DIY Ribbon Part I

Here comes the missing part I of my DIY Ribbon article - look at "Ribbon I" under "Lautsprecher" at http://www.michaelgaedtke.de/.

Here comes the missing part I of my DIY Ribbon article - look at "Ribbon I" under "Lautsprecher" at http://www.michaelgaedtke.de/.

Transformer for Ribbon-Speakers

Here I show how I constructed transformers for my ribbons:

http://www.michaelgaedtke.de/Ribbon_3.htm

Here I show how I constructed transformers for my ribbons:

http://www.michaelgaedtke.de/Ribbon_3.htm

Magnetic field strength

Hello again,

from a friend I borrowed a gaussmeter which measures the strength of magnetic fields with a probe small enough to be positioned in the gap of my ribbon speakers. Here are my findings: Fortunately the field is

a) highly concentrated in the gap

b) linear across the length of the gap; linear part begins after half of first magnet block (some 10 mm) so that total homogeneous field ist just one neodym block shorter than magnet row (9 out of 10)

c) as far as the old gauge is correct field is strong at some 0,5 Tesla (5000 Gauss) in the middle of a 12 mm wide gap between double rows of magnets - see foto.

By the way: I also tested if the field is influenced by the addition of iron pieces across the ends of the frame to close the magnetic flux in the rear of the ribbon. Varnhagen seems to be right in his finding that this doesn't make much of a difference in efficiency - I could hardly see a deflection of the meter pin.

Hello again,

from a friend I borrowed a gaussmeter which measures the strength of magnetic fields with a probe small enough to be positioned in the gap of my ribbon speakers. Here are my findings: Fortunately the field is

a) highly concentrated in the gap

b) linear across the length of the gap; linear part begins after half of first magnet block (some 10 mm) so that total homogeneous field ist just one neodym block shorter than magnet row (9 out of 10)

c) as far as the old gauge is correct field is strong at some 0,5 Tesla (5000 Gauss) in the middle of a 12 mm wide gap between double rows of magnets - see foto.

By the way: I also tested if the field is influenced by the addition of iron pieces across the ends of the frame to close the magnetic flux in the rear of the ribbon. Varnhagen seems to be right in his finding that this doesn't make much of a difference in efficiency - I could hardly see a deflection of the meter pin.

Attachments

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

This is my new ribbon. 150 cm long, 2 cm wide

ABJensen said:This is my new ribbon. 150 cm long, 2 cm wide [/B]

How did you corrugated your ribbon ONLY vertically so that you don´t get any other wrinkles which may cause bad sound? What kind of tool do you have?

I tested similar idea last weekend with 10x2cm ribbon. It sound practically as good as free ribbon. The best thing was that this construction is absolutely no sensitive to air movement from bass, people, wind etc as traditional long ribbons are. Extremely practical magnetostatic line source!

But I found it pretty hard to corrugate it. My problem was that somehow you should be able to do corrugation without any other wrinkles. Horizontally it is easier since you need to press only 2cm of ribbon at time. But vertically you should ether press the whole length (which is impossible if you have 1-2m long ribbon) or have some kind of corrugeted wheels which to roll on the ribbon.

What is easiest way?

Made another ribbon.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

I have made some ajustements. The ribbons look like a UU now. Now it allmost look like a fullrange driver.

http://www.hifi-musik.dk/richedit/upload/2k0475068c85.jpg

http://www.hifi-musik.dk/richedit/upload/2k0475068c85.jpg

ABJensen, nice ribbon, be carefull not to burn that paper

Michael, you still make impressive documentation

But the reason why you dont measure any difference with iron at the ends, is because it simply dont work - you need to have curved iron from side to side across each magnet pair, to have an easy path fore the magnets and avoiding field stray(loss ?) - if thats the right word

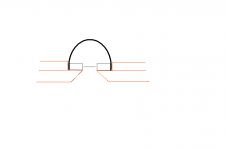

Like this

Michael, you still make impressive documentation

But the reason why you dont measure any difference with iron at the ends, is because it simply dont work - you need to have curved iron from side to side across each magnet pair, to have an easy path fore the magnets and avoiding field stray(loss ?) - if thats the right word

Like this

Attachments

ABJensen, pictures are gone ... ? and last link dont work either ... ?

Will you discuss your constuction in detail .... maybe we could learn something ?

edit,... ahhh, I see, you are Andre and not the owner of first the linked site .... and found some nice details too "New Type of Ribbon - visiting Andre "

"New Type of Ribbon - visiting Andre "

You must be one of the guys who have payed a small fortune in magnets

Will you discuss your constuction in detail .... maybe we could learn something ?

edit,... ahhh, I see, you are Andre and not the owner of first the linked site .... and found some nice details too

You must be one of the guys who have payed a small fortune in magnets

tinitus said:

But the reason why you dont measure any difference with iron at the ends, is because it simply dont work - you need to have curved iron from side to side across each magnet pair, to have an easy path fore the magnets and avoiding field stray(loss ?) - if thats the right word

Hi tinitus,

Would you kindly elaborate?

Do you mean a cylindrical magnet with a strip cut along the axis on the tube wall as the gap?

Cheers

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Diy ribbon