Forming and suspension of the membrane

In order to keep the folds better I am thinking about having horisontal alu strips as well.

Perhaps five in total, that is once every fourth centimeter.

They will be on the back of the membrane and thus not included in the coil.

Also, to prevent sagging of the membrane, I thought of suspending the membrane from the top to the bottom using a sturdy cotton thread.

Let´s say every tenth fold or so. The free suspension is about one centimeter.

To cover the air gaps at the top and bottom some cloth could be used.

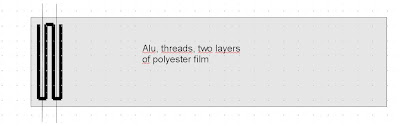

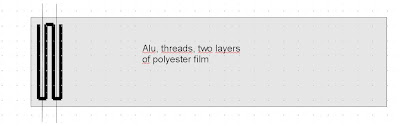

Then I´m thinking of making the membrane with polyester on both sides of the coil.

In order to keep the folds better I am thinking about having horisontal alu strips as well.

Perhaps five in total, that is once every fourth centimeter.

They will be on the back of the membrane and thus not included in the coil.

Also, to prevent sagging of the membrane, I thought of suspending the membrane from the top to the bottom using a sturdy cotton thread.

Let´s say every tenth fold or so. The free suspension is about one centimeter.

To cover the air gaps at the top and bottom some cloth could be used.

Then I´m thinking of making the membrane with polyester on both sides of the coil.

7my.alu is too thin I think.I have used 30my adhesive alu 3mm wide.Use one at top and bottom too.Dont place them at regular distances.Try 3cm,7cm, 12cm. to prevent ressonances.

I have the masking tape 3mmx 30my.

I am not sure it is a good idea to tape the back.It ads weight.

Are you worried about shortning?

Bernt

I have the masking tape 3mmx 30my.

I am not sure it is a good idea to tape the back.It ads weight.

Are you worried about shortning?

Bernt

Yeah, I have some of that tape (burglar alarm tape) too. Great idea!

Yes, I´m worried about shortening. I don´t think that the extra weight is much of an issue.

Getting this to work, I don´t need the glue. Also, the membrane is 960 square centimeters so some tenths of a gram more should be an issue.

Yes, I´m worried about shortening. I don´t think that the extra weight is much of an issue.

Getting this to work, I don´t need the glue. Also, the membrane is 960 square centimeters so some tenths of a gram more should be an issue.

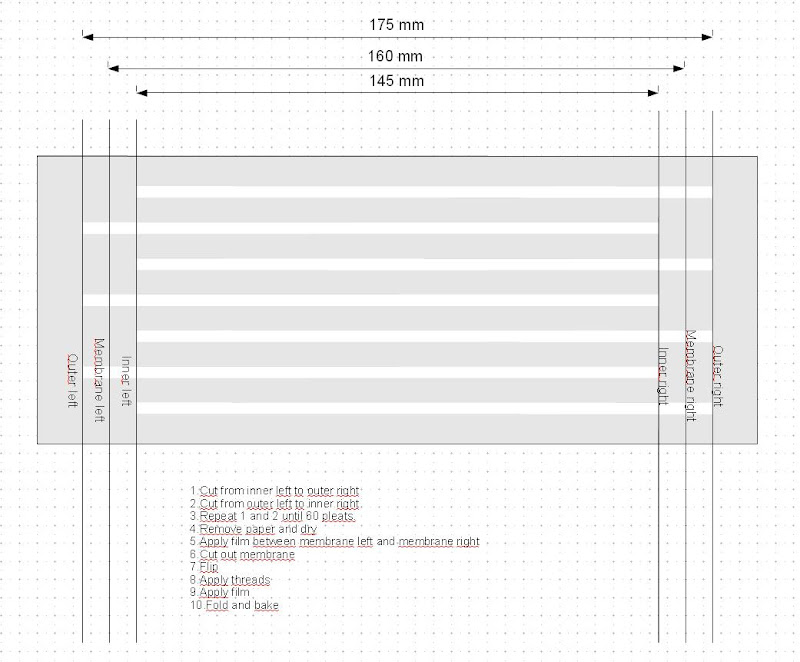

How to make a membrane, first attempt.

So here´s an idea on how to do it.

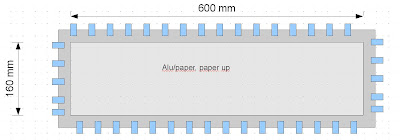

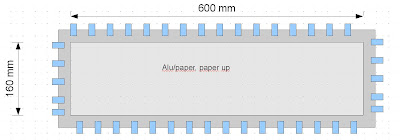

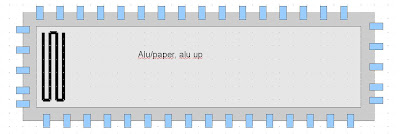

First I put some 200x800 mm alu/paper on a piece of glass with alu down:

Fold and bake.

Comments?

So here´s an idea on how to do it.

First I put some 200x800 mm alu/paper on a piece of glass with alu down:

- Tape at the edges

- Draw the voice coil traces on the paper side

- Cut according to the traces

- Remove the alu residue

- Cut the edge tapes

- Place a second glass over the first one

- Flip over

- Remove the top glass

- Tape at the edges

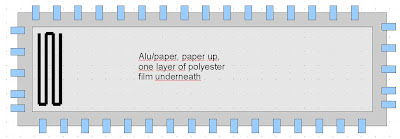

- Apply the polyester film, 160x600 mm

- Tape horisontal stripes at 30, 70 and 120 mm height (might be omitted)

- Cut the edge tapes

- Place a second glass over the first one

- Flip over

- Remove the top glass

- Tape at the edges

- Remove paper from alu/paper

- Cut bottom and top edge tapes

- Put cotton thread in every fifth fold

- Apply polyester film

- Cut out the membrane

Fold and bake.

Comments?

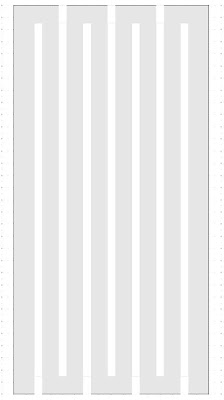

and how to cut it.

First I make parallell cuts 3 mm apart at every 10 mm:

(these values correlates to the actual folding tool)

Then every other is cut all the way to the edge:

Remove the cut out area and be careful at the end of the cut so that it doesnt get ripped apart.

First I make parallell cuts 3 mm apart at every 10 mm:

(these values correlates to the actual folding tool)

Then every other is cut all the way to the edge:

Remove the cut out area and be careful at the end of the cut so that it doesnt get ripped apart.

Last edited:

I dont think it is good to cut at glass ,but I have not tried it.The knifes have to be wery sharp,or alu/paper will be ripped.

Bernt

we used to cut at glass, back the building apogee clones

yes, sharp knife

but not only that

blade edge have to be 100% smooth without any trace of 'roughness'

using only very light pressure

knife should cut almost by itself

but its still ...

but you know that better than anyone by now

but you know that better than anyone by now I´ve always used glass since I first started to cut foil for the ribbon speakers.

So for me glass is the natural choice.

Of course I then used a rotary cutter because otherwise the alu would have been torn as you say, båndsei.

Cutting from the paper side though provides enough friction to avoid tearing.

It works perfect.

I´ll try to make a fifth of a membrane, that is 120 mm, first to prove the process.

So for me glass is the natural choice.

Of course I then used a rotary cutter because otherwise the alu would have been torn as you say, båndsei.

Cutting from the paper side though provides enough friction to avoid tearing.

It works perfect.

I´ll try to make a fifth of a membrane, that is 120 mm, first to prove the process.

Well the double knife didn´t work out.

But I can fairly easy make cuts 3 mm apart with a single knife using the same rods I used when I built the motor; they are 3 mm by 10 mm.

So I have the spacers for doing two 3 mm parallell cuts, 10 mm apart.

@båndsei: After wetting the paper, does one only carefully peel it off?

But I can fairly easy make cuts 3 mm apart with a single knife using the same rods I used when I built the motor; they are 3 mm by 10 mm.

So I have the spacers for doing two 3 mm parallell cuts, 10 mm apart.

@båndsei: After wetting the paper, does one only carefully peel it off?

I make half of the cuts and tape them ,cut the rest ,tape them and peel the taped alu/paper off the cutting plate,powder the alu side,wipe the rest of the powder away.

Place the 3m tape with the adhesive up,and place careful the taped alu/paper with paper up.

Rub careful,turn it over and rub again from the other side.

I go to the kitchen and pour a little water in the zink,ad a little dishwash soap and pce the diaphragm with the paper down,wait a minute ,turn it over and the paper and microporre tape is easy peeled off,in one piece.

![URL]](/community/proxy.php?image=http%3A%2F%2F%5BURL%3Dhttp%3A%2F%2Fimg213.imageshack.us%2Fi%2F80x65mmmembran008.jpg%2F%5D%5BIMGHTTPDEAD%5Dhttp%3A%2F%2Fimg213.imageshack.us%2Fimg213%2F5153%2F80x65mmmembran008.jpg%5B%2FIMGHTTPDEAD%5D%5B%2FURL%5D&hash=878ac624111d3df71c123e55c7d99097)

Bernt

Place the 3m tape with the adhesive up,and place careful the taped alu/paper with paper up.

Rub careful,turn it over and rub again from the other side.

I go to the kitchen and pour a little water in the zink,ad a little dishwash soap and pce the diaphragm with the paper down,wait a minute ,turn it over and the paper and microporre tape is easy peeled off,in one piece.

![URL]](/community/proxy.php?image=http%3A%2F%2F%5BURL%3Dhttp%3A%2F%2Fimg213.imageshack.us%2Fi%2F80x65mmmembran008.jpg%2F%5D%5BIMGHTTPDEAD%5Dhttp%3A%2F%2Fimg213.imageshack.us%2Fimg213%2F5153%2F80x65mmmembran008.jpg%5B%2FIMGHTTPDEAD%5D%5B%2FURL%5D&hash=878ac624111d3df71c123e55c7d99097)

Bernt

Last edited:

Conclusion

I will try to follow this scheme:

I think that this scheme is safer but I will be grateful for any caveat.

I will try to follow this scheme:

- Cut between inner left and outer right

- Cut between outer left and inner right

- Repeat 1 and 2 until finished

- Lift up membrane and put it away (membrane is still in one piece)

- Powder the cutting table

- Place the membrane with paper side down on the cutting table (no need to wipe excessive powder away)

- Apply film (the film is applied and not a delicate membrane.)

- Flip membrane (paper side up)

- Cut out membrane along membrane left and right

- Remove paper with water and

- Place the membrane with film down (optional)

- Apply threads (optional)

- Apply film (optional)

- Fold and bake

I think that this scheme is safer but I will be grateful for any caveat.

You dont mention taping ?

First, I tape the alu/paper to the cutting plate at all sides.

Powder has to be on the alu side to make the tape placed on the cuttings less sticky.

I cut all left-right tape them, turn and cut all left right tape them.

If you look at my pictures you might see it.

Bernt

First, I tape the alu/paper to the cutting plate at all sides.

Powder has to be on the alu side to make the tape placed on the cuttings less sticky.

I cut all left-right tape them, turn and cut all left right tape them.

If you look at my pictures you might see it.

Bernt

I think i see your idea.It is not the same way i do it.

You say film,do you meen 3m tape?

I think it will be wery difficult to aply the film to the cutted alu/paper.

I apply the cutted, taped and powderet alu/tape to the 3m tape,wich is taped to table or cutting plate.

The 3m tape gets electric charged and wery difficult to handle.

The cutted taped and powderet, I use, is easier to handle.

Try a small scale test!

Bernt

Looks good

You say film,do you meen 3m tape?

I think it will be wery difficult to aply the film to the cutted alu/paper.

I apply the cutted, taped and powderet alu/tape to the 3m tape,wich is taped to table or cutting plate.

The 3m tape gets electric charged and wery difficult to handle.

The cutted taped and powderet, I use, is easier to handle.

Try a small scale test!

Bernt

Looks good

You pin pointed the dilemma I will be facing: film to membrane or membrane to film.

I think it is a higher risk with the latter as the membrane is quite large.

I´m used to the film to membrane technique since when I made my ribbons.

Yes, film = 3M 74 tape.

Small scale test? I don´t think so.

Small scale test = small scale problem.

Real scale test = real scale problem.

I think it is a higher risk with the latter as the membrane is quite large.

I´m used to the film to membrane technique since when I made my ribbons.

Yes, film = 3M 74 tape.

Small scale test? I don´t think so.

Small scale test = small scale problem.

Real scale test = real scale problem.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Yet another DIY AMT