OK-I am an amateur- But I am a huge ESL enthusiast. I currently have a Martin Logan reference system and the ability they have to pick up the nuances is enough to hypnotize me.

Now, I want to make my own ESL's for my bedroom and mostly just for fun. I figure they will sound better than most market speakers I could buy for the same price.

The problem is...I dont know how much I should expect to pay. I have heard $90.00 all the way to $500.00+. At $500.00, my fun project would be to much considering I may simply fail and have to scrap it.

So, I am looking for the CHEAPEST way possible for my first project. After I complete it, I will have more confidence/experiance and will then embark on a "quality" ESL.

Any help is much appreciated. I am new to "fooling around" with electroncs.

WarrenO suggested this site to me if any of you know him.

Thank You,

Dominick in New Jersey

Now, I want to make my own ESL's for my bedroom and mostly just for fun. I figure they will sound better than most market speakers I could buy for the same price.

The problem is...I dont know how much I should expect to pay. I have heard $90.00 all the way to $500.00+. At $500.00, my fun project would be to much considering I may simply fail and have to scrap it.

So, I am looking for the CHEAPEST way possible for my first project. After I complete it, I will have more confidence/experiance and will then embark on a "quality" ESL.

Any help is much appreciated. I am new to "fooling around" with electroncs.

WarrenO suggested this site to me if any of you know him.

Thank You,

Dominick in New Jersey

the cheapest way is to sacrifice efficency and save on the transfomer cost

get a lower voltage xfrmer and up it with a simple voltage multiplier circuit

the cost of the panels is minimal in comparison to the xfrmer cost

you can go as big, wide, difficult as you like... and cost will be fairly similar

the mylar is very cheap... the perforated steel is quite cheap and everything else is labor

get a lower voltage xfrmer and up it with a simple voltage multiplier circuit

the cost of the panels is minimal in comparison to the xfrmer cost

you can go as big, wide, difficult as you like... and cost will be fairly similar

the mylar is very cheap... the perforated steel is quite cheap and everything else is labor

cheap and reliable

To get started I agree don't worry too much about transformer cost as most old tube amp output transformers will work and probably surprise you with how well your new speaker will sound. You can always upgrade to your hearts content. High voltage supplies can be bought new and smaller than a soft pack of cigaretts for $60.00. You only need one to charge both diaphragms.

I still think that a simple clone of an Acoustat made with Kynar wire wrap wire 28 or 30 guage or double build magnet wire on a styrene frame will last a life time. Yes a bit more work than perf metal but industrictable and with the dielectric quality of these wires no surprises (sparks/breakdown). You can wind as many wires per inch as you like (20 or 32) with a simple jig made with a threaded rod and have a high efficiency stator which will not require an big expensive amp to drive.

I have had very good success with Acoustat panels and Inner Sound panels driving them with 70 volt line matching transformers running backwards. These transformers can be bought all day long for $10.00 each. You probably have a set of speakers now that don't owe you a dime that you can salvage for bass duty. All in all a very inexpensive hybrid. I am sure that once you get a taste for electrostats that you will develope plans for you next project in a hurry. Selling one pair to build another or building a couple of first pairs to pay for a third is an option. So you can practice and get paid to do so. $200-300 ought to get you up and running with out much difficulty and if you get a little help and a few breaks I should think that you could do as well with half that amount. That said the sky is the limit but that is for you to decide.

One thing for sure I can tell you is that you have a tremendous advantage on your side. The wealth of knowledge here on this site alone is incredible. Not only that but the good will and generousity shown by the members here is astounding. You are in the best of company and you need only ask for assistance. If you give this an honest try I cannot see how you could possibly end up with less than an excellent sounding pair of loudspeakers. This is a fine set of people that you are associated with who want you to achieve your goals. Jump in the water is fine! Very best regards Moray James.

To get started I agree don't worry too much about transformer cost as most old tube amp output transformers will work and probably surprise you with how well your new speaker will sound. You can always upgrade to your hearts content. High voltage supplies can be bought new and smaller than a soft pack of cigaretts for $60.00. You only need one to charge both diaphragms.

I still think that a simple clone of an Acoustat made with Kynar wire wrap wire 28 or 30 guage or double build magnet wire on a styrene frame will last a life time. Yes a bit more work than perf metal but industrictable and with the dielectric quality of these wires no surprises (sparks/breakdown). You can wind as many wires per inch as you like (20 or 32) with a simple jig made with a threaded rod and have a high efficiency stator which will not require an big expensive amp to drive.

I have had very good success with Acoustat panels and Inner Sound panels driving them with 70 volt line matching transformers running backwards. These transformers can be bought all day long for $10.00 each. You probably have a set of speakers now that don't owe you a dime that you can salvage for bass duty. All in all a very inexpensive hybrid. I am sure that once you get a taste for electrostats that you will develope plans for you next project in a hurry. Selling one pair to build another or building a couple of first pairs to pay for a third is an option. So you can practice and get paid to do so. $200-300 ought to get you up and running with out much difficulty and if you get a little help and a few breaks I should think that you could do as well with half that amount. That said the sky is the limit but that is for you to decide.

One thing for sure I can tell you is that you have a tremendous advantage on your side. The wealth of knowledge here on this site alone is incredible. Not only that but the good will and generousity shown by the members here is astounding. You are in the best of company and you need only ask for assistance. If you give this an honest try I cannot see how you could possibly end up with less than an excellent sounding pair of loudspeakers. This is a fine set of people that you are associated with who want you to achieve your goals. Jump in the water is fine! Very best regards Moray James.

LowCost

Hi,

I´d opt for a hybrid design where the ESL-panel is supported by an dynamic bass (8-12inches) up till 150-250Hz.

The reason therefore is, that You can use a panel with app. 1mm d/s-spacing which will give You high efficiency and eases the need for pricey high quality trannies. You can get away with a pair of cheap series connected 9V/230V (lucky Germany ) standard toroids to give You an really good working trannie which steps up by a factor of 1:50.

) standard toroids to give You an really good working trannie which steps up by a factor of 1:50.

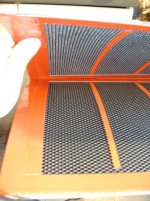

Use perforated metal sheets of 1mm thickness and 3-5mm holes. For insulation paint (spray) the stators with an PU-laquer several times until the paint-thickness reaches 0.3-0.5mm. As spacers You may use the excellent double sticky foam tapes from 3M, or You cut thin PVC or Lexan-stripes and glue it with double sided carpet-tape or special glue.

To contact the diaphragm You can cut Aluminium foil for household purposes into narrow strips.

For diaphragm coating I prefer liquids that can be painted or sprayed onto the film. Imo You get a more consistent and even coating and You don´t stress the film by heavy rubbing action (as with grafite). I use a clear waterbased compound mainly consisting of a childfriendly hobby glue (very cheap, flexible and easy to use).

The HV-supply can be easily and cheaply built from a cascade.

When installing the membrane use high mechanical tension. This will give You a high resonance frequency.

The benefits are:

- high efficiency

- high SPLmax

- You can use the fs together with an simple passive high pass filter (just one C!) to give You the desired frequency response (no heavy equalization of the Fs will be needed).

jauu

Calvin

Hi,

I´d opt for a hybrid design where the ESL-panel is supported by an dynamic bass (8-12inches) up till 150-250Hz.

The reason therefore is, that You can use a panel with app. 1mm d/s-spacing which will give You high efficiency and eases the need for pricey high quality trannies. You can get away with a pair of cheap series connected 9V/230V (lucky Germany

Use perforated metal sheets of 1mm thickness and 3-5mm holes. For insulation paint (spray) the stators with an PU-laquer several times until the paint-thickness reaches 0.3-0.5mm. As spacers You may use the excellent double sticky foam tapes from 3M, or You cut thin PVC or Lexan-stripes and glue it with double sided carpet-tape or special glue.

To contact the diaphragm You can cut Aluminium foil for household purposes into narrow strips.

For diaphragm coating I prefer liquids that can be painted or sprayed onto the film. Imo You get a more consistent and even coating and You don´t stress the film by heavy rubbing action (as with grafite). I use a clear waterbased compound mainly consisting of a childfriendly hobby glue (very cheap, flexible and easy to use).

The HV-supply can be easily and cheaply built from a cascade.

When installing the membrane use high mechanical tension. This will give You a high resonance frequency.

The benefits are:

- high efficiency

- high SPLmax

- You can use the fs together with an simple passive high pass filter (just one C!) to give You the desired frequency response (no heavy equalization of the Fs will be needed).

jauu

Calvin

Attachments

comparison

Hi,

this is a comparison between my DIY-Panel (very similar to ML-Sequel) and an ML Prodigy-Panel.

Both were driven by an Amplimo 1:75 Trannie without and with filtering. Measurememts were taken in the nearfiled of the panels with 2.83V. SPL is recalculated to 1m distance.

As can be seen, the Prodigy panel uses a 12µm membrane that can be stretched harder than my 3.5µm film, giving the Prodigy a higher fs around 250Hz versus 160Hz. The thinner film on my Panel allows for an extended response at the upper end of the frequency range. Both panels can be trimmed with an damped 12dB filter to a very linear falling response -no need for fs equalization! Efficiency of both panels is quite high and can be adjusted by the Trannies factor to lower or even higher levels. I got nearly identical frequency responses (apart from efficiency) by using simple toroids 230/9V.

jauu

Calvin

Hi,

this is a comparison between my DIY-Panel (very similar to ML-Sequel) and an ML Prodigy-Panel.

Both were driven by an Amplimo 1:75 Trannie without and with filtering. Measurememts were taken in the nearfiled of the panels with 2.83V. SPL is recalculated to 1m distance.

As can be seen, the Prodigy panel uses a 12µm membrane that can be stretched harder than my 3.5µm film, giving the Prodigy a higher fs around 250Hz versus 160Hz. The thinner film on my Panel allows for an extended response at the upper end of the frequency range. Both panels can be trimmed with an damped 12dB filter to a very linear falling response -no need for fs equalization! Efficiency of both panels is quite high and can be adjusted by the Trannies factor to lower or even higher levels. I got nearly identical frequency responses (apart from efficiency) by using simple toroids 230/9V.

jauu

Calvin

Attachments

Re: comparison

Hi Calvin

A bit of a digression, but I was wondering about the details of your filters. Are the resistors wired in parallel with the coil/transformer to reduce the MR impedance, or in series with the coil to tailor the curve?

I am currently using a pair of Innersound panels, originally crossed over at 500 Hz, but have been listening to them full-range with a sub, and I am in love with the clarity and detail. The problem is that they start popping when driven hard with bass-heavy material, so I will have to consider some kind of high-pass filter. I am thinking that a passive design might be less noticeable than my Marchand active filter (which definitely imparts some harshness to the highs) so would like to try something like yours to test that.

Thanks

Phil

Hi Calvin

A bit of a digression, but I was wondering about the details of your filters. Are the resistors wired in parallel with the coil/transformer to reduce the MR impedance, or in series with the coil to tailor the curve?

I am currently using a pair of Innersound panels, originally crossed over at 500 Hz, but have been listening to them full-range with a sub, and I am in love with the clarity and detail. The problem is that they start popping when driven hard with bass-heavy material, so I will have to consider some kind of high-pass filter. I am thinking that a passive design might be less noticeable than my Marchand active filter (which definitely imparts some harshness to the highs) so would like to try something like yours to test that.

Thanks

Phil

hi Calvin,

Thanks for the interesing ideas, nice to see that someon here has hands on experience A few questons though...

A few questons though...

- What is PU-laquer?

- can you give us a bit more info on the coating, what kind of glue

- it seems from the dividing curcuit you posted that the panels are voltage driven but the frequency plots doesn't show any 6db/okt raise

Thanks for the interesing ideas, nice to see that someon here has hands on experience

- What is PU-laquer?

- can you give us a bit more info on the coating, what kind of glue

- it seems from the dividing curcuit you posted that the panels are voltage driven but the frequency plots doesn't show any 6db/okt raise

Hi,

PU means PolyUrethane. Availabilty of those laquers is good, even though I prefer to purchase the stuff from a prof-store and not the DIY-market. PolyUrethane hasthe desirable features of relatively low surface- and volume-resistivity paired with an acceptable high dielectric constant. If You can get a Nylon-based coating (think Rohm&Haas offers such stuff) opt for this.

I won´t offer the recipe of my diaphragm coating in public, but there are a lot of recipes and liquids around that work well.

A lot of acrylic and epoxy glues work well. The electrostatic circuit is a worthy knowledge pool.

You´re right. I left out the resistor in series to the polarizing voltage. It is in Fact a constant charge design with a high valued resistive coating ion the diaphragm.

jauu

Calvin

PU means PolyUrethane. Availabilty of those laquers is good, even though I prefer to purchase the stuff from a prof-store and not the DIY-market. PolyUrethane hasthe desirable features of relatively low surface- and volume-resistivity paired with an acceptable high dielectric constant. If You can get a Nylon-based coating (think Rohm&Haas offers such stuff) opt for this.

I won´t offer the recipe of my diaphragm coating in public, but there are a lot of recipes and liquids around that work well.

A lot of acrylic and epoxy glues work well. The electrostatic circuit is a worthy knowledge pool.

You´re right. I left out the resistor in series to the polarizing voltage. It is in Fact a constant charge design with a high valued resistive coating ion the diaphragm.

jauu

Calvin

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Homemade Esl Cost???