Yes, I guess it´ll have to be something like that.

My first tests with the nail strips didn´t work out so well.

It is very hard to get the strips straight enough, it´ll be a sloppy membrane if any.

So I guess I´ll go hunting for some 2 - 2,5 times 6 - 7 mm bars tomorrow then.

My first tests with the nail strips didn´t work out so well.

It is very hard to get the strips straight enough, it´ll be a sloppy membrane if any.

So I guess I´ll go hunting for some 2 - 2,5 times 6 - 7 mm bars tomorrow then.

My first attempt with nail strips didn´t work out so well.

They are impossible to get straight and are also too thin.

I need some sort of rod, capable of 170 degrees Celsius, 1-3 mm thick and 6-8 mm wide.

In case of 1 mm thick, I´d have to use 2 or 3 of them between each fold.

Any ideas on the material?

They are impossible to get straight and are also too thin.

I need some sort of rod, capable of 170 degrees Celsius, 1-3 mm thick and 6-8 mm wide.

In case of 1 mm thick, I´d have to use 2 or 3 of them between each fold.

Any ideas on the material?

Attachments

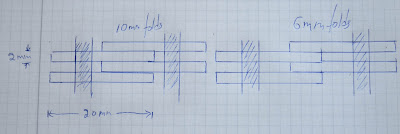

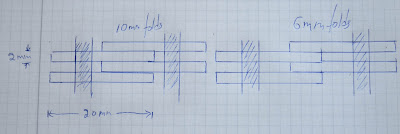

I got me some 2 mm x 15 mm aluminium bars.

The deepth of the pleats must be decided now before I make the acentric holes.

6, 7 or 8 mm in a 10 mm gap?

9.5 mm

I like your second suggestion better.

The first one will make it hard to control the sharpness of the folds if the width is large.

It will also require the dubble amount of rods, thus more expensive and more mass to heat.

Both suggestions means though that the 10 mm rods should be 20 mm:

Just before posting this I saw your latest picture, it would seem that we agree on a way forward.

The first one will make it hard to control the sharpness of the folds if the width is large.

It will also require the dubble amount of rods, thus more expensive and more mass to heat.

Both suggestions means though that the 10 mm rods should be 20 mm:

Just before posting this I saw your latest picture, it would seem that we agree on a way forward.

@RayCtech: 9,5 mm would be ideal, but I think it will be hard to get it right using DIY tools.

@Båndsei:15 mm will be hard to make, too little material around the holes.

With 20 mm and if I go for 6 mm folds, I can always support any rod drop with washers.

I´m not so sure that I will use a frame for the membrane, but I can make the extra vertical fold anyway.

I guess it can be easily cut off.

@Båndsei:15 mm will be hard to make, too little material around the holes.

With 20 mm and if I go for 6 mm folds, I can always support any rod drop with washers.

I´m not so sure that I will use a frame for the membrane, but I can make the extra vertical fold anyway.

I guess it can be easily cut off.

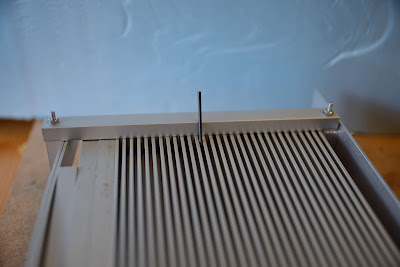

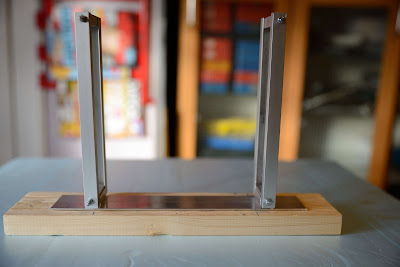

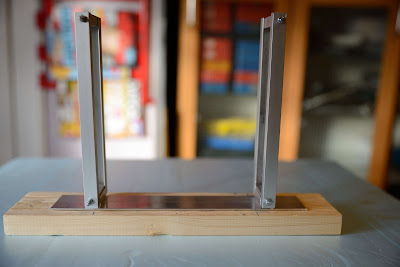

Folding tool, mk II

So I never got the tolerances correct for the drilled aluminium rods.

I also suspect that it´ll be hard to get the membrane out of the tool once it had baked.

I had to come up with something else where I could rely upon any materials intrisic dimensions as far as possible.

I had figured out that in order to have a 8 mm deep membrane, two 20 mm rods need to be 32 mm in total if they overlap.

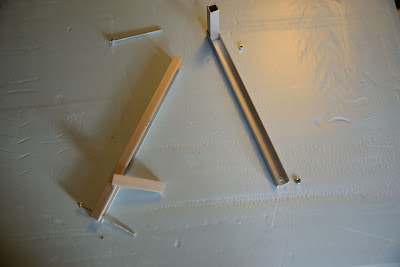

So I took some U-shaped aluminium and screwed them 160 mm apart, the height of the finished membrane:

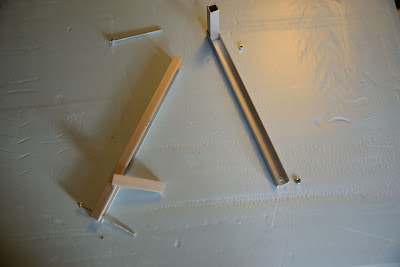

Build two sides:

Mounted them in the Us:

Made some spacers from the 20 mm rods:

Placed the rods and spacers,

and started to fold:

If I need to adjust something or just take a rest from my folding, I can put a temporary stopper at the top:

Once the membrane has baked, the tool should easily fall apart if I remove these screws:

Now it is time to cut some aluminium foil.

The aluminium foil, if I have calculated it correctly, is over 7 meters long in all.

So I have to make the strips as wide as possible, considering the thickness of the foil (7 um).

So I never got the tolerances correct for the drilled aluminium rods.

I also suspect that it´ll be hard to get the membrane out of the tool once it had baked.

I had to come up with something else where I could rely upon any materials intrisic dimensions as far as possible.

I had figured out that in order to have a 8 mm deep membrane, two 20 mm rods need to be 32 mm in total if they overlap.

So I took some U-shaped aluminium and screwed them 160 mm apart, the height of the finished membrane:

Build two sides:

Mounted them in the Us:

Made some spacers from the 20 mm rods:

Placed the rods and spacers,

and started to fold:

If I need to adjust something or just take a rest from my folding, I can put a temporary stopper at the top:

Once the membrane has baked, the tool should easily fall apart if I remove these screws:

Now it is time to cut some aluminium foil.

The aluminium foil, if I have calculated it correctly, is over 7 meters long in all.

So I have to make the strips as wide as possible, considering the thickness of the foil (7 um).

Last edited:

I consider making a full dummy membrane with a 80 um paper like the one in post #51 in order to get a general feel about length and the tool handling.

That paper is 80 um thick. The alu+paper is 30 um and the polyester film is 20 um but it should do.

Then I need to correlate it to a piece of the real membrane as you suggested.

That paper is 80 um thick. The alu+paper is 30 um and the polyester film is 20 um but it should do.

Then I need to correlate it to a piece of the real membrane as you suggested.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Yet another DIY AMT

![URL]](/community/proxy.php?image=http%3A%2F%2F%5BURL%3Dhttp%3A%2F%2Fimg221.imageshack.us%2Fi%2Ftooljpeg.jpg%2F%5D%5BIMGDEAD%5Dhttp%3A%2F%2Fimg221.imageshack.us%2Fimg221%2F4640%2Ftooljpeg.jpg%5B%2FIMGDEAD%5D%5B%2FURL%5D&hash=40df544a32865a09f4c020eab732bdef)

![URL]](/community/proxy.php?image=http%3A%2F%2F%5BURL%3Dhttp%3A%2F%2Fimg834.imageshack.us%2Fi%2Ffixtur001.jpg%2F%5D%5BIMGHTTPDEAD%5Dhttp%3A%2F%2Fimg834.imageshack.us%2Fimg834%2F9653%2Ffixtur001.jpg%5B%2FIMGHTTPDEAD%5D%5B%2FURL%5D&hash=6dfbba784b1a078c6b6dbe6f9c032fdc)

![URL]](/community/proxy.php?image=http%3A%2F%2F%5BURL%3Dhttp%3A%2F%2Fimg248.imageshack.us%2Fi%2Ftegningtool.jpg%2F%5D%5BIMGDEAD%5Dhttp%3A%2F%2Fimg248.imageshack.us%2Fimg248%2F4439%2Ftegningtool.jpg%5B%2FIMGDEAD%5D%5B%2FURL%5D&hash=3ee7a723c86115eb3202236f88155347)

![URL]](/community/proxy.php?image=http%3A%2F%2F%5BURL%3Dhttp%3A%2F%2Fimg841.imageshack.us%2Fi%2Fbilledtool002.jpg%2F%5D%5BIMGHTTPDEAD%5Dhttp%3A%2F%2Fimg841.imageshack.us%2Fimg841%2F3861%2Fbilledtool002.jpg%5B%2FIMGHTTPDEAD%5D%5B%2FURL%5D&hash=49812719e9a90ccf10d89fe26303777e)