Have just finished another 60 x 40 cm 5 kilo using neos 50 x 12.7 x 3 mm magnets using 180 magnets on each one. Another 7 to go of this design. all hanging up in the living room. Full home cinema layout. I am getting organized at last. This will hopefully be my last rebuilding, I hope. Will finish my 2 headphone designs soon, and will probably make an electronic piano design using 3 diaphragms, which means I will have to buy more magnets from China. As I've said before it keeps my brain working and helps me pass the time usefully. Important at my age.

Have just finished another 60 x 40 cm 5 kilo using neos 50 x 12.7 x 3 mm magnets using 180 magnets on each one. Another 7 to go of this design. all hanging up in the living room. Full home cinema layout. I am getting organized at last. This will hopefully be my last rebuilding, I hope. Will finish my 2 headphone designs soon, and will probably make an electronic piano design using 3 diaphragms, which means I will have to buy more magnets from China. As I've said before it keeps my brain working and helps me pass the time usefully. Important at my age.

Tell us more about the electronic piano system. Sounds interesting...

Greg

Another person brought up this idea, and it got me interested, as a piano is mono ,I was interested in building it . Using 3 diaphragms for the bass, middle and top, using an electronic crossover. I bought one so I can build it. It should sound good, piano music is beautiful and is very difficult to produce using speakers or so they say. I will have to get some more magnets, Neos or Ferrites, not decided which yet.

Have finished my latest blue rebuild, only 3 more to do, then will probably finish my 2 planar headphone designs, still a few more rebuilds to do, not many tho'. Then I will probably get some more neo magnets. So I can build a piano based full range planar using electronic crossover.

Hey JamesBos.

I have received my magnets and wanted to start by making a small tweeter.

Aluminium Tape = The Masking Shop - Aluminium Foil Tape

Mylar = 6uM = Still looking for a supplier in Aus (is 6uM good for tweeters)

Perf Steel = Still looking again for suppliers in Aus.... What would be your recommendations for the perf steel spec (eg... hole size/spacing/steel thickness)

Cheers and I hope you have finally finished all your rebuilds

Dean.

PS. I have read through the thread but may have missed a few of these answers.

I have received my magnets and wanted to start by making a small tweeter.

Aluminium Tape = The Masking Shop - Aluminium Foil Tape

Mylar = 6uM = Still looking for a supplier in Aus (is 6uM good for tweeters)

Perf Steel = Still looking again for suppliers in Aus.... What would be your recommendations for the perf steel spec (eg... hole size/spacing/steel thickness)

Cheers and I hope you have finally finished all your rebuilds

Dean.

PS. I have read through the thread but may have missed a few of these answers.

6 um ok for tweeter, but I would build a full range one using 12 um 6 um is a bit delicate all right for ESL's but too fragile for sticking tape to. I have built full range ones A4 size, sounded quite good compared to my bigger sizes. You can get the mylar on EBAY from china post free. THAT IS WHAT I USE. The perf I use has 50% hole and the holes are 4.8 mm wide and it is .7 mm thick. Get mine from Electromail RS. It comes in 2 sizes 500 x 500 cm and 1000 x 500 cm. I use the larger size as it fits my big 4' 2' sized speakers. I use large steel scissors to cut it to size.Have 3 more rebuilds of my blue 60 x 40 cm ones I use in my theatre set up. 11 altogether. You will find all data and details you need in this forum started by me. Good luck, and be very careful with the neo magnets as they can jump a long distance, especially the big ones 50 x 12.7 x 3mm, my size, can give you blood blisters.Hey JamesBos.

I have received my magnets and wanted to start by making a small tweeter.

Aluminium Tape = The Masking Shop - Aluminium Foil Tape

Mylar = 6uM = Still looking for a supplier in Aus (is 6uM good for tweeters)

Perf Steel = Still looking again for suppliers in Aus.... What would be your recommendations for the perf steel spec (eg... hole size/spacing/steel thickness)

Cheers and I hope you have finally finished all your rebuilds

Dean.

PS. I have read through the thread but may have missed a few of these answers.

No, I got the bug by reading an article in the HI-FI NEWS magazine over twenty years ago. I built a pair of 4' x 2' ones to my own design. Then a few years later when neos appeared on the scene. I really got the bug and have been building and rebuilding ever since!? Gives me something to do, now I am retired.I'm curious.....did you get the bug to make planars after having owned some Maggies or other brand?

Greg

Thanks for the info. You are very inspiring to say the least. I'm too lazy and just buy Bohlender Graebner planars like the Neo10 to fit into multiway designs. Have you ever attempted a push-pull with magnets on both sides of the diaphragm?

I owned the smallest Maggies, the MMG for several years. Actually I still have them, but the damn voice coil wire started to delaminate from the mylar and I have not felt like removing the fabric to try to re-glue it. This is a common problem after some time. They need to switch all of their models to the kind of diaphragm with the vapor deposited conductors rather than the glued on magnet wire style.

I owned the smallest Maggies, the MMG for several years. Actually I still have them, but the damn voice coil wire started to delaminate from the mylar and I have not felt like removing the fabric to try to re-glue it. This is a common problem after some time. They need to switch all of their models to the kind of diaphragm with the vapor deposited conductors rather than the glued on magnet wire style.

No I haven't tried magnets on both sides of the diaphragm, but I did try it with 2 diaphragms on opposite sides , with 2 sets of magnets, but wasn't worth the effort or the weight. Have finished my last blue rebuild yesterday, so will probably finish my planar headphone design.

Hi all,

I wanted to have a go too...

I put this together with bits to hand around the office.

It will be a class demo to demonstrate that there are alternatives to ‘cones’.

This is a steel 2U 19” rack ventilation panel. The painted surface reduces the friction so you may need double-sided tape to prevent the magnets slipping together.

Thanks Henry for making it look so easy

I wanted to have a go too...

I put this together with bits to hand around the office.

It will be a class demo to demonstrate that there are alternatives to ‘cones’.

This is a steel 2U 19” rack ventilation panel. The painted surface reduces the friction so you may need double-sided tape to prevent the magnets slipping together.

Thanks Henry for making it look so easy

Attachments

On the first attempt I didn't get enough tension on the mylar film before sticking the aluminium tape. It locks in wrinkles.

I started with the plywood sandwich but separated them to use the ply for the second attempt. Double-sided tape holds diaphram tension.

I distributed the magnets between the two by leaving gaps (see photo).

They are fine for demonstrating the operating principals...

Refinements for next time: Stick magnets, brace the 19" panel, try narrower tape, try wider panel.

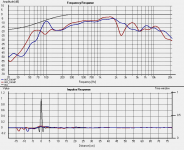

Red trace first attempt, Blue trace second attempt. (100Hz Highpass)

Chris

I started with the plywood sandwich but separated them to use the ply for the second attempt. Double-sided tape holds diaphram tension.

I distributed the magnets between the two by leaving gaps (see photo).

They are fine for demonstrating the operating principals...

Refinements for next time: Stick magnets, brace the 19" panel, try narrower tape, try wider panel.

Red trace first attempt, Blue trace second attempt. (100Hz Highpass)

Chris

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Full range planar speaker using neo magnets