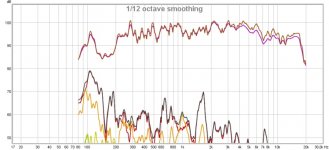

Some readers may not be used to reading these REW charts. So here I am providing an absolutely worst imaginable loudspeaker as a comparison: my elderly MacBook internal micro-speaker being picked up by the internal 25-cent mic.

The lines are 20dB apart. Not bad performance.... compared to some recent posts.

Enjoy.

Ben

The lines are 20dB apart. Not bad performance.... compared to some recent posts.

Enjoy.

Ben

Attachments

Last edited:

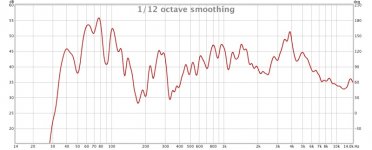

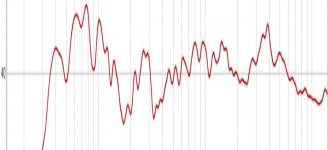

here is a distotion graph of mine, still not the best.

there is a high shelf at around 14khz

and a 4db low shelf af 400 hz

but it is not about the feq response , distortion at 1.6khz is 3.6% after that up high it is 0.6% or lower.

almost 95% of the thd is 2e order. not sure why

there is a high shelf at around 14khz

and a 4db low shelf af 400 hz

but it is not about the feq response , distortion at 1.6khz is 3.6% after that up high it is 0.6% or lower.

almost 95% of the thd is 2e order. not sure why

Attachments

Some readers may not be used to reading these REW charts. So here I am providing an absolutely worst imaginable loudspeaker as a comparison: my elderly MacBook internal micro-speaker being picked up by the internal 25-cent mic.

The lines are 20dB apart. Not bad performance.... compared to some recent posts.

Enjoy.

Ben

yeah when you use 20Db increments it looks good very fast, so thats not fair

I agree with WrineX's sound remarks, once again.but it is not about the few response...

But I would also add, if you look at the distortion curve (and together with the frequency response curve), you see the very horrible collection nasty resonances which causes the THD curve to look like the Rocky Mountains. Other systems might have some distortion, but the curve is pretty smooth (like in my MacBook traces).

Yes, the 2nd harmonic is pretty gruesome. In fact, at lower frequencies it really is the whole output. Curiously, there's good tolerance for 2nd harmonic since that is one octave and almost musical! But it certainly suggests a speaker mechanism that is grossly dysfunctional.

Ben

All the proportions are the same regardless. Would people say you are only two inches tall if they saw you down the street?yeah when you use 20Db increments it looks good very fast, so thats not fair

Need I add

Ben

one other thing is that, what you measure with the mac mic is not really distortion i thin form the speaker. i mean difference betweeen meaured sisnal an distortion is only 20 dB, that is rather low to draw conclusion from. or the the distortion is really that high but i can believe that. every speaker even ESL's have peaks. not as heavy as the DML of course , but i dont think this is comparable. i do agree about DIY speakers that sound good to the builders ears. although i im pretty used to failures and i dont fall for that easily. 80% of the time i am not convinced hence the amount of different project without finishing one !

Yes, proper procedure to ensure test gear is working well.

I think what I'd do next is to examine speaker performance from loud to soft, step by step. You might find a knee-point below which the speaker is working notably better. that will be a hint for what to explore next.

I'd also try a 50-Ohm resistor in series with the exciter to see if impairing the amp damping influence on the exciter matters. Nice to run an impedance curve on the exciter - all you have to do is read the voltage across the exciter when the 50-Ohm resistor is in series (doesn't have to be calibrated, you just want to see where the resonance(s) show up in the electrical back EMF... make sure you know which is the ground side).

Then two exciters, push-pull to explore that 2nd harmonic issue.

Ben

I think what I'd do next is to examine speaker performance from loud to soft, step by step. You might find a knee-point below which the speaker is working notably better. that will be a hint for what to explore next.

I'd also try a 50-Ohm resistor in series with the exciter to see if impairing the amp damping influence on the exciter matters. Nice to run an impedance curve on the exciter - all you have to do is read the voltage across the exciter when the 50-Ohm resistor is in series (doesn't have to be calibrated, you just want to see where the resonance(s) show up in the electrical back EMF... make sure you know which is the ground side).

Then two exciters, push-pull to explore that 2nd harmonic issue.

Ben

Last edited:

Carbon fiber store www.carbonfibreshop.com

No longer 'unobtanium'.

Small quantities available to large consumers and DIY'ers

https://carbonfibreshop.com

Sourcing materials

Carbon fiber and nomex are both individually regarded as unobtanium for most of us DIYers. Personally my threshold for a DIY project is that if I'm already investing my time, even if it's probably going to sound really good, I'd like to keep it under $100 in case the whole project is a wash.

You can buy prefab carbon + nomex honeycomb sandwich in form very close to what's in the Tectonic video I posted earlier (probably thicker, but probably not substantially heavier or less stiff): here it is at Dragon Plate for $40/6x6" square: Carbon Fiber Nomex Honeycomb Core 0.5" x 6" x 6"

In larger sheets for a little under $100/sq. ft.: Carbon Fiber Sheet with Honeycomb Core, 1/8 inch thick - Pegasus Auto Racing Supplies

Even if you buy separate, nomex honeycomb itself is pretty expensive, like $120 for a 40x48" sheet: Nomex Honeycomb Sandwich Core Material in stock | Fibre Glast. Bigger than I thought I'd need, at least for an initial build, but also over total budget.

Likewise carbon fiber: $27/sq. ft. panel: Carbon Fiber Sheets & Fabric - Carbon Fiber Gear.

So I had to get a little more creative...

No longer 'unobtanium'.

Small quantities available to large consumers and DIY'ers

https://carbonfibreshop.com

Attachments

Hi guys,

I must say that i highly admire your dedication and will to experiment, the DML technology has certainly huge advantages in many aspects.

Just a thought about the possible issues with your sandwich- is it possible, that it is just too thick and too stiff to start bending properly, and isn´t this the exact reason for surprisingly low sensitivity and bad frequency response? Perhaps the thick, stiff sandwich that you have used is just not willing to participate on the bending and is absorbing a lot of the energy?

I am attaching a picture of a back of small BMR speaker, which works on similar principle and the membrane is of size about 4 inch. You can clearly see, that there are two layers of relatively thin paper with a not so thick honeycomb in the middle.

The overall thickness of the sandwich is around 3-3,5 mm max, so perhaps you could try to focus on something less stiff, less thick and more cardboard like

I must say that i highly admire your dedication and will to experiment, the DML technology has certainly huge advantages in many aspects.

Just a thought about the possible issues with your sandwich- is it possible, that it is just too thick and too stiff to start bending properly, and isn´t this the exact reason for surprisingly low sensitivity and bad frequency response? Perhaps the thick, stiff sandwich that you have used is just not willing to participate on the bending and is absorbing a lot of the energy?

I am attaching a picture of a back of small BMR speaker, which works on similar principle and the membrane is of size about 4 inch. You can clearly see, that there are two layers of relatively thin paper with a not so thick honeycomb in the middle.

The overall thickness of the sandwich is around 3-3,5 mm max, so perhaps you could try to focus on something less stiff, less thick and more cardboard like

Attachments

Last edited:

Hello everyone... Another person getting caught with the DML bug..

So far i have just been reading up on the technology and trying to understand it all, and there is *alot* of new things to grasp..

I did come by something when browsing one of the links posted in this thread and that is:

* Soller Composites * Epoxy & Related products

"Carbon Nanotube Enhanced Epoxy Resin"

Was thinking is might be possible to coat XPS sheets with this at home, but don't have a clue about the performance.. But for $50 for a pint or quart for $80 it may be something worth trying out.

My target is to replace my current home-theater setup with DML speakers and, preferably increase the size of the sweet-spot.

My wants:

- Thin, preferably enclosed, wall mounter speakers with as little vibrations passing to the wall. (suspending the panels with either fish-line or foam?)

- "good enough" sound that at least matches clarity of my QLN 604 MKII but do not have to match in power.

- The front-speakers can be up to 1m x 2m in size. Center up to 1.5m square. Rear should preferably be no larger than 1m square. For imperial people - 1m is about 40 inches

- Not a strict requirement to go below 100hz, but nice if it had a bit at least for casual viewing. (some seems to have had some promising results in this thread)

What thoughts might you have on this? Achievable? Just a dream? Willing to put in some work on it, but would be nice to get some feedback first.

Thanks in advance for any suggestions or "continue dreaming" replies.

My first build, when my first exciters arrive, will probably be a pair of smallish (similar in size to WrineX's DML's) stero-speakers to start trying things out.. But could not wait with posting here to thank you all for publishing your results so far..

So far i have just been reading up on the technology and trying to understand it all, and there is *alot* of new things to grasp..

I did come by something when browsing one of the links posted in this thread and that is:

* Soller Composites * Epoxy & Related products

"Carbon Nanotube Enhanced Epoxy Resin"

Was thinking is might be possible to coat XPS sheets with this at home, but don't have a clue about the performance.. But for $50 for a pint or quart for $80 it may be something worth trying out.

My target is to replace my current home-theater setup with DML speakers and, preferably increase the size of the sweet-spot.

My wants:

- Thin, preferably enclosed, wall mounter speakers with as little vibrations passing to the wall. (suspending the panels with either fish-line or foam?)

- "good enough" sound that at least matches clarity of my QLN 604 MKII but do not have to match in power.

- The front-speakers can be up to 1m x 2m in size. Center up to 1.5m square. Rear should preferably be no larger than 1m square. For imperial people - 1m is about 40 inches

- Not a strict requirement to go below 100hz, but nice if it had a bit at least for casual viewing. (some seems to have had some promising results in this thread)

What thoughts might you have on this? Achievable? Just a dream? Willing to put in some work on it, but would be nice to get some feedback first.

Thanks in advance for any suggestions or "continue dreaming" replies.

My first build, when my first exciters arrive, will probably be a pair of smallish (similar in size to WrineX's DML's) stero-speakers to start trying things out.. But could not wait with posting here to thank you all for publishing your results so far..

An externally hosted image should be here but it was not working when we last tested it.

It´s importent with low mass!!

Perhaps not always, but being able to control mass/stiffness is extremely important when designing a panel. This seems to be one reason why so much is built around honeycomb-structures since they can be easily adjusted to the wanted weight/stiffness-ratio.

https://pdfs.semanticscholar.org/469f/4e86248384fc05f4ba680d5e5221918e6172.pdf

Page 27 is quite interesting when designing a panel.

What i get from this is that the higher the mass the less stiff, and the lower the mass the stiffer it should be.

Not making any claims since i have still not done any types of tests myself, but it's a good read, for novices, to try and understand the physics behind DML's.

If only my exciter-delivery would arrive.. Been stuck in transit for a week now.

https://pdfs.semanticscholar.org/469f/4e86248384fc05f4ba680d5e5221918e6172.pdf

Page 27 is quite interesting when designing a panel.

What i get from this is that the higher the mass the less stiff, and the lower the mass the stiffer it should be.

As a consequence, one usually wants the B/m” ratio lower, which means either the

mass per unit area should be higher, or the bending stiffness should be lower. The

choice is often to find a material with lower bending stiffness since high density

implies low radiated sound power and that is usually one does not want to see.

Another important reason to keep f0 low is that the asymptotic modal density is

inversely proportional to the ratio of bending stiffness B and the mass per unit area

m”, and one wants it as high as possible. The same reason applies for the critical

frequency, because below the critical frequency the directivities of DML behave more

omni-directional. However, to achieve a proper radiation efficiency and radiated

sound power, the Young’s modulus cannot be too low. Thus one needs to carefully

trade between E and the density ρ to accomplish one’s goal of designing

Not making any claims since i have still not done any types of tests myself, but it's a good read, for novices, to try and understand the physics behind DML's.

If only my exciter-delivery would arrive.. Been stuck in transit for a week now.

I have been reading this thread and in all the DML sounds I have heard online, the best sounding board came from this guy who used an guitar as a sounding board. YouTube

Natural sound..Well comes from a guitar so guitars sound amazing! He put the exciter behind, which is not ideal as it should be placed at the sound board spruce top near the bridge. As a result the vocals sounded "hollow" as the sound is reflected from inside the guitar before exiting from the front hole.

So if we use exciters in respective instruments like violin, piano, drums etc, I believe we would get sounds which are smooth and natural to that instrument.

Natural sound..Well comes from a guitar so guitars sound amazing! He put the exciter behind, which is not ideal as it should be placed at the sound board spruce top near the bridge. As a result the vocals sounded "hollow" as the sound is reflected from inside the guitar before exiting from the front hole.

So if we use exciters in respective instruments like violin, piano, drums etc, I believe we would get sounds which are smooth and natural to that instrument.

I have been reading this thread and in all the DML sounds I have heard online, the best sounding board came from this guy who used an guitar as a sounding board. YouTube

Natural sound..Well comes from a guitar so guitars sound amazing! He put the exciter behind, which is not ideal as it should be placed at the sound board spruce top near the bridge. As a result the vocals sounded "hollow" as the sound is reflected from inside the guitar before exiting from the front hole.

So if we use exciters in respective instruments like violin, piano, drums etc, I believe we would get sounds which are smooth and natural to that instrument.

well i dont want to stick a feather in my own ars

YouTube

another problem with a guitar body is.... well it is a guitar body thats is tuned to a specific task. making guitar noises

Last edited:

- Home

- Loudspeakers

- Planars & Exotics

- Carbon fiber + nomex honeycomb sandwich DML panel construction project