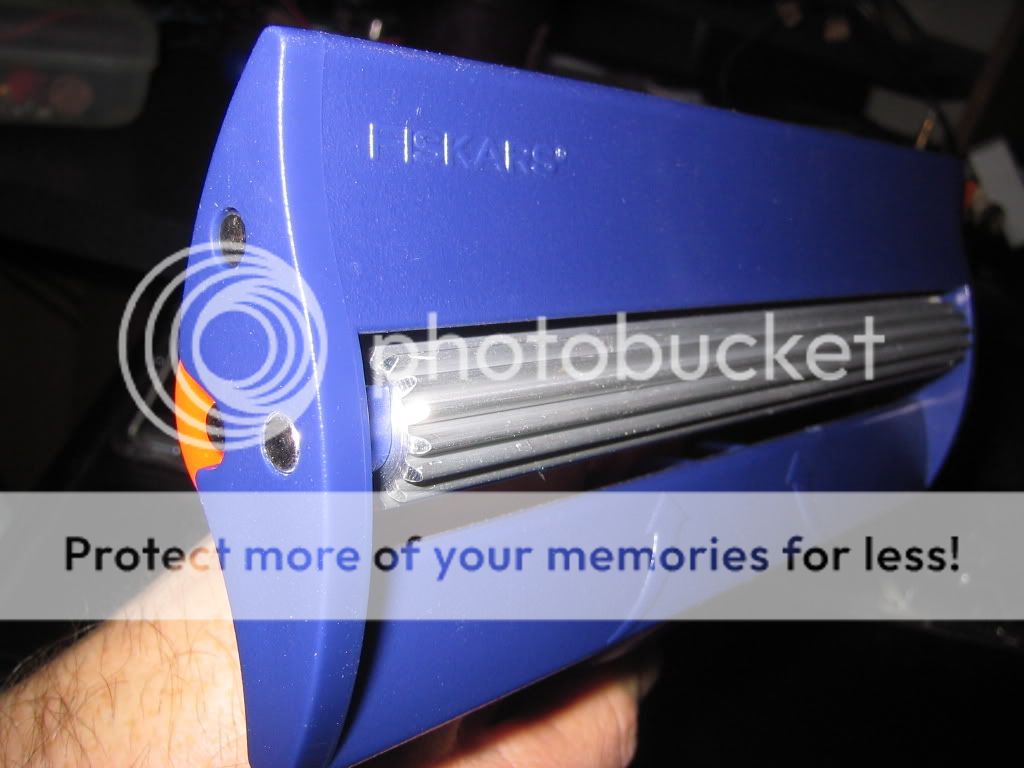

here are a cpl pics of the corrugator I used:

paul

Hello Paul ,

thanks for the response and yes i do understand what you have done with your ribbon diaphragm, just wanted a bit of clarification as 4 ohm seemed pretty high for the diaphragm., I usually see 2.8

Thanks for the link on the fiskars ....................................................

thanks for the response and yes i do understand what you have done with your ribbon diaphragm, just wanted a bit of clarification as 4 ohm seemed pretty high for the diaphragm., I usually see 2.8

Thanks for the link on the fiskars ....................................................

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Paul's Lousy 60" Ribbons