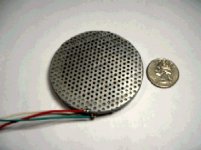

Before I put my ES headphones on I need a reliable insulating coating for my perforated steel stators. I will run my own tests but would like to hear your experiences with epoxy garage floor paint, powder coating, latex, etc. before I do my experiments.

I know some of you have used diluted ferric chloride to smoothen perforated aluminum. What has worked well for etching perforated steel? The smoother the perforation the more uniform the coating I expect.

I have perforated aluminum stators as well, they warped (melted) when I tried to use aluminum solder to attach the copper lead wires to them. I could use tiny steel machine screws passed through the perforations to solder to--but steel and aluminum tend to react when in close proximity. Recommendations?

...j

I know some of you have used diluted ferric chloride to smoothen perforated aluminum. What has worked well for etching perforated steel? The smoother the perforation the more uniform the coating I expect.

I have perforated aluminum stators as well, they warped (melted) when I tried to use aluminum solder to attach the copper lead wires to them. I could use tiny steel machine screws passed through the perforations to solder to--but steel and aluminum tend to react when in close proximity. Recommendations?

...j

Attachments

You can search a little but...

nylon 66 powder coating is probably the best suited that you will find. Not to say that there is not a lot of coatings that will work but nylon 66 is the best suited. Nylon 66 powder coat has the least amount of "creap" that you will find. That means that it will build up thicker on a sharp edge than any powder coating that you will find. Sharp edges are where you are going to have the most amount of problems in an ESL and what you will have the most of with a perf stator. So there you go. You will also want to find a well experienced coater if you plan to move on to full range ESL's where you will have much higher voltages to deal with. With a head phone the voltages will be low so you might get away with any coating low creap or not. Have you considered deburring your stators with a dremel tool? You won't have all that much to do for only one pair.

nylon 66 powder coating is probably the best suited that you will find. Not to say that there is not a lot of coatings that will work but nylon 66 is the best suited. Nylon 66 powder coat has the least amount of "creap" that you will find. That means that it will build up thicker on a sharp edge than any powder coating that you will find. Sharp edges are where you are going to have the most amount of problems in an ESL and what you will have the most of with a perf stator. So there you go. You will also want to find a well experienced coater if you plan to move on to full range ESL's where you will have much higher voltages to deal with. With a head phone the voltages will be low so you might get away with any coating low creap or not. Have you considered deburring your stators with a dremel tool? You won't have all that much to do for only one pair.

I have my current stators powder coated (not sure what type exactly). They are less insulated than my prototypes actually. I am using aluminum perf like you, although not etched. My prototypes used 3 coats of rustoleum thinned slightly rolled onto the stators followed by 3 coats of polyeurathane rolled onto the stators. Those things worked great, and I could grab them with impunity.

Sheldon

Sheldon

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.