Hi all,

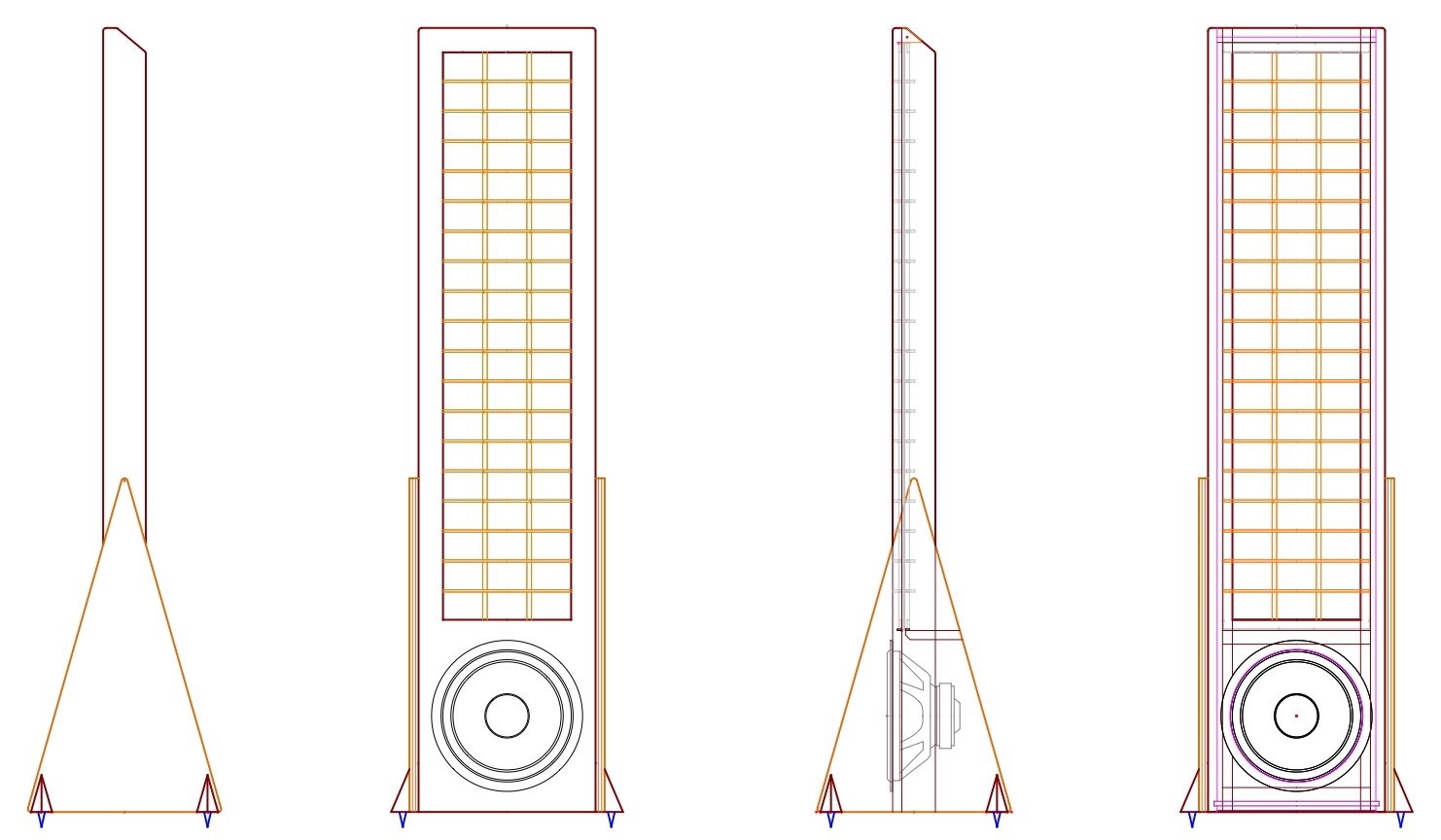

I need a sanity check on a speaker design I’m drawing up for a hi-fi buddy (see image below). Lest anyone ask; I’m not building it-- just helping with the design and letting my buddy use my stretching jig so he can pay someone else to build it.

If I ever learn how to build a passive crossover for an ESL I may build a few to sell on Etsy in my old age but right now I have full time job and I haven’t the energy or time for it.

My friend likes my wire panels but prefers dipole bass and he didn’t like multi-woofer dipole line array I suggested. So we compromised with a woofer-under-panel design, using a Peerless SLS 12 in a modified U-baffle crossing in at around 250Hz.

Perhaps this could be a stand-alone speaker up to moderate volume but I figure the SLS 12’s in an OB would max out early on the bottom end. But since my friend has a pair of OB subs (two AE 15’s in each one) for the the low bass the SLS’s can be chopped off sharply at around 60Hz, which we think solves that problem.

I like the look of the design but I have some concerns -- comments and opinions welcomed:

First concern: The speaker might be easy to tip over forward, since the feet do not extend forward of the baffle board and there isn’t much weight on the rear. The step up transformers will be placed at the rear end of the base but their weight alone might not be sufficient. I suppose we could place a dumb bell back there, lol.

Bigger concern: With the woofer so close to the panel and no box around it, would its pressure waves overwhelm the diaphragm; driving it into the stators or just adding a nasty boom? I recall the old ML Statements used a vertical dipole woofer array with a space between it and the panel which I believe served to vent the woofers’ pressure waves. So-- I’m wondering if we should add a slot in the baffle board between the woofer and panel as a pressure vent. Adding a slot there would detract from the esthetics so I suspect my friend wouldn't like that.

So now I’m wondering if we could add a slot between the baffle board and base, to vent the pressure into the space between the base and floor-- a vent there would not be visible from the front. Would that be an effective option? Do we need to I need to worry about any of this anyway or is it just my paranoia?

Chaz

I need a sanity check on a speaker design I’m drawing up for a hi-fi buddy (see image below). Lest anyone ask; I’m not building it-- just helping with the design and letting my buddy use my stretching jig so he can pay someone else to build it.

If I ever learn how to build a passive crossover for an ESL I may build a few to sell on Etsy in my old age but right now I have full time job and I haven’t the energy or time for it.

My friend likes my wire panels but prefers dipole bass and he didn’t like multi-woofer dipole line array I suggested. So we compromised with a woofer-under-panel design, using a Peerless SLS 12 in a modified U-baffle crossing in at around 250Hz.

Perhaps this could be a stand-alone speaker up to moderate volume but I figure the SLS 12’s in an OB would max out early on the bottom end. But since my friend has a pair of OB subs (two AE 15’s in each one) for the the low bass the SLS’s can be chopped off sharply at around 60Hz, which we think solves that problem.

I like the look of the design but I have some concerns -- comments and opinions welcomed:

First concern: The speaker might be easy to tip over forward, since the feet do not extend forward of the baffle board and there isn’t much weight on the rear. The step up transformers will be placed at the rear end of the base but their weight alone might not be sufficient. I suppose we could place a dumb bell back there, lol.

Bigger concern: With the woofer so close to the panel and no box around it, would its pressure waves overwhelm the diaphragm; driving it into the stators or just adding a nasty boom? I recall the old ML Statements used a vertical dipole woofer array with a space between it and the panel which I believe served to vent the woofers’ pressure waves. So-- I’m wondering if we should add a slot in the baffle board between the woofer and panel as a pressure vent. Adding a slot there would detract from the esthetics so I suspect my friend wouldn't like that.

So now I’m wondering if we could add a slot between the baffle board and base, to vent the pressure into the space between the base and floor-- a vent there would not be visible from the front. Would that be an effective option? Do we need to I need to worry about any of this anyway or is it just my paranoia?

Chaz

Forgot to mention: I already had several sealed box and TL configurations drawn up but my friend is dead set on dipole bass. Whatever we end up with will be tri-amp’d with Sunfire amps thru a Rane DSP crossover. Hopefully, it will be easier to build than previous designs, not too pricey, and a parts list and drawing will be available to anyone who wants it thru my website.

Exciting the diaphragm resonance frequency with the back and forth particle velocity along the null axis of the dipole woofer is certainly a concern. Having a single woofer at the end of the panel rather than a whole row along the length of the panel will excite the resonance less. But, it is tough to predict if it will be intrusive or not without testing it. You have some SLS woofers in your Ripoles, so you might “borrow” one and hold it in free air while playing a sine wave close to the resonance frequency of your ESL panels. Then try bringing the woofer near the panel’s middle and ends and see what happens.… With the woofer so close to the panel and no box around it, would its pressure waves overwhelm the diaphragm; driving it into the stators or just adding a nasty boom? I recall the old ML Statements used a vertical dipole woofer array with a space between it and the panel which I believe served to vent the woofers’ pressure waves. So-- I’m wondering if we should add a slot in the baffle board between the woofer and panel as a pressure vent. Adding a slot there would detract from the esthetics so I suspect my friend wouldn't like that.

If excitation of the diaphragm is a problem you could add some acoustic damping in the form of thin crafting felt to the rear stator between the first few crossbars closest to the woofer…a minimal aesthetic impact. Another alternative you might try is to extend the top of the U-frame for the woofer to lengthen the path for the air motion directed upward and thru the panel. As it is now, that path looks to be shorter than to the sides(ie path of least resistance), so that is where the highest particle velocity will be.

Thanks Steve,

Your advice is insightful as usual. Some felt tucked between the rear crossbars would be easy to do!

Another mitigating factor just occurred to me: Since my friend will use the big AE dipole subs for the low end, the SLS woofer below the panel will be chopped off sharply at 60 Hz (possibly higher), which should limit the cone excursion significantly.

My only interest in this project is having a simpler and verified design to post on my website. However, I fear that if my friend can't find someone to build this thing from my drawing, I may get roped into it and I really don't have time for it (getting lazy in my old age).

Chaz

Your advice is insightful as usual. Some felt tucked between the rear crossbars would be easy to do!

Another mitigating factor just occurred to me: Since my friend will use the big AE dipole subs for the low end, the SLS woofer below the panel will be chopped off sharply at 60 Hz (possibly higher), which should limit the cone excursion significantly.

My only interest in this project is having a simpler and verified design to post on my website. However, I fear that if my friend can't find someone to build this thing from my drawing, I may get roped into it and I really don't have time for it (getting lazy in my old age).

Chaz

Last edited:

I ran a giant OB bass for a while and agree the sound can be nice. I had several feet of irregularly shaped perimeter and other baffling pieces. But as wiser others have commented, it's a challenge.

There's a compromise that might be called "leaky sealed box" where you have a large foamy filled box with no or little back on it. Lord only knows how to simulate that, but I sure wouldn't care. Sort of like a Linkwitz U and the basic driver Fo stays where it belongs (naturally boosting a bit the lower end of the music band*); but unlike a simple baffle, while mostly passing woofer frequencies out the back it is absorbing a lot of upper freq and noise emanating out the back.

B.

* you do want only naturally sourced music, don't you?

There's a compromise that might be called "leaky sealed box" where you have a large foamy filled box with no or little back on it. Lord only knows how to simulate that, but I sure wouldn't care. Sort of like a Linkwitz U and the basic driver Fo stays where it belongs (naturally boosting a bit the lower end of the music band*); but unlike a simple baffle, while mostly passing woofer frequencies out the back it is absorbing a lot of upper freq and noise emanating out the back.

B.

* you do want only naturally sourced music, don't you?

Last edited:

What are the speakers in your avatar?

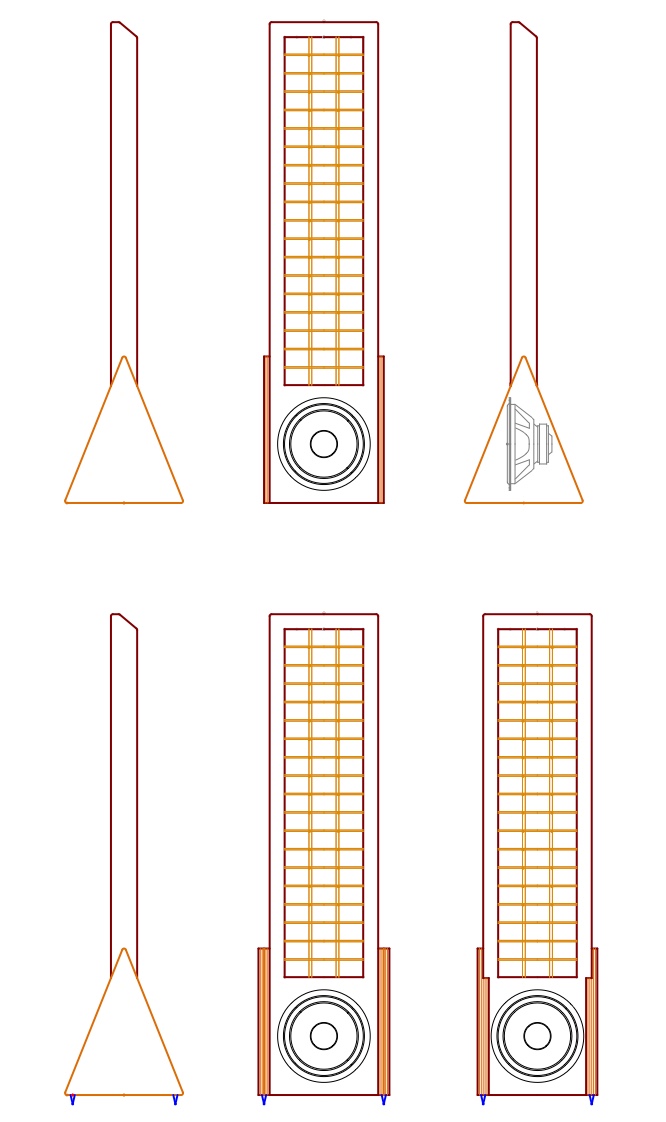

Those were my first ESL's built in 2008 using perforated metal stators. My latest speaker shown below uses segmented wire stators:

I have made a open baffle with 2 woofers in a v shape. Is this an option for you ?

Nice work Jeronimo. I see a pair of transformers stuffed in there so there must be an ESL panel somewhere-- would love to see it.

I had hoped to simply create a design and drawing using my existing wire panel and jigs, which my friend would have built, without me having to build and test prototypes. That is; my friend would have his dream speakers and I would have an easier-build design to post on my website and an option to build and sell a few on Etsy after I retire (I’m already 64).

This is looking increasingly unlikely without a lot more work on my part. Not to mention; my friend is covering the costs and has his own preferences so I don’t have the total vote on a design.

I’m coming to appreciate how problems start snowballing when so constrained, rather than starting off with a clean sheet. For example; a two woofer W-baffle may crank enough low bass to play loud without added subs. Whereas, a single woofer in a U or H baffle would be significantly more limited. Yet; implementing a W-baffle in a reasonably sized package would require aligning it vertically and reducing the panel height (would have to build another wire jig too).

The only sufficiency compact two-woofer dipole I know of is a Ripol, which would fit nicely under the existing 12 x 48 panel. The concern with playing a Ripole that high is its nasty-loud chamber resonance, which would fall right about where crossover needs to be. There may also be phasing issues affecting its blending with the panel. I think Calvin built something like that once-- too bad I don't have his smarts to know how to make it work. But at least I already have a pair of SLS 12 Ripol subs, so I could do some testing if my friend is open to that option.

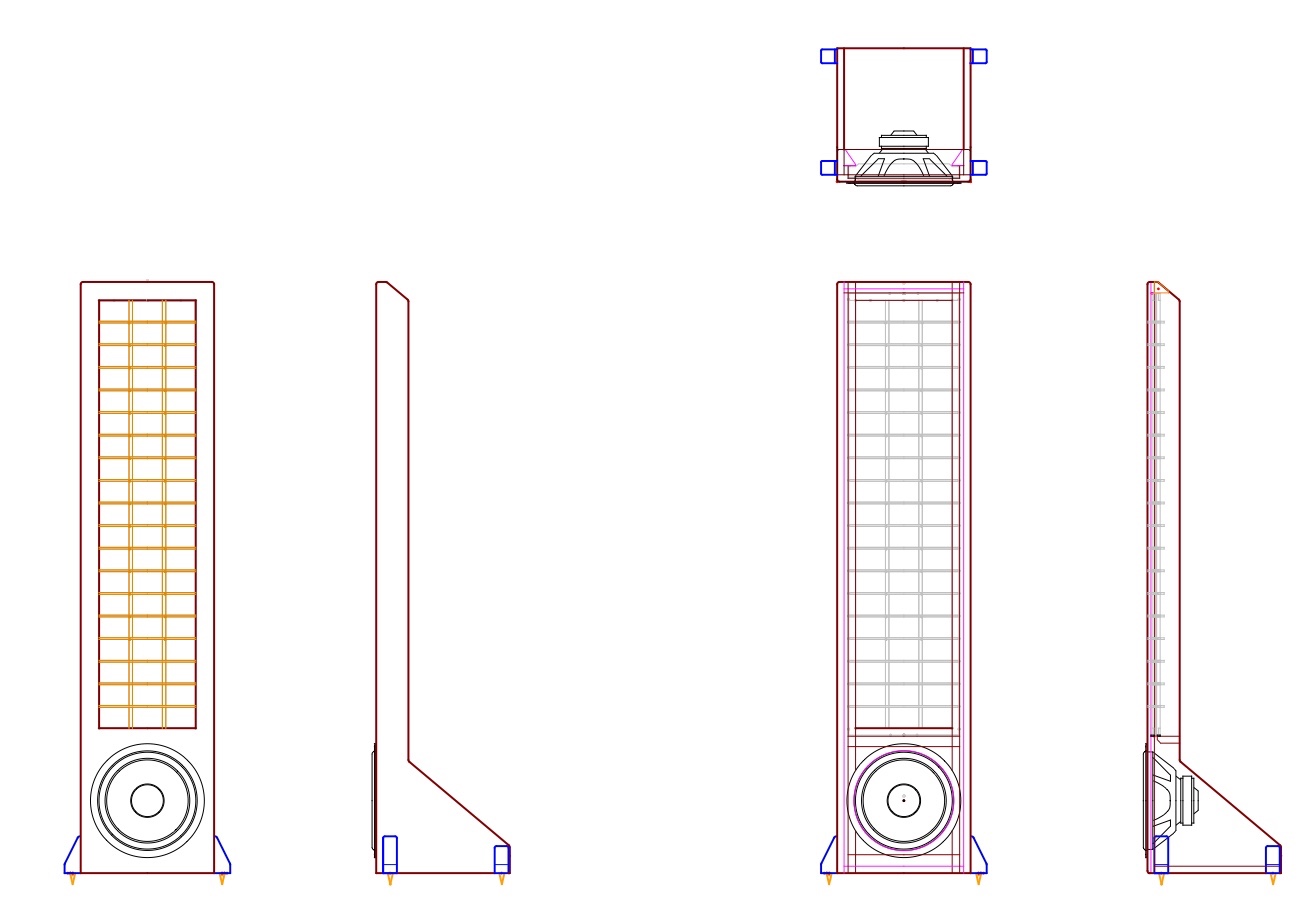

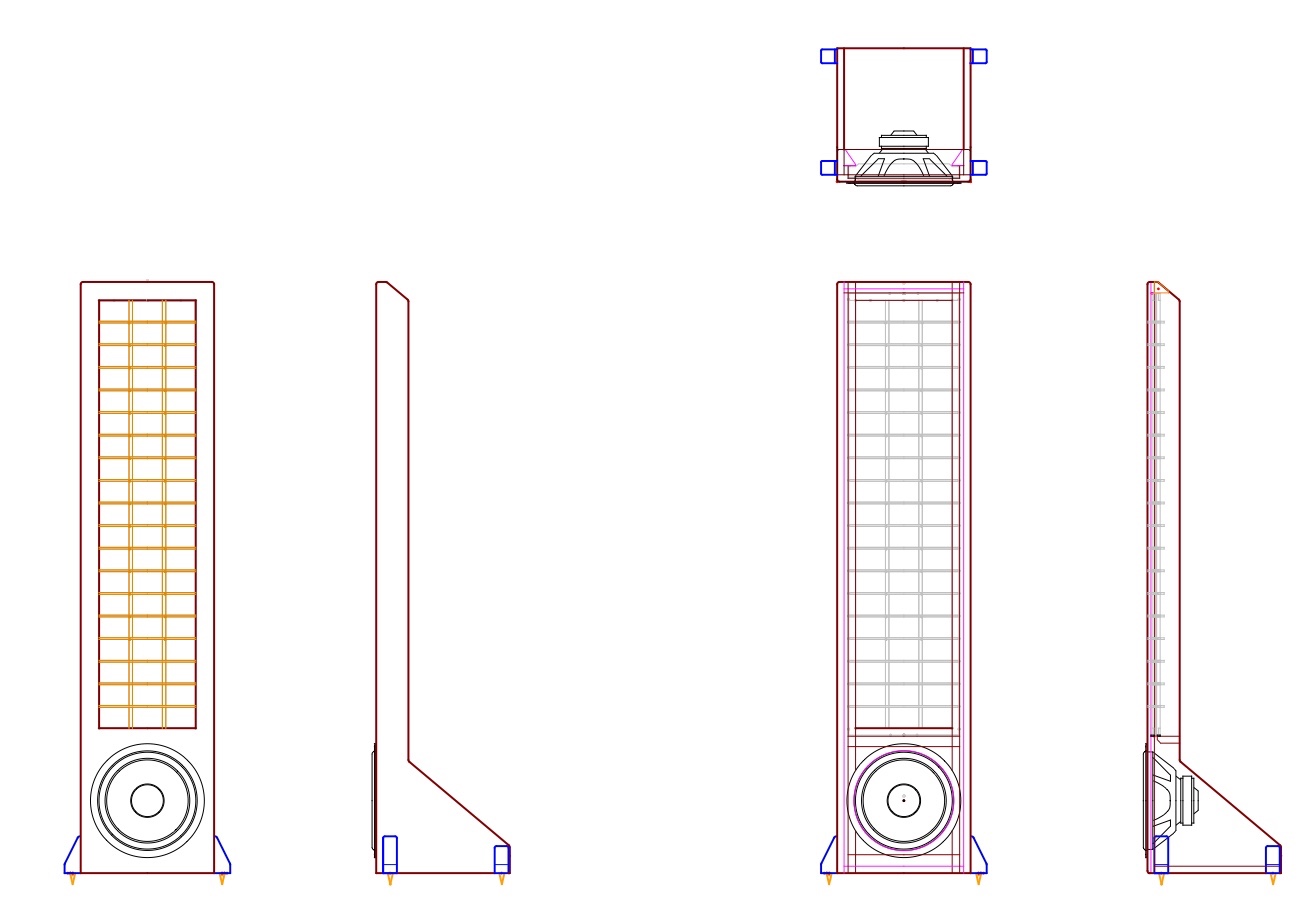

Below is another single woofer arrangement, which I drew up a few minutes ago to provide a more stable base, not as prone to tipping over. The upper configuration uses a triangular base made from a single ply of ¾ A-A oak plywood with no feet. The two lower configurations form the triangular base with a double thickness of plywood in order to support adding spike feet.

Last edited:

I have made a open baffle with 2 woofers in a v shape. Is this an option for you ?

BTW, what woofers are you using there and how tall is the cabinet?

I'm going to build a couple of W-frame OB subs, 2 drivers per. Here is the driver and there are links to the servo amp plans for W-frame and H-frame:

SW-12-16FR

SW-12-16FR

Quick thought: most of the woofer mass is in the magnet so you may be overcompensating with your front-projecting feet. Also, if you rear-mount the woofers (mount their faces to the back of the baffles) you'll move the woofers back by a distance equal to the baffle thickness so that'll help a tiny bit as well---plus it can look nice! In any case, as you visualize the distance the front feet must project forward, bear in mind where the center of mass of the woofers will be. A simple drawing may make things look worse than they are.

Few

Few

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- sanity check