Has anybody ever taken apart a ribbon tweeter?

Ribbons such as the Ravens, Arum Cantus and the like.

What's inside? What is the air chamber like?

I've been inspired by the likes of dhenryp of this board, to try and build a ribbon tweet. I have most of the design issues resolved but I am unsure how the acoustical volumn is handled, so as to reduce unwanted backwave interferrence.

Ribbons such as the Ravens, Arum Cantus and the like.

What's inside? What is the air chamber like?

I've been inspired by the likes of dhenryp of this board, to try and build a ribbon tweet. I have most of the design issues resolved but I am unsure how the acoustical volumn is handled, so as to reduce unwanted backwave interferrence.

I think the biggest problems would be response anomolies caused by resonances of a back chamber and the reflected back wave. Small-ish chambers can have modes in the tweeter's range caused by the physical dimensions. Another disadvantage of a small chamber is that you have to work harder to abosrb the back wave in a small space. Almost all commercial ribbons I've seen use the back and side walls of the chamber to complete the magnetic path. They can't make it too big without paying a big weight/cost penalty for all the extra steel.

One big advantage of the open-back design I'm using in the other thread is that you can make the box behind it as big as you want and stuff as much sound absorbing material as you want. Alternately you could run it as a dipole. One option that I'm strongly considering is no box in the back, but a fairly thick layer of sound absorbing material instead. The advantage is that you should be able to absorb a good deal of the back wave. Hopefully, whatever is left won't give so much of a dipole effect that it makes it hard to match to box mid/woofs.

Please don't flame me about thinking out of the box and going dipole!

I'm worried that they might produce an exagerated sound stage in my HT. One last thing; I don't think the 36 mid-woofs I already have would be good for a dipole. I might try diploe but if it it doesn't work out, this approach could help.

I'm worried that they might produce an exagerated sound stage in my HT. One last thing; I don't think the 36 mid-woofs I already have would be good for a dipole. I might try diploe but if it it doesn't work out, this approach could help.

One big advantage of the open-back design I'm using in the other thread is that you can make the box behind it as big as you want and stuff as much sound absorbing material as you want. Alternately you could run it as a dipole. One option that I'm strongly considering is no box in the back, but a fairly thick layer of sound absorbing material instead. The advantage is that you should be able to absorb a good deal of the back wave. Hopefully, whatever is left won't give so much of a dipole effect that it makes it hard to match to box mid/woofs.

Please don't flame me about thinking out of the box and going dipole!

I'm worried that they might produce an exagerated sound stage in my HT. One last thing; I don't think the 36 mid-woofs I already have would be good for a dipole. I might try diploe but if it it doesn't work out, this approach could help.

I'm worried that they might produce an exagerated sound stage in my HT. One last thing; I don't think the 36 mid-woofs I already have would be good for a dipole. I might try diploe but if it it doesn't work out, this approach could help.I have listen to some Raven R1's and thought they were absolutly delightful.I would "assume" other examples of true ribbons from the likes of Raven, Arum Cantus and others sound as nice or better. All of these ribbons have a simular closed chamber be hind the ribbon. some how they manage to reduce back wave problems to a manageable degree. I am very concerened with efficiency (don't flame me about semmantics, you know what i mean) baced on the above I think it might be easer to deal with the back wave in an efficient magnetic design than to have no backwave problems and an inefficient mag. design. Alltho I'm very interested to see how the "open back's" turn out.

Stuffing the backs with fiberglass and wool would be my first thought too.

but I would like to see how it's done before I reinvent the wheel.

Stuffing the backs with fiberglass and wool would be my first thought too.

but I would like to see how it's done before I reinvent the wheel.

Dipole ribbons are good. Listen to the Magneplanars for a good example.

I Don't believe Magneplanars are true ribbons.

The Magneplanar planar drivers are not and were never meant to be ribbons. I was referring to their ribbon tweeters.

Jim Winey is the one who received a patent on the direct drive ribbon--i.e. no transformer. They sound very good, indeed. He is directly responsible for the current popularity of ribbon tweeters. They had been exceedingly rare devices prior to the early '80s when he released the Tympani IV. Now they're everywhere.

Grey

Jim Winey is the one who received a patent on the direct drive ribbon--i.e. no transformer. They sound very good, indeed. He is directly responsible for the current popularity of ribbon tweeters. They had been exceedingly rare devices prior to the early '80s when he released the Tympani IV. Now they're everywhere.

Grey

The Magneplanar planar direct drive ribbon--i.e. no transformer. They sound very good, indeed.

I would be vey much interested in seeing the design of these Magneplanar direct drive ribbon tweeters.

Great pictures Linesource. Do you know what the copper covered block in the back of the Raven is? I might guess it's another big magnet but I don't know why it would be covered with copper. Also, you wouldn't happen to have a picture of the Raven transformer would you? I can just get a peek at it in the picture. I'm wondering if it's EI or torroid.

PS

I got you aluminium samples - THANKS!. I hope to try them this weekend.

Denis

PS

I got you aluminium samples - THANKS!. I hope to try them this weekend.

Denis

The copper covering appears to be a flux band. It's wrapped around either a magnet or steel spacer that's located right behind the transformer. Perhaps they found that there was too much flux leaking from the transformer circuit into the main field circuit. It's interesting that they would have chosen to wrap the adjoining magnetic structure instead of the transformer. I'll bet there was a lot of experimenting before the design was final.

Graeme

Graeme

Wow ! Great pics, Linesourse. Thanks allot - just what the doctor ordered.

It's interesting to see how othe poeple solve the same problems I've been strugling with. If you got any more keep them coming.

After many many runs with FEMM I come up with a good design of a ribbon tweeter simular to raven and arum cantus high end designs. I've soursed all the materials including the ribbon alum. and the x-former core material. It's not cheep but still considerlbly cheeper than the store bought units. It will be awhile be for I build so there's plenty of time to tweek the design.

As an alternate,I designed a line sourse ribbon that looks interesting on paper. A 40-60 inch long x .25 wide closed back ribbon unit. The ribbon would have a resistance of about 1-2 ohms with enough effiency to put a 2-3 ohm resister in series with it and still have92-96 dB/w eff - no transformer. This is all just vaper at this point but would be interesting to try some day.

It's interesting to see how othe poeple solve the same problems I've been strugling with. If you got any more keep them coming.

After many many runs with FEMM I come up with a good design of a ribbon tweeter simular to raven and arum cantus high end designs. I've soursed all the materials including the ribbon alum. and the x-former core material. It's not cheep but still considerlbly cheeper than the store bought units. It will be awhile be for I build so there's plenty of time to tweek the design.

As an alternate,I designed a line sourse ribbon that looks interesting on paper. A 40-60 inch long x .25 wide closed back ribbon unit. The ribbon would have a resistance of about 1-2 ohms with enough effiency to put a 2-3 ohm resister in series with it and still have92-96 dB/w eff - no transformer. This is all just vaper at this point but would be interesting to try some day.

gl said:The copper covering appears to be a flux band. It's wrapped around either a magnet or steel spacer that's located right behind the transformer. Perhaps they found that there was too much flux leaking from the transformer circuit into the main field circuit. It's interesting that they would have chosen to wrap the adjoining magnetic structure instead of the transformer. I'll bet there was a lot of experimenting before the design was final.

Graeme

I thought it might be some kind of shorting ring like they put in coli driven drivers but I can't understand it in this context. The shorting ring only helps in a varying magnetic field. In the ribbon core the, magnetic field is constant. The only thing I can think of is that it's intended to shield the trasnformer from the varying magnetic field around the ribbon itself. If that's the case, it would seem to be more effective around the transformer, as you said.

Hi Denis,

I believe that the flux band here is meant to absorb the stray audio frequency flux from the transformer and keep it from modulating the the magnetic field of the field magnet which, as you say, needs to stay constant. The ribbon itself is too far away and too short to cause a problem. The transformer on the other hand is right up against the metal block. I have a sneaking suspicion that a flux band on a small toriod running at high audio frequencies would cause frequency and phase problems. But that's just a gut feeling.

By the way I second the person who said that the patent office was a great source of info. The patent number for the Winey/Magnepan tweeter referred to in other posts here is 4,319,096.

Graeme

I believe that the flux band here is meant to absorb the stray audio frequency flux from the transformer and keep it from modulating the the magnetic field of the field magnet which, as you say, needs to stay constant. The ribbon itself is too far away and too short to cause a problem. The transformer on the other hand is right up against the metal block. I have a sneaking suspicion that a flux band on a small toriod running at high audio frequencies would cause frequency and phase problems. But that's just a gut feeling.

By the way I second the person who said that the patent office was a great source of info. The patent number for the Winey/Magnepan tweeter referred to in other posts here is 4,319,096.

Graeme

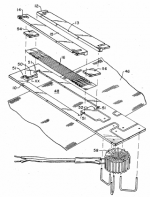

I've attached a diagram of the Magnepan dipole ribbon. I believe it is about 72" tall and 0.2" wide, built from corrugated 2.5 micron thick aluminum foil. The ribbon is very narrow and very, very thin, and this allows conventional ferrite magnets to create adequate efficiency, plus a high enough resistive impedance for direct drive without a transformer using standard amplifiers. The modest size allows a slotted steel frame construction which gives a complete magnetic circuit around the back plus adequate open gaps for the rear sound waves to create a dipole. Seems like a very nice low cost, mass production design.

The copper ring on the Raven is mainly to isolate the magnetic fields from the transformer, as the currents can be very high on the ribbon side, but it would also provide some shielding of the stray magnetic flux between the sides and back iron pieces, thus increasing the total gap flux plus minimizing how this stray flux might bias the rear movement of the ribbon.

The copper ring on the Raven is mainly to isolate the magnetic fields from the transformer, as the currents can be very high on the ribbon side, but it would also provide some shielding of the stray magnetic flux between the sides and back iron pieces, thus increasing the total gap flux plus minimizing how this stray flux might bias the rear movement of the ribbon.

Attachments

I would be vey much interested in seeing the design of these Magneplanar direct drive ribbon tweeters.

There is a whole section on nothing but over at www.audioasylum.com

One of the patents has the name "Nelson Pass" on it as well.

A major part of why they sound as they do relates to the essential nature of dipoles regardless of how they are otherwise constructed. Siegfried Linkwitz (www,linkwitzlab.com) has info on this. The basic factor is that all dipoles create a "null" orthagonal to the axis of radiation. I'vee seen a demo computer simulation of this. What it means is that there is very little interaction with side walls, floor or cieling. If you ever get a chance just walk past one that is playing. As you reach the point where you are exactly 90 deg to the side, the sound suddenly drops away and almost dissapears -- very wierd sensation.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Inside a Ribbon Tweeter ?