I'm thinking about building a dipole ribbon speaker soon and I have some questions about the approach. First of all I was wondering if many small ribbon modules stacked in series parallel would be the equivalent of one larger ribbon? What is the sonic effect of ribbon length? I would imagine that smaller modules would flap less and be more precise.

I also have a question about the magnetic field, what is the best approach to making it uniform? Magnetic field uniformity is one of the main contributors to distortion in ribbon speakers right?

Lastly what is your opinion on ribbon width?

I also have a question about the magnetic field, what is the best approach to making it uniform? Magnetic field uniformity is one of the main contributors to distortion in ribbon speakers right?

Lastly what is your opinion on ribbon width?

Did you come across my dipole tweeter design?

DIY ribbon dipole tweeter, reduction ad minimum

I tried to minimise the vertical bundling by keeping the height as small as possible, to still have some surface are I made the ribbon 19mm wide. As you can see from the measurements it starts to drop off above 16kHz because of this. It's all about finding the compromise that works best for you.

You could probably create a line array of these ribbons but then you'd need to figure out a different ribbon mounting scheme to minimise the distance between the ribbons. My approach would be to increase the height of the single ribbons with the goal of lowering the crossover frequency, if possible down to 1kHz, and just connect all the ribbons in series.

By the way, the ribbons are in use for three years now and still going strong.

regards,

Gerrit

DIY ribbon dipole tweeter, reduction ad minimum

I tried to minimise the vertical bundling by keeping the height as small as possible, to still have some surface are I made the ribbon 19mm wide. As you can see from the measurements it starts to drop off above 16kHz because of this. It's all about finding the compromise that works best for you.

You could probably create a line array of these ribbons but then you'd need to figure out a different ribbon mounting scheme to minimise the distance between the ribbons. My approach would be to increase the height of the single ribbons with the goal of lowering the crossover frequency, if possible down to 1kHz, and just connect all the ribbons in series.

By the way, the ribbons are in use for three years now and still going strong.

regards,

Gerrit

If you stack ribbons and the distance is to far between them, you wont get the benefit of a long ribbon but rather the downside of a number of spaced transducers trying to work as one but fails. This results in beaming etc....

Also, as a ribbon gets shorter, one could anticipate that the negative aspects of it being fastened in both ends will increase. Surely, if a pistonic movement of the whole ribbon could be achieved it would be good - but the tied ends stop that.... but as the ends go further away, the center of ribbon tends to move more pistonic...

We all paid our dues in the search function... be our guest.. You will also learn a lot more by doing this. Read Gerrits thread linked above is my advice - all of it.

You will also learn a lot more by doing this. Read Gerrits thread linked above is my advice - all of it.

//

Also, as a ribbon gets shorter, one could anticipate that the negative aspects of it being fastened in both ends will increase. Surely, if a pistonic movement of the whole ribbon could be achieved it would be good - but the tied ends stop that.... but as the ends go further away, the center of ribbon tends to move more pistonic...

We all paid our dues in the search function... be our guest..

//

Some aspects need another approach but in general it all works really nice.

"The tall neodymium ribbon". Part 1

"The tall neodymium ribbon". Part 1

To make decisions on your questions we first need to know what you want? What system are you looking to end up with? How low in freq. do you want to go with the ribbon. What will be the woofer size? Cabinet or no? etc.I'm thinking about building a dipole ribbon speaker soon and I have some questions about the approach. First of all I was wondering if many small ribbon modules stacked in series parallel would be the equivalent of one larger ribbon? What is the sonic effect of ribbon length? I would imagine that smaller modules would flap less and be more precise.

I also have a question about the magnetic field, what is the best approach to making it uniform? Magnetic field uniformity is one of the main contributors to distortion in ribbon speakers right?

Lastly what is your opinion on ribbon width?

So if you can give some more detail I can direct you much better.

That said....

small ribbons have certain advantages in certain situations BUT usually best to do a long continuous ribbon.

Width and length of ribbon will depend on how low you want distortion. More surface area generally will result in less distortion.

"Uniform" field strength is NOT a large contributor to low distortion as so many think. Its really more important to keep stiff large pleat foil only ribbons from cracking. If you use a plastic backed ribbon or a flatter profile foil only that can flex easily without building large stress then the field uniformity is basically a non issue within reason of course.

ribbon width is interesting. Sure you can get great horizontal dispersion with really narrow ribbons BUT IMO its often overdone and in my experience its best to build ribbons somewhere between 15 and 20 mm wide. Around 17-19 being best overall balance of perf and dispersion.

Vertical dispersion is always an issue with most ribbon that is used below about 1.5 khz. In a effort to get low distortion and a lower crossover point you end up making a longer ribbon. IMO its best to ether stay below about 7 inches long OR make the ribbon about 40 inches long or longer. Yes every thing in between has been made to work well BUT IMO ether short or long is best. Anything in between in my experience is too critical of exact placement and listener position in average room.

Last edited:

To make decisions on your questions we first need to know what you want? What system are you looking to end up with? How low in freq. do you want to go with the ribbon. What will be the woofer size? Cabinet or no? etc.I'm thinking about building a dipole ribbon speaker soon and I have some questions about the approach. First of all I was wondering if many small ribbon modules stacked in series parallel would be the equivalent of one larger ribbon? What is the sonic effect of ribbon length? I would imagine that smaller modules would flap less and be more precise.

I also have a question about the magnetic field, what is the best approach to making it uniform? Magnetic field uniformity is one of the main contributors to distortion in ribbon speakers right?

Lastly what is your opinion on ribbon width?

So if you can give some more detail I can direct you much better.

That said....

small ribbons have certain advantages in certain situations BUT usually best to do a long continuous ribbon.

Width and length of ribbon will depend on how low you want distortion. More surface area generally will result in less distortion.

"Uniform" field strength is NOT a large contributor to low distortion as so many think. Its really more important to keep stiff large pleat foil only ribbons from cracking. If you use a plastic backed ribbon or a flatter profile foil only that can flex easily without building large stress then the field uniformity is basically a non issue within reason of course.

ribbon width is interesting. Sure you can get great horizontal dispersion with really narrow ribbons BUT IMO its often overdone and in my experience its best to build ribbons somewhere between 15 and 20 mm wide. Around 17-19 being best overall balance of perf and dispersion.

Vertical dispersion is always an issue with any ribbon that is used below about 2 khz. In a effort to get low distortion and a lower crossover point you end up making a longer ribbon. IMO its best to ether stay below about 7 inches long OR make the ribbon about 40 inches long or longer. Yes every thing in between has been made to work well BUT IMO ether short or long is best. Anything in between in my experience has too critical of exact placement and listener position in average room.

Thanks for the responses guys, appreciate it

1: full range

2: lowest distortion

3: I want to make a headphone ribbon driver before I make a speaker

I'm not concerned about sensitivity or drive capability, I have that part sorted out. I am purely interested in results.

I'm also looking into this I found somewhere a while back but I can't seem to find where I saw it

A six arm ribbon. Seems like it would need no corrugation. What do you think about its potential capabilities?

How far is too far? Is the side width of a magnet (1.57mm) sufficiently close? I could use ribbons in a side by side a magnet array.If you stack ribbons and the distance is to far between them, you wont get the benefit of a long ribbon but rather the downside of a number of spaced transducers trying to work as one but fails. This results in beaming etc....

My goals in order of importance areTo make decisions on your questions we first need to know what you want? What system are you looking to end up with? How low in freq. do you want to go with the ribbon. What will be the woofer size? Cabinet or no? etc.

So if you can give some more detail I can direct you much better.

1: full range

2: lowest distortion

3: I want to make a headphone ribbon driver before I make a speaker

I'm not concerned about sensitivity or drive capability, I have that part sorted out. I am purely interested in results.

But does that translate into combined surface area or surface area per ribbon? For example many small strips vs one big one. My thinking is, the less each ribbon moves the less distortion each will produce.Width and length of ribbon will depend on how low you want distortion. More surface area generally will result in less distortion.

What is your opinion about these magnets? Polymagnet: 1000325"Uniform" field strength is NOT a large contributor to low distortion as so many think. Its really more important to keep stiff large pleat foil only ribbons from cracking. If you use a plastic backed ribbon or a flatter profile foil only that can flex easily without building large stress then the field uniformity is basically a non issue within reason of course.

Both of these statements come back to my question of, what about many small ones?ribbon width is interesting. Sure you can get great horizontal dispersion with really narrow ribbons BUT IMO its often overdone and in my experience its best to build ribbons somewhere between 15 and 20 mm wide. Around 17-19 being best overall balance of perf and dispersion.

Vertical dispersion is always an issue with any ribbon that is used below about 2 khz. In a effort to get low distortion and a lower crossover point you end up making a longer ribbon. IMO its best to ether stay below about 7 inches long OR make the ribbon about 40 inches long or longer. Yes every thing in between has been made to work well BUT IMO ether short or long is best. Anything in between in my experience has too critical of exact placement and listener position in average room.

I'm also looking into this I found somewhere a while back but I can't seem to find where I saw it

A six arm ribbon. Seems like it would need no corrugation. What do you think about its potential capabilities?

If your going to make a "full range" ribbon then you have a tall order but it can be done. about the best you can do is take a tall (5-6 feet) ribbon with a large open back baffle down to about 80 hz then over to a sub.

I have made them this way and the best result I had was with 2 inch wide ribbons and large magnets. I wouldn't use NEO magnets in this. Grade 5 or 8 ceramics are better. Neos are waaayyy too expensive in this size anyway.

I have taken them "full range" (no subs). With EQ and wide baffle they will go low, quite low in fact BUT really only loud to about 50hz. However it was the best quality bass/mid I have ever heard. Ever.

You need to keep the gap between ribbon edge and magnet face small, about 1mm or less to avoid loss of low frequency sensitivity.

It can be done with a ribbon only 1 inch wide too BUT the 2 inch wide works much better at avoiding ribbon flapping around at low freq. and will play louder. HOWEVER now you may find that the dispersion of a 2 inch is not what you are looking for and you will need another ribbon less wide next to the 2 inch.

Combined surface area of many smaller ribbons will give good low distort, BUT one big ribbon avoids the problems with interference effects of multiples. I do not have enough real world side by side comparison of one long VS many small to say for sure if its better one way or other but I suspect problems at higher freq. with multiples..

The magnet you show is a multi pole magnet and is not suitable for ribbon. You need a more standard rectangular magnet that has one pole per side

I have tried a few strange ribbon configurations. The one you show is interesting and I dont know for sure BUT I suspect its best to stay with the classic ribbon / magnet arraignment.

I would not get too stressed over distortion. Big ribbon will be low, AND I have been building ribbons for 30+ years. The best sounding ones are not always the lowest distortion ones

I have made them this way and the best result I had was with 2 inch wide ribbons and large magnets. I wouldn't use NEO magnets in this. Grade 5 or 8 ceramics are better. Neos are waaayyy too expensive in this size anyway.

I have taken them "full range" (no subs). With EQ and wide baffle they will go low, quite low in fact BUT really only loud to about 50hz. However it was the best quality bass/mid I have ever heard. Ever.

You need to keep the gap between ribbon edge and magnet face small, about 1mm or less to avoid loss of low frequency sensitivity.

It can be done with a ribbon only 1 inch wide too BUT the 2 inch wide works much better at avoiding ribbon flapping around at low freq. and will play louder. HOWEVER now you may find that the dispersion of a 2 inch is not what you are looking for and you will need another ribbon less wide next to the 2 inch.

Combined surface area of many smaller ribbons will give good low distort, BUT one big ribbon avoids the problems with interference effects of multiples. I do not have enough real world side by side comparison of one long VS many small to say for sure if its better one way or other but I suspect problems at higher freq. with multiples..

The magnet you show is a multi pole magnet and is not suitable for ribbon. You need a more standard rectangular magnet that has one pole per side

I have tried a few strange ribbon configurations. The one you show is interesting and I dont know for sure BUT I suspect its best to stay with the classic ribbon / magnet arraignment.

I would not get too stressed over distortion. Big ribbon will be low, AND I have been building ribbons for 30+ years. The best sounding ones are not always the lowest distortion ones

Last edited:

Is the interference due to spacing or some sort of mismatch?Combined surface area of many smaller ribbons will give good low distort, BUT one big ribbon avoids the problems with interference effects of multiples.

I want to start off with a headphone ribbon before I move to speakers, do you have any feedback on that?

Also do you have any feedback on the six arm ribbon? To my eyes it seems to avoid the flaws of normal ribbons, does that seem correct to you?

Is the interference due to spacing or some sort of mismatch?

I want to start off with a headphone ribbon before I move to speakers, do you have any feedback on that?

Also do you have any feedback on the six arm ribbon? To my eyes it seems to avoid the flaws of normal ribbons, does that seem correct to you?

Its a spacing issue mostly. BUT look at the Infinity IRS. Some earlyer versions have multiple small "ribbons". I havent heard them but perhaps if enough distance to the listener the multi driver ting is not a serious issue not sure really.

Yes good to start with small headphone ribbon. You will get good hands on experience with making the diaphragm. I have made a few ribbon headphones and even some planer magnetic ones.

I would say just start with the crudest easyest way to throw together some cheap frame carved from any wood and hot melt glue some magnets down. Glue a strap on them so it fits over your head AND then go about making many ribbons of different construction to fit. Keep it simple and crude. Then once youve learned a thing or two you can build nicer ones.

When you say "flaws" what do you mean specifically??

I see little if anything to make me interested in the six arm. I wouldnt bother with that construction.

BTW by far one of the biggest hurdles for a DIY guy and ribbons will be the adhesive type and thickness if making laminated plastic backed type diaphragms. Spay adhesives like super 77 actuall work quite well BUT you need a full can to get the pressure to spray an even coat AND you need to keep the coating very thin. Yes of course it will work if not exact BUT the fidelity and sensativity suffers. And super 77 turns to dust in a year or two.

Basically plastic backed ribbons come alive when the plastic backing and the adhesive are less than about 8 microns. There really isnt anything commercially available to get that thin but a very light coat of super 77 spray and mylar backing around 6 -8 microns will get you there

Last edited:

In my limited knowledge, I understand that corrugation is the cause of resonance frequencies in the typical ribbon. The 6 arm ribbon doesn't look like it needs corrugation at all. Aside from that it is in the magnetic field of 12 magnets controlling all sides of the center "transducer" which should give extremely good control and response.When you say "flaws" what do you mean specifically??

Which leads me to believe it can be used to produce a larger range of frequencies than typical ribbons. Tell me if I am wrong.

In my limited knowledge, I understand that corrugation is the cause of resonance frequencies in the typical ribbon.

The size of the corrugations can influence the response in the treble region. Small corrugations will bend more easily and therefore the resonance will be at a lower freq than larger stiffer corrugations. This usually is seen as a small glitch in freq response in treble. You can play around with the size and often come to a point where the glitch is smooth enough.

That said this "problem" is mostly an issue with wider foil only ribbons. Plastic backed versions usually will be made with very small corrugations and are very flexy designs BUT they are much better damped than foil only.

The 6 arm ribbon doesn't look like it needs corrugation at all. Aside from that it is in the magnetic field of 12 magnets controlling all sides of the center "transducer" which should give extremely good control and response.

Which leads me to believe it can be used to produce a larger range of frequencies than typical ribbons. Tell me if I am wrong.

I doubt it. I see all sorts of problems with that theory. Its a complex arraignment and Im not even sure the "center" part will have proper magnet flux orientation.

I don't understand what you mean by the center not having a proper magnetic flux orientation.

If you treat the arms as 6 separate "conventional" ribbons then the center should simply act as a piston.

The equal distribution of opposing magnets around the center should cancel out the motive force from the flux in the middle I think. If not just add enough arms so that you can carefully pick the current paths until you create a field cancelling effect in the middle.

If you treat the arms as 6 separate "conventional" ribbons then the center should simply act as a piston.

The equal distribution of opposing magnets around the center should cancel out the motive force from the flux in the middle I think. If not just add enough arms so that you can carefully pick the current paths until you create a field cancelling effect in the middle.

Last edited:

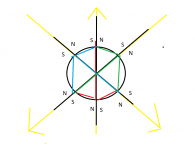

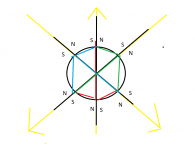

For a 6 arm ribbon this direction of current seems like it would do a reasonable job of flux cancellation in the middle

The currents would probably be more accurately described as this I think.

10 arms would give a much more even distribution of opposing currents. I don't know if it is required to go that far. The center axis is missing one symmetrical opposing current path in the 6 arm version.

The currents would probably be more accurately described as this I think.

10 arms would give a much more even distribution of opposing currents. I don't know if it is required to go that far. The center axis is missing one symmetrical opposing current path in the 6 arm version.

Last edited:

Well far be it from me to hold someone back from trying strange new designs. To be honest some of the better ideas Ive stumbled on were from trying strange ideas  .

.

However I see a few issues here.

1- its complex. complexity can make the fragile ribbon very difficult to get right. It may be a looooong process of trial and error experaments to get the bugs worked out both in construction and performance.

2- maybe theres somthing im missing BUT I do not see that senter section being driven uniformly by a clean magnet flux. I see the center section as dead weight.

3- i suspect even if it does work you will have limited horizontal dispersion due to the width.

Dont underestimate the value of simply making really crude, slaped together ribbons to get your mind thinking and give you real world knowladge of what practical to do. Of course dont be afrade to try all sorts a different ideas, but I find untill I have an awful lot of knowladge that its best to take what I got and build somthing crude that wont last but will give me a better view of the possabilities. Then things become much clearer

However I see a few issues here.

1- its complex. complexity can make the fragile ribbon very difficult to get right. It may be a looooong process of trial and error experaments to get the bugs worked out both in construction and performance.

2- maybe theres somthing im missing BUT I do not see that senter section being driven uniformly by a clean magnet flux. I see the center section as dead weight.

3- i suspect even if it does work you will have limited horizontal dispersion due to the width.

Dont underestimate the value of simply making really crude, slaped together ribbons to get your mind thinking and give you real world knowladge of what practical to do. Of course dont be afrade to try all sorts a different ideas, but I find untill I have an awful lot of knowladge that its best to take what I got and build somthing crude that wont last but will give me a better view of the possabilities. Then things become much clearer

Last edited:

Yeah I was considering using kitchen foil for the 6 armed experiment. Easy to source and cut and a lot less fragile.its complex. complexity can make the fragile ribbon very difficult to get right. It may be a looooong process of trial and error experaments to get the bugs worked out both in construction and performance.

The middle isn't supposed to be driven by flux. The purpose of the "arms" isn't to produce sound, it's to move the center up and down like a piston. The center is supposed to be the actual transducer, like a dynamic driver shaped ribbon.maybe theres somthing im missing BUT I do not see that senter section being driven uniformly by a clean magnet flux. I see the center section as dead weight.

The "arms" are effectively a bunch of conventional ribbon mechanisms attached to a slab of foil in the center. So when the ribbons move the center foil vibrates up and down producing the sound.

Last edited:

"kitchen foil" is fine and cheap. BTW I advise using the standard foil, not the heavy duty foil . Standard kitchen foil is around 17 microns thick, heavy duty foil around 24 microns.Many who haven't built and refined a lot of ribbons generally believe that you must use much thinner foil than what you get from the grocery store. While there are certain advantages to going thinner, there are also many disadvantages AND in the end, within reason, its largely in the execution. Heres an example, the Apogee Stage tweeter ribbon uses foil the same thickness as standard kitchen foil.Yeah I was considering using kitchen foil for the 6 armed experiment. Easy to source and cut and a lot less fragile.

The middle isn't supposed to be driven by flux. The purpose of the "arms" isn't to produce sound, it's to move the center up and down like a piston. The center is supposed to be the actual transducer, like a dynamic driver shaped ribbon.

The "arms" are effectively a bunch of conventional ribbon mechanisms attached to a slab of foil in the center. So when the ribbons move the center foil vibrates up and down producing the sound.

OK I see what your saying on the arms and center section. Yes it will do as you say. However the biggest reason a ribbon sounds the way it does is because the entire surface area of diaphragm is driven directly. With this arraignment the main part of the transducer is not driven directly anymore, AND the "motor" (the arms) are will be sending mechanical waves into the center from all directions where they will meet and ether cancel or add likely resulting in a ragged freq. response.

There are designs that are in a way opposite of the six arm in that instead of the energy propagating into the center , they start with the drive force in the center and the energy propagates out away from that point and is absorbed in a "lossy" mechanism of some kind, usually just a large surface area film planer with graded damping. This to avoid waves reflecting off a boundary and propagating back into the driver. Basically even a cone is made this way where the surround construction will absorb the unwanted energy.

There was a design a number of years ago that was a large, tensioned , mylar film like an electrostat BUT no drive forces over the film area. Right in the center of this large film was a small aluminum dome maybe 1-1.5 inches diameter with a long travel coil motor. The large surface area around the dome was the suspension and I believe it was damped in a graded fashion with acoustic resistance out to the edge.

Basically you had a small point source with a freq response of about 50-20khz. Anyway the energy propagates out away from the drive point and is absorbed.

Another design was a planer magnetic midrange about 2 by 3 inch square, BUT it too was rideing in the center of a much larger tensioned film that was in very close proximity to a solid unmovable surface.This close proximity damped larger motions holding the driven section in its proper place and allowing the vibrations at center to dissipate out away from that area.

NOW, having said all that and admitting that I hardly know everything ha, I would say hey give the six arm a try if for no other reason than to learn. And like I said, just about every good idea I've ever stumbled on was from trying strange things. Not that the strange thing worked BUT that what was learned brought me to something valuable that I never would have expected.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Ribbon question