I've been making many pairs of electrostatic headphones in the past few years, and now I want to come back to make my ESL. I've learned from making headphones that the tension on the diaphragm makes a huge difference in sound - especially the bass. I guess it should be similar to ESL.

In the past, using the inner tyre stretcher similar to what Jazzman is using, I tend to stretch the diaphragm to around 1.5% elongation. But, I've found that even when I stretch the Mylar to around 0.6-0.8% (with 3 and 6 microns Mylar), the diaphragm is stable enough and actually sounds better in the mid and low region. I'm now using 2 mm spacer, the diaphragm width is 200 mm and the bias voltage is around 3.6KV.

What is your experience on this? What's the benefit for higher tension?

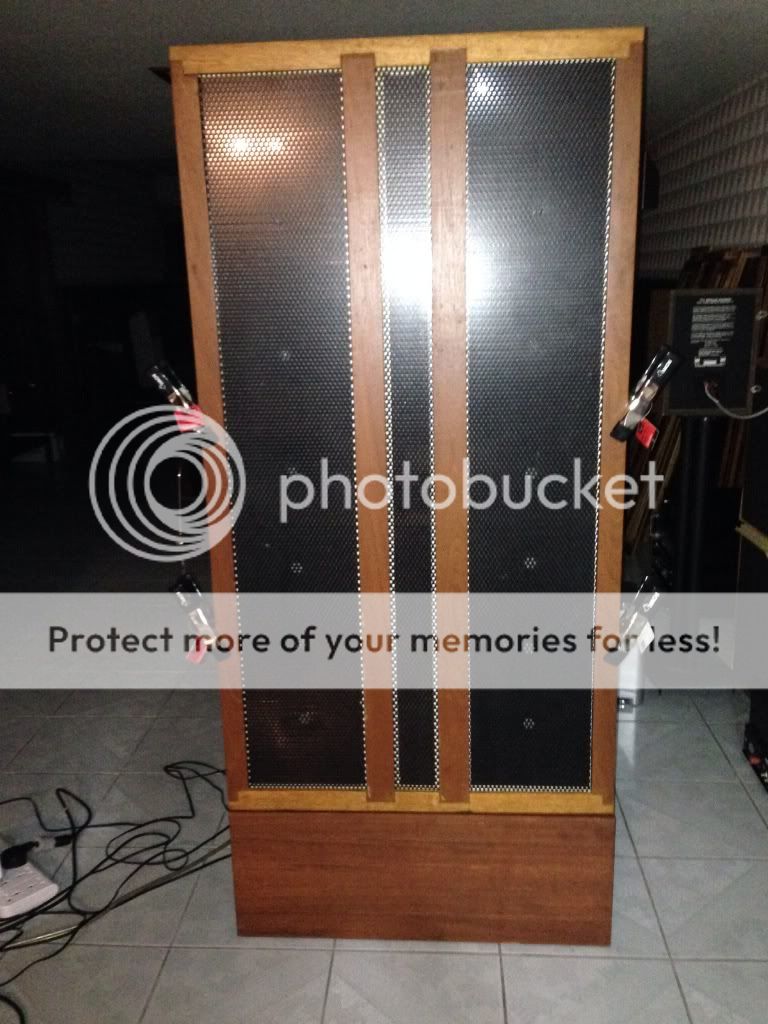

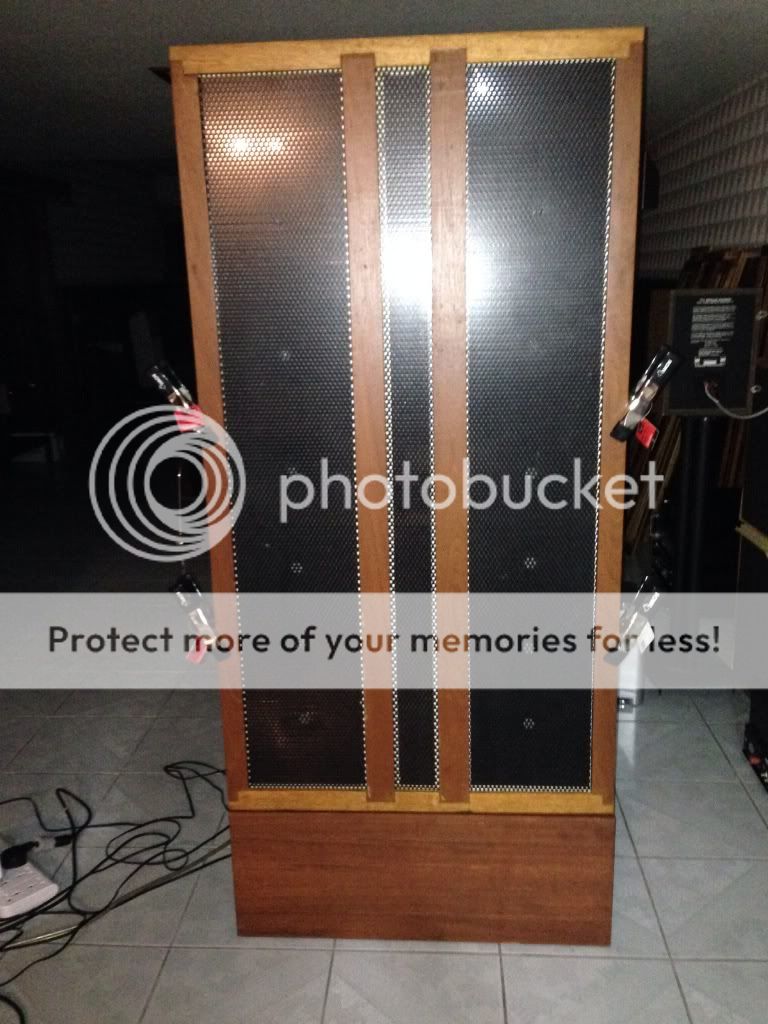

This is the latest pair of full ranger I'm working on right now.

Wachara C.

In the past, using the inner tyre stretcher similar to what Jazzman is using, I tend to stretch the diaphragm to around 1.5% elongation. But, I've found that even when I stretch the Mylar to around 0.6-0.8% (with 3 and 6 microns Mylar), the diaphragm is stable enough and actually sounds better in the mid and low region. I'm now using 2 mm spacer, the diaphragm width is 200 mm and the bias voltage is around 3.6KV.

What is your experience on this? What's the benefit for higher tension?

This is the latest pair of full ranger I'm working on right now.

Wachara C.

for a fullranger extreme high tension is useless because a fullrange extends down till the resonance frequency. high tendsion can be usefull for mid and high frequency esl's. using small spacings menbrames wil stick easy to one side. increasing tension increases stability. because the panel is used for mid and high frequency the resonance is alloud to be allot higher.

in fullrange the bass extendsion is determend by the resonance freq. so in the end you want the lowest stable resonance. that means lower tension , usually more unstable or not alloud to have high HV bias. this is the reasons why people try to cheat with dots of silicone, stil having low resonance but helping stablitity of the menbrame. or just not letting it havinghis way

oh also when the resonance freq is hit with low tension membrame expect huge excursion, slapping it into the stators .. always try to damp it, no see trough but better sounding.

.. always try to damp it, no see trough but better sounding.

in fullrange the bass extendsion is determend by the resonance freq. so in the end you want the lowest stable resonance. that means lower tension , usually more unstable or not alloud to have high HV bias. this is the reasons why people try to cheat with dots of silicone, stil having low resonance but helping stablitity of the menbrame. or just not letting it havinghis way

oh also when the resonance freq is hit with low tension membrame expect huge excursion, slapping it into the stators

Last edited:

Hi,

I have no definite and proven answer about this , but I have had subjective impression that : high mechanical tension can give roughness to the sound and kind of resonant mid-bass and low mid-range.

From the ESL measurements it looks like the first few(perhaps two?) resonance modes are prominent, not just the fundamental. With high tension it could rise too much in frequency. I do not know if that is one of the reasons why Quad, acoustat and some other manufacturers used a combination of mechanical and thermal treatment.

There was a guy capaciti who built(and manufactured) loads of ESLs and he suggested multiple times against using strong mechanical tension.

http://www.diyaudio.com/forums/plan...licon-dots-resonance-control.html#post1943884

Regards,

Lukas

I have no definite and proven answer about this , but I have had subjective impression that : high mechanical tension can give roughness to the sound and kind of resonant mid-bass and low mid-range.

From the ESL measurements it looks like the first few(perhaps two?) resonance modes are prominent, not just the fundamental. With high tension it could rise too much in frequency. I do not know if that is one of the reasons why Quad, acoustat and some other manufacturers used a combination of mechanical and thermal treatment.

There was a guy capaciti who built(and manufactured) loads of ESLs and he suggested multiple times against using strong mechanical tension.

http://www.diyaudio.com/forums/plan...licon-dots-resonance-control.html#post1943884

Regards,

Lukas

Thanks for your inputs. I've now seen for myself that the tension shouldn't be too high -especially if you want to build full range ESL.

I still like the inner tyre stretcher though. However, I'll just have to be very careful not to stretch the diaphragm too much.

I've just finished my new ESL today. I'm very happy with the sound.

I still like the inner tyre stretcher though. However, I'll just have to be very careful not to stretch the diaphragm too much.

I've just finished my new ESL today. I'm very happy with the sound.

Thanks for your pic............Vary Nice...

I have been looking at King ESLs.........thay put the tweeter on one side.............you may have seen......you went with the Quad57 type setup..

all flat pantels................are you happy with the sound?........what coating did you use?

I have Acoustat M3a made of 9"panels onlys... all flat in a frame... run fulrang with 121 interfaces.......................

I have done lot work on the ML 30 dagrees crive panels an got them to give all of the output thay can with some mods......an to my ears if the panels are crved........ or setup like the older Acoustas ...with ea panel at a diff angel...this add more daly than is in the sound when its mixed... LP..or CD !.............flat adds nothing....more real....well too me anyway............have fun

I have been looking at King ESLs.........thay put the tweeter on one side.............you may have seen......you went with the Quad57 type setup..

all flat pantels................are you happy with the sound?........what coating did you use?

I have Acoustat M3a made of 9"panels onlys... all flat in a frame... run fulrang with 121 interfaces.......................

I have done lot work on the ML 30 dagrees crive panels an got them to give all of the output thay can with some mods......an to my ears if the panels are crved........ or setup like the older Acoustas ...with ea panel at a diff angel...this add more daly than is in the sound when its mixed... LP..or CD !.............flat adds nothing....more real....well too me anyway............have fun

There was a guy capaciti who built(and manufactured) loads of ESLs and he suggested multiple times against using strong mechanical tension.

There was one other informative thread with advice from Capaciti on diaphragm tension and minimizing diaphragm resonances:

http://www.diyaudio.com/forums/planars-exotics/168069-esls-have-bad-decay-plots.html#post2209642

Hi Wachara,

WOW...nice built !

!

Tell me more please with few words... How did you strech if no using bicycle tyre bench ?

3 diaphragms ? 3 ways or just segmented ? (sorry i'm newbie in ESL understanding).

Powder coating for the stators, how-much openess and thichness ? 3M Tape spacers ? 6 micron mylar diaphragm ?

Difference with these products for diagphram coating in relation to ther one Jazzman use ?

Surface is very impressive for me, how-much is the resonance in the low end ? Did you damp the rear stator with fabric textile ?

I'm very hesitate with magneplanar+ribbon (Neo10 + ?...raal to expensive)in semi cardioid (midrange) type because of the rear distance to the wall & WAF in my home for future project (no more 1 meter to the rear wall !)

WOW...nice built

Tell me more please with few words... How did you strech if no using bicycle tyre bench ?

3 diaphragms ? 3 ways or just segmented ? (sorry i'm newbie in ESL understanding).

Powder coating for the stators, how-much openess and thichness ? 3M Tape spacers ? 6 micron mylar diaphragm ?

Difference with these products for diagphram coating in relation to ther one Jazzman use ?

Surface is very impressive for me, how-much is the resonance in the low end ? Did you damp the rear stator with fabric textile ?

I'm very hesitate with magneplanar+ribbon (Neo10 + ?...raal to expensive)in semi cardioid (midrange) type because of the rear distance to the wall & WAF in my home for future project (no more 1 meter to the rear wall !)

Last edited:

Hi Wachara,

WOW...nice built!

Tell me more please with few words... How did you strech if no using bicycle tyre bench ?

3 diaphragms ? 3 ways or just segmented ? (sorry i'm newbie in ESL understanding).

Powder coating for the stators, how-much openess and thichness ? 3M Tape spacers ? 6 micron mylar diaphragm ?

Difference with these products for diagphram coating in relation to ther one Jazzman use ?

Surface is very impressive for me, how-much is the resonance in the low end ? Did you damp the rear stator with fabric textile ?

I'm very hesitate with magneplanar+ribbon (Neo10 + ?...raal to expensive)in semi cardioid (midrange) type because of the rear distance to the wall & WAF in my home for future project (no more 1 meter to the rear wall !)

Hi Eldam,

I actually did use an inner tyre stretcher similar to what Jazzman suggested. However, I didn't put a lot of air to stretch the diaphragm so much. Since I was building full range ESLs, I stretched the diaphragms so that they elongated around 0.6-0.8%. I learned that when I made my electrostatic headphones.

Each side of the ESL has three panels. The big ones are 1.2 m x 0.25 m and the small one in the middle is 1.2 m x 0.1 m. I use 2 mm plastic as spacers. I use a combination of contact cement and the very thin double sided tape to glue the diaphragm to the spacer. I apply contact cement to the plastic spacer and use it to give the double sided tape the extra bonding strength to the spacer. The other side of the double sided tape is bonded directly with the Mylar. I find this method to work very well.

My stators are 1.5 mm and the open area is around 40%. But, I'm not so sure. They are powder coated 3 times with 2 layers of white color and black on the on the third.

About the diaphragm thicknesses, I just want to try something different. So, I end up using 3 microns on the small panel and 6 and 11 microns on the big ones. If I were to do them again, I would probably only choose to use 6 microns Mylar for the big panels.

I haven't done any measurement yet and all of these panels are now running full range. I'll do some low pass filters for the bigger panels later.

I do have some problems. I think my room is having too much reflection. The sound seems to bounce on the wall and echoing quite a bit. I know I need to do something.

Wachara C.

Hi,

It's possible to simulate what resistor values you need for frequency filtering. You can use the segmented ESL simulator for it:

http://www.diyaudio.com/forums/newreply.php?do=newreply&noquote=1&p=3703470

Nice job and congrats. Some questions :

Don't you get problems with membrane collapsing to stators for big panels(2mm d/s spacing and 250 mm stator width gives way over 1 : 100 d/s to dimension ratio?

Have you tried to run the speakers at low frequencies to determine Fs and try to locate any vibrations of metal sheets or buzzing noises(if there are any)?

Regards,

Lukas.

It's possible to simulate what resistor values you need for frequency filtering. You can use the segmented ESL simulator for it:

http://www.diyaudio.com/forums/newreply.php?do=newreply&noquote=1&p=3703470

Nice job and congrats. Some questions :

Don't you get problems with membrane collapsing to stators for big panels(2mm d/s spacing and 250 mm stator width gives way over 1 : 100 d/s to dimension ratio?

Have you tried to run the speakers at low frequencies to determine Fs and try to locate any vibrations of metal sheets or buzzing noises(if there are any)?

Regards,

Lukas.

Hi Lukas,

Thanks for the link to the simulator.

Actually the active diaphragm width is 200 mm. The width of the spacer is 25 mm - so left side and right side add up to 50 mm.

Just for you know, for headphones, I use stator thickness to active diaphragm width ratio of as much as 1:160. The trick is to find the right tension so that you get all the frequencies covered.

So far I haven't noticed the diaphragm hitting the stator yet. But, we'll see.

I'll try to run some FR tests when I have time.

Wachara C.

Thanks for the link to the simulator.

Actually the active diaphragm width is 200 mm. The width of the spacer is 25 mm - so left side and right side add up to 50 mm.

Just for you know, for headphones, I use stator thickness to active diaphragm width ratio of as much as 1:160. The trick is to find the right tension so that you get all the frequencies covered.

So far I haven't noticed the diaphragm hitting the stator yet. But, we'll see.

I'll try to run some FR tests when I have time.

Wachara C.

Last edited:

Hi again,

Your idea to use different film thickness is quite intriguing. Have you done that to distribute resonances of panels? Could target fs ~= 40 Hz for one large panel and ~60-70 Hz for the other to fill up the range from ~40 to ~100hz.

I have a little bit of concern about the resonance of the middle panel affecting mid range. If you happen to get some decent software for CSD plots(like ARTA) it could help.

Your system reminds me idea used in Quad ESL 57 a little bit. The center element there was damped with three layers of felt and run through a high-pass filter(although just light). Bass panels were run via low pass up to ~1 kHz or so.

Regards,

Lukas.

Your idea to use different film thickness is quite intriguing. Have you done that to distribute resonances of panels? Could target fs ~= 40 Hz for one large panel and ~60-70 Hz for the other to fill up the range from ~40 to ~100hz.

I have a little bit of concern about the resonance of the middle panel affecting mid range. If you happen to get some decent software for CSD plots(like ARTA) it could help.

Your system reminds me idea used in Quad ESL 57 a little bit. The center element there was damped with three layers of felt and run through a high-pass filter(although just light). Bass panels were run via low pass up to ~1 kHz or so.

Regards,

Lukas.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- How much tension do you put to stretch on your full range ESL diaphragm?