Hello my friend, i posted my answer in your post to be more precise.

Yup i know. I remember the butterfly membrane shape vs round, cilinder like tests...

In the end, to get this speaker working there are a huge amount of small details wich, if get right, the result may be outstanding.

Cheers

Serg

Hi Serg !

more turns is more force , just how it works in magnetneticsgoing up in turns thus increasing resistance will net in no gain no lose. if you bring back that impedance you will gain. yes it does mean you got more weight more turns of thicker wire weighs more

I believe that the truth is somewhere in the midle..Yes you might gain more force but at the cost of weight+ suplimentary glue aded. Adding more glue or harder glue you make the coil more rigid but limit the upper end extension plus increasing mass and inevitably gain a restrained sound. Not adding a hard glue may cause the turns from the coil move independetly between the two cilinders. Again using thicker foil means more thinner turns thus decreasing the total contact area between each independent winding with the membrane wich may favorise the hights to sound more proeminent and loosen the grip on the reproduction of the mids and midbass. An interesting thing that happends when we have more turns is that each suplimentar turn acts almost as a barrier in the path of the previous one (from inside to outside of the coil speaking) thus again, screwing the overall frecv resp and sound ballance .

These 3dB may be a gain but in quantity not quality if not approached accordingly and may not be perceived if only a 1~2dB remains practically ( maybe thats why i didnt heard any dB gain). I did made allot of coils by hand and a huge amount of them where gaining something here but loosing something elsewhere. There must be an obligatory balance between the turns/thickness of wire or foil/weight of coil/gap and magnetic structure to get it just right.

Another thought is that you may gain something on the 4ohms or less impedance. If we remember well my friend, from the youtube, the producer of the most expensive ruban ever, after optimising the coil to get the optimum gain/impedance extention balance right he ended up with a 2 ohm coil and a special silly Ag winded input trafo to get 4-8 ohms (an inevitable trade of).

In my case, i ended up with a coil of 7.5ohm dc with a total of 4 *1.5mm large traces and less than 1mm spacing between the turns to get a 1:1 coil vs gap ratio and a good frecv responce.

So my conclusion is to keep the ratios in the limits, have huge magnetic field strenght (i am thinking to actually make some electromagnets instead of neodims some day) , ultra light coil, and very light membrane and yet very rigid....

good point about the surface area. although i made fast version yesterday with wire al packed together and response was the same. i think the V shape ***** up more of the high end then anything else to be honestof mic i reached 18 khz in the middle it gets bumpy

Yup i know. I remember the butterfly membrane shape vs round, cilinder like tests...

In the end, to get this speaker working there are a huge amount of small details wich, if get right, the result may be outstanding.

Cheers

Serg

Sergiu, WrineX,Many thanks for very valuable information.

I found a 2-sided foil-coated glass fiber glass with a thickness of 0.55 mm.

First I'll try to wind the coil with a wire then etch on glass textolite.

Youre wellcome.

Interesting Oleg, can you post some pics with this combo.

One of our colleagues tested the ruba with membranes made from fiberglass and carbon fiber if i remember well and didnt had such a good succes.

So far the materials that hasnt been tested are: rice paper, cottone paper, washy paper,thicker backing paper, thinner electroinsulated paper (used for trafo windings and insulation), thinner myllar foil and who knows maybe new technology materials..

Another aspect that i forgot to mention is that the deflection slot as i use or as the one used in the most expensive rubans are a must have.. They really add more roundness to the voices and the small details (when the song has huge sound stage) are abit more pronounced and reproduced better (like you can pick them from the sound stage even if you are deaf---you know what i mean). I didnt kmow how to measure this aspect but this is what i heard and my wife confirmed when compared a naked ruba vs the final one as i use now.

It doesnt matter if they are flat or round as i use.

Cheers

Sergiu

The problem with 10mm did a magnets is the fact your metal is 10 wide unless you use the sideways.

Here 4 pieces of steel 20x10x600 bender by only 40x20x1mm magnets

Gap was 3.5 mm now 0

And how you struggled with it?

I think that this is still abit too heavy. Wrine used thin laminae copper coil. Ask him where he finds it. See if its sourceable in your country.Sergiu you misunderstood me (the shortcomings of using an interpreter)

I'm talking about fiberglass for making printed circuit boards.

I have found fiberglass a very thin 0.55 mm (with 2-sided foil)

Sergiu, WrineX,Many thanks for very valuable information.

I found a 2-sided foil-coated glass fiber glass with a thickness of 0.55 mm.

First I'll try to wind the coil with a wire then etch on glass textolite.

I found the laminate at eBay once it we called polyester copper laminate. I now very often use laminate Mylar film with aluminium. You can get this thicker then 12micron micron to. I'll take a look

finished project at last!!

Hello and a happy new year to you all,

In december 2017, in my holidays i just finished my speakers, and forgot to post. Here are some pics with the finished rubas, bass, cables and filters.

You may not see many changes but they are all actually repainted and everything has now the finishing touches. I added a burned wood effect on the sides of each ruban and aded some handles. Those speaker cables are 6*2.5mm wires twisted two by two, then braided and have 3m long, and the + and - are holded together by wooden supports at 10cm distance from each other. This may be overkill but i noticed that cables do affect the sound abit..

The filters are basically butterworth but fine tuned to eliminate the peak at 220hz. The caps used are pp filled with oil motor run (posted a pic where i made a burn in with them at 220v mains for 10mins ) bypassed with pio and pp caps for the rubas and litics for the bass.

) bypassed with pio and pp caps for the rubas and litics for the bass.

Cheers

Sergiu

Hello and a happy new year to you all,

In december 2017, in my holidays i just finished my speakers, and forgot to post. Here are some pics with the finished rubas, bass, cables and filters.

You may not see many changes but they are all actually repainted and everything has now the finishing touches. I added a burned wood effect on the sides of each ruban and aded some handles. Those speaker cables are 6*2.5mm wires twisted two by two, then braided and have 3m long, and the + and - are holded together by wooden supports at 10cm distance from each other. This may be overkill but i noticed that cables do affect the sound abit..

The filters are basically butterworth but fine tuned to eliminate the peak at 220hz. The caps used are pp filled with oil motor run (posted a pic where i made a burn in with them at 220v mains for 10mins

Cheers

Sergiu

Attachments

Hi adason,

The measurements are what i want too because my second good computer that's still working is my old dual core tablet. My pc died at the begining of december 2017 from a current surge from the mains.... It will take me 2-3 months from now on to make a new one so please be patient with me.

Till then i have taken by good a measurement that i posted a few pages back with the ruban and the woofer in free air. The ruban measurements should remain valid because i used exactly the same type of implementation and everything else as that one but cannot say the same for the bass..

The off axis of the ruba should be tiny bit better with the peaks and dips moved abit to the high frequencies compared to the on axis responce but wil remeasure that too.

Cheers

The measurements are what i want too because my second good computer that's still working is my old dual core tablet. My pc died at the begining of december 2017 from a current surge from the mains.... It will take me 2-3 months from now on to make a new one so please be patient with me.

Till then i have taken by good a measurement that i posted a few pages back with the ruban and the woofer in free air. The ruban measurements should remain valid because i used exactly the same type of implementation and everything else as that one but cannot say the same for the bass..

The off axis of the ruba should be tiny bit better with the peaks and dips moved abit to the high frequencies compared to the on axis responce but wil remeasure that too.

Cheers

Hello my friend,

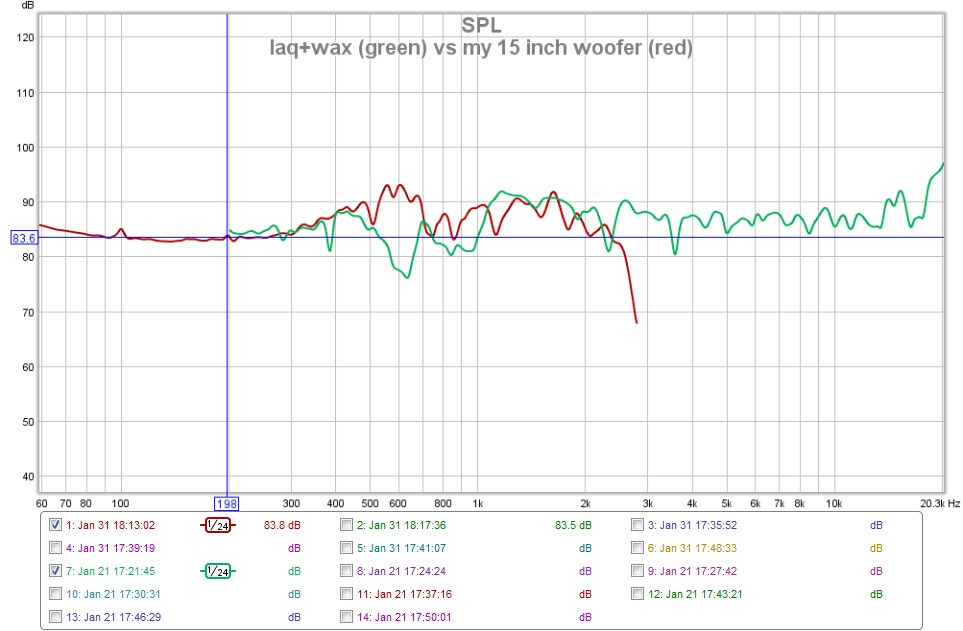

I forgot to post a pic with the 15 inch woofer+ ruban. After the listening sessions i dissasembled th ruban to make the final coils and seen that the gap was smaller and rubbing as i sayed earlyier. Here are some measurements. The mic was at the level of the frame of the 15 " bass and after i measured the bass, i positionned the mic perpendicullary, on axis at the level of the round edges of the ruba cils, with the bass disconected, to measure the laq+wax almost finall version prototype ruba..

I listened to this interesting combo and making adjustments for about 2 hours then diassembly everithing. The filtering was second order for bass and first order for ruba(300hz cutting point). The ruba was positionned 10cm in the back (still on axis with the bass) for my bass tastes to be fullfilled.

The sound was very powerfull (at 10W mono@jlh 69 amp @75% volume from the phone), in a way that i could barelly hear my wife speaking (from almost a meter a way, where she was)in a listening room of 20sqm at 3 m away from the speakers. The sound quality was even more staggerring now with the adenum of the bass. Its pitty that the ruban cant go lower than 150~200hz. Its interesting how the bass contures and spices everithing up.

Cheers

Sergiu

Ps: the measurements where made with no filtering. I cutted the frequencies from REW, then joined the graphs togheter.

Here they are..

Last edited:

Many thanks to all for the advices, especially Sergiu 209 and Wrinex.

I have made my own(until the test) version.

The chinese magnets ( 49x9x9mm) are declared N50.

Steel magnetic circuit (CT-3) - 15x6x25cm

The gap is 3.3 mm, the copper coil wire 0.14, 8 Ohm.

The coil is made as in # 969 on a mandrel with БФ glue.

The weight of the coil is 1.19gr.

Membrane-paper 200gr \ m (I will redo from 120 gr \ m)

The sound really liked, surpasses everything I heard before.

I have made my own(until the test) version.

The chinese magnets ( 49x9x9mm) are declared N50.

Steel magnetic circuit (CT-3) - 15x6x25cm

The gap is 3.3 mm, the copper coil wire 0.14, 8 Ohm.

The coil is made as in # 969 on a mandrel with БФ glue.

The weight of the coil is 1.19gr.

Membrane-paper 200gr \ m (I will redo from 120 gr \ m)

The sound really liked, surpasses everything I heard before.

Last edited:

- Home

- Loudspeakers

- Planars & Exotics

- A DIY Ribbon Speaker of a different Kind